A kind of preparation method of inorganic composite white pigment with high hiding power

An inorganic composite, white pigment technology, applied in inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of no advantages in production cost and environmental protection, high production cost, large water consumption, etc., to alleviate the problem of titanium dioxide The effect of tight supply of raw materials, alleviation of environmental protection pressure, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

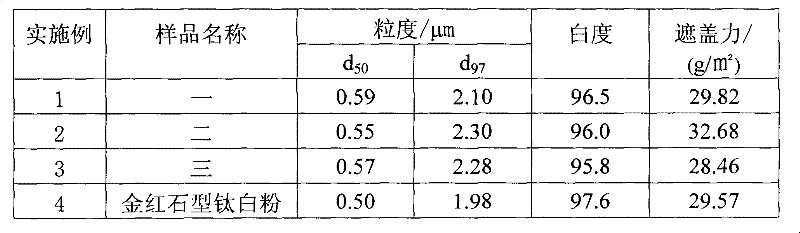

Embodiment 1

[0016] Example 1: Take 1000g of rutile titanium dioxide, add 1800ml of water, and 4g of sodium polyacrylate (ACUMER9400) as a dispersant, after dispersion and slurry adjustment, put it into a laboratory sand mill for circular grinding; at the same time, take 1000g of calcined kaolin and add 1000ml of water , dispersant sodium polycarboxylate (ACUMER 9460) 5g, stir and disperse to configure calcined kaolin slurry; when titanium dioxide is ground to the median particle size D 50 About 0.5μm, negative cumulative particle size D 97 After ≤2μm, add the prepared calcined kaolin slurry to the titanium dioxide slurry, and at the same time add glacial acetic acid to adjust the pH of the mixed slurry of titanium dioxide and calcined kaolin to 5, and then perform ultrafine grinding; mix titanium dioxide and white mineral powder The average particle size or median particle size D of the composite powder 50 Grinding to about 0.5μm, negative cumulative particle size D 97 After <3 μm, fil...

Embodiment 2

[0017] Example 2: Take 1000g of rutile titanium dioxide, add 1800ml of water, and 4g of sodium polyacrylate (ACUMER9400) as a dispersant. After dispersion and slurry preparation, put it into a laboratory sand mill for circular grinding; at the same time, take natural talc and calcite composite ore Powder 1000g, add water 800ml, dispersant sodium polycarboxylate (ACUMER 9460) 4g, stir and disperse to configure natural talc and calcite composite mineral powder slurry; when titanium dioxide is ground to the median particle size D 50 About 0.5μm, negative cumulative particle size D 97 After ≤2μm, add the prepared natural talc and calcite composite mineral powder slurry to the titanium dioxide slurry, and add glacial acetic acid to adjust the pH of the mixed slurry of titanium dioxide, natural talc and calcite composite mineral powder to 6.5, and then carry out ultra- Fine grinding; the average particle size or median particle size of the composite powder of titanium dioxide, natur...

Embodiment 3

[0018] Example 3: Take 1000g of rutile titanium dioxide, add 1800ml of water, 4g of sodium polyacrylate (ACUMER9400) as a dispersant, after dispersion and slurry adjustment, put it into a laboratory sand mill for circular grinding; simultaneously take 1000g of natural saponite mineral powder , add water 900ml, dispersant sodium polycarboxylate (ACUMER 9460) 5g, stir and disperse to configure saponite mineral powder slurry; when titanium dioxide is ground to the median particle size D 50 About 0.5μm, negative cumulative particle size D 97 After ≤2μm, add the prepared saponite mineral powder slurry to the titanium dioxide slurry, add glacial acetic acid at the same time to adjust the pH of the mixed slurry of titanium dioxide and saponite mineral powder to 4.5, and then carry out ultrafine grinding; the titanium dioxide Average particle size or median particle size D of composite powder with saponite mineral powder 50 Grinding to about 0.5μm, negative cumulative particle size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com