Rigid superhard material precision cutting tool passivating machine

A technology of superhard materials and precision tools, which is applied in the field of tool manufacturing, can solve the problems that there is no way to passivate the precision tools of superhard materials, the edge of the tool cannot be passivated, and the processing efficiency is not high, so that the passivation effect is good, The effect of high cost performance and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

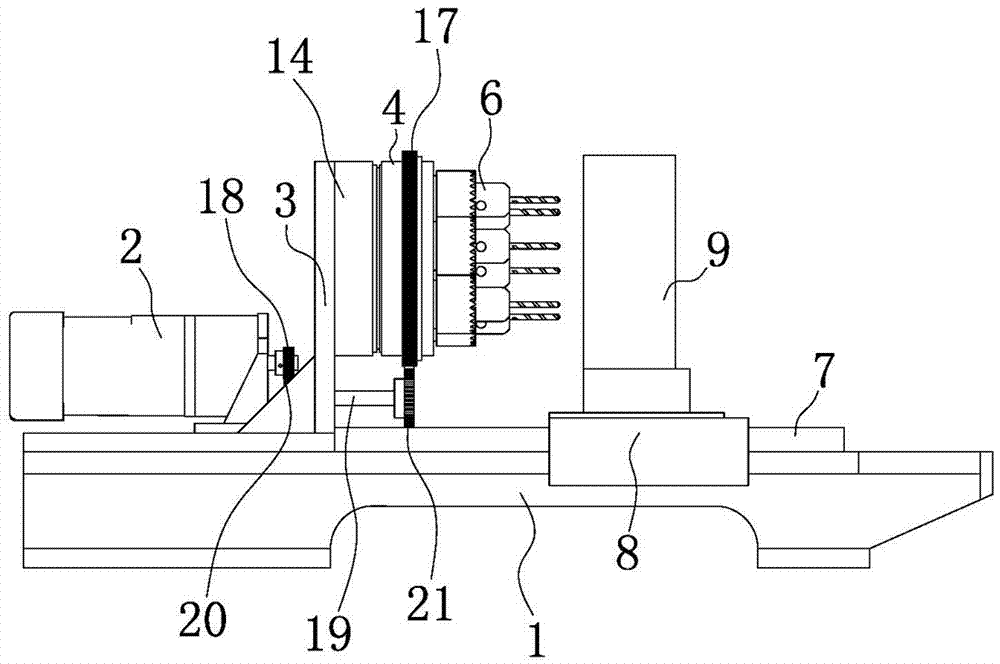

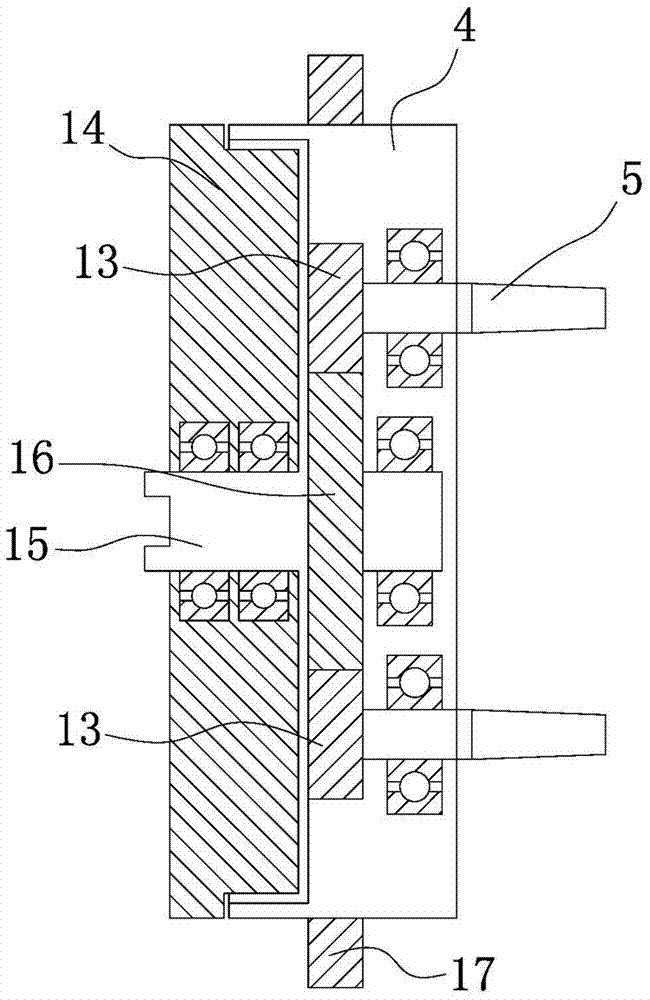

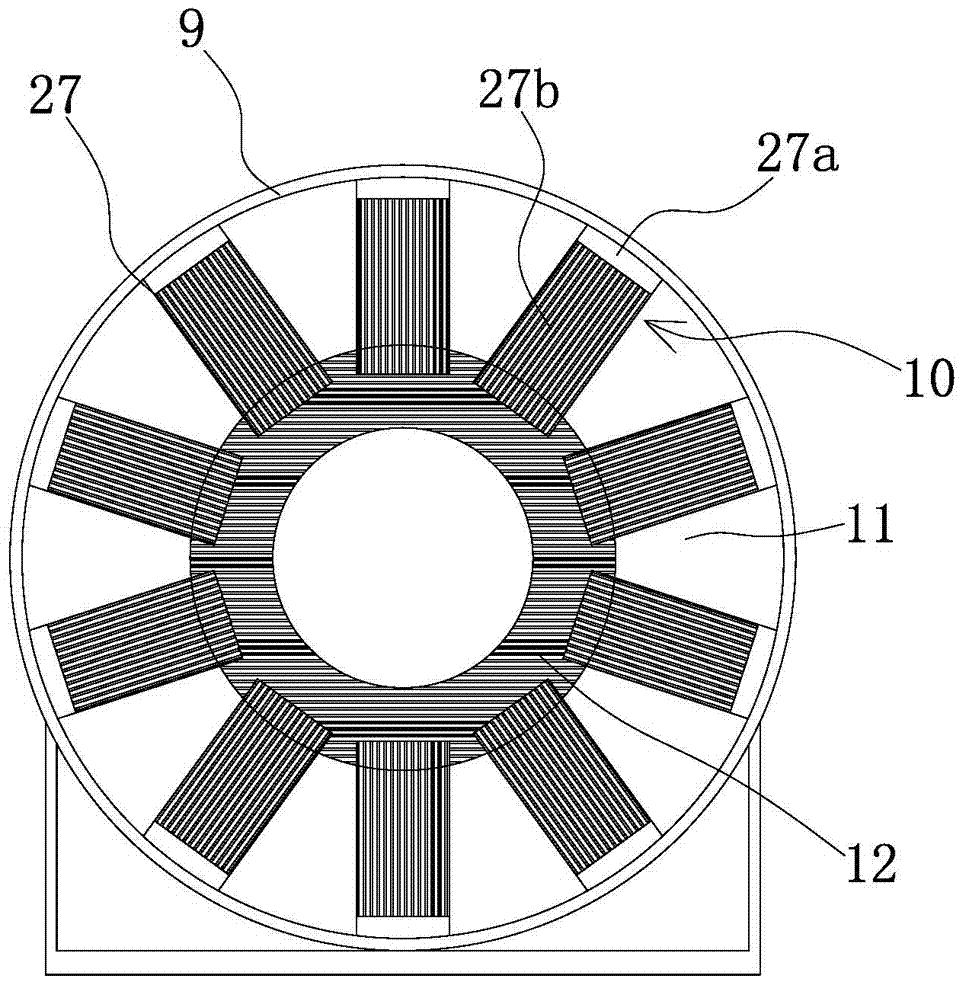

[0028] Such as figure 1 and image 3 As shown, the hard superhard material precision tool passivation machine includes a base 1 and a servo motor 2, the base 1 is provided with a frame 3, and the frame 3 is provided with a turntable 4 that is columnar and has a horizontal axis. 4. A plurality of rotating shafts 5 arranged around their axes are perforated. Fixtures 6 are connected to the rotating shafts 5. The servo motor 2 drives each rotating shaft 5 to rotate through the driving mechanism. The machine base 1 is provided with a horizontal guide rail 7. There is a carriage 8, and the carriage 8 is provided with a passivation cylinder 9 that is cylindrical and coaxial with the turntable 4. The inner wall of the passivation cylinder 9 is provided with a circle of radially protruding radial brushes 10. The passivation cylinder 9 The end away from the turntable 4 is connected to a mounting plate 11, and the inner end surface of the mounting plate 11 facing the turntable 4 is prov...

Embodiment 2

[0034] Such as Figure 4 and Figure 5 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that an axial adjustment structure capable of adjusting the axial position of the passivation cylinder 9 is provided between the passivation cylinder 9 and the carriage 8, The axial adjustment structure includes a cylindrical outer cylinder 22 fixedly connected to the carriage 8. The outer cylinder 22 is arranged coaxially with the passivation cylinder 9 and is sleeved on the outside of the passivation cylinder 9. The outer cylinder 22 is provided with four channels in the axial direction. Sliding holes 23, each sliding hole 23 is provided with a scale mark 26, and the passivation cylinder 9 is perforated with a bolt 24 located in the corresponding sliding hole 23, and the threaded column of the bolt 24 extends out of the sliding hole 23 and is threadedly connected to the outer cylinder 22 Nut 25 on the outside. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com