Method for preparing TiAl alloy through melting with consumable vacuum arc furnace

A vacuum consumable arc and alloy technology, applied in the field of smelting TiAl alloys in a vacuum consumable arc furnace, can solve the problems of large difference in melting point, high melting reaction heat, and easy cracks, etc., and achieve uniform structure size and simple process , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

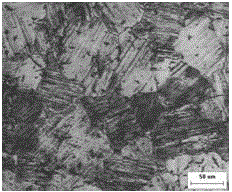

Image

Examples

Embodiment 1

[0021] The TiAl alloy is smelted in a vacuum consumable electric arc furnace, and the specific steps are as follows:

[0022] (a) Weighing: Weigh and mix metal Ti and metal Al according to the mass ratio of Ti 87.5% and Al 12.5%;

[0023] (b) Pressed electrodes: press the mixed metal Ti and Al in proportion to make electrodes, and each electrode is controlled at 2.2 kg;

[0024] (c) Welding electrodes: every two pressed electrodes are welded into smelting electrodes by argon tungsten arc welding;

[0025] (d) Vacuum consumable melting primary ingot: melt the welded TiAl electrode in a 10kg vacuum consumable arc melting furnace with a current of 2.0kA and a working vacuum of 1.0×10E -1 Pa, use a copper crucible with a diameter of 80mm to melt a TiAl primary ingot with a diameter of 80mm;

[0026] (e) Welding secondary smelting electrodes: remove the head and flat tail of the smelted primary ingots with a lathe, and weld each 6 primary ingots into secondary electrodes by tungs...

Embodiment 2

[0029] The TiAl alloy is smelted in a vacuum consumable electric arc furnace, and the specific steps are as follows:

[0030] (a) Weighing: Weigh and mix metal Ti and metal Al according to the mass ratio of Ti 75% and Al 25%;

[0031] (b) Pressed electrodes: Weigh the mixed metal Ti and Al in proportion to press them into electrodes, and each electrode is controlled at 4.0 kg;

[0032] (c) Welding electrodes: every two pressed electrodes are welded into smelting electrodes by argon tungsten arc welding;

[0033] (d) Vacuum consumable melting primary ingot: melt the welded TiAl electrode in a 10kg vacuum consumable arc melting furnace with a current of 1.8kA and a working vacuum of 1.0×10E -1 Pa, use a copper crucible with a diameter of 80mm to melt a TiAl primary ingot with a diameter of 80mm;

[0034] (e) Welding secondary smelting electrodes: remove the head and flat tail of the smelted primary ingots with a lathe, and weld each 6 primary ingots into secondary electrodes b...

Embodiment 3

[0037] The TiAl alloy is smelted in a vacuum consumable electric arc furnace, and the specific steps are as follows:

[0038] (a) Weighing: Weigh and mix metal Ti and metal Al according to the mass ratio of Ti 64% and Al 36%;

[0039] (b) Pressed electrodes: Weigh the mixed metal Ti and Al in proportion to press them into electrodes, and each electrode is controlled at 2.8 kg;

[0040] (c) Welding electrodes: every two pressed electrodes are welded into smelting electrodes by argon tungsten arc welding;

[0041] (d) Welding secondary smelting electrodes: Melt the welded TiAl electrodes in a 10kg vacuum consumable arc melting furnace with a current of 1.5kA and a working vacuum of 1.0×10E -1 Pa, use a copper crucible with a diameter of 80mm to melt a TiAl primary ingot with a diameter of 80mm;

[0042] (e) Vacuum self-consumption smelting of secondary ingots: remove the heads and tails of the smelted primary ingots with a lathe, and weld each 6 primary ingots into secondary e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com