A method for evaluating the passivation effect of sulfur-iron compounds

A compound, iron sulfide technology, applied in coatings, instruments, analytical materials, etc., can solve the problems of low activity, low temperature rise, difficult spontaneous combustion, etc., to achieve high activity, simple handling, and good passivation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention proposes a method for evaluating the passivation effect of iron sulfide compounds. In order to make the advantages and technical solutions of the present invention clearer and clearer, the present invention will be further explained clearly and completely with reference to specific embodiments.

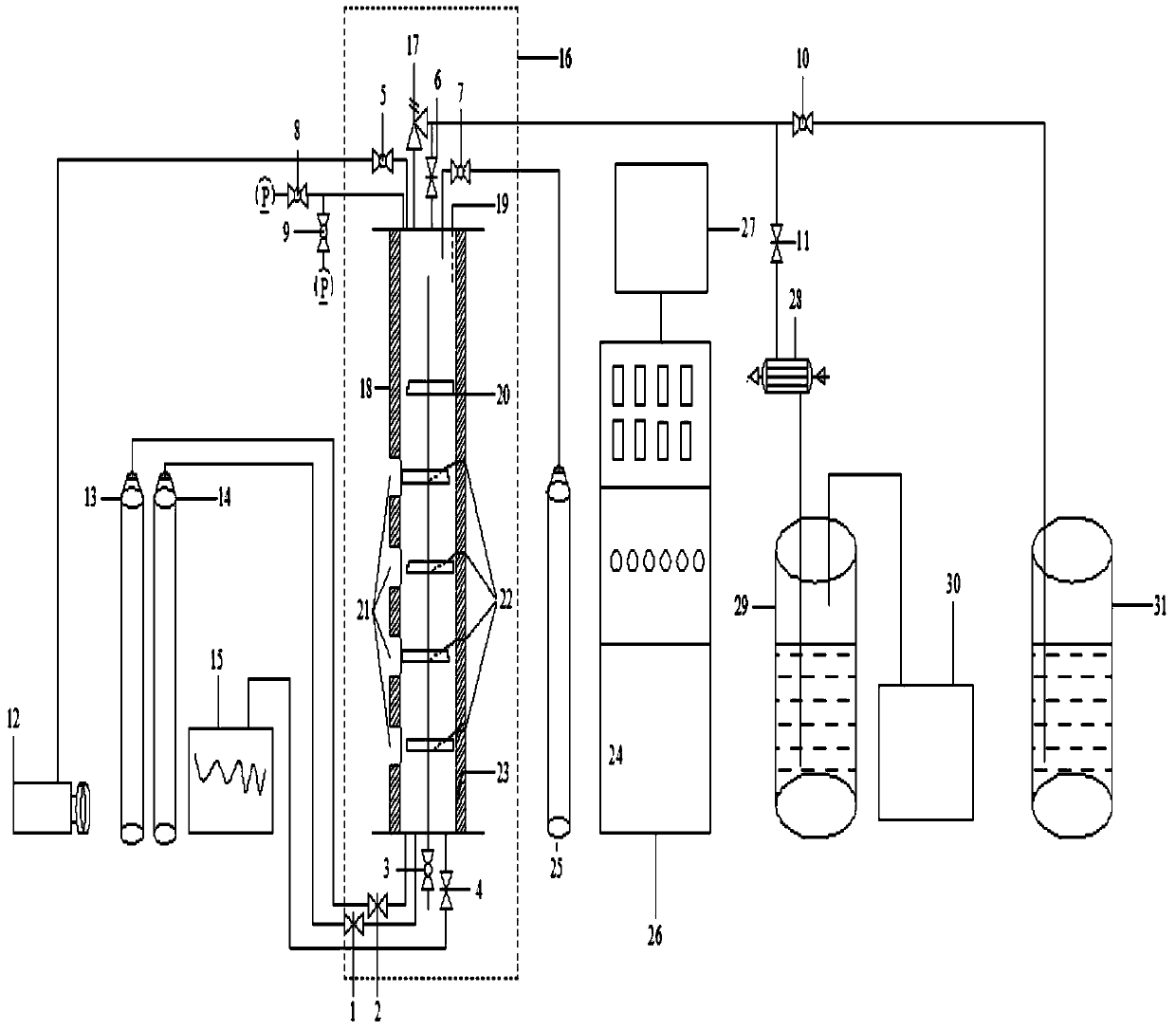

[0039] Combine figure 1 As shown, the device selected by the present invention mainly includes a gas supply device, a passivation device, a detection device and an exhaust gas absorption device.

[0040] The gas supply device is mainly composed of an inert gas cylinder, an oxygen-enriched air cylinder 13, a steam generator 15 and a hydrogen sulfide cylinder 14. The inert gas cylinder is preferably nitrogen, and hydrogen sulfide, nitrogen and oxygen-enriched air are all made of their own The gas cylinder enters the passivation device through valve 1, valve 2 and valve 4, and the mass flow meter; water vapor is generated by the steam generating bottle 15, and when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com