Preparation method of hollow mesoporous silica nanospheres

A silica and hollow mesoporous technology, applied in the direction of silica, silica, nanotechnology, etc., to achieve the effect of mild synthesis and post-processing conditions, strong operability, and good industrial synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 400 mg of silica nanospheres to 45 ml of water, and obtain an aqueous dispersion of silica nanospheres after ultrasonication for 10 minutes, then reflux at 95° C. for 6 hours, and then centrifuge to collect silica nanospheres.

[0028] (2) Disperse the silica nanospheres obtained in step (1) into 10 ml of water, add 20 mg of CTAB, and stir for 3 h.

[0029] (3) Add 140 mg of NaOH to the dispersion obtained in step (2), and etch at 25° C. for 2 hours. Stand to cool, collect the precipitate, wash and dry to obtain a white powder, and remove the cationic surfactant from the white powder to obtain hollow mesoporous silica nanospheres containing larger pores.

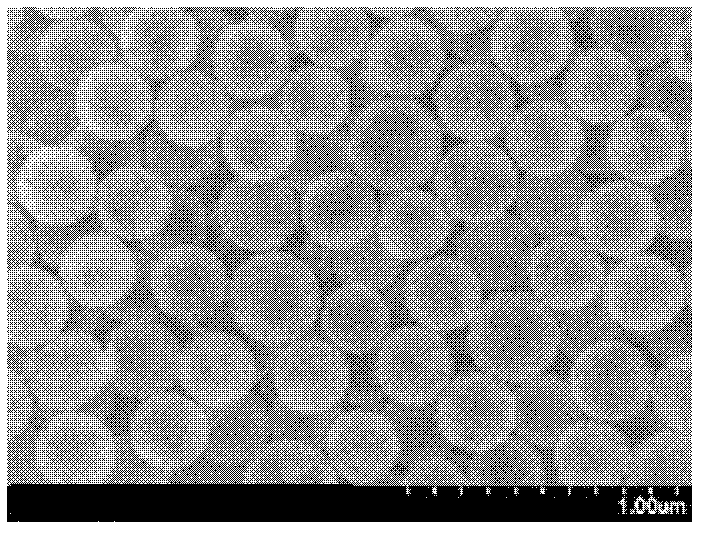

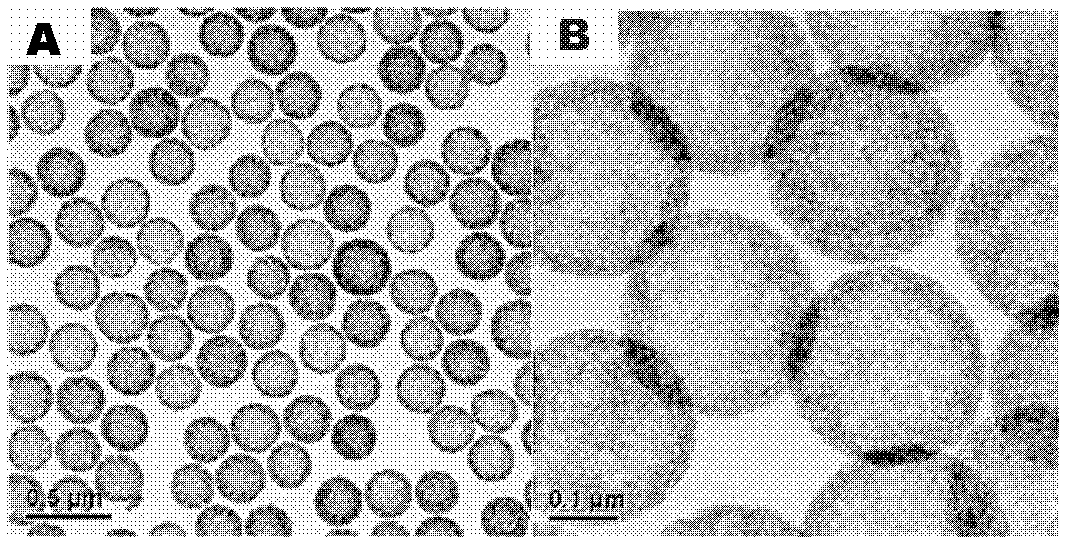

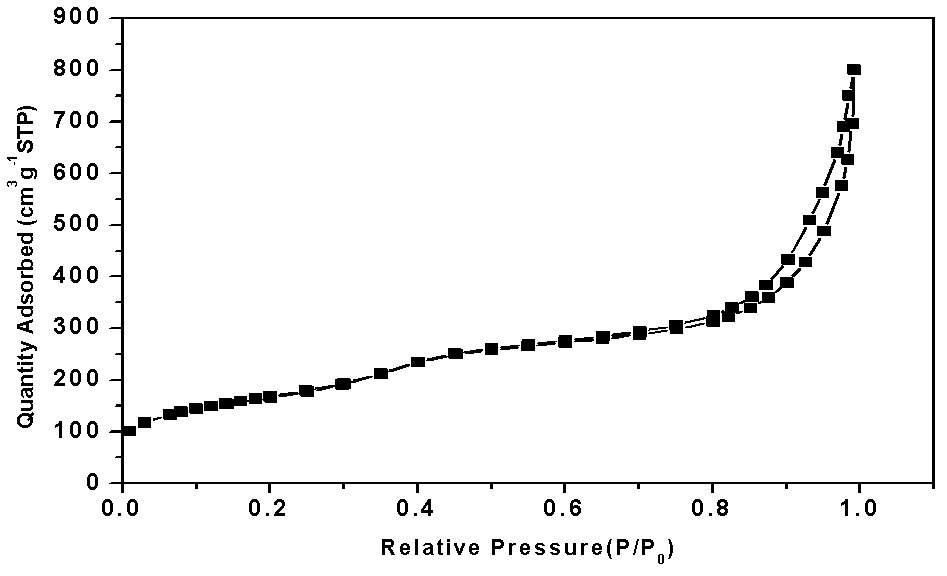

[0030] Prepared by the embodiment of the present invention is a uniform hollow mesoporous silica nanosphere with relatively large pores (see figure 1 and 2 ). Nitrogen adsorption curves based on hollow mesoporous silica nanospheres (see image 3 ), it can be seen that mesoporous silica hollow nanospheres h...

