Acidic oil extraction medium corrosion inhibitor

A technology of corrosion inhibitor and mass ratio, applied in the field of acid oil production medium corrosion inhibitor, can solve the problems of high price, low yield and difficult preparation, and achieve the effect of meeting the requirements of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

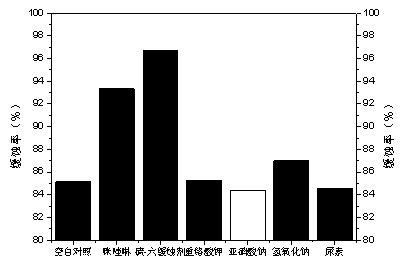

[0018] Embodiment 1: Research on the corrosion inhibition performance of different corrosion inhibitors

[0019] (1) Turn on the constant temperature water bath and set the temperature of the water bath to 80°C;

[0020] (2) First number 7 N80 steel sheets 1, 2, 3, 4, 5, 6, 7, and then put them all into a 100ml beaker, pour 100ml petroleum ether into the beaker, and soak the N80 steel sheets for 10 minutes , after taking it out, wipe off the dirt on the surface, dry it at 30°C, weigh it three times, and calculate the average value;

[0021] (3) Put the above-mentioned treated N80 steel sheets into 7 conical flasks respectively, add 70ml of ammonium persulfate solution with a mass fraction of 8% in each conical flask, and then add 0.500g of imidazoline, 0.400g of sulfur Add urea, 0.100g hexamethylenetetramine, 0.050g potassium dichromate, 0.050g sodium nitrite, 0.500g sodium hydroxide and 0.500g urea to Erlenmeyer flasks No. 1, 2, 3, 4, 5 and 6 respectively , No. 7 as a blank...

Embodiment 2

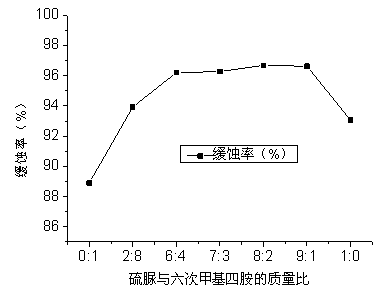

[0026] Example 2: Research on corrosion inhibition performance of different proportioning corrosion inhibitors

[0027] (1) Turn on the constant temperature water bath and set the temperature of the water bath to 80°C;

[0028] (2) First, take out 7 pieces of N80 steel sheets numbered 1, 2, 3, 4, 5, 6, 7, and then put them all into a 100ml beaker, pour 100ml of petroleum ether into the beaker, soak the N80 steel sheets for 10 After taking it out, wipe off the dirt on the surface, dry it at 30°C, weigh it three times, and calculate the average value;

[0029] (3) Put the above-mentioned treated N80 steel sheets into 7 Erlenmeyer flasks respectively, add 70ml of ammonium persulfate solution with a mass fraction of 8% in each Erlenmeyer flask respectively, then add 0.500g thiourea, 0.450g sulfur Urea and 0.050g hexamethylenetetramine, 0.400g thiourea and 0.100g hexamethylenetetramine, 0.350g thiourea and 0.150g hexamethylenetetramine, 0.300g thiourea and 0.200g hexamethylenetetr...

Embodiment 3

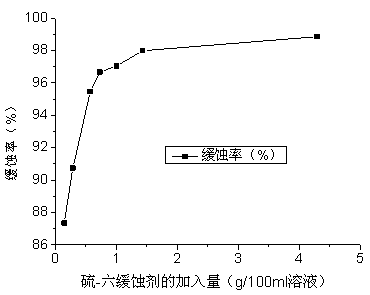

[0034] Embodiment 3: Research on the corrosion inhibition performance of corrosion inhibitors with different additions

[0035] (1) Turn on the constant temperature water bath and set the temperature of the water bath to 80°C;

[0036] (2) First, take out 7 pieces of N80 steel sheets numbered 1, 2, 3, 4, 5, 6, 7, and then put them all into a 100ml beaker, pour 100ml of petroleum ether into the beaker, soak the N80 steel sheets for 10 After taking it out, wipe off the dirt on the surface, dry it at 30°C, weigh it three times, and calculate the average value;

[0037] (3) the above-mentioned processed N80 steel sheets are put into 7 conical flasks respectively, add the ammonium persulfate solution of 70ml mass fraction 8% in each conical flask respectively, then 2.400g thiourea and 0.600g six Methylenetetramine, 0.800g thiourea and 0.200g hexamethylenetetramine, 0.560g thiourea and 0.140g hexamethylenetetramine, 0.400g thiourea and 0.100 hexamethylenetetramine, 0.320g sulfur U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com