Environment-friendly silicate passivation solution for galvanization, and preparation method and application thereof

An environmentally friendly, silicate technology, which is applied in the coating process of metal materials, can solve the problems of human body and environmental damage, hexavalent chromium is highly toxic, etc., and achieve high passivation efficiency, good anti-white rust performance, The preparation process and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The conventional process of hot-dip galvanizing of steel plates is as follows: degreasing in hot alkaline bath → hot water rinsing → pickling and rust removal → cold water rinsing → plating flux aid → drying → hot dip galvanizing → water cooling.

[0031] Silicate solution and treatment process:

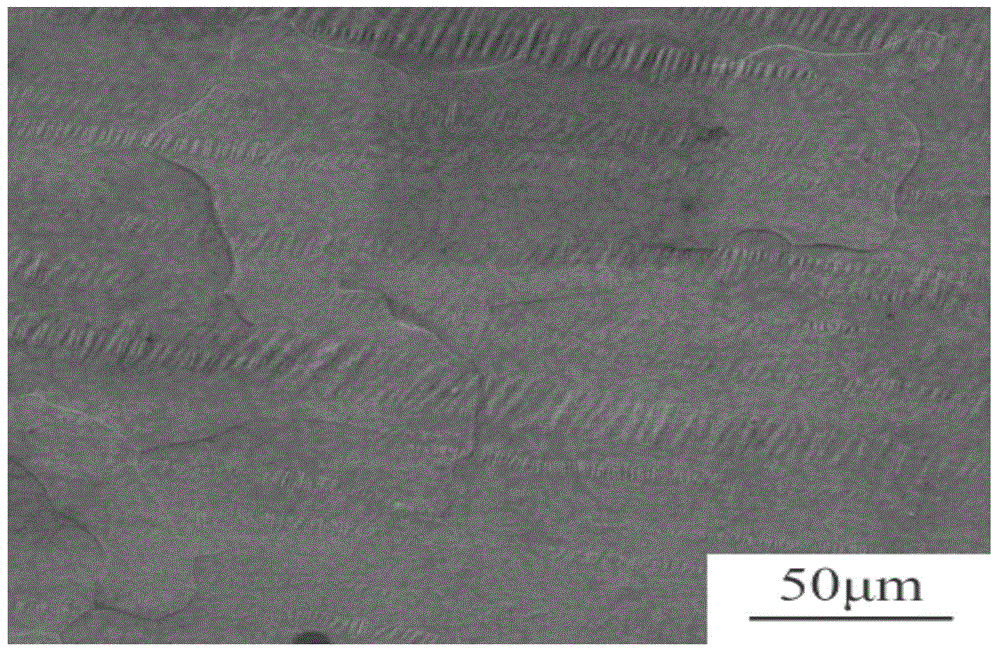

