Self-emulsified nonionic terpenyl epoxy resin polyalcohol emulsion and preparation method and application

A terpene-based epoxy resin, non-ionic technology, applied in the field of polyols, can solve problems such as complex synthesis process, and achieve the effects of excellent ultraviolet resistance, simple manufacturing method, and excellent mechanical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

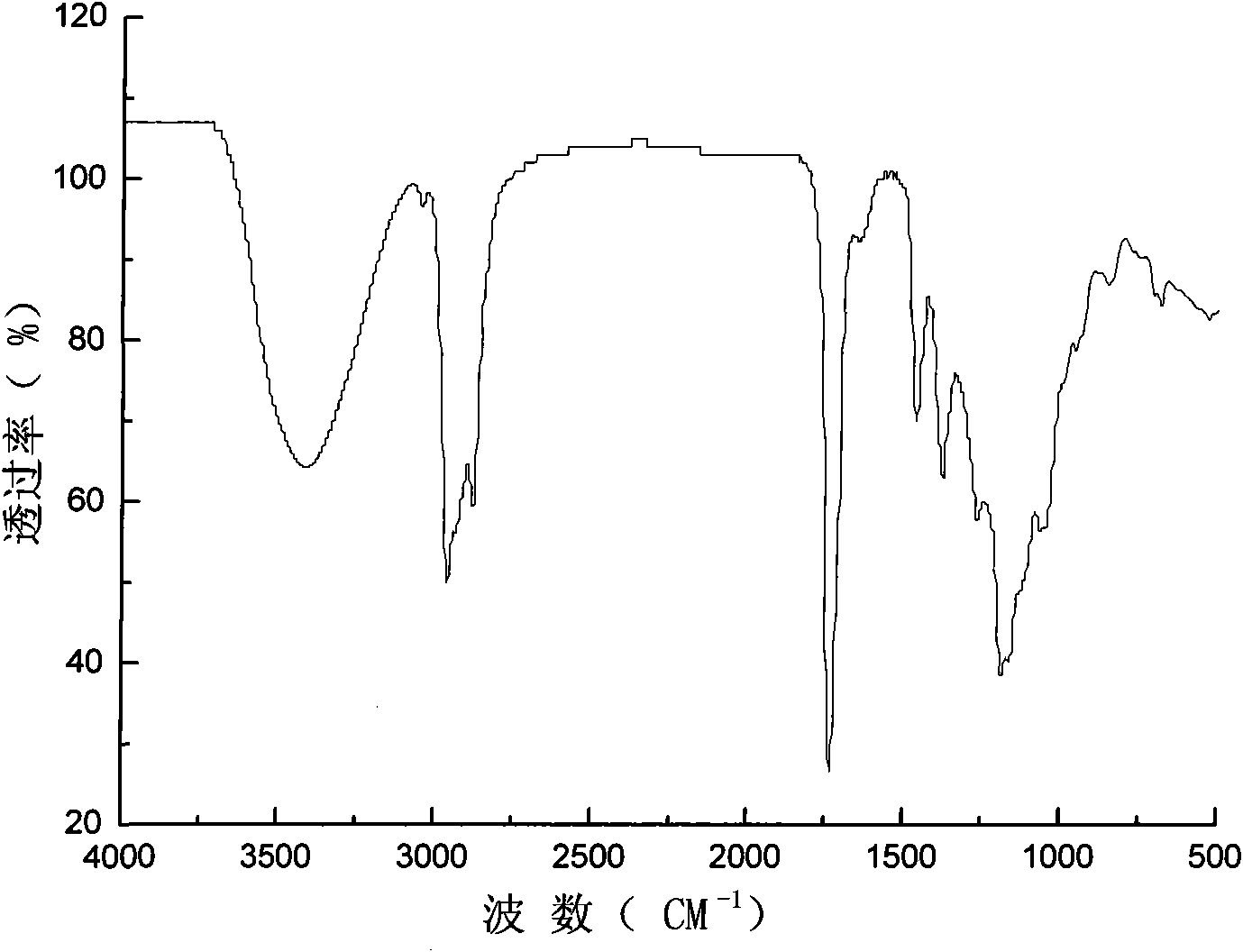

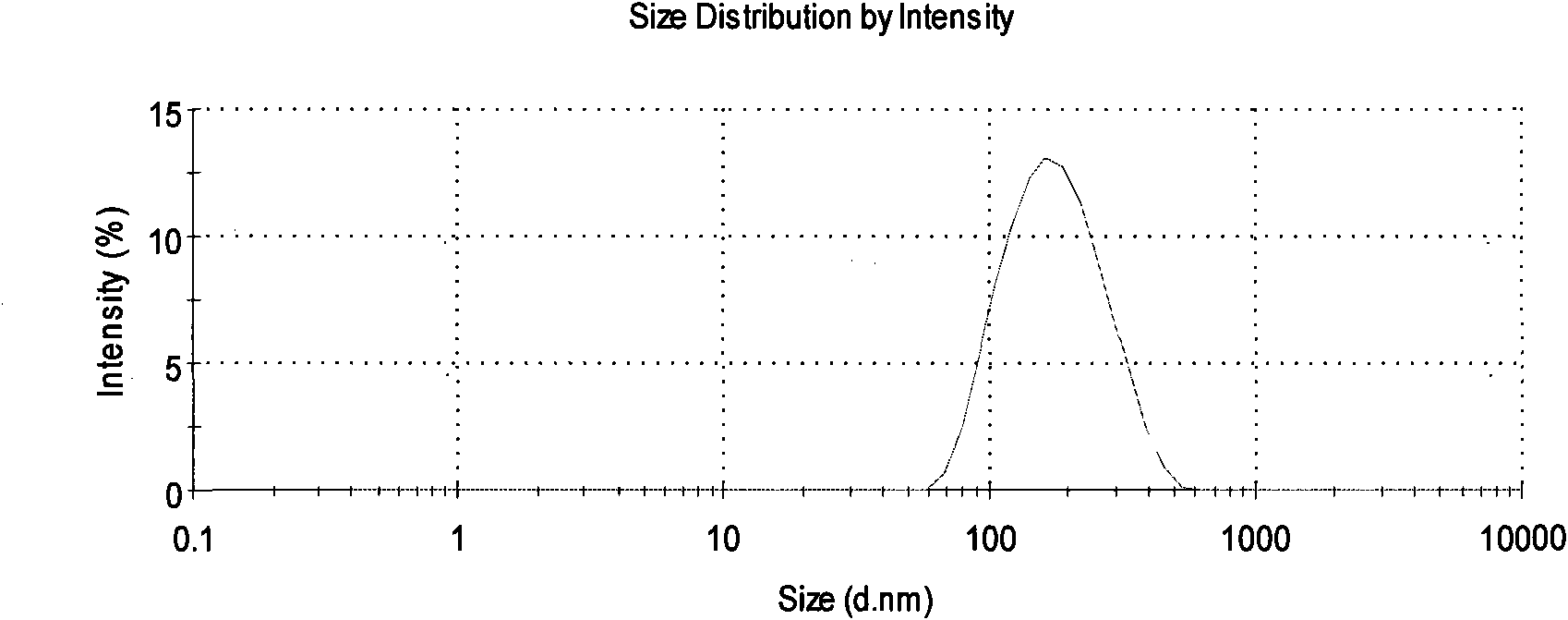

[0032] Add 80.1g TME, 6.4g PEG with an average relative molecular weight of 6000, and 7.4g TMP to a three-neck flask equipped with a thermometer, a stirrer, and a condenser tube, heat and stir to 90°C, add 1.21g sulfuric acid (diluted with 5.6g acetone) , maintain the reaction at 110°C for 1 hour; after the reaction, stir and disperse directly with deionized water to obtain a milky white polyol emulsion with a hydroxyl value of 100mg / g (solid resin) and a viscosity of 61mPa·s (25°C, 40% solid content) , Z average particle size 194nm. The infrared spectrum of the polyalcohol is shown as figure 1 As shown, the particle size distribution is as figure 2 shown.

