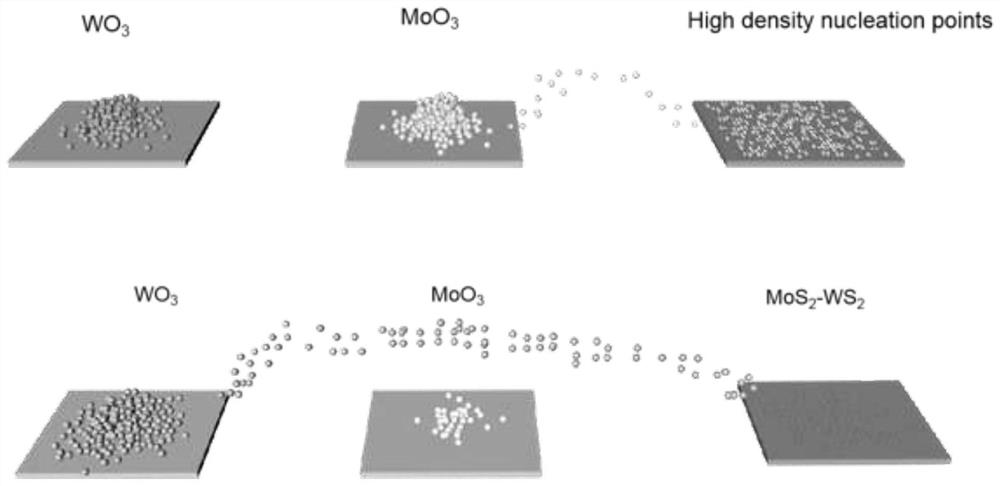

Method for preparing single-layer MoS2/WS2 two-component gradient material by one-step method

A gradient material, two-component technology, applied in chemical instruments and methods, sustainable manufacturing/processing, metal material coating technology, etc., can solve the problems of poor size controllability, scarcity, complex preparation process, etc. The effect of domain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] One-step preparation of monolayer MoS 2 / WS 2 A method for a two-component gradient material, comprising the following steps:

[0046] 1. Ultrasonic cleaning of SiO with acetone and ethanol 2 / Si substrate, and with N 2 blow dry;

[0047] 2. Use argon to clean the quartz tube and corundum boat of the multi-temperature zone tube furnace;

[0048] 3. Place the weighed 1.0g of sulfur powder on one side of a corundum boat with a length of 5cm, and compress the sulfur powder with a spatula. Seal the corundum boat containing the sulfur powder with aluminum foil, and use a thin steel needle in the container. Two small holes with a diameter of 0.5mm are made on the side where the sulfur powder is placed, and then the corundum boat containing the sulfur powder is placed in the low temperature area upstream of the multi-temperature zone tube furnace; 0.5g tungsten oxide and 1mg sodium chloride are mixed. The mixed powder and 0.2 g of molybdenum oxide powder were sequentially...

Embodiment 2

[0053] One-step preparation of monolayer MoS 2 / WS 2 A method for a two-component gradient material, comprising the following steps:

[0054] 1. Ultrasonic cleaning of SiO with acetone and ethanol 2 / Si substrate, and with N 2 blow dry;

[0055] 2. Use argon to clean the quartz tube and corundum boat of the multi-temperature zone tube furnace;

[0056] 3. Place the weighed 2.0g sulfur powder on one side of a corundum boat with a length of 4cm, and compress the sulfur powder with a spatula. Seal and wrap the corundum boat containing the sulfur powder with aluminum foil, and use a thin steel needle in the container. Three small holes with a diameter of 0.5mm are made on the side where the sulfur powder is placed, and then the corundum boat containing the sulfur powder is placed in the low temperature zone upstream of the multi-temperature zone tube furnace; 0.8g of tungsten oxide and 0.1mg of sodium chloride are mixed The mixed powder and 0.35g of molybdenum oxide powder we...

Embodiment 3

[0061] One-step preparation of monolayer MoS 2 / WS 2 A method for a two-component gradient material, comprising the following steps:

[0062] 1. Ultrasonic cleaning of SiO with acetone and ethanol 2 / Si substrate, and with N 2 blow dry;

[0063] 2. Use argon to clean the quartz tube and corundum boat of the multi-temperature zone tube furnace;

[0064] 3. Place the weighed 1.8g of sulfur powder on one side of a corundum boat with a length of 6cm, and compress the sulfur powder with a spatula. Seal the corundum boat containing the sulfur powder with aluminum foil, and use a thin steel needle in the container. Three small holes with a diameter of 0.5mm are made on the side where the sulfur powder is placed, and then the corundum boat containing the sulfur powder is placed in the low temperature area upstream of the multi-temperature zone tube furnace; 1.3g of tungsten oxide and 0.06mg of chlorinated The mixed powder of sodium and 0.5 g of molybdenum oxide powder were sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com