High-energy and high-potential gradient tin dioxide varistor composite powder and preparation method

A technology of composite powder and tin dioxide, applied in the high-energy field, can solve the problems that the uniformity of additive doping cannot be improved continuously, the electrical performance of varistor cannot be greatly improved, etc. control, improve electrical properties, and refine the effect of grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

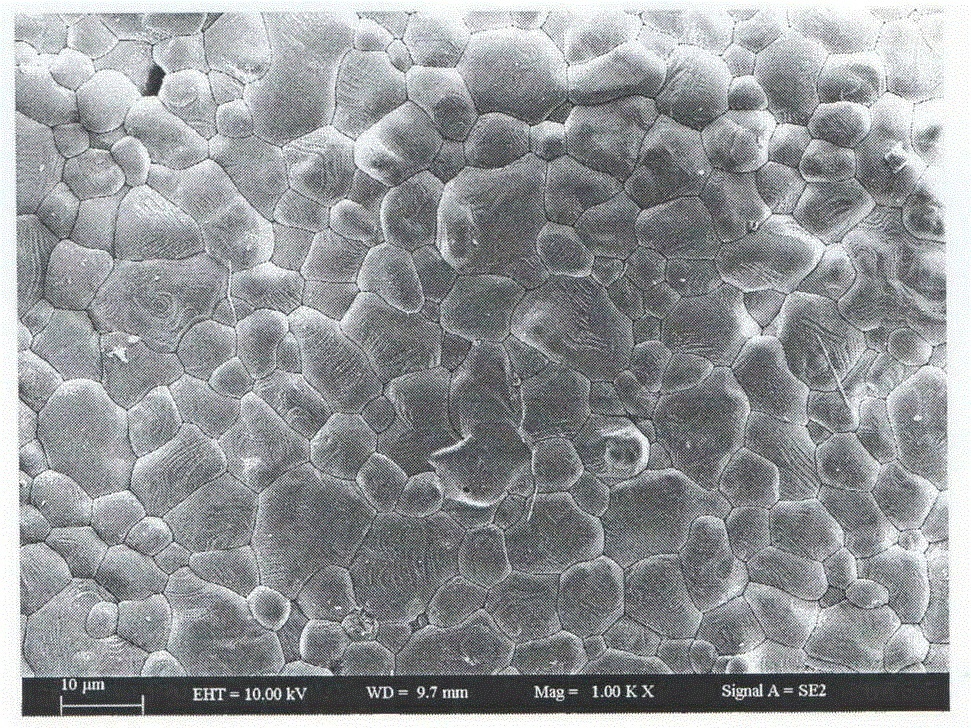

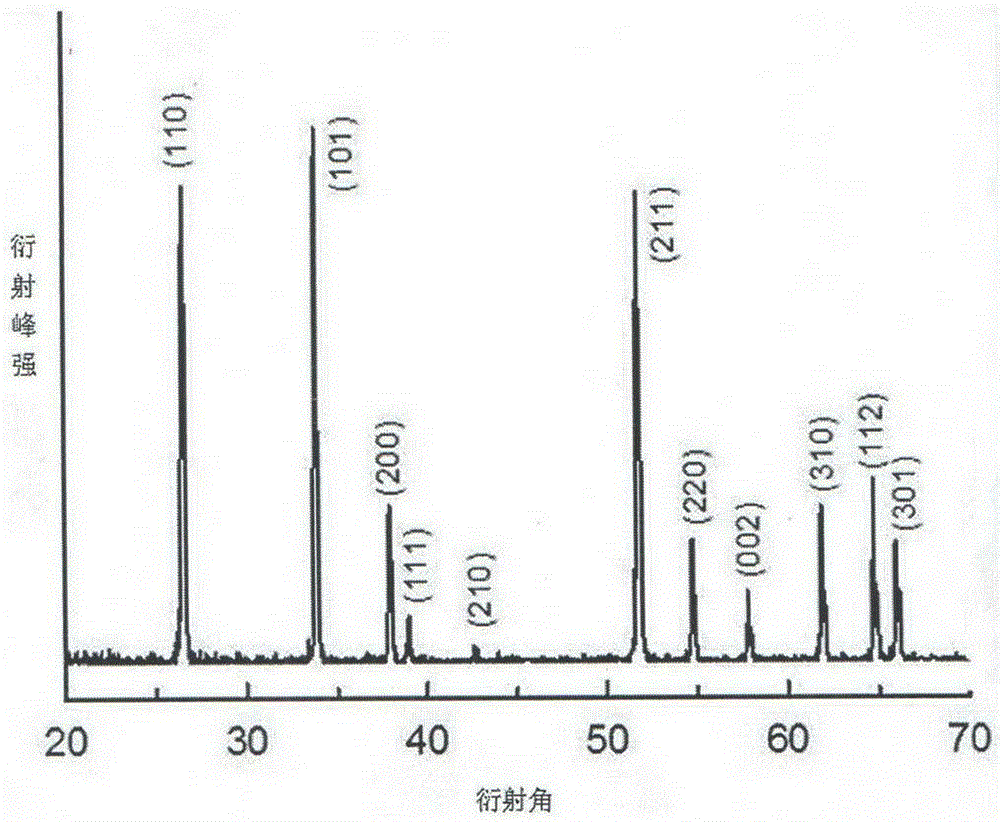

Embodiment 1

[0024] In a ball mill, 0.1 mol% of nano-titanium dioxide particles, 0.9 mol% of cobalt trioxide powder, 0.1 mol% of niobium pentoxide powder, 0.5 mol% of hexapraseodymium oxide powder, and 0.5 mol% of diyttrium trioxide powder were mixed, Ball milling for 4 hours to make a mixture, wherein the titanium dioxide particles are monodisperse nano-scale particles, which are mixed into the composite powder in the form of a hydrosol, and the content of titanium dioxide in the hydrosol is 10w%;

[0025] Add 97.85 mol% of submicron tin dioxide powder and 0.05 mol% of nano antimony pentoxide particles to the obtained mixture, and then ball mill for 2 hours to make a mixture, wherein the nano antimony pentoxide particles are monodisperse nano Grade particles, mixed into the composite powder in the form of hydrosol, the content of antimony pentoxide in the hydrosol is 10w%;

[0026] The obtained mixture is dried and sieved to obtain a powder of the mixture;

[0027] Then place the powder ...

Embodiment 2

[0030]In a ball mill, mix 1 mol% of nano-titanium dioxide particles, 1.5 mol% of cobalt trioxide powder, 0.4 mol% of niobium pentoxide powder, 0.5 mol% of hexapraseodymium oxide powder and 0.5 mol% of diyttrium trioxide powder, and ball mill 3 hours,

