Ceramic layer for improving antifriction and corrosion resistance of inner wall of venturi tube and preparation method thereof

A Venturi tube and ceramic layer technology, which is applied in the direction of coating, surface reaction electrolytic coating, anodic oxidation, etc., can solve the problems of exhaust gas detection system failure, easy corrosion of the inner wall, and inaccurate measurement, so as to improve the service life, Strong corrosion resistance, excellent bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

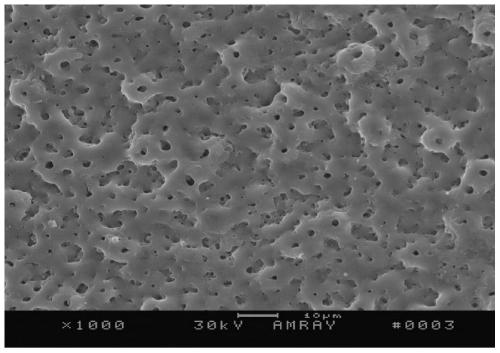

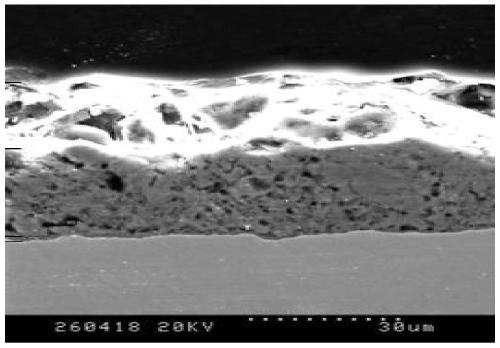

[0041] Embodiment 1 of the present invention: as figure 1 and figure 2 As shown, a ceramic layer that improves the anti-friction and corrosion resistance of the inner wall of the Venturi tube is grown on the surface of the Venturi tube substrate. The composition of the ceramic layer is alumina and aluminum silicate, and the thickness is 5-15 μm. It can be seen from the figure that a ceramic layer with nanoscale, disorderly, and crater-shaped blind micropores is formed on the surface of the aluminum substrate of the Venturi tube. Combination, this combination method leads to excellent bonding between the ceramic layer and the substrate, and a large number of nanoscale holes on the surface of the ceramic layer are blind micropores that do not penetrate into the substrate, which is conducive to improving the anti-corrosion performance of the entire ceramic layer. Specifically, the ceramic layer is very uniform, because it contains α-AL 2 o 3 (commonly known as corundum) makes...

Embodiment 2

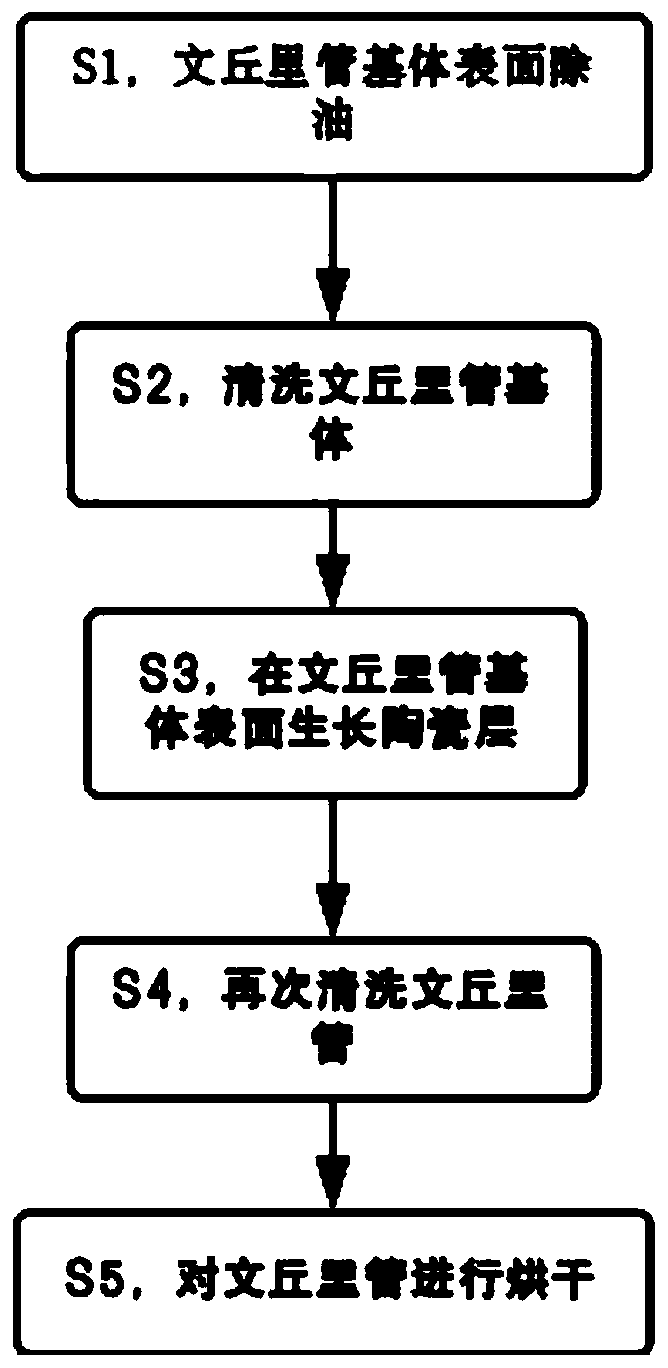

[0042] Embodiment 2: as Figure 1-Figure 3 Shown, a kind of preparation method of the ceramic layer that improves anti-friction and corrosion resistance performance of Venturi tube inner wall, is used for preparing aforementioned ceramic layer that improves the anti-friction and corrosion resistance performance of Venturi tube inner wall, comprises the following process:

[0043] S1, degreasing the surface of the Venturi tube substrate; specifically includes: fixing the qualified Venturi tube substrate on the hanger to ensure that the Venturi tube base workpiece and the hanger are unimpeded and fixed firmly to ensure that there will be no short circuit; The pipe matrix workpiece and hanger are hoisted into the ultrasonic degreasing tank by the mechanical arm for degreasing. The degreasing liquid in the ultrasonic degreasing tank is 2-10% sodium hydroxide solution, the temperature is 40-60°C, and the time is 3-5 minute;

[0044] S2, cleaning the Venturi tube matrix; specifical...

Embodiment 3

[0048] Embodiment 3: as figure 1 , figure 2 and Figure 4 Shown, a kind of preparation method of the ceramic layer that improves anti-friction and corrosion resistance performance of Venturi tube inner wall, is used for preparing aforementioned ceramic layer that improves the anti-friction and corrosion resistance performance of Venturi tube inner wall, comprises the following process:

[0049] S1, degreasing the surface of the Venturi tube substrate; specifically includes: fixing the qualified Venturi tube substrate on the hanger to ensure that the Venturi tube base workpiece and the hanger are unimpeded and fixed firmly to ensure that there will be no short circuit; The pipe matrix workpiece and hanger are hoisted into the ultrasonic degreasing tank by the mechanical arm for degreasing. The degreasing liquid in the ultrasonic degreasing tank is 2-10% sodium hydroxide solution, the temperature is 40-60°C, and the time is 3-5 minute;

[0050] S2, cleaning the Venturi tube ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com