Surface passivation method for germanium-based MOS (Metal Oxide Semiconductor) device substrate

A MOS device and substrate surface technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, metal material coating technology, etc., can solve problems such as interface state density increase, defects, and gate dielectric quality deterioration, and reduce the Effects of interface state density, diffusion suppression, and passivation efficiency enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

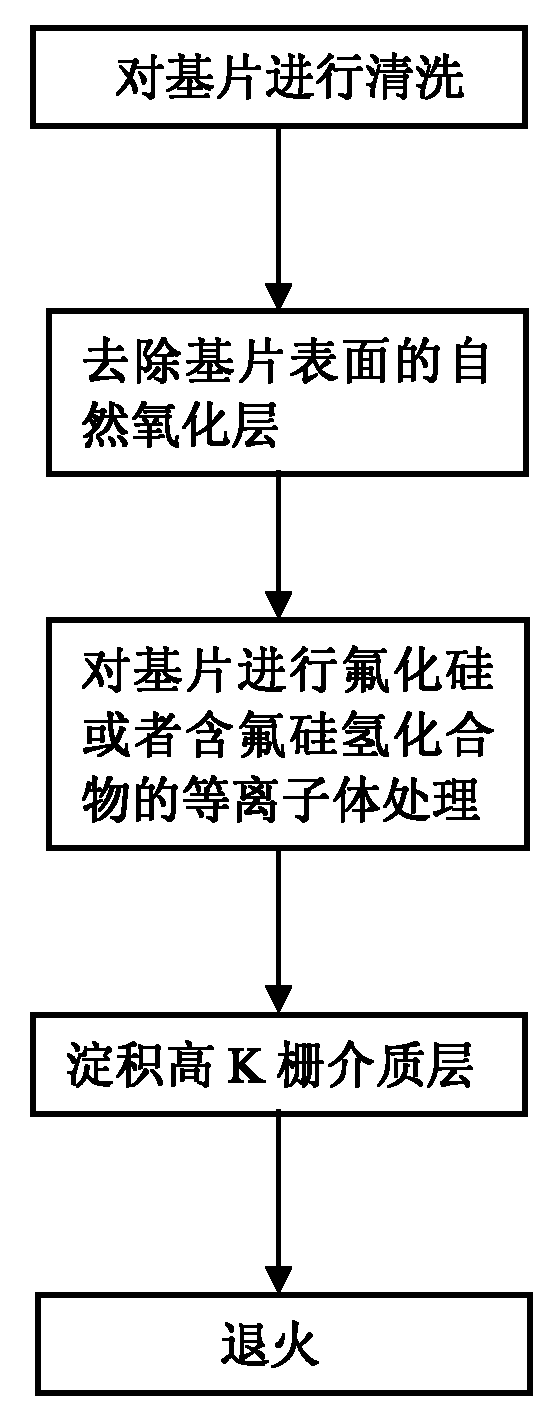

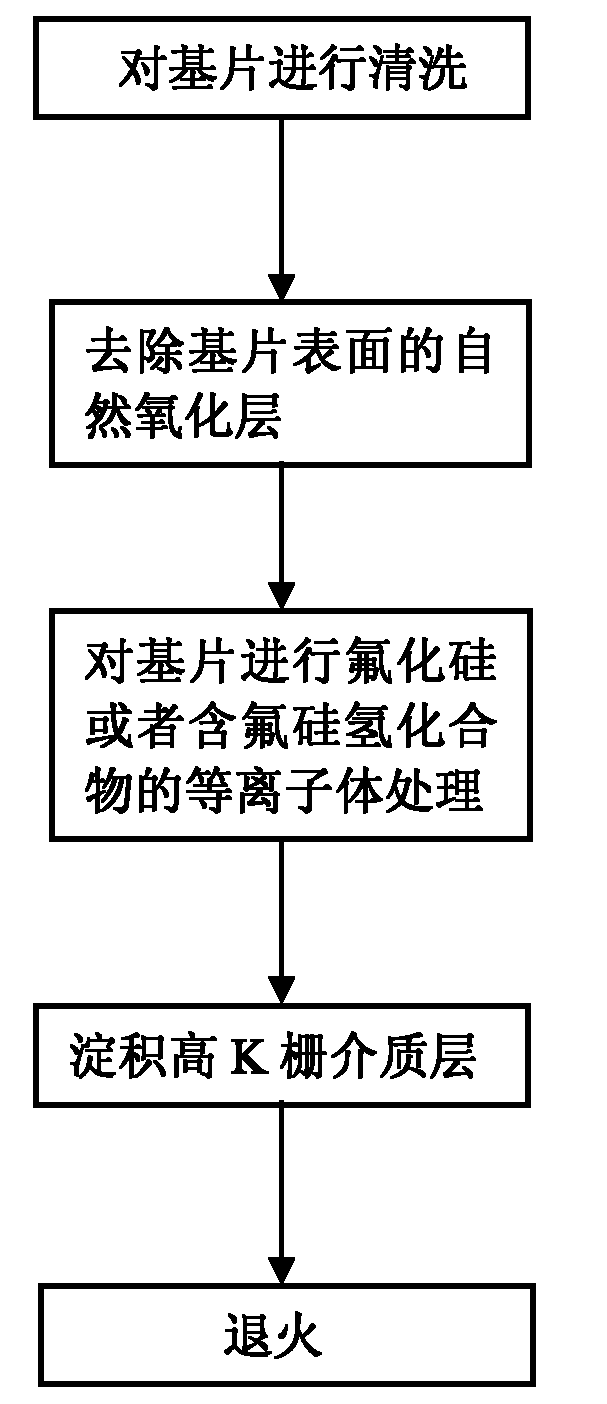

[0026] The method of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

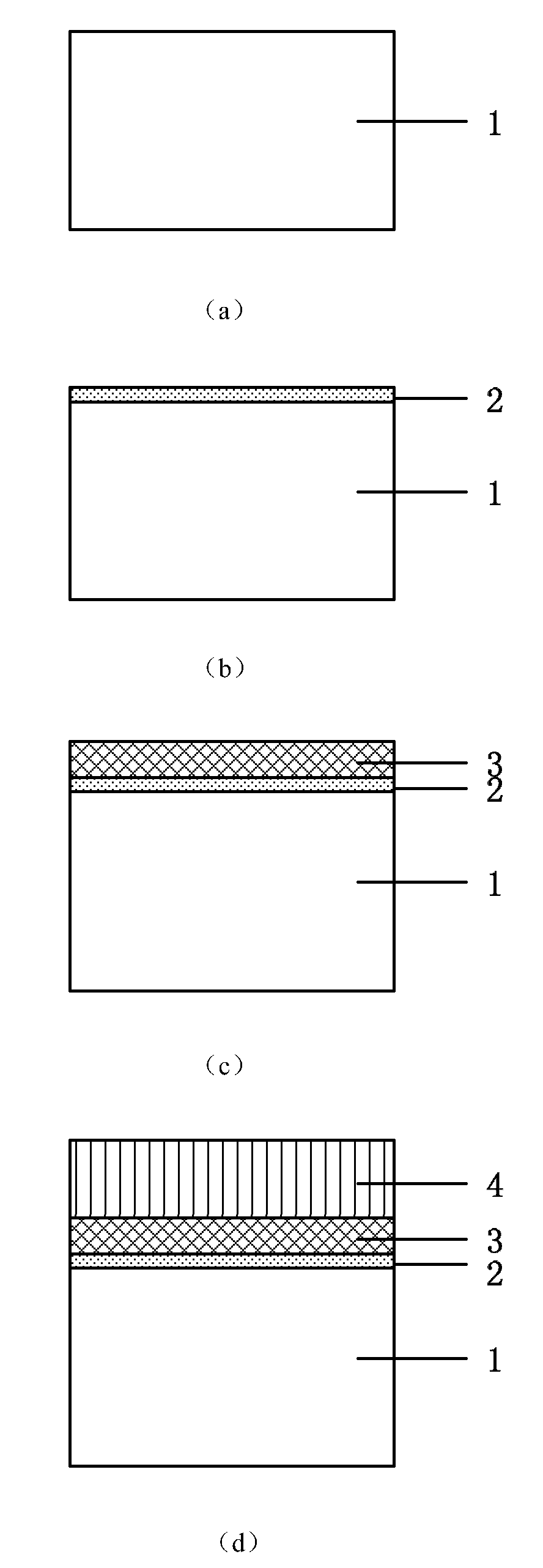

[0027] Step 1. Select a semiconductor germanium substrate, which can be a bulk germanium substrate, a GeOI (Germanium on Insulator) substrate, or epitaxial germanium (Germanium-on-silicon) on silicon, etc. The preferred example of this embodiment is a bulk germanium substrate, such as figure 2 as shown in (a);

[0028] Step 2. Cleaning the germanium substrate. First, the germanium substrate is organically cleaned, soaked and cleaned with acetone and ethanol in turn, and then rinsed with DI water to remove oil and organic pollutants on the germanium substrate. Then wash with hydrochloric acid, heat and boil in dilute hydrochloric acid, and then rinse with DI water to remove inorganic pollutants, metal particles, etc.;

[0029] Step 3. Removing the oxide on the surface of the germanium substrate. The method of soaking in HF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com