Web-type three-dimensional perforated macroporous-mesoporous-structure titanium dioxide material, and preparation method and application thereof

A technology of titanium dioxide and mesoporous structure, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of low photocatalytic efficiency, low high-rate performance, low electronic conductivity, etc., and achieve excellent Cycling performance, less harsh process conditions, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

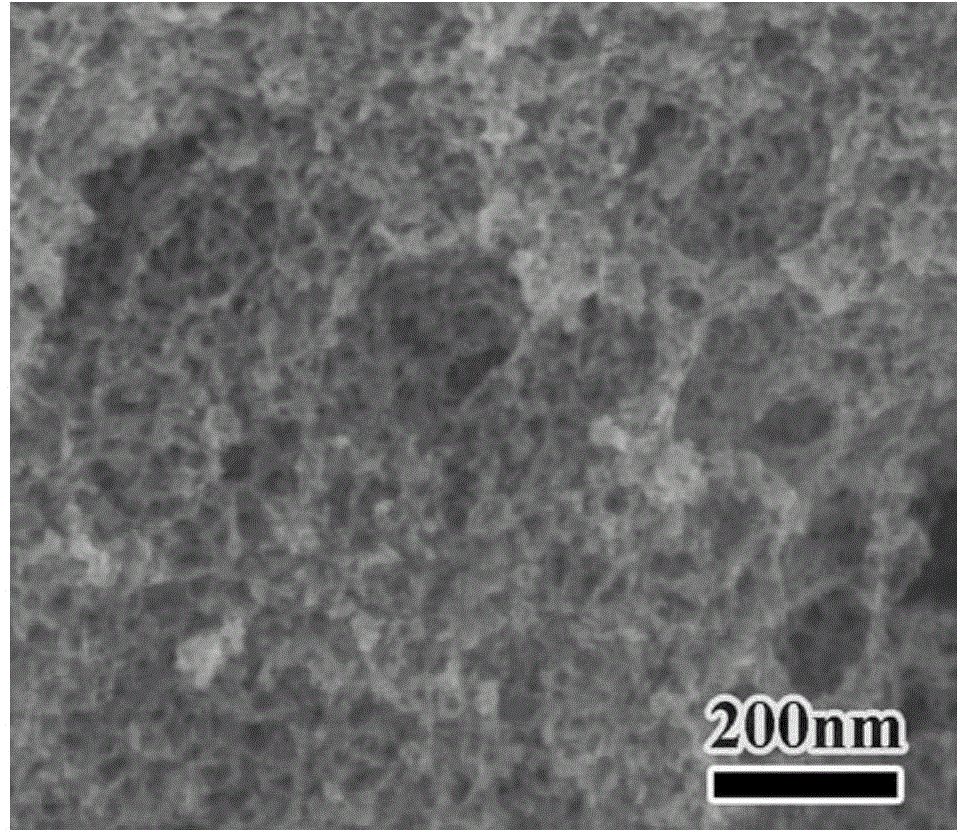

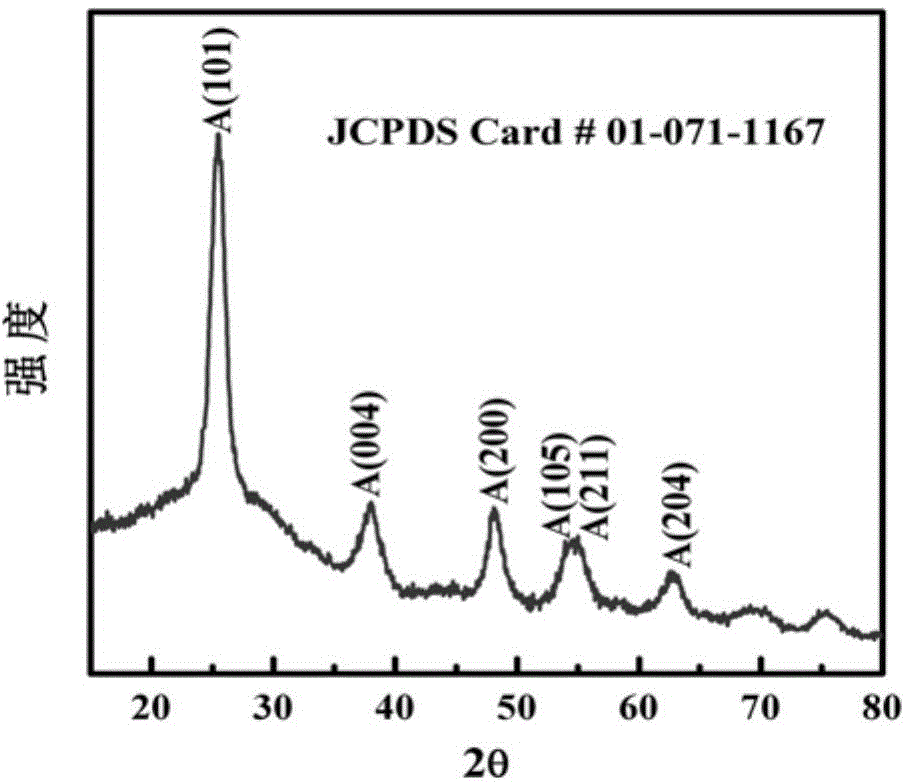

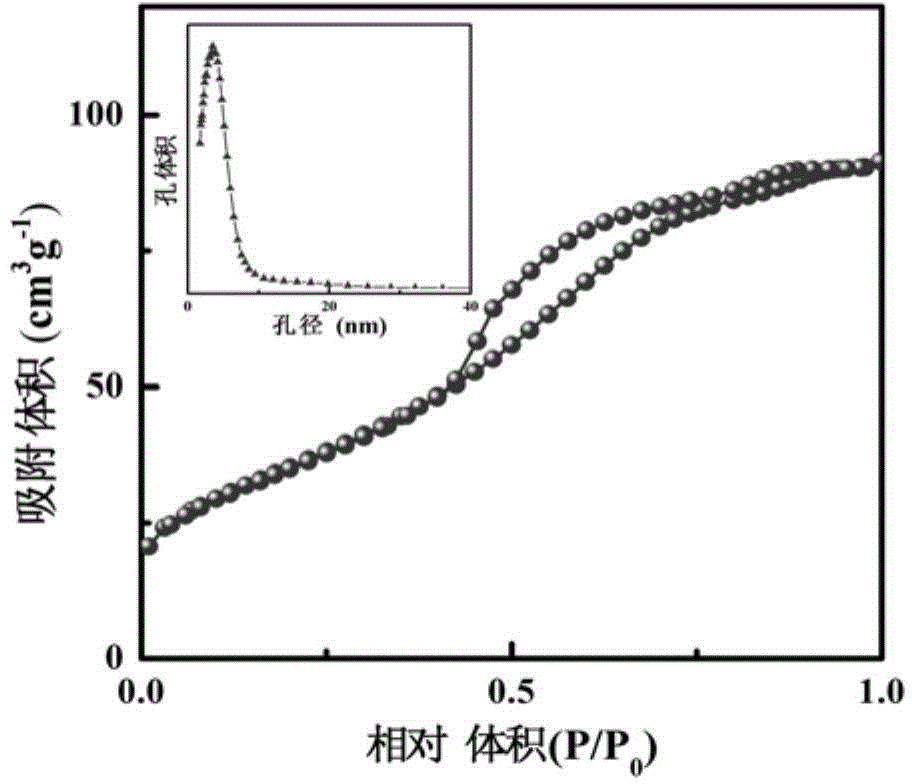

[0054] Disperse 5 g of rapeseed pollen into 50 ml of absolute ethanol and stir for 24 hours, then filter to obtain 40 ml of supernatant containing pollen film. Add 0.4g (6.9*10 -5 mol) P123, and stirred evenly to obtain a supernatant containing P123. Add 8g of titanium sulfate (0.033mol in mole) into 100ml of absolute ethanol and stir for 24h. Then take 10ml of completely dissolved titanium sulfate ethanol solution and add it dropwise to the supernatant containing P123, and stir for 2h. Then add 40ml of water and stir for 30min to mix evenly, transfer it to a glass watch glass with a diameter of 20cm, place it in an oven at 40°C for 72h, and keep the relative humidity above 60%. Then the obtained gel was crystallized at 60°C for 12 hours, and the product was calcined in air at 500°C to remove the biological template agent and surfactant, and then the three-dimensional through macropore-mesoporous structure titanium dioxide could be obtained. During this process, the surfact...

Embodiment 2