Embodiment 2

[0032] (1) Add 400 mg of silica nanospheres to 50 ml of water, and obtain a dispersion of silica nanospheres in an aqueous phase after ultrasonication for 30 minutes, then reflux at 95° C. for 6 hours, and then centrifuge to collect silica nanospheres.

[0033] (2) Disperse the silica nanospheres obtained in step (1) into 10 ml of water, add 20 mg of CTAB, and stir for 5 h.

[0034] (3) Add 140 mg of NaOH to the dispersion obtained in step (2), and etch at 25° C. for 5.5 h. Stand to cool, collect the precipitate, wash and dry to obtain a white powder, and remove the cationic surfactant from the white powder to obtain hollow mesoporous silica nanospheres containing larger pores.

Embodiment 3

[0036] (1) Add 400 mg of silica nanospheres to 50 ml of water, and obtain a dispersion of silica nanospheres after ultrasonication for 30 minutes, then reflux at 95° C. for 12 hours, and then centrifuge to collect silica nanospheres.

[0037] (2) Disperse the silica nanospheres obtained in step (1) into 10 ml of water, add 20 mg of CTAB, and stir for 5 h.

[0038] (3) Add 160 mg of NaOH to the dispersion obtained in step (2), and etch at 15° C. for 7 hours. Stand to cool, collect the precipitate, wash and dry to obtain a white powder, and remove the cationic surfactant from the white powder to obtain hollow mesoporous silica nanospheres containing larger pores.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com