Galvanized part passivation device

A technology of component and passivation solution, which is applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of passivation solution residue, increase production cost, increase consumption of passivation solution, etc., and achieve stability Good performance and uniform passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

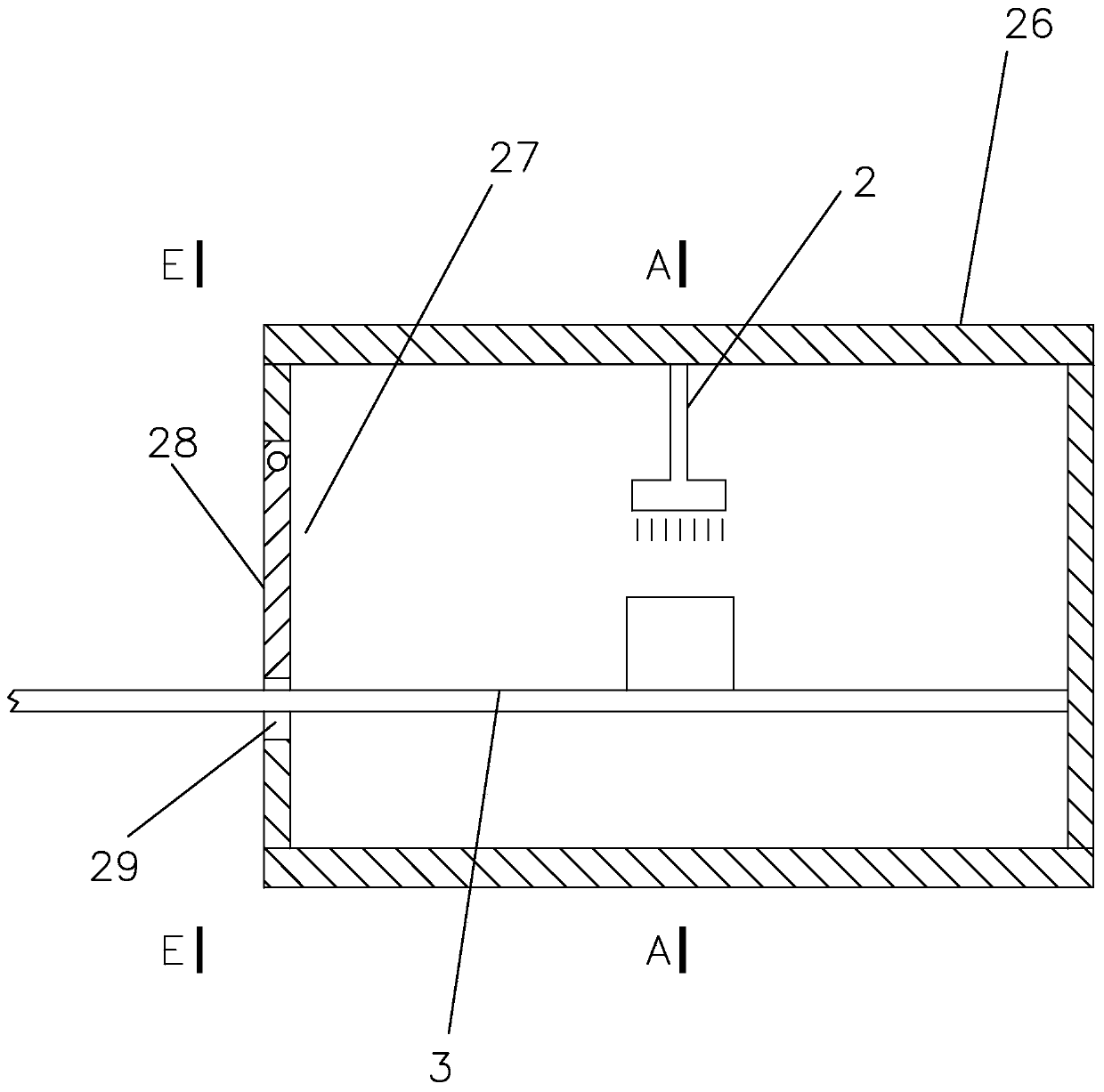

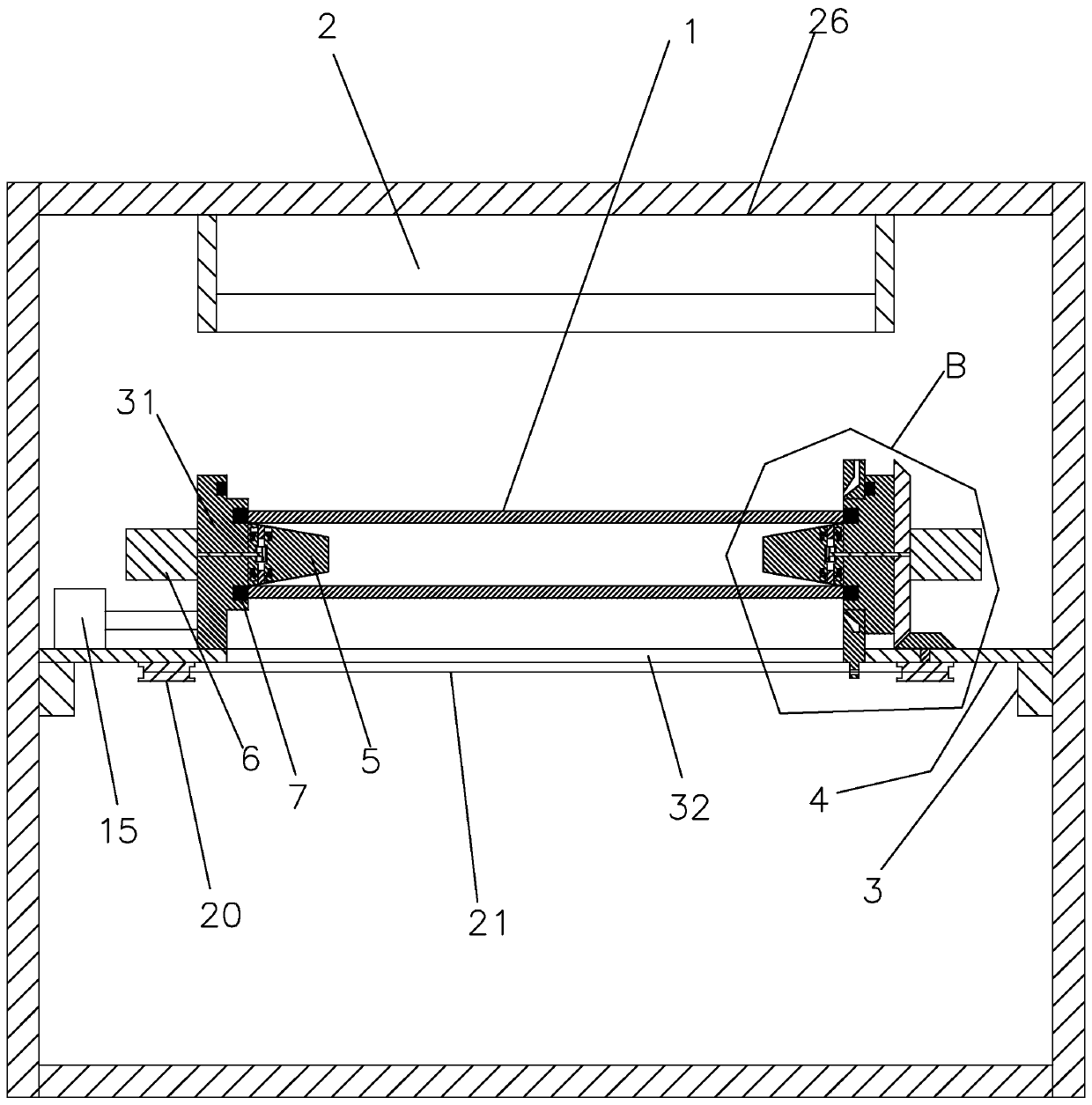

[0027] see Figure 1 to Figure 9 , a passivation device for galvanized components, including a nozzle 2 for spraying passivation solution on the surface of a round tube 1, a clamping mechanism for clamping both ends of the round tube 1, and two guide rails slidingly connected with the clamping mechanism 3. Shell 26; the nozzle 2 is located on the upper side of the shell 26, and one side of the shell 26 is provided with an inlet and outlet 27, and the upper end of the inlet and outlet 27 is rotatably connected with a rotating plate that prevents the passivation liquid from spreading outside the shell 26 28. Both ends of the lower side of the rotating plate 28 are provided with avoidance grooves 29 for the passage of the guide rail 3 .

