Film stripping tooling and process for decontamination of peelable film in hot chamber

A film stripping and film stripping technology, applied in the fields of decommissioning and radioactive waste treatment, operation and maintenance of nuclear facilities, can solve the problems of poor film-forming integrity of water-based strippable coatings, difficult for personnel to enter the decontamination operation, and high dose level, and achieve decontamination. High utilization rate of agent, good market prospect, less scattering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

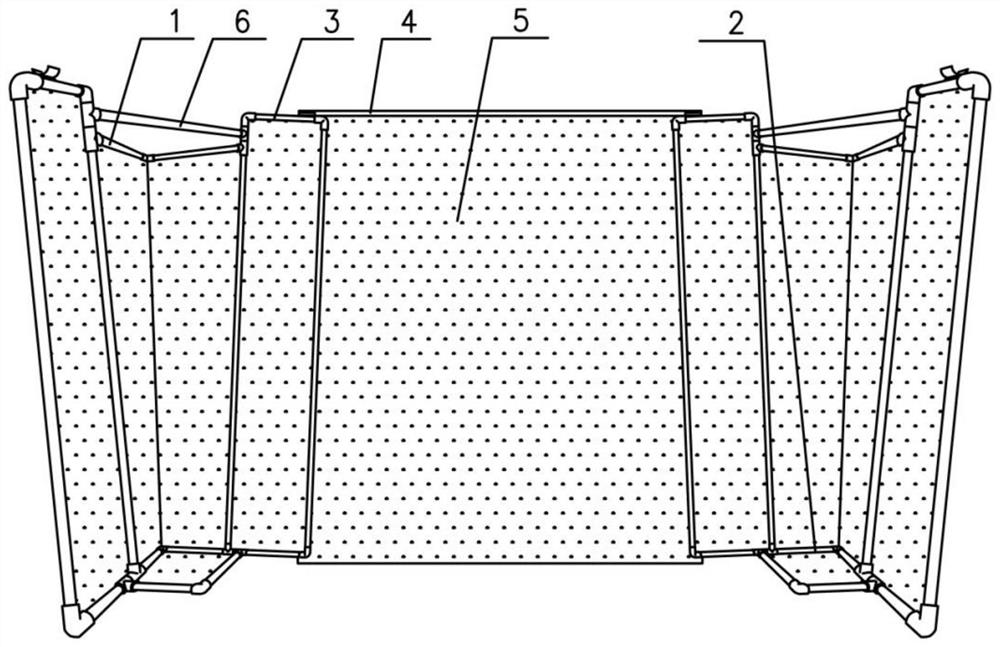

[0056] Such as figure 1 As shown, the stripping tooling used for the decontamination of the peelable film in the hot chamber includes 4 supporting components that cooperate with the corners of the hot chamber, and a film forming component is arranged between the 2 supporting components on the same wall;

[0057] The supporting assembly includes a first L-shaped fixing piece 1 and a second L-shaped fixing piece 2, and the first L-shaped fixing piece 1 and the second L-shaped fixing piece 2 respectively cooperate with the top surface and the bottom surface of the corner of the heat chamber, The two ends of the first L-shaped fixing part 1 and the second L-shaped fixing part 2 are connected by a rectangular frame 3;

[0058] The film-forming component includes a horizontal connecting rod 4, and the two ends of the horizontal connecting rod 4 are respectively connected to the tops of two rectangular frames 3 located on the same wall by buckling, specifically, on the tops of the re...

Embodiment 2

[0061] Such as figure 1 As shown, this embodiment is based on Embodiment 1; the lengths of the two sides of the first L-shaped fixing member 1 are equal, the lengths of the two sides of the second L-shaped fixing member 2 are equal, and the first The side length of the L-shaped fixture 1 is greater than the length of the two L-shaped fixtures 2; the rectangular frame 3 is inclined at an angle of 3-5° to the vertical; 2 rectangular frames 3 on the same support assembly A cross bar 6 is arranged between the inner side walls of the inner wall.

Embodiment 3

[0063] A kind of decontamination process based on the decontamination tooling of the decontamination of peelable film in hot chamber described in embodiment 1, comprises the following steps:

[0064] S1. Arranging the film stripping tooling: arrange the 4 supporting components correspondingly at the 4 corners of the hot chamber, then install the horizontal connecting rod 4 between the 2 rectangular frames 3, fill the film-forming adsorption net 5, and place the cotton fiber fabric (Film-forming adsorption net 5) is placed on the wall and bottom surface around the simulated hot chamber; the humidity of the simulated hot chamber is 40%, and the temperature is 10°C;

[0065] S2. Pretreatment of peelable detergent (complex type): heat treatment to control the viscosity of the peelable detergent at 1000mPa·s; the peelable detergent is a translucent, viscous liquid, and the film body is broken The elongation rate is 0.6N / m, the density is 1.1g / cm3, the pH value is 6.0, and the tensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com