Method for treating arsenic in nonferrous smelting waste acid with modified red mud cooperated CuO powder

A technology of red mud and sewage acid, applied in water/sludge/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., to achieve the effect of low economic cost, simple process flow and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for treating arsenic in colored smelting sewage acid with modified red mud and CuO powder, specifically comprising the following steps:

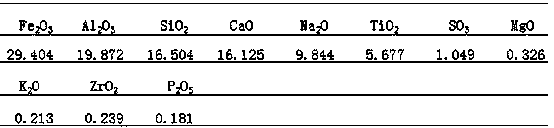

[0026] (1) Dry the red mud at 500°C for 6 hours and then perform ball milling. After ball milling, the particle size of the red mud is controlled below 200 mesh; the ball milling conditions are: the speed is 100r / min, and the grinding time is 10min; the composition of the red mud is shown in Table 1.

[0027] Table 1 red mud composition

[0028]

[0029] (2) Pretreat the red mud obtained in step (1) with 1.0 mol / L HCl solution for 1 hour according to the liquid-solid ratio of HCl solution to red mud (mL:g: 10:1), and then rinse with deionized water for 4 hours Once, dry at 120°C for 6 hours before use.

[0030] (3) Mix the activated red mud and CuO powder obtained in step (2) evenly according to the mass ratio of activated red mud and CuO powder of 8:1.

[0031] (4) Press H 2 o 2 With a molar ratio of 1:1 to arsenic, t...

Embodiment 2

[0039] A method for treating arsenic in colored smelting sewage acid with modified red mud and CuO powder, specifically comprising the following steps:

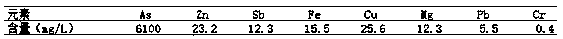

[0040] (1) After drying the red mud at 500°C for 6 hours, perform ball milling. After ball milling, the particle size of the red mud is controlled below 200 mesh; the ball milling conditions are: the speed is 200r / min, and the grinding time is 15min; the composition of the red mud is shown in Table 4.

[0041] Table 4 red mud composition

[0042]

[0043] (2) Pretreat the red mud obtained in step (1) with 1.0 mol / L HCl solution for 2 hours according to the liquid-solid ratio of HCl solution to red mud (mL:g: 15:1), and then rinse with deionized water for 4 hours Once, dry at 120°C for 6 hours before use.

[0044] (3) Mix the activated red mud and CuO powder obtained in step (2) evenly according to the mass ratio of activated red mud and CuO powder of 10:1.

[0045] (4) Press H 2 o 2 With a molar ratio of 1.1:1 to arsen...

Embodiment 3

[0053] A method for treating arsenic in colored smelting sewage acid with modified red mud and CuO powder, specifically comprising the following steps:

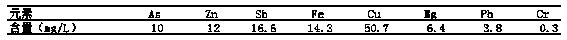

[0054] (1) After drying the red mud at 500°C for 6 hours, perform ball milling. After ball milling, the particle size of the red mud is controlled below 200 mesh; the ball milling conditions are: the rotation speed is 150r / min, and the grinding time is 13min. The composition of the red mud is shown in Table 7.

[0055] Table 7 red mud composition

[0056]

[0057] (2) Pretreat the red mud obtained in step (1) with 1.0mol / L HCl solution for 1.5h according to the ratio of the liquid-solid ratio of HCl solution to red mud (mL:g: 13:1), and then rinse with deionized water 4 times, dry at 120°C for 6 hours before use.

[0058] (3) Mix the activated red mud and CuO powder obtained in step (2) evenly at a mass ratio of activated red mud and CuO powder of 9:1;

[0059] (4) Press H 2 o 2 With a molar ratio of 1:1 to arsenic, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com