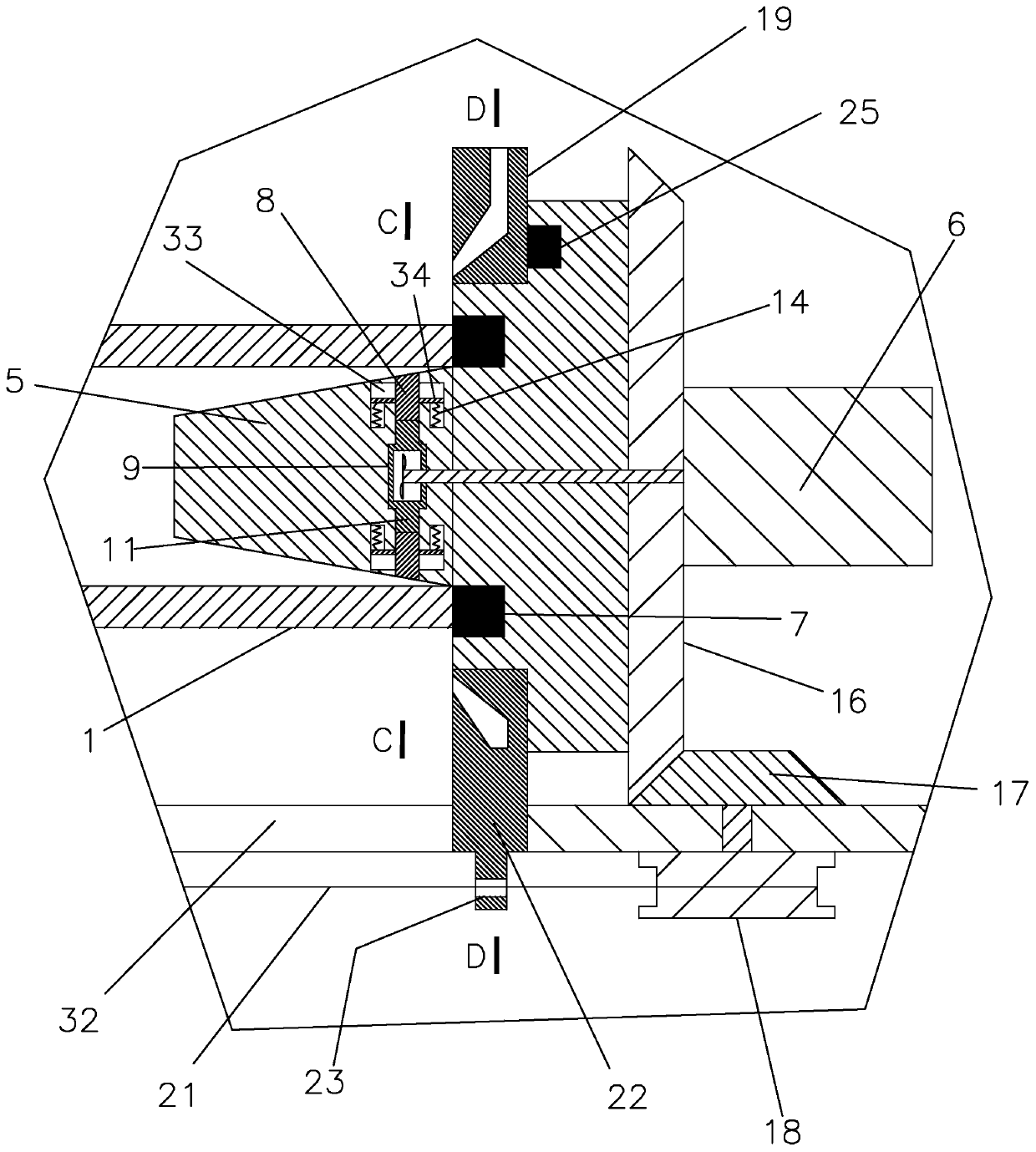

[0028] The clamping mechanism includes a bottom plate 4 slidably connected to the guide rail 3, a clamping block 31 located at both ends of the round tube 1 for clamping the round tube 1, a positioning block rotatably connected to the clamping b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com