Pretensioning method construction technology of 50m broken line reinforced concrete T-shaped beam

A technology of broken line reinforcement and construction technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of large reaction beam stress, difficult construction, large structural span, etc., to achieve scientific design, beam body High stability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

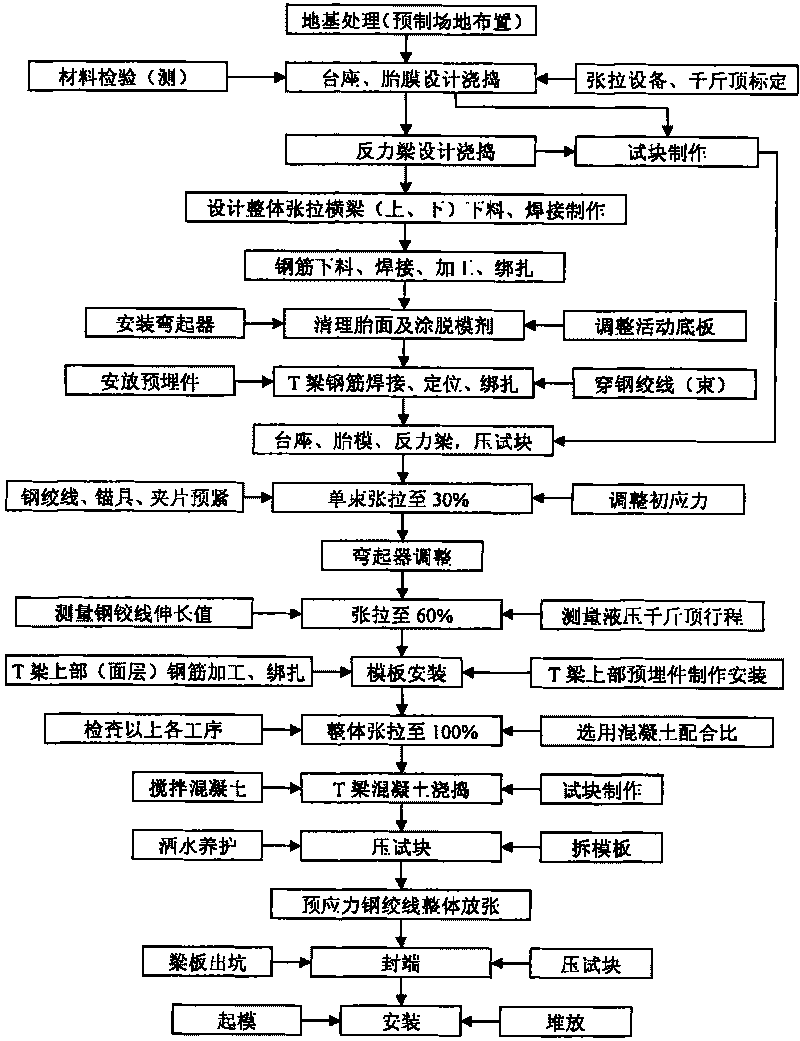

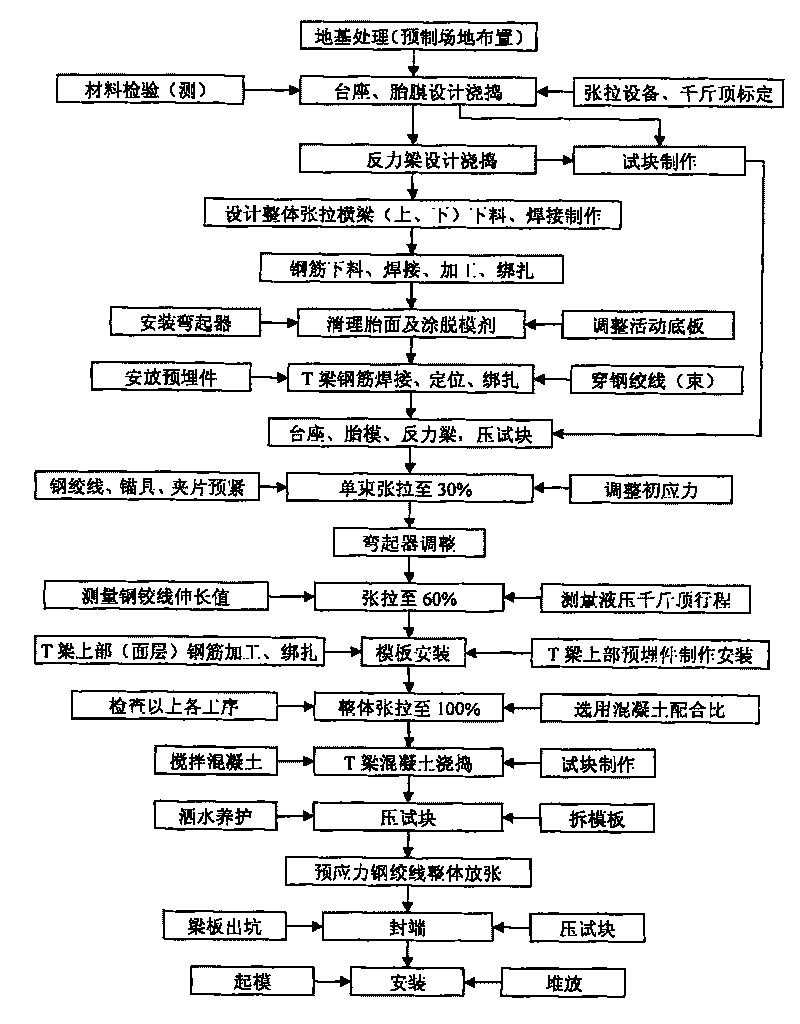

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

[0026] First, foundation treatment is carried out, including the layout of the prefabricated site. According to the layout requirements of the prefabricated site, in the middle area of the pedestal, according to the load of the T-beam produced, the foundation treatment is carried out on the original foundation. At both ends of the pedestal, after the prestress is released The concentrated force at both ends caused by the arching of the T-beam requires treatment of the foundation at the end of the pedestal to ensure that the pedestal will not be damaged after the T-beam is stretched and arched; at the same time, materials, equipment transportation roads, construction water, Operating conditions such as power consumption and on-site drainage. The treatment method for the middle part of the pedestal is as follows: first fill with gravel pond slag, after rolling and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com