Method for preparing porous polymer material by selective biodegradation

A technology for porous polymers and degradable polymers, which is applied in the field of selective biodegradation to prepare porous polymer materials, which can solve the problems of unfavorable application of human tissue scaffolds, poor connectivity between pores, and cytotoxicity, so as to avoid cytotoxic hazards, Good mechanical properties, controllable pore size and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Method for preparing porous polymer material through selective biodegradation:

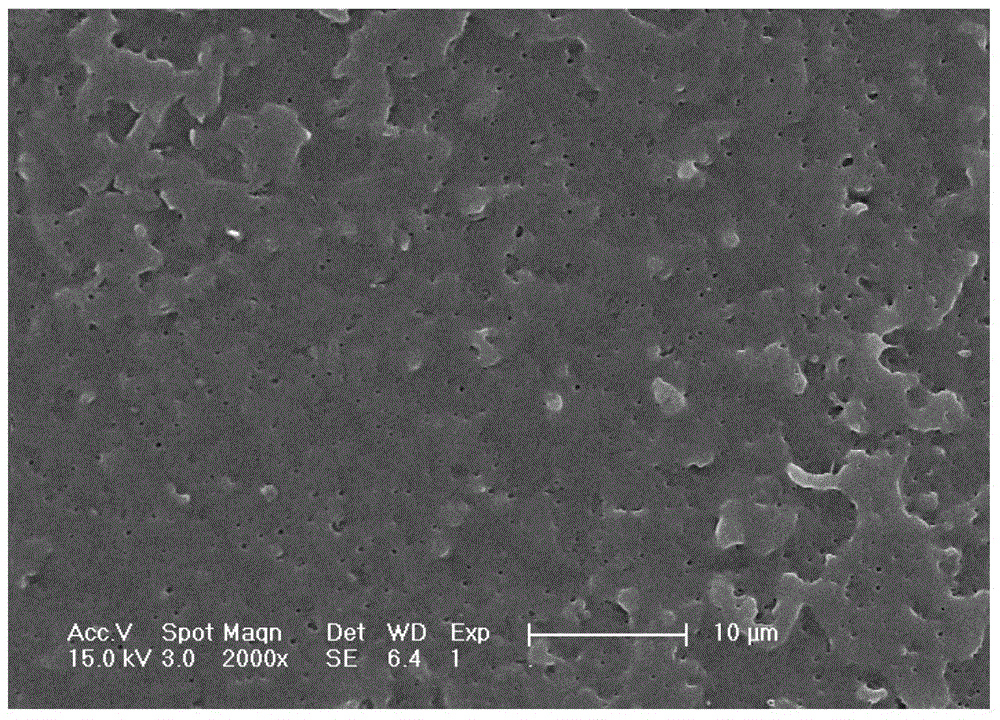

[0065] (1) Both PLA and PP were placed in a vacuum oven and dried under vacuum at 80°C for 24 hours. Weighed 18g of PLA and 42g of PP, and carried out melt blending in an internal mixer (HaakeRheomix600, Karlsruhe, Germany) to obtain a blended material. The blending conditions are: temperature 175°C, rotation speed 50 rpm, time 5-8 minutes;

[0066] (2) After preparing the sample of the blended material, put the sample into a sterile room for ultraviolet irradiation for 20 minutes, then put it into a 250ml Erlenmeyer flask containing 100ml of hydrochloric acid buffer solution (pH=8.6), and add proteinase K at the same time, After marking, put it on a shaker at 37°C (140r / min), and when the PLA component on the brittle section of the sample is completely degraded (the quality remains constant), take out the sample;

[0067] (3) Rinse the sample with distilled water and dry to constant weigh...

Embodiment 2

[0069] Method for preparing porous polymer material through selective biodegradation:

