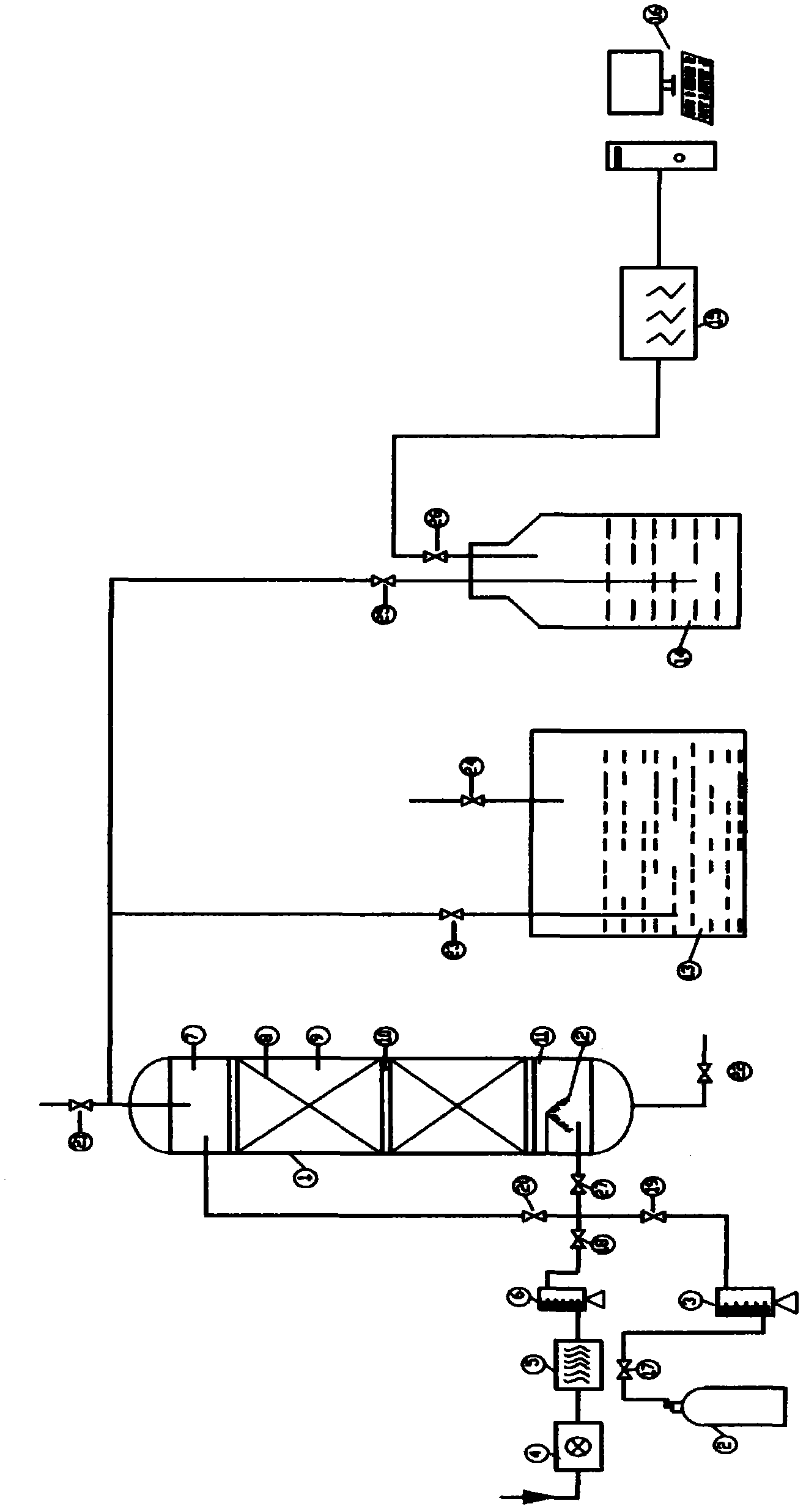

Ferrous sulfide gas phase passivation device

A gas-phase passivation and ferrous sulfide technology, which is applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of high cost and large consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] Gas phase passivation is a method of controlled oxidation of ferrous sulfide using water vapor as a carrier and using oxidizing gas to prevent people who open the device from spontaneous combustion and explosion accidents of ferrous sulfide inside the petrochemical plant before maintenance.

