Method for preventing corrosion in large waste animal and vegetable oil carbon steel storage tank

A technology for discarded animals, plants, and steel storage tanks, which is applied in the direction of anti-corrosion coatings, coatings, and adhesive additives. It can solve the problems of difficult maintenance and shortened service life of large carbon steel storage tanks, and achieve low construction difficulty and low production costs. Low, the effect of meeting the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Anticorrosion method in large-scale waste animal and vegetable oil carbon steel storage tank

[0024] S1. Carry out sandblasting and derusting treatment on the inner wall and bottom plate of the storage tank. The level of sandblasting and rust removal on the inner wall and bottom plate of the storage tank must class;

[0025] S2. Coat the tank wall and bottom plate after derusting with a primer layer. After the primer layer is hardened, use resin cement to repair the uneven parts of the concave-convex holes and the inner and outer corners;

[0026] S3. Coating anti-corrosion resin on the primer layer, then laying high-density glass fiber cloth, and then coating anti-corrosion resin to form a layer of chopped strand mat, laying three layers continuously, and then coating sequentially on the uppermost layer of chopped strand mat Anti-corrosion resin, laying low-density glass fiber cloth, and then coating anti-corrosion resin to form a surface mat. The inner...

Embodiment 2

[0029] Embodiment 2 Anticorrosion method in large-scale waste animal and vegetable oil carbon steel storage tank

[0030] S1. Carry out sandblasting and derusting treatment on the inner wall and bottom plate of the storage tank. The level of sandblasting and rust removal on the inner wall and bottom plate of the storage tank must class;

[0031] S2. Coat the tank wall and bottom plate after derusting with a primer layer. After the primer layer is hardened, use resin cement to repair the uneven parts of the concave-convex holes and the inner and outer corners;

[0032] S3. Coating anti-corrosion resin on the primer layer, then laying high-density glass fiber cloth, and then coating anti-corrosion resin to form a layer of chopped strand mat, laying three layers continuously, and then coating sequentially on the uppermost layer of chopped strand mat Anti-corrosion resin, laying low-density glass fiber cloth, and then coating anti-corrosion resin to form a surface mat. The inner...

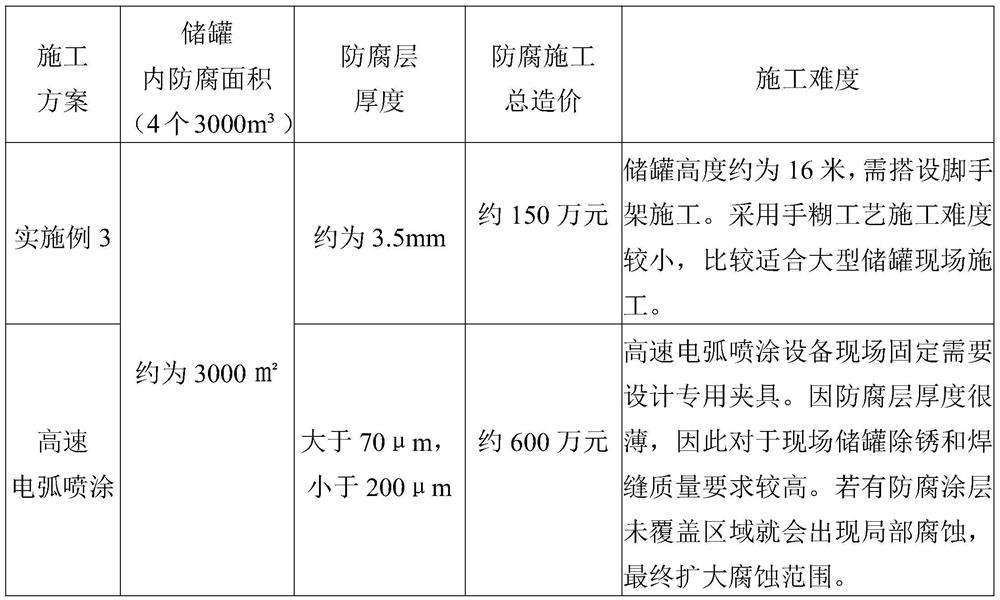

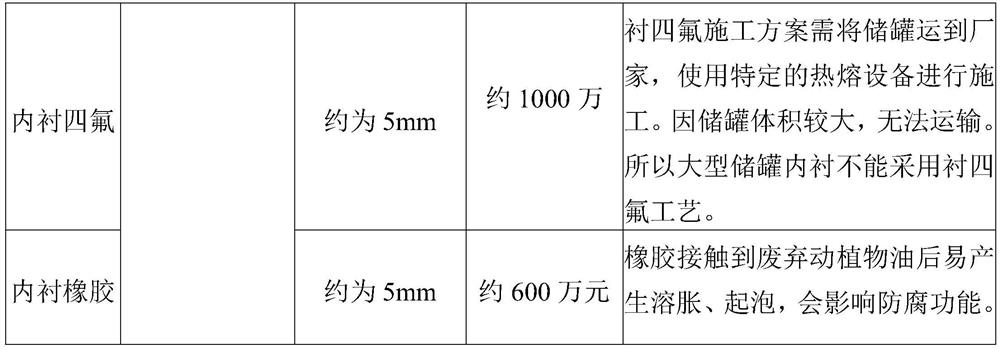

Embodiment 3

[0035] Embodiment 3 Anticorrosion method in large-scale waste animal and vegetable oil carbon steel storage tank

[0036] S1. Carry out sandblasting and derusting treatment on the inner wall and bottom plate of the storage tank. The level of sandblasting and rust removal on the inner wall and bottom plate of the storage tank must class;

[0037] S2. Coat the tank wall and bottom plate after derusting with a primer layer. After the primer layer is hardened, use resin cement to repair the uneven parts of the concave-convex holes and the inner and outer corners;

[0038] S3. Coating anti-corrosion resin on the primer layer, then laying high-density glass fiber cloth, and then coating anti-corrosion resin to form a layer of chopped strand mat, laying three layers continuously, and then coating sequentially on the uppermost layer of chopped strand mat Anti-corrosion resin, laying low-density glass fiber cloth, and then coating anti-corrosion resin to form a surface mat. The inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com