Preparation method and apparatus of chitosan beads

A preparation device and chitosan technology, applied in the field of preparation of chitosan beads, can solve problems such as unstable process conditions and difficult high-efficiency production, and achieve the effects of good uniformity, simple method, and clean preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

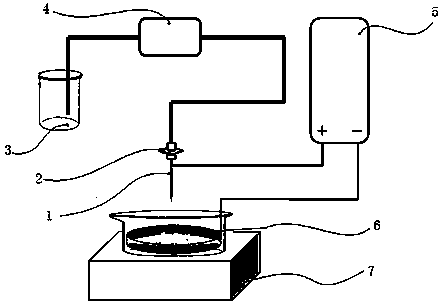

[0033] Example 1: It is a basic embodiment of the chitosan bead preparation method of the present invention. A kind of preparation method of chitosan beads, it is to use chitosan as raw material to prepare chitosan beads, comprising the steps:

[0034] A. Prepare chitosan solution and coagulation bath: dissolve chitosan in acetic acid solution to prepare chitosan solution; add sodium hydroxide to ethanol solution to dissolve, and prepare to promote chitosan to coagulate into beads coagulation bath;

[0035] B. Chitosan condenses into beads: inject the chitosan solution into the dropper, drop it into the coagulation bath through the dropper and stir; the dropper is a conductive hollow tube, and the dropper is transported with the chitosan solution The tube is also connected with a direct current power supply used to control the voltage between the dropper and the liquid level of the coagulation bath, and the particle size of the chitosan beads is adjusted by adjusting the vo...

Embodiment 2

[0038] Example 2: is a further example. Different from Example 1: the dropper is selected from medical needles; the residue on the washing chitosan beads is to wash the sodium hydroxide on the chitosan beads with deionized water; the chitosan beads after washing Store in PBS buffer at low temperature. The chitosan solution is injected into the dropper through a constant flow pump; the chitosan solution is dropped into the coagulation bath through the dropper and stirred by a magnetic stirrer. The concentration of the chitosan solution is 1.5% to 2.5% based on the mass of chitosan and the W / V percentage of the acetic acid solution volume, wherein the concentration of the acetic acid solution is 0.5% to 2% based on the W / V percentage of the mass of acetic acid and the volume of water The concentration of the coagulation bath liquid is 3.5% to 4.5% in terms of the mass of sodium hydroxide and the percentage of the volume of ethanol solution W / V, wherein the concentration of th...

Embodiment 3

[0039] Example 3: is a preferred embodiment. The difference from Embodiment 2 is that the adjustment range of the DC power supply voltage is 1000-6000 V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com