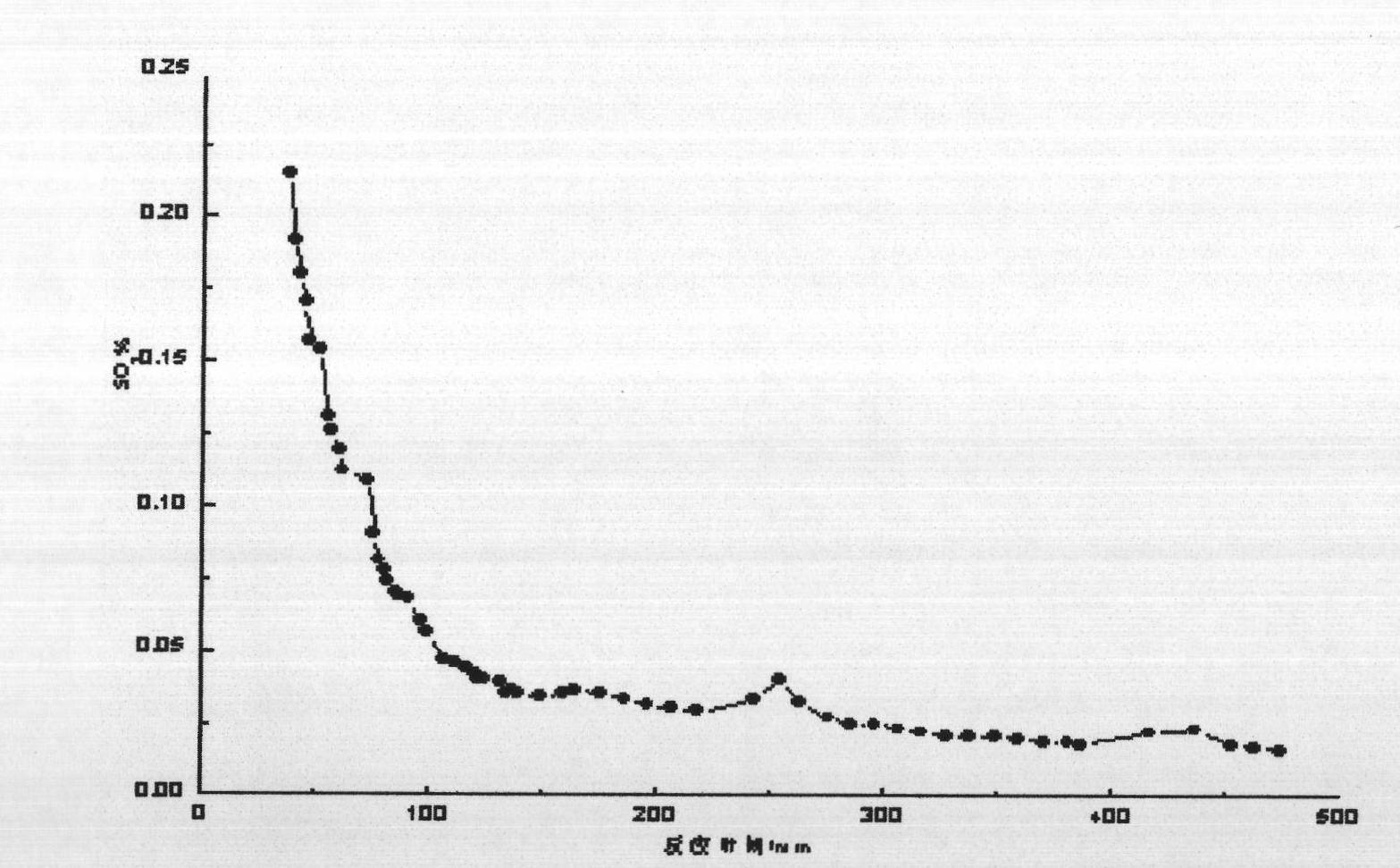

[0083] The gas-phase passivation method of ferrous sulfide in the petrochemical device of the present invention is carried out in the middle and later stages of the distillation tower, and the low-pressure steam (0.3-0.4Mpa) carries oxygen-enriched air with a certain oxygen content (21%-35%) into the distillation tower for implementation. The gas phase passivation of ferrous sulfide, the heat released by the passivation is absorbed by the steam with a large heat capacity and will not cause the accumulation of heat in the tower. Part of the sulfur dioxide gas generated by the passivation is carried out of the tower by the steam and then passed through the ammonia It can be directly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com