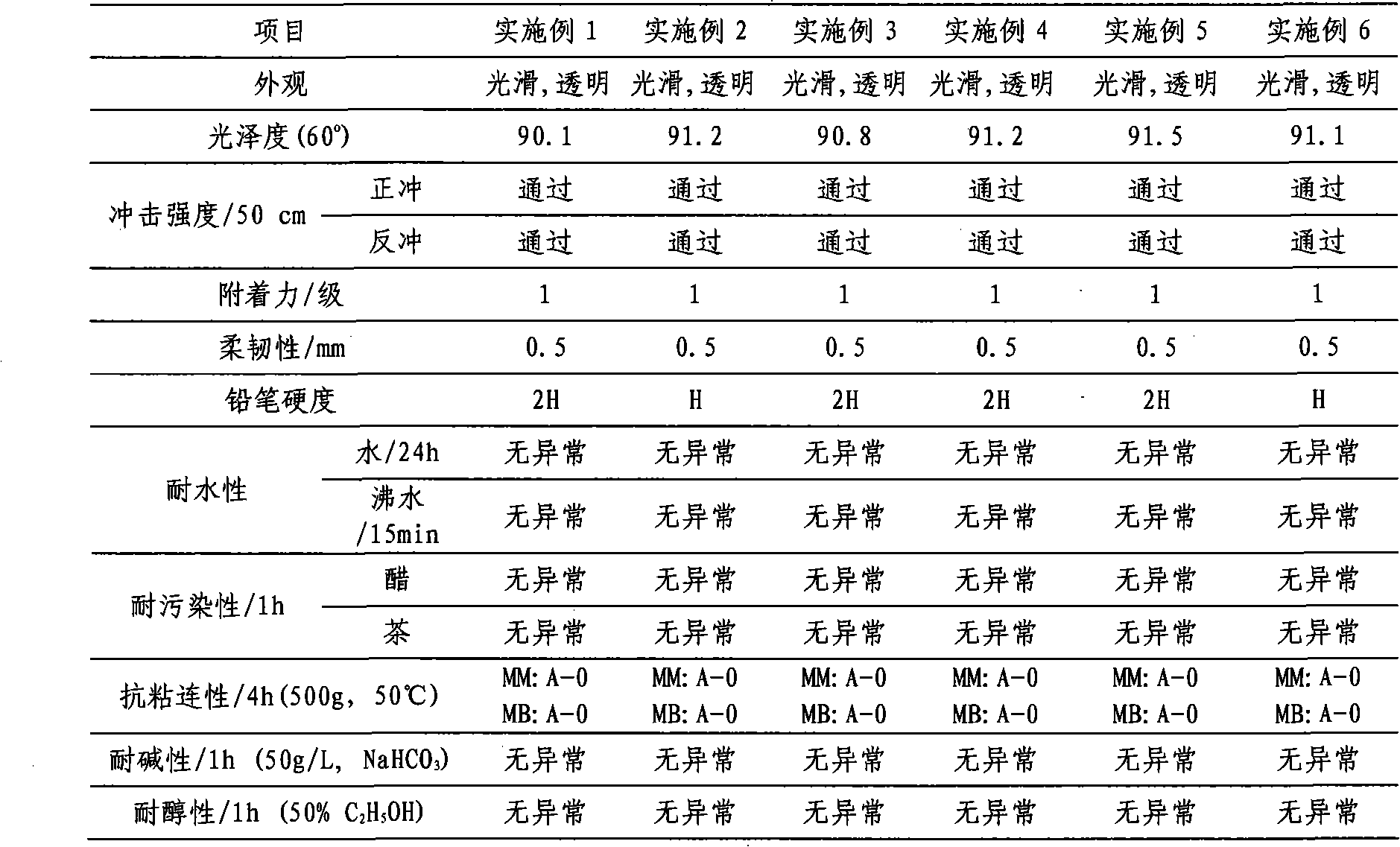

[0033] Take 10.0g of the above-mentioned polyol emulsion (40% solid content), add 2g of hydrophilic modified polydiisocyanate S100, stir and mix evenly, dilute with 2g of water, coat the film, and measure the performance of the paint film after 7 days of maintenance at room temperature. Table 1.

Embodiment 2

[0035] In a three-neck flask equipped with a thermometer, a stirrer, and a condenser tube, add 40g HTME, 7.2g PEG with an average relative molecular weight of 10000, and 7.5g TMP respectively, heat and stir to 90°C, add 0.40g boron trifluoride diethyl ether (with 2.7g Diluted with acetone), maintain the reaction at 110°C for 2h; after the reaction, stir and disperse directly with deionized water to obtain a milky white polyol emulsion with a hydroxyl value of 200mg / g (solid resin) and a viscosity of 579mPa·s (25°C, 30% Solid content), Z average particle size 256nm.

[0036]Take 10.0g of the above-mentioned polyol emulsion (30% solid content), add 2g of hydrophilic modified polydiisocyanate S100, stir and mix evenly, dilute with 2g of water, coat the film, and measure the performance of the paint film after 7 days of maintenance at room temperature. Table 1.

Embodiment 3

[0038] In a three-neck flask equipped with a thermometer, a stirrer, and a condenser tube, add 37g TME, 3.7g PEG with an average relative molecular weight of 4000, and 7.6g TMP respectively, heat and stir to 90°C, add 0.46g boron trifluoride diethyl ether (with 2.6g Diluted with acetone), maintain the reaction at 115°C for 2h; after the reaction, stir and disperse directly with deionized water to obtain a milky white polyol emulsion with a hydroxyl value of 250mg / g (solid resin) and a viscosity of 21mPa·s (25°C, 40% Solid content), Z average particle size 295nm.

[0039] Take 10.0g of the above-mentioned polyol emulsion (40% solid content), add 3.2g of hydrophilic modified polydiisocyanate S100, stir and mix evenly, dilute with 1g of water, apply a film, and measure the performance of the paint film after 7 days of maintenance at room temperature As in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com