[0064] Disperse 5 g of rapeseed pollen into 50 ml of absolute ethanol and stir for 24 hours, then filter to obtain 40 ml of supernatant containing pollen film. Add 0.4g (6.9*10 -5 mol) P123, and stirred evenly to obtain a supernatant containing P123. A certain amount of tetrabutyl titanate was added dropwise to the above supernatant containing P123, and stirred for 2 h. Then add 40ml of water and stir for 30min to mix evenly, transfer it to a glass watch glass with a diameter of 20cm, place it in an oven at 40°C for 72h, and keep the relative humidity above 60%. Then the obtained gel was crystallized at 60°C for 12 hours, and the product was calcined at 500°C in the air to remove the biological template agent and surfactant, and the three-dimensional macroporous-mesoporous structure titanium dioxide could be obtained. Transfer it to a glass watch glass with a diameter of 20 cm, place it in an oven at 40° C. for 72 h, and keep the relative humidity above 60%. Then the obtain...

Embodiment 3

[0067] Disperse 5 g of lotus pollen in 50 ml of absolute ethanol and stir for 24 hours, and filter to obtain 40 ml of supernatant containing pollen film. Add 0.4g (6.9*10 -5 mol) P123, and stirred evenly to obtain a supernatant containing P123. Add 8g of titanium sulfate (0.033mol in mole) into 100ml of absolute ethanol and stir for 24h. Then take 10ml of completely dissolved titanium sulfate ethanol solution and add it dropwise to the supernatant containing P123, and stir for 2h. Then add 40ml of water and stir for 30min to mix evenly, transfer it to a glass watch glass with a diameter of 20cm, place it in an oven at 40°C for 72h, and keep the relative humidity above 60%. Then the obtained gel was crystallized at 60°C for 12 hours, and the product was calcined in air at 500°C to remove the biological template agent and surfactant, and then the three-dimensional through macropore-mesoporous structure titanium dioxide could be obtained. Transfer it to a glass watch glass wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Large hole size | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com