Stainless steel passivation treatment method

A passivation treatment, stainless steel technology, applied in the direction of anodic oxidation, metal material coating process, etc., can solve the problems of aging and shedding, phosphorus in the polishing solution, and reduced corrosion resistance of the tank, so as to avoid harm to human health and reduce Risk of corrosion, effect of improving surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A stainless steel passivation treatment method, comprises the steps:

[0036] (A1), soak the stainless steel product in the electrolytic pickling solution for electrolytic pickling treatment for 4 minutes, and then wash it with water;

[0037] (A2), soak the stainless steel product after step (A1) in the electrolytic passivation agent with 0.2A / dm 2 Electrolytic passivation at a temperature of 30°C for 5 minutes, and then washed with water;

[0038] (A3), soak the stainless steel product treated in step (A2) in a chromium-free passivation solution for chemical passivation for 4 minutes, and then wash it with water.

[0039] The stainless steel product is a stainless steel stretch tank.

[0040] In the step (A1), the electrolytic pickling treatment is carried out at 2.8A / dm 2 The current density is used to clean stainless steel products at a temperature of 60 °C.

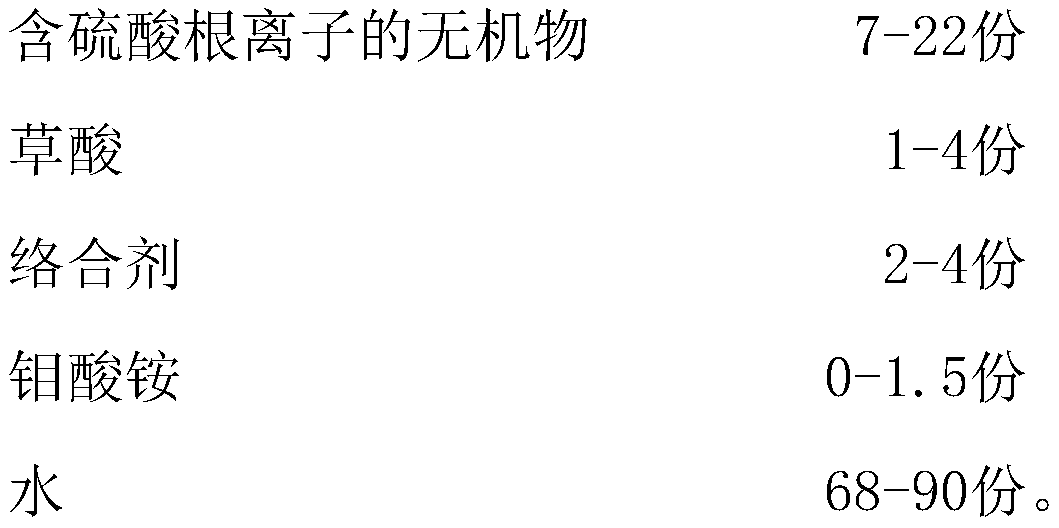

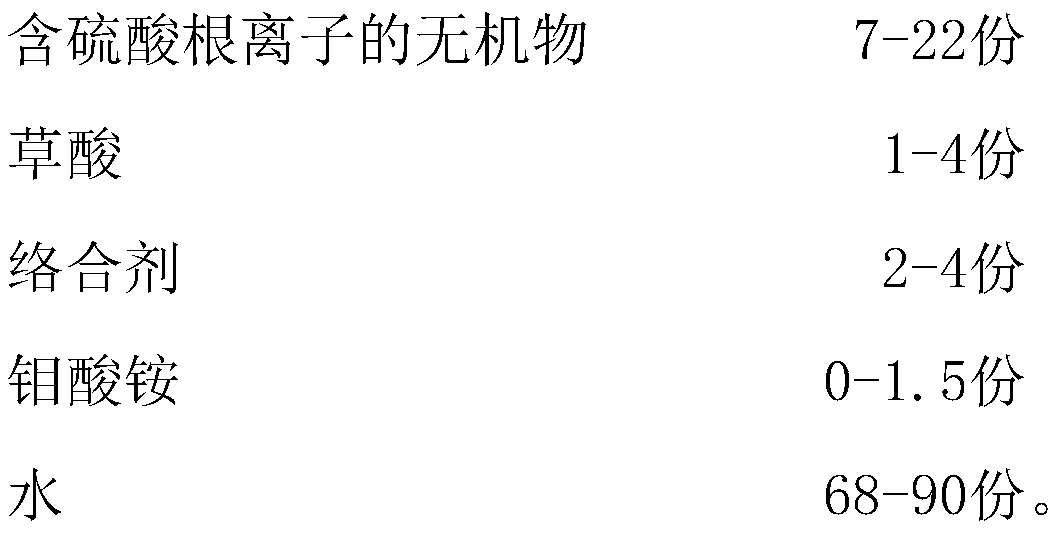

[0041] In the step (A1), the electrolytic pickling solution includes the following raw materials in par...

Embodiment 2

[0055] A stainless steel passivation treatment method, comprises the steps:

[0056] (A1), soak the stainless steel product in the electrolytic pickling solution for electrolytic pickling treatment for 3 minutes, and then wash it with water;

[0057] (A2), soak the stainless steel product after step (A1) in the electrolytic passivation agent with 0.05A / dm 2 Electrolytic passivation at a temperature of 20°C for 3 minutes, and then washed with water;

[0058] (A3) Soak the stainless steel product treated in step (A2) in a chromium-free passivation solution for chemical passivation for 3 minutes, and then wash it with water.

[0059] The stainless steel product is a stainless steel stretch tank.

[0060] In the step (A1), the electrolytic pickling process is carried out at 2A / dm 2 The current density is used to clean stainless steel products at a temperature of 50 °C.

[0061] In the step (A1), the electrolytic pickling solution includes the following raw materials in parts b...

Embodiment 3

[0073] A stainless steel passivation treatment method, comprises the steps:

[0074] (A1), soak the stainless steel product in the electrolytic pickling solution for electrolytic pickling treatment for 5 minutes, and then wash it with water;

[0075] (A2), soak the stainless steel product after step (A1) in the electrolytic passivation agent with 0.3A / dm 2 Electrolytic passivation at a temperature of 40°C for 8 minutes, and then washed with water;

[0076] (A3) Soak the stainless steel product treated in step (A2) in a chromium-free passivation solution for chemical passivation for 5 minutes, and then wash it with water.

[0077] The stainless steel product is a stainless steel stretch tank.

[0078] In the step (A1), the electrolytic pickling treatment is carried out at 3.5A / dm 2 The current density is used to clean stainless steel products at a temperature of 70 °C.

[0079] In the step (A1), the electrolytic pickling solution includes the following raw materials in part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com