[0031] A mixture is made, wherein the titanium dioxide particles are monodisperse nanoscale particles, which are mixed into the composite powder in the form of a hydrosol, and the content of titanium dioxide in the hydrosol is 30w%;

[0032] Add 95.6 mol% of submicron tin dioxide powder and 0.5 mol% of nano antimony pentoxide particles to the obtained mixture, and then ball mill for 1 hour to make a mixture, wherein the antimony pentoxide particles are monodisperse nano-scale Particles are mixed into the composite powder in the form of hydrosol, and the content of antimony pentoxide in the hydrosol is 30w%;

[0033] The obtained mixture is dried and sieved to obtain the powder of the mixture;

[0034] Then place the powder of ...

Embodiment 3

[0037] In a ball mill, 0.1 mol% of nano titanium dioxide particles, 1.5 mol% of cobalt trioxide powder, 0.4 mol% of niobium pentoxide powder, 0.5 mol% of hexapraseodymium oxide powder and 0.5 mol% of diyttrium trioxide powder are mixed, Ball milling for 6 hours to make a mixture, wherein the titanium dioxide particles are monodisperse nano-scale particles, which are mixed into the composite powder in the form of a hydrosol, and the content of titanium dioxide in the hydrosol is 15w%;

[0038] Add 96.5 mol% of submicron tin dioxide powder and 0.5 mol% of nano antimony pentoxide particles to the obtained mixture, and then ball mill for 3 hours to make a mixture, wherein the antimony pentoxide particles are monodisperse nano-scale The particles are mixed into the composite powder in the form of hydrosol, and the content of antimony pentoxide in the hydrosol is 20w%;

[0039] The obtained mixture is dried and sieved to obtain the powder of the mixture;

[0040] Then place the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com