Preparation method of modified remediation plant biochar for remediation of cadmium-contaminated soil

A technology for cadmium-contaminated soil and repairing plants, applied in the field of repairing plant biochar, can solve the problems of increasing the risk of heavy metal leaching, high economic cost, and poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

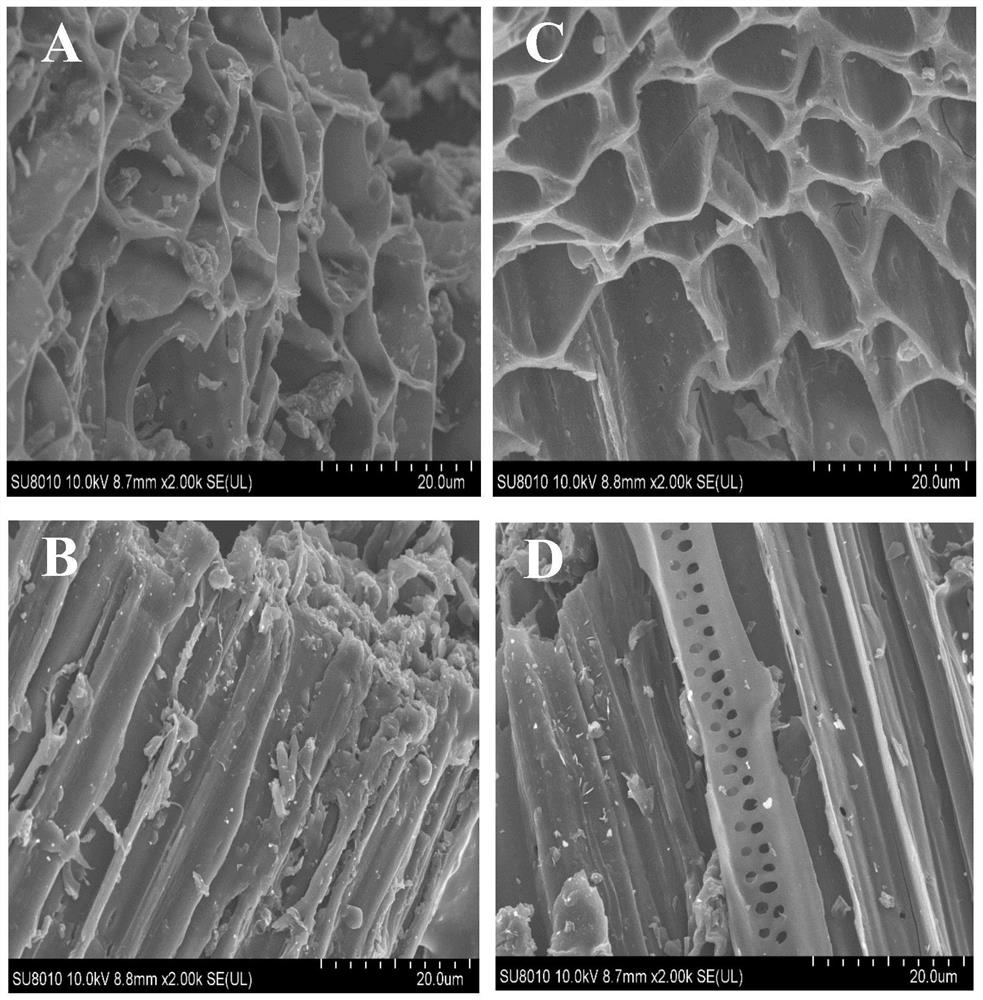

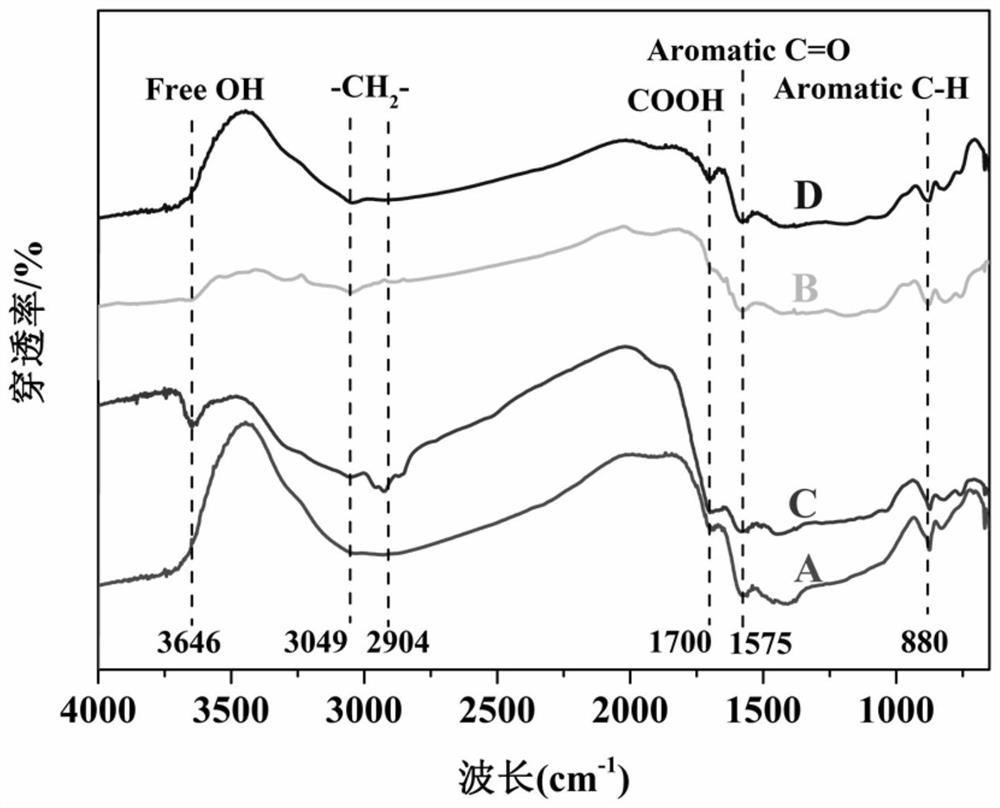

Image

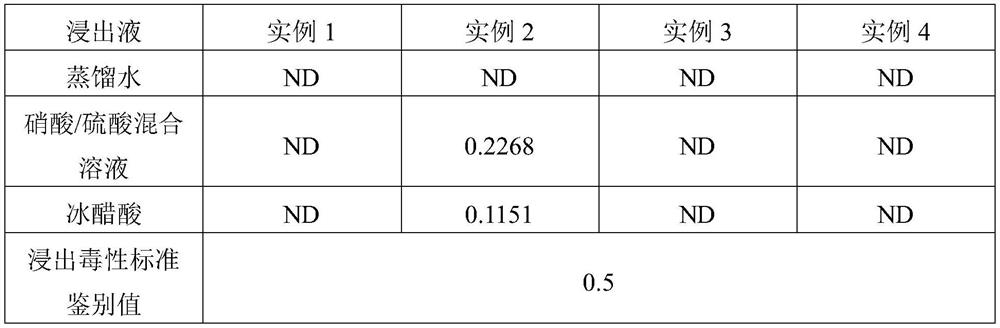

Examples

Embodiment 1

[0030] The present embodiment provides a method for preparing a modified and repaired plant biochar for remediation of cadmium-contaminated soil. The specific process is as follows:

[0031] (1) Take the cadmium content as 0.14 mg·kg -1 The rapeseed is washed with deionized water, dried in an oven to constant weight, ground and passed through a 50-mesh sieve to obtain biomass raw materials, which are ready for use;

[0032] (2) Put rapeseed in a tube furnace, at 0.5L·min -1 The rate of continuous feeding of nitrogen, heating to 600 ℃, the residence time is 1h, after the temperature in the furnace is naturally cooled to room temperature, it is taken out, and after grinding through a 100-mesh sieve, rape biochar is obtained, which is ready for use;

[0033] (3) Take 10 g of rape biochar and spread it on a glass vessel of about 2 mm, and place the petri dish on an electric hot plate to keep the temperature of the biochar at 80°C. Then it was placed under a 250W UV lamp for 16h,...

Embodiment 2

[0036] The present embodiment provides a method for preparing a modified and repaired plant biochar for remediation of cadmium-contaminated soil. The specific process is as follows:

