Ferrous sulfide gas phase passivation method

A ferrous sulfide, gas phase passivation technology, applied in the direction of iron oxide/iron hydroxide, etc., can solve the problems of uneven passivation, high passivation cost, long passivation time, etc., and achieve uniform passivation and long contact time. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

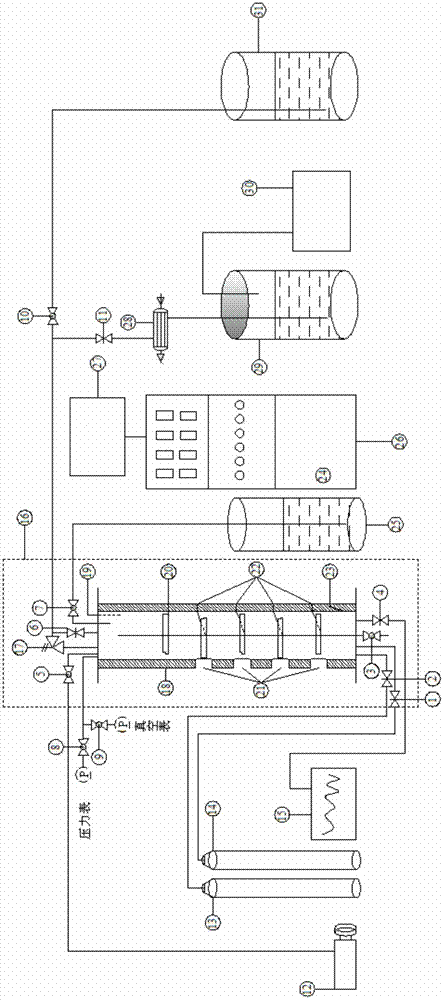

[0025] in such as figure 1 The gas-phase passivation of ferrous sulfide is carried out on the device shown, the vacuum pump is connected to the tower body with a φ6 steel pipe, and the ball valve connected to the pipe is used to control the vacuum degree. The heat preservation system consists of electric heating belt, heat preservation cotton and temperature controller. The temperature sensor of the temperature controller is placed on the tower wall. The outer layer of the tower wall is covered with a layer of thermal insulation cotton. The temperature range of electric heating belt is 0~250℃.

[0026]The passivation tower has a length of 1500mm, an inner diameter of 95mm, and a wall thickness of 20mm. There are four hand holes on the side wall with a diameter of 70mm. Four temperature sensors are installed directly opposite the hand holes to record temperature signals. The tower is equipped with a tray, and the generated ferrous sulfide is placed on the tray for passivation...

Embodiment 2

[0049] According to the conditions and steps described in Example 1, only the reaction temperature is 110° C., and the water vapor pressure is 0.1 MPag.

Embodiment 3

[0051] According to the conditions and steps described in Example 1, only the reaction temperature is 170° C., and the water vapor pressure is 0.9 MPag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com