Nonferrous metallurgy arsenic-containing impure acid harmless disposal method

A disposal method and technology of arsenic polluted acid, applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., to achieve the effect of low cost of treating polluted acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: The harmless disposal method of the non-ferrous smelting arsenic-containing sewage acid is as follows:

[0022] (1) The laterite nickel ore (composition shown in Table 1) is subjected to dry ball milling and magnetic separation (the speed of the ball mill is 740r / min, the grinding time is 11min, and the magnetic separation intensity of the magnetic separator is 700mT) to obtain iron-rich nickel ore and other impurities, and other impurities are piled up for treatment;

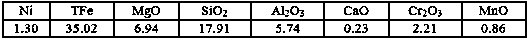

[0023] Table 1

[0024]

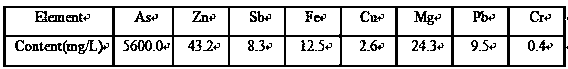

[0025] (2) According to the ratio of iron:arsenic molar ratio of 2.5:1, according to H 2 o 2 : The molar ratio of arsenic is 1:1, and the iron-rich nickel ore, polluted acid and H 2 o 2 The solution was uniformly mixed, and the arsenic precipitation reaction was carried out at 70°C and 180r / min stirring conditions for 10 hours to obtain a solid-liquid mixture A, which was separated to obtain arsenic-containing solid A and filtrate A; the dirty acid came from...

Embodiment 2

[0032] Embodiment 2: The harmless disposal method of the non-ferrous smelting arsenic-containing sewage acid is as follows:

[0033] (1) The laterite nickel ore (composition shown in Table 4) is subjected to dry ball milling and magnetic separation (the speed of the ball mill is 860r / min, the grinding time is 9min, and the magnetic separation intensity of the magnetic separator is 900mT) to obtain iron-rich nickel ore and other impurities, and other impurities are piled up for treatment;

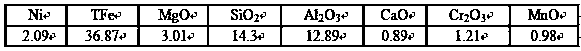

[0034] Table 4

[0035]

[0036] (2) According to the ratio of iron:arsenic molar ratio of 3:1, according to H 2 o 2 : The molar ratio of arsenic is 1.2:1, and the iron-rich nickel ore, polluted acid and H 2 o 2 The solution was uniformly mixed, and the arsenic precipitation reaction was carried out under the condition of 80°C and 200r / min stirring for 11 hours to obtain a solid-liquid mixture A, and the solid-liquid separation obtained arsenic-containing solid A and filtrate A; the p...

Embodiment 3

[0043] Embodiment 3: The harmless disposal method of the non-ferrous smelting arsenic-containing sewage acid is as follows:

[0044] (1) Dry the laterite nickel ore (the composition is shown in Table 7) to dry ball mill magnetic separation (the speed of the ball mill is 900r / min, the grinding time is 7min, and the magnetic separation intensity of the magnetic separator is 1000mT) to obtain iron-rich nickel ore and other impurities, and other impurities are piled up for treatment;

[0045] Table 7

[0046]

[0047] (2) According to the ratio of iron:arsenic molar ratio of 3.5:1, according to H 2 o 2 : The molar ratio of arsenic is 1.6:1, and the iron-rich nickel ore, polluted acid and H 2 o 2 The solution was uniformly mixed, and the arsenic precipitation reaction was carried out under the condition of 80°C and 220r / min stirring for 12 hours to obtain a solid-liquid mixture A, and the solid-liquid separation obtained arsenic-containing solid A and filtrate A; the pollute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com