Germanium silicate based elastic stress light-emitting material and preparation method therefor

A technology of luminescent materials and elastic stress, which is applied in luminescent materials, luminescent coatings, chemical instruments and methods, etc., can solve the problems of unstable chemical properties, complicated preparation process, and increased preparation cost, and achieve good repeatability and low cost. Low, less resource consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020]

[0021] Concrete preparation steps are as follows:

[0022] (1) Selection of raw materials: Zn uses its oxides as raw materials during preparation, Si and Ge elements use their oxides as raw materials, Mn, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Er and Yb Using oxides or carbonates as raw materials, each element is weighed according to its stoichiometric ratio, and then an appropriate amount of absolute ethanol or deionized water is added to the mixed raw materials, and ground in an agate bowl and stirred for 1 to 4 hours to obtain Grind uniform powder;

[0023] (2) Put the uniformly ground powder in an alumina crucible, raise the temperature to 800-1500°C at a rate of 1-10°C / min in the atmosphere or reducing atmosphere, burn for 2-8 hours, and cool down with the furnace;

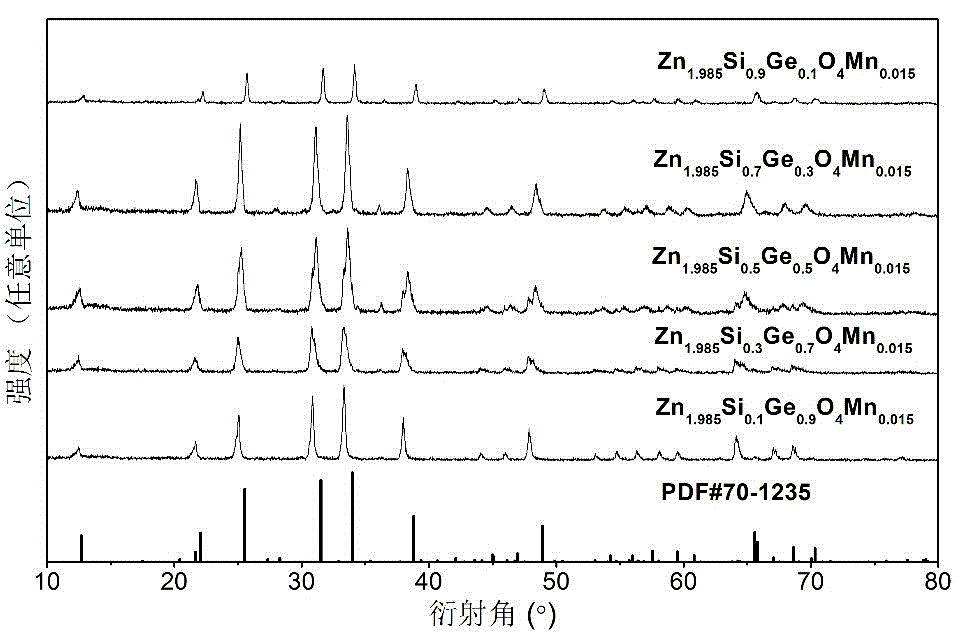

[0024] (3) Grinding the cooled powder obtained in step (2) for 10 to 30 minutes to obtain the germanosilicate-based high-performance elastic stress luminescent material Zn 2-x Si y Ge 1-y R x o ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com