Passivator with self-repairing function as well as preparation method and application thereof

A passivation agent and self-healing technology, applied in chemical instruments and methods, transportation and packaging, solid waste removal, etc., can solve the difficulty of increasing the passivation of tailings, affecting the stability of the passivation film, and the difficulty of the passivation film Increase and other problems to achieve the effects of cost controllable, reduced treatment cost, and long passivation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

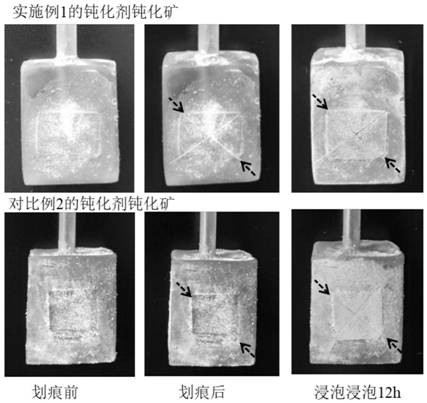

Embodiment 1

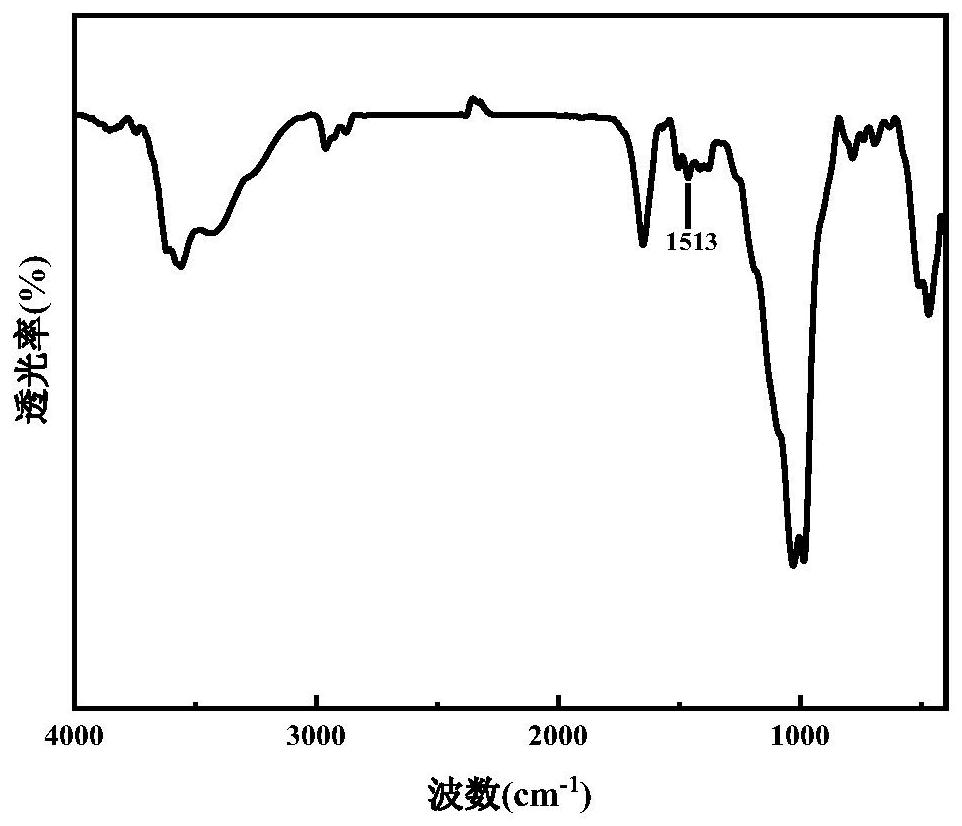

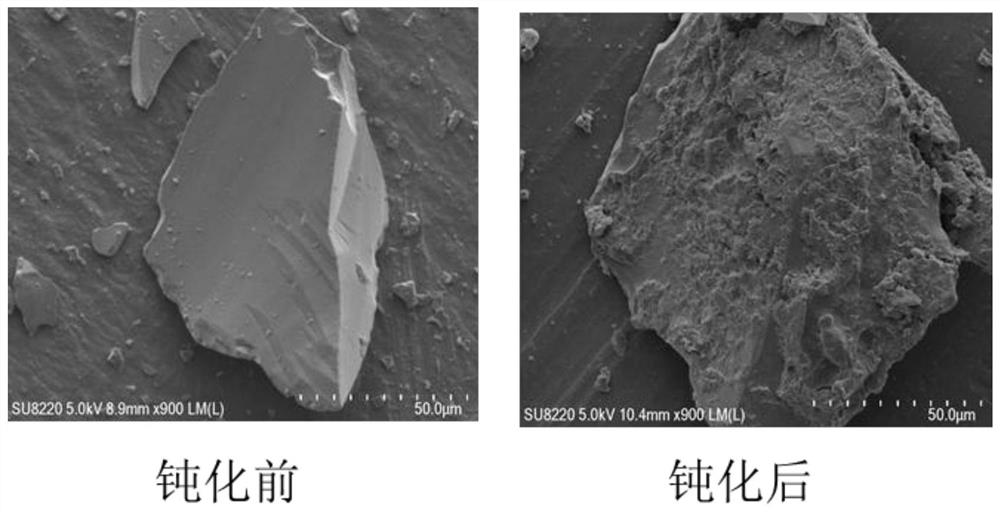

[0052] (1) Disperse 5g of natural attapulgite clay (ATP) in 250ml, 4mol / L HCl, stir at room temperature for 4h; separate and wash and then disperse in 50ml, 3mol / L NaOH solution, stir at room temperature for 1h; separate and wash with 2 The heating rate of °C / min was raised to 350 °C and kept for calcination for 1 h. Finally, 2 g of the modified ATP was dispersed in 50 mL, 50 mg / mL of 8-HQ ethanol solution, stirred for 24 h, separated and dried to obtain the nanofiller.

[0053] (2) Add gamma-mercaptopropyltrimethoxysilane and tetraethoxysilane with a volume ratio of 4:1 to a water / ethanol mixed solvent with a volume ratio of 1:8, wherein the mixed organic silane accounts for 1% of the mixed solvent mass 2wt%, then add sodium alginate with 1wt% mixed solvent mass (that is, the mass ratio of organosilane to sodium alginate is 2:1), adjust the pH of the solution to 4.0 with 0.1mol / L hydrochloric acid, and hydrolyze at 40°C for 2h , to obtain a silanol-sodium alginate solution. ...

Embodiment 2

