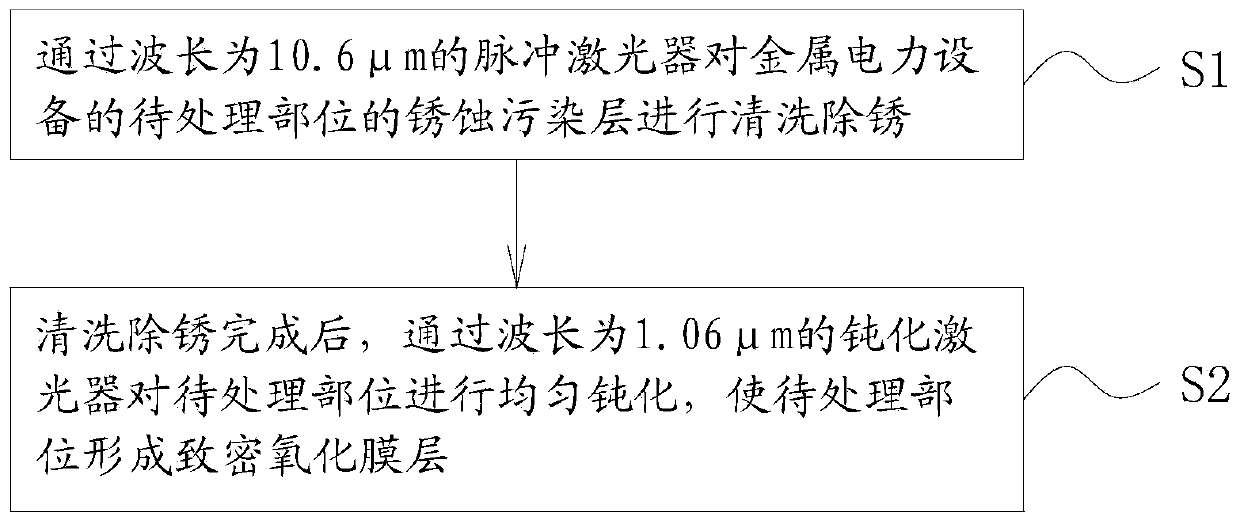

Double-laser derusting method

A technology of laser rust removal and laser, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of poor corrosion resistance and difficult decontamination, achieve high cleaning efficiency, solve difficult decontamination, and delay corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

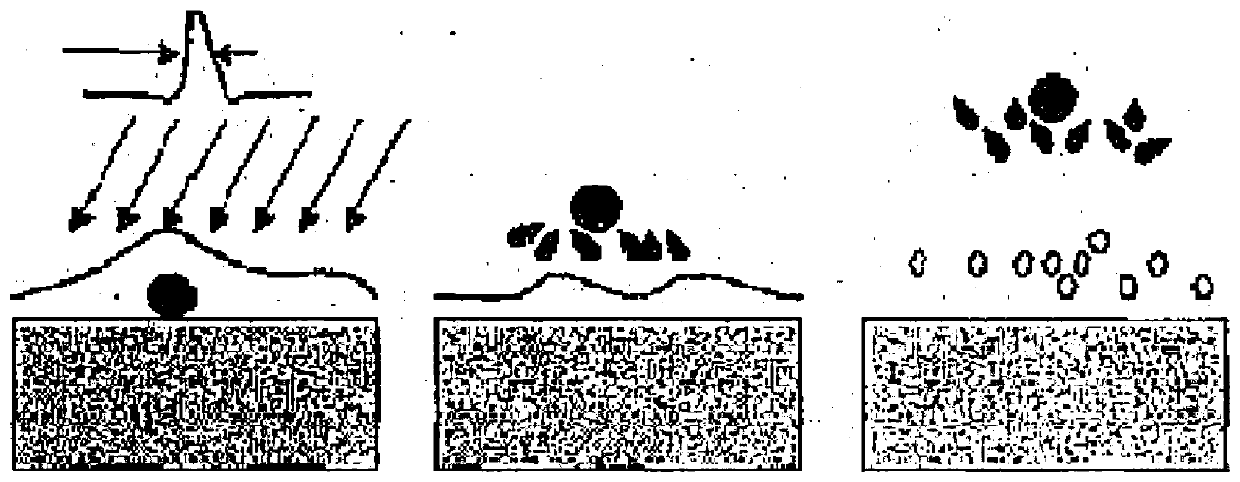

Method used

Image

Examples

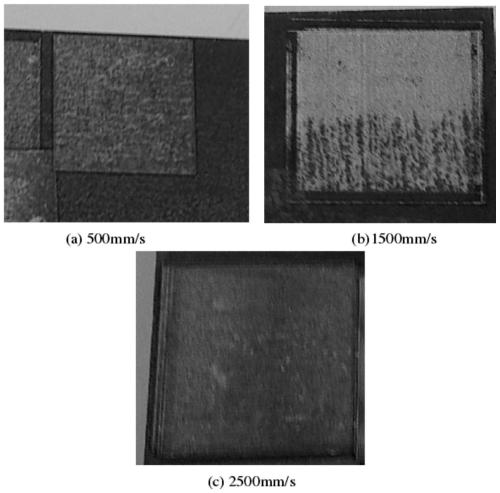

Embodiment 1

[0072] The scanning of the pulse laser is divided into: the first scanning stage, the second scanning stage and the third scanning stage, in which the number of scanning in the first scanning stage is 5 times, the laser power is adjusted to 19.5W, and the scanning speed is 500mm / s; The number of scans in the second scanning stage is 2 times, the laser power is adjusted to 19.5W, and the scanning speed is 1500mm / s; the number of scanning in the third scanning stage is 2 times, the laser power is adjusted to 19.5W, and the scanning speed is 2500mm / s.

Embodiment 2

[0074] The scanning of the pulse laser is divided into: the first scanning stage and the second scanning stage, wherein, the number of scanning in the first scanning stage is 4 times, the laser power is adjusted to 19.5W, and the scanning speed is 800mm / s; the scanning in the second scanning stage The number of times is 2, the laser power is adjusted to 19.5W, and the scanning speed is 2500mm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com