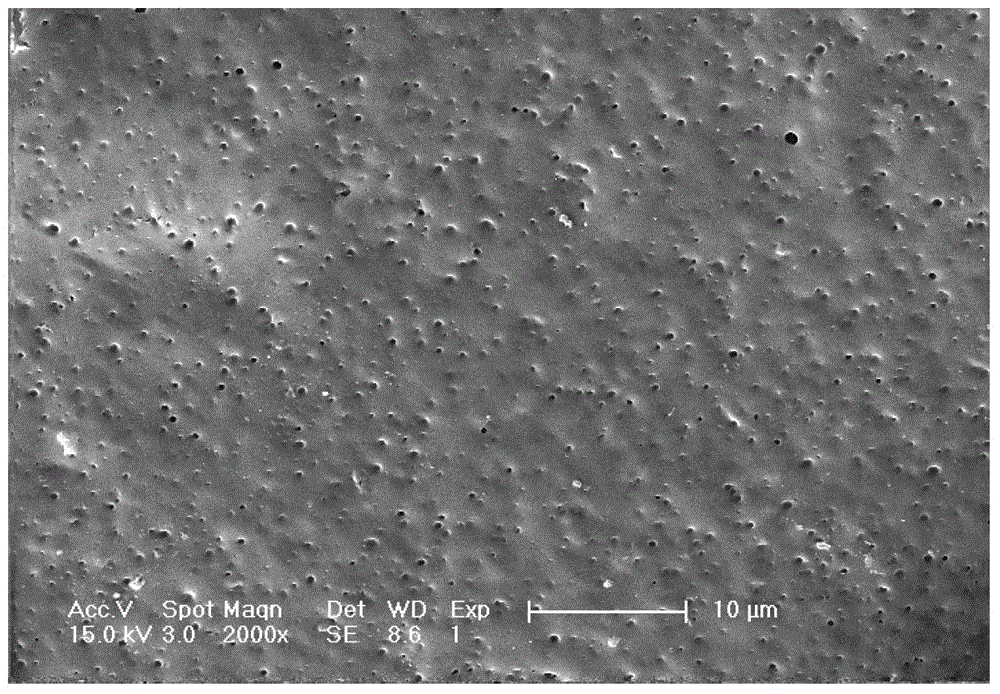

[0070] (1) Place PCL and PE in a vacuum oven and dry them under vacuum at 40°C and 80°C for 24 hours respectively, weigh 24g of PCL and 36g of PE, and carry out melt blending in an internal mixer (HaakeRheomix600, Karlsruhe, Germany) to obtain a blend For mixing materials, the blending conditions are: temperature 140°C, speed 50 rpm, time 5-8 minutes;

[0071] (2) After preparing the sample of the blended material, put the sample into a sterile room for ultraviolet irradiation for 20 minutes, then put it into a 250ml Erlenmeyer flask containing 100ml of phosphate buffer solution (pH=7.0), and add Rhizopus aeruginosa (Rhizopus arrhizus), after marking, put it on a shaking table at 30°C (140r / min), and when the PCL component on the brittle section of the sample is completely degraded (the quality remains constant), take out the sample;

[0072] (3) Rinse the sample with distilled water and d...

Embodiment 3

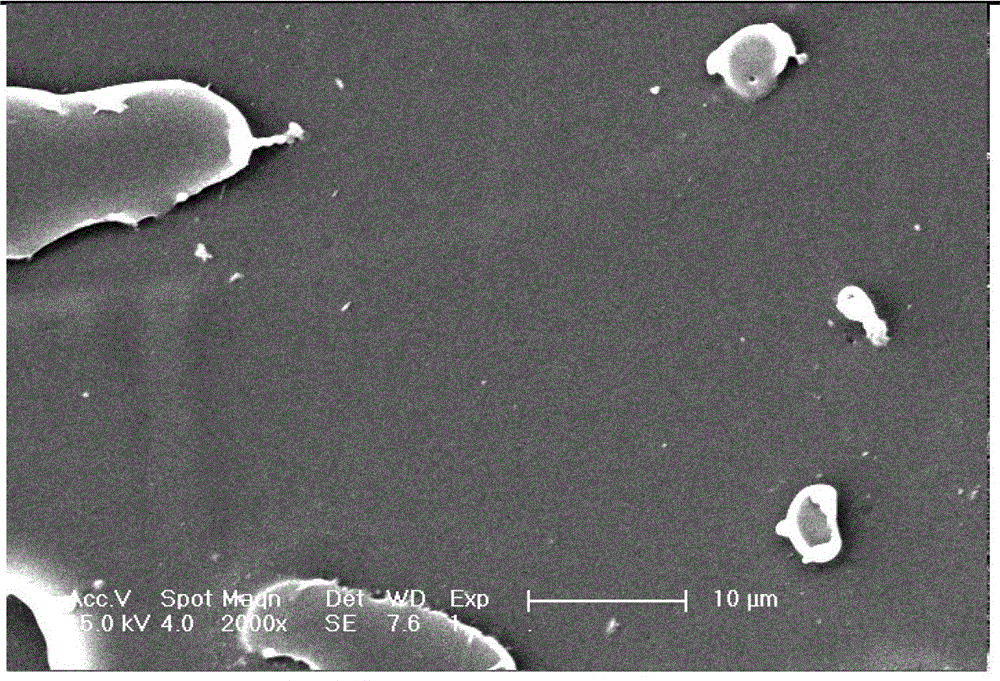

[0074] Method for preparing porous polymer material through selective biodegradation:

[0075] (1) Place PCL, PLA, and PE in a vacuum oven at 40°C, 80°C, and 80°C for 24 hours in a vacuum, and then weigh 24g of PCL, 12g of PLA, and 24g of PE in an internal mixer (Haake Rheomix600, Karlsruhe, Germany). Melt-blending in a medium to obtain a blended material, the blending conditions are: temperature 175°C, rotating speed 50 rpm, time 5-8 minutes;

[0076] (2) After preparing the sample of the blended material, put the sample into a sterile room for ultraviolet irradiation for 20 minutes, then put it into a 250ml Erlenmeyer flask containing 100ml of phosphate buffer solution (pH=7.0), and add Rhizopus aeruginosa After marking, put it on a shaking table at 30°C (140r / min). When the PCL component on the brittle section of the sample is completely degraded (the quality remains constant), take out the sample, wash it and dry it to a constant weight, and then put it in Add proteinase ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com