An electroplating passivation device

A technology of passivation and passivation solution, applied in the direction of metal material coating process, etc., can solve the problems of unreasonable structure of passivation product placement cylinder, low product qualification rate, increased production cost, etc., and achieve simple structure and simple device structure , high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

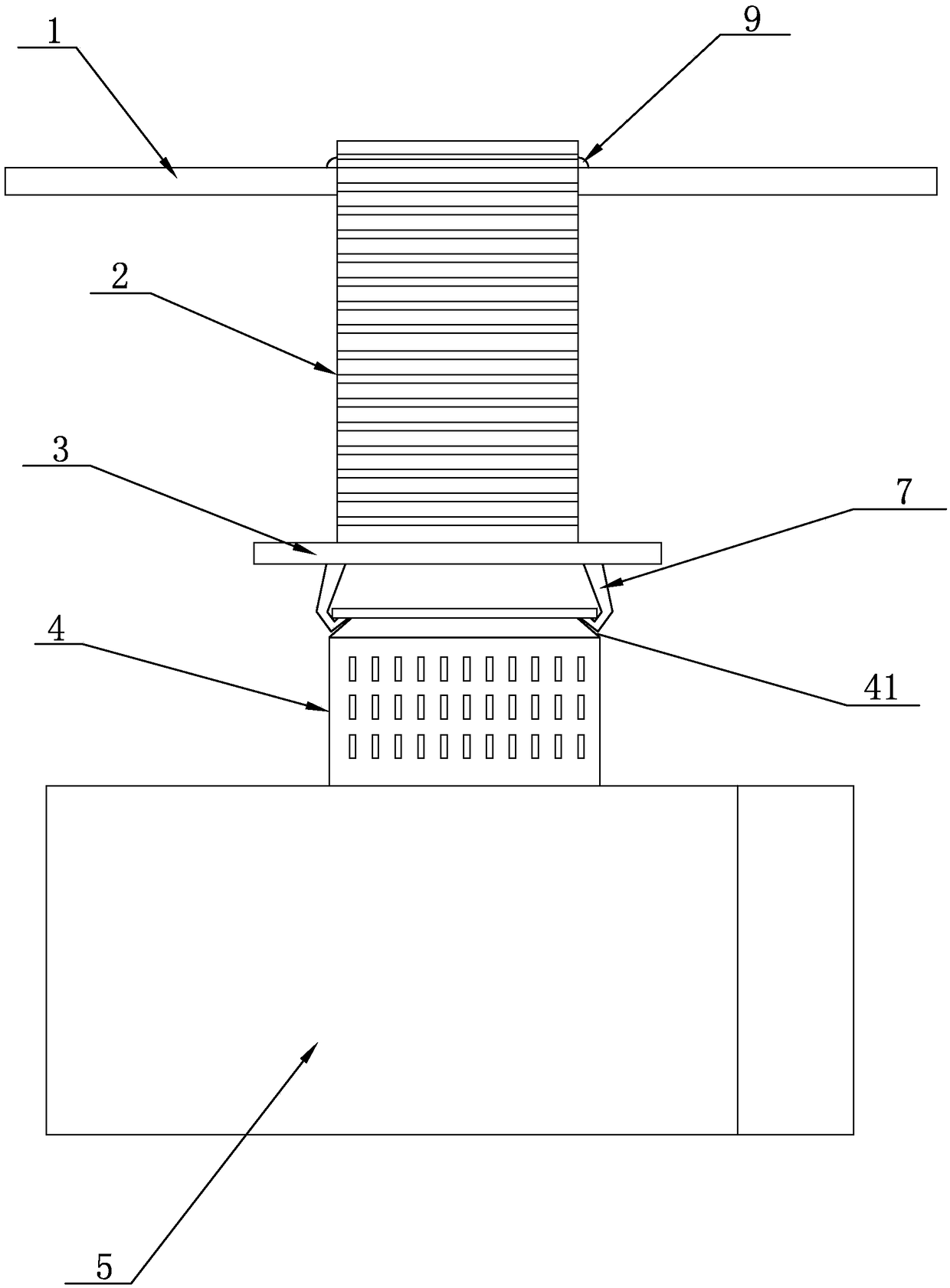

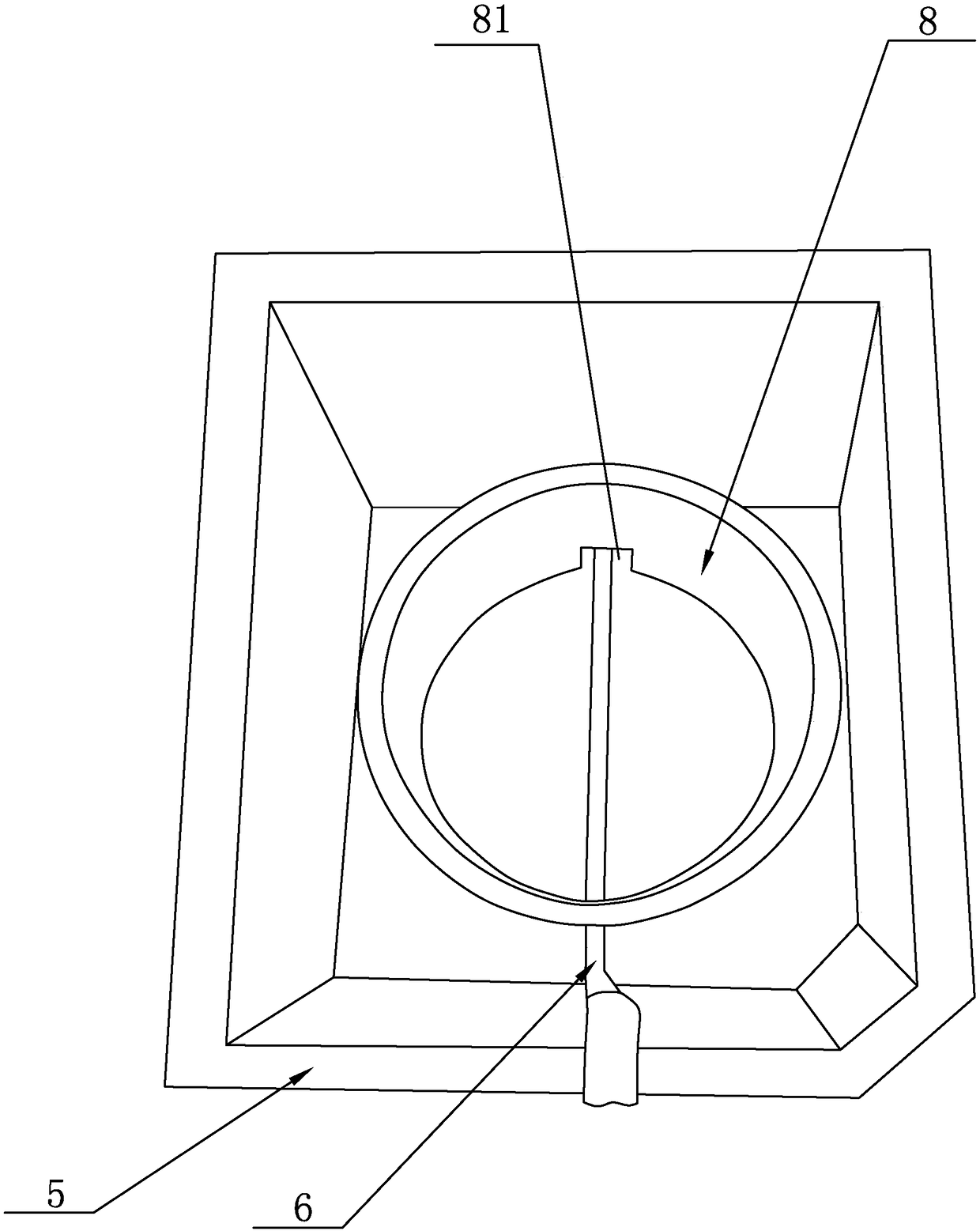

[0019] See figure 1 with figure 2 , The electroplating passivation device disclosed in the present invention includes a guide rail 1, a driving device 2, a connecting device 3, a passivation product placement cylinder 4, and a passivation tank 5, in which a passivation liquid delivery pipe is set 6. The guide rail 1 is arranged horizontally, the upper end of the driving device 2 is connected with the guide rail 1, and the lower end of the driving device 2 is connected with the connecting device 3, and the connecting device 3 is provided with a claw 7, and the passivation product is placed The lower end of the cylinder 4 is fixedly provided with a cylinder bottom, and a claw positioning groove 41 is provided on the outer wall surface of the upper end of the passivation product placement cylinder 4, and the connecting device 3 is clamped or separated from the claw positioning groove 41 through the claw 7; The passivation product placement cylinder 4 is located directly above the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com