[0057] (1) Disperse 2g ATP in 60ml, 2mol / L HCl, stir at room temperature for 2h; separate and wash and then disperse in 20ml, 3mol / L NaOH solution, stir at room temperature for 1h; separate and wash at a heating rate of 2°C / min Heat up to 350°C and heat-preserve for calcination for 1h. Finally, 2 g of the modified ATP was dispersed in 100 ml, 10 mg / ml 8-HQ ethanol solution, stirred for 20 h, separated and dried to obtain the nanofiller.

[0058] (2) Add gamma-mercaptopropyltrimethoxysilane and tetraethoxysilane with a volume ratio of 1:4 to a water / ethanol mixed solvent with a volume ratio of 1:8, wherein the mixed organic silane accounts for 1% of the mixed solvent mass 0.5wt%, and then add 0.5wt% sodium alginate mixed solvent, adjust the pH of the solution to 3.5 with 0.1mol / L hydrochloric acid, hydrolyze at 40°C for 1.5h, and obtain a silanol-sodium alginate solution.

[0059] (3) Add 0.4 wt% of the mixed solvent mass of the nanofiller prepared in step (1) to the above sil...

Embodiment 3

[0062] (1) Disperse 4g ATP in 120ml, 3mol / L HCl, stir at room temperature for 3h; after separation and washing, disperse in 50ml, 4mol / L NaOH solution, stir at room temperature for 1.5h; after separation and washing, heat up at 3°C / min Raise the temperature to 400°C and heat-preserve for 1.5h. Finally, 2 g of the modified ATP was dispersed in 50 mL, 50 mg / mL of 8-HQ ethanol solution, stirred for 22 h, separated and dried to obtain the nanofiller.

[0063] (2) Add γ-mercaptopropyltrimethoxysilane and tetraethoxysilane with a volume ratio of 2:3 to a water / ethanol mixed solvent with a volume ratio of 4:1, wherein the mixed organic silane accounts for 2% of the mixed solvent mass 1 wt%, and then add 2 wt% sodium alginate mixed solvent, adjust the pH of the solution to 4.0 with 0.1 mol / L hydrochloric acid, and hydrolyze at 35°C for 2 hours to obtain a silanol-sodium alginate solution.

[0064] (3) Add 0.6 wt% of the mixed solvent mass of the nanofiller prepared in step (1) to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com