Zirconium-silver alloy target and preparation method and application thereof

A technology of zirconium-silver alloy and target material, which is applied in metal material coating process, ion implantation plating, coating and other directions to achieve the effects of uniform structure, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

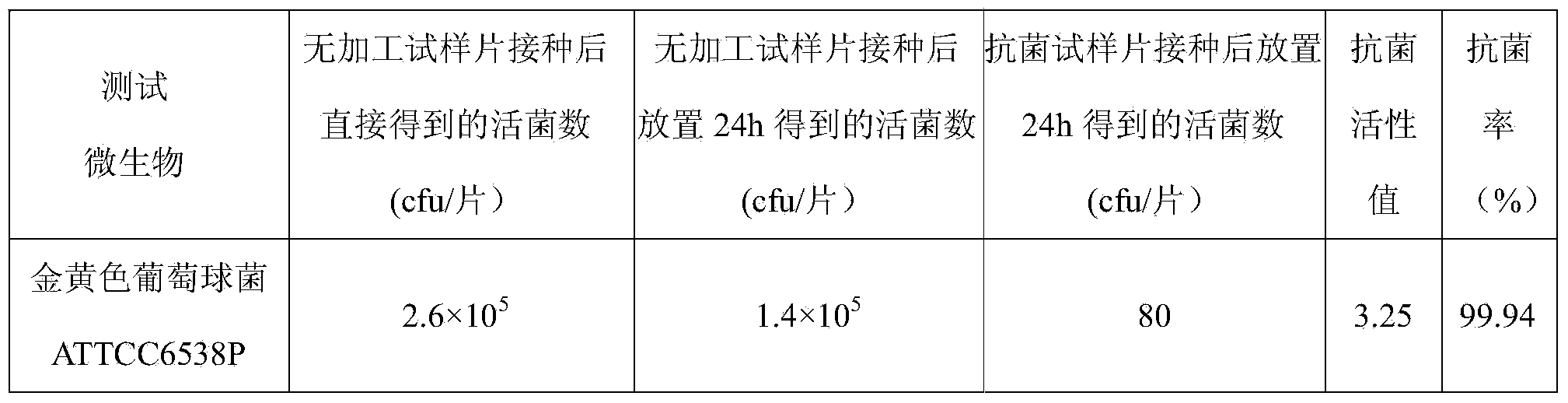

Image

Examples

Embodiment 1

[0035] The invention relates to a method for preparing a zirconium-silver alloy target, comprising the following steps:

[0036] (1), weighing and mixing: the nuclear-grade spongy metal zirconium (the purity of zirconium is 99.8%) and silver scraps with a purity of 99.99% are weighed and mixed according to the mass percentage of 98% for zirconium and 2% for silver;

[0037] (2) Electrode pressing: place the mixed metal zirconium and silver alloy materials in a nitrogen protective atmosphere to prevent the materials from being damp and oxidized, and put the prepared zirconium silver materials evenly into the press to press them into electrodes. Each electrode is controlled at 6kg, in which zirconium and silver are evenly mixed and clothed, and the pressed electrode is placed in a nitrogen protective atmosphere to prevent the material from being damp and oxidized;

[0038] (3) Welding electrodes: The two pressed electrodes are welded into smelting electrodes by tungsten argon ar...

Embodiment 2

[0056] The invention relates to a method for preparing a zirconium-silver alloy target, comprising the following steps:

[0057] (1), weighing and mixing: the nuclear-grade spongy metal zirconium (the purity of zirconium is 99.8%) and silver scraps with a purity of 99.99% are weighed and mixed according to the mass percentage of 97% for zirconium and 3% for silver;

[0058] (2) Electrode pressing: place the mixed metal zirconium and silver alloy materials in a nitrogen protective atmosphere to prevent the materials from being damp and oxidized, and put the prepared zirconium silver materials evenly into the press to press them into electrodes. Each electrode is controlled at 4.4kg, in which zirconium and silver are evenly mixed and clothed, and the pressed electrode is placed in a nitrogen protective atmosphere to prevent the material from being damp and oxidized;

[0059] (3) Welding electrodes: The two pressed electrodes are welded into smelting electrodes by tungsten argon ...

Embodiment 3

[0073] The invention relates to a method for preparing a zirconium-silver alloy target, comprising the following steps:

[0074] (1), weighing and mixing: the nuclear-grade spongy metal zirconium (the purity of zirconium is 99.8%) and silver scraps with a purity of 99.99% are weighed and mixed according to the mass percentage of 99.5% for zirconium and 0.5% for silver;

[0075] (2) Electrode pressing: place the mixed metal zirconium and silver alloy materials in a nitrogen protective atmosphere to prevent the materials from being damp and oxidized, and put the prepared zirconium silver materials evenly into the press to press them into electrodes. Each electrode is controlled at 8.0kg, in which zirconium and silver are evenly mixed and clothed, and the pressed electrode is placed in a nitrogen protective atmosphere to prevent the material from being damp and oxidized;

[0076] (3) Welding electrodes: The two pressed electrodes are welded into smelting electrodes by tungsten ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com