[0037] (1) Take the cadmium content as 0.14 mg·kg -1 The rapeseed is washed with deionized water, dried in an oven to constant weight, ground and passed through a 50-mesh sieve to obtain biomass raw materials, which are ready for use;

[0038] (2) Put rapeseed in a tube furnace, at 0.5L·min -1 Nitrogen was continuously introduced into the furnace at a rate of 400°C, and the residence time was 2h. After the temperature in the furnace was naturally cooled to room temperature, it was taken out, and after being ground through a 100-mesh sieve, the rape biochar was obtained, which was ready for use;

[0039] (3) Take 10 g of rape biochar and spread it on a glass vessel of about 2 mm, and place the petri dish on an electric hot plate to keep the temperature of the biochar at 80°C. Then it was placed ...

Embodiment 3

[0042] The present embodiment provides a method for preparing a modified and repaired plant biochar for remediation of cadmium-contaminated soil. The specific process is as follows:

[0043] (1) Take the cadmium content as 3.86 mg·kg -1 The ryegrass were washed with deionized water, dried in an oven to a constant weight, ground and passed through a 50-mesh sieve to obtain biomass raw materials, which are ready for use;

[0044] (2) Place the ryegrass in a tube furnace, at 0.5L·min -1 The rate of continuous feeding of nitrogen, heating to 600 ℃, the residence time is 1h, after the temperature in the furnace is naturally cooled to room temperature, take it out, grind through a 100-mesh sieve, and obtain ryegrass biochar, which is ready for use;

[0045] (3) Take 10 g of ryegrass biochar and spread it on a glass vessel of about 2 mm, and place the petri dish on an electric hot plate to keep the temperature of the biochar at 80°C. Then it was placed under a 250W UV lamp for 16h, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com