Preparation method for nanometer yttrium doped zirconia powder

A technology of zirconia powder and zirconia powder, which is applied in the field of nano-powder preparation, can solve the problems of difficulty in achieving pure phase, poor sintering activity, and coarse powder particle size when doped with zirconia, so as to achieve easy sintering and formation Effect of low phase temperature and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

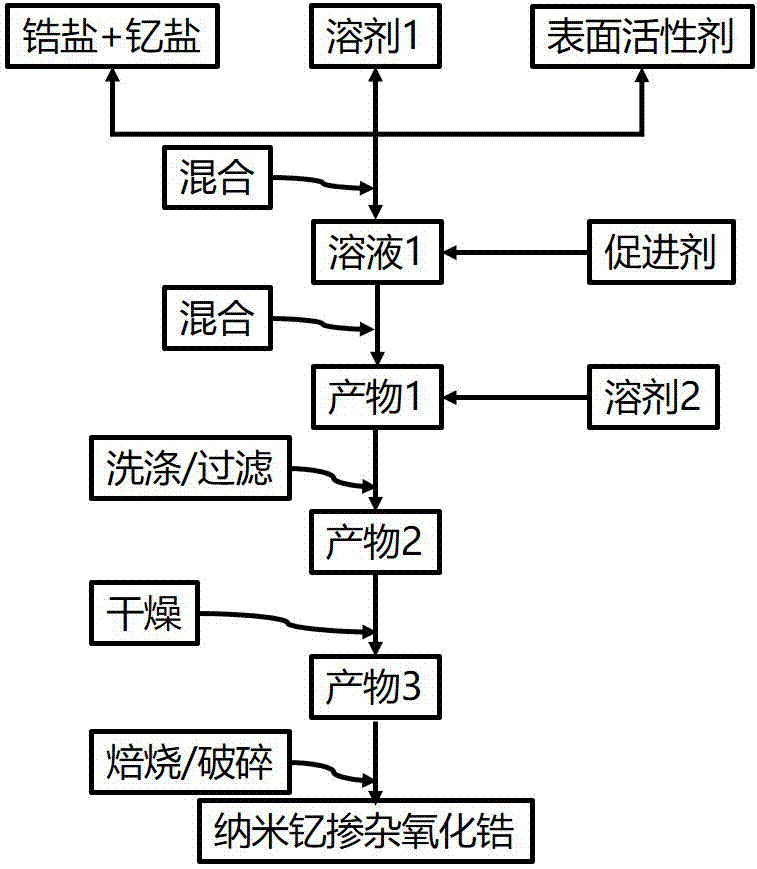

[0011] As mentioned above, in view of the many defects of the prior art, the inventor of this case proposed a preparation method of nano-yttrium-doped zirconia after long-term research and practice, in order to realize the low-cost, Large-scale and high-performance preparation. The specific embodiment of the present invention is as follows:

[0012] 1) Mix 1 part of inorganic yttrium salt, 8 to 50 parts of inorganic zirconium salt, 20 to 100 parts of solvent 1, and 0.1 to 3 parts of surfactant to form a uniform solution;

[0013] 2) Add 5-100 parts of accelerator to the solution prepared in 1);

[0014] 3) adding solvent 2 to the product obtained in step 2), heating and stirring;

[0015] 4) The product obtained in step 3) is filtered and dried;

[0016] 5) Roasting the product obtained in step 4);

[0017] 6) The powder prepared in step 5) is crushed and granulated to obtain nano-doped zirconia powder.

[0018] Further, the inorganic yttrium salt is one or a mixture of y...

Embodiment 1

[0028] Dissolve 61.28 grams of yttrium nitrate, 311.88 grams of zirconium nitrate and 10 grams of polyethylene glycol 400 in 5000 grams of deionized water. After the dissolution is complete, 300 grams of glycidol is added dropwise and allowed to stand for 5 hours. The obtained solid product is subjected to centrifugal dehydration. Add 20,000 grams of deionized water to the dehydrated solids, heat to 80 degrees, wash at 200 rpm for 3 hours, and then dehydrate the product by centrifugation; Roasting in a furnace at 500°C for 2 hours; dry-milling the calcined powder with a ball mill for 3 hours to obtain nano-doped zirconia powder. The zirconia powder prepared by this method is a fully stable cubic phase, with a primary particle size of 40nm and a secondary particle size of 500nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com