Numerical control assembly device for automobile radiator core production line

An automobile radiator and assembly device technology, applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problem of uneven arrangement of heat dissipation pipes and heat sinks, manual arrangement of heat dissipation pipes and heat sinks, and manual assembly of main piece installation and other problems, to achieve the effect of saving manpower, compact structure and high installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

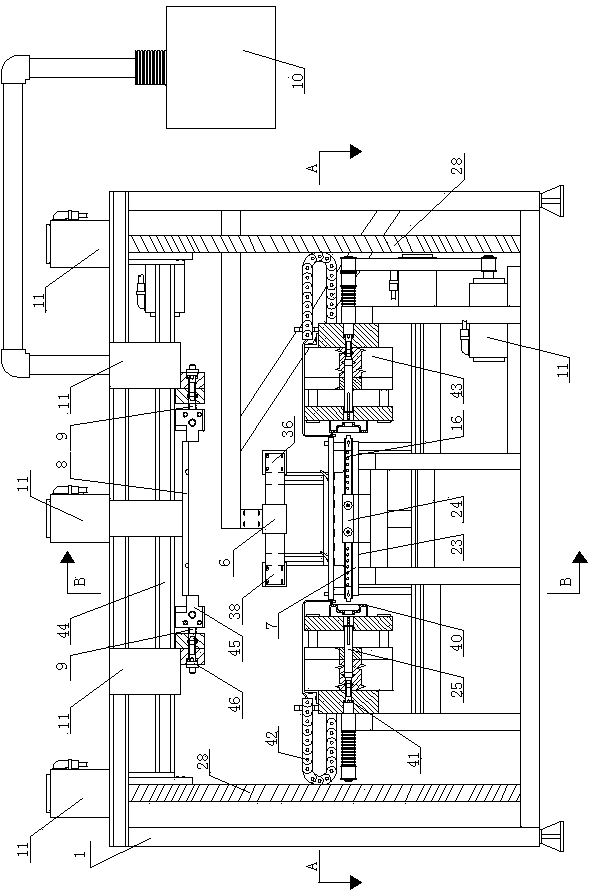

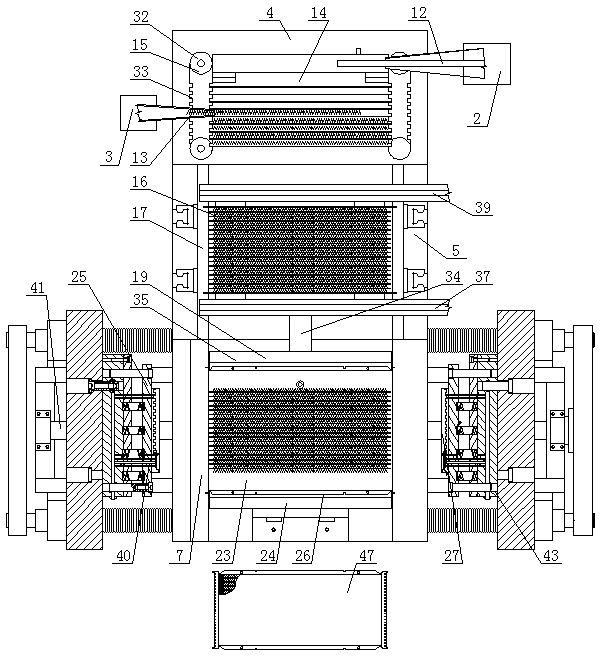

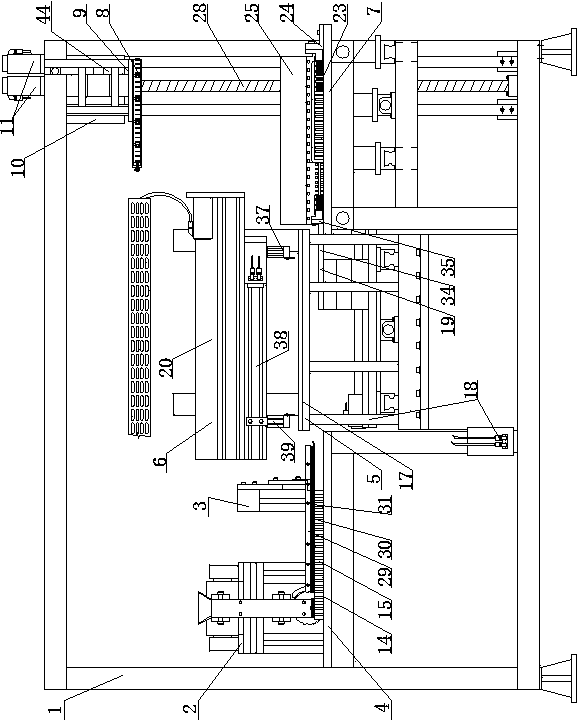

[0041] A numerically controlled assembly device for an automobile radiator core production line according to the present invention, its structure includes a frame 1, a heat dissipation pipe conveying device 2 arranged on the frame 1, a heat dissipation belt turning belt conveying device 3, a heat dissipation pipe and a heat dissipation belt automatic Arrangement table 4, core lifting and conveying table 5, overall automatic operation mechanism of front and rear manipulators 6, radiator core assembly table 7, core pressing device 8, belt alignment device 9, controller 10, servo motor 11;

[0042] The heat pipe and heat dissipation belt automatic arrangement table 4, the core body lifting and conveying table 5, and the radiator core body assembly table 7 are arranged in sequence from back to front on the frame 1;

[0043]The heat dissipation pipe delivery device 2 and the heat dissipation belt turning belt delivery device 3 are respectively located on the left and right sides of ...

Embodiment 2

[0053] A numerically controlled assembly device for an automobile radiator core production line according to the present invention, its structure includes a frame 1, a heat dissipation pipe conveying device 2 arranged on the frame 1, a heat dissipation belt turning belt conveying device 3, a heat dissipation pipe and a heat dissipation belt automatic Arrangement table 4, core lifting and conveying table 5, overall automatic operation mechanism of front and rear manipulators 6, radiator core assembly table 7, core pressing device 8, belt alignment device 9, controller 10, servo motor 11;

[0054] The heat pipe and heat dissipation belt automatic arrangement table 4, the core body lifting and conveying table 5, and the radiator core body assembly table 7 are arranged in sequence from back to front on the frame 1;

[0055] The heat dissipation pipe delivery device 2 and the heat dissipation belt turning belt delivery device 3 are respectively located on the left and right sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com