Method for continuously extracting wheat germ oil by using microwave-assisted solvent

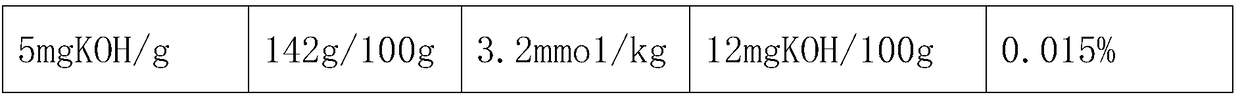

A technology of wheat germ oil and wheat germ, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems of reduced utilization rate of raw materials, inability to effectively extract wheat germ oil, low extraction efficiency, etc., and reach the goal of impurity The effect of less content, reduced impurity content, and high extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for continuous extraction of wheat germ oil by a microwave-assisted solvent, comprising the following steps:

[0036] S1. Raw material screening, the wheat germ is screened by the screening machine to remove the damaged part, then the wheat germ is put into the water, and the water is vibrated with a vibrator, the vibration frequency is 150Hz, and the cleaning time is 30 minutes. The wheat germ is cleaned , the water temperature is 30°C;

[0037] S2. Wheat germ drying. Put the wheat germ treated in S1 into the drying equipment to remove the moisture on the surface of the wheat germ. The drying temperature is 65°C. While drying, the wheat germ is blown at a uniform speed at a wind speed of 8m. / s, the humidity of the airflow entering the wind is 3%, stop drying when the humidity of wheat germ is 7%, the airflow temperature is 66°C, and the cleanliness of the air is 100;

[0038] S3, preparation of wheat germ powder, the wheat germ processed in S2 is put into a ...

Embodiment 2

[0046] A method for continuous extraction of wheat germ oil by a microwave-assisted solvent, comprising the following steps:

[0047] S1. Raw material screening, the wheat germ is screened by the screening machine to remove the damaged part, then the wheat germ is put into the water, and the water is vibrated with a vibrating machine. The vibration frequency is 200Hz, and the cleaning time is 60 minutes. The wheat germ is cleaned. , the water temperature is 45°C;

[0048] S2. Wheat germ drying. Put the wheat germ treated in S1 into the drying equipment to remove the moisture on the surface of the wheat germ. The drying temperature is 70°C. While drying, the wheat germ is blown at a uniform speed at a wind speed of 14m. / s, the airflow humidity entering the wind is 7%, stop drying when the wheat germ humidity is 9%, the airflow temperature is 68°C, and the cleanliness of the air is 100 grades;

[0049] S3, preparation of wheat germ powder, the wheat germ treated in S2 is put i...

Embodiment 3

[0057] A method for continuous extraction of wheat germ oil by a microwave-assisted solvent, comprising the following steps:

[0058] S1. Raw material screening, the wheat germ is screened by the screening machine to remove the damaged part, then the wheat germ is put into the water, and the water is vibrated with a vibrator, the vibration frequency is 151Hz, and the cleaning time is 31 minutes. The wheat germ is cleaned , the water temperature is 31°C;

[0059] S2. Wheat germ drying. Put the wheat germ treated in S1 into the drying equipment to remove the moisture on the surface of the wheat germ. The drying temperature is 66°C. While drying, the wheat germ is blown at a uniform speed at a wind speed of 9m. / s, the airflow humidity entering the wind is 4%, stop drying when the wheat germ humidity is 8%, the airflow temperature is 67°C, and the cleanliness of the air is 100 grades;

[0060] S3, preparation of wheat germ powder, the wheat germ processed in S2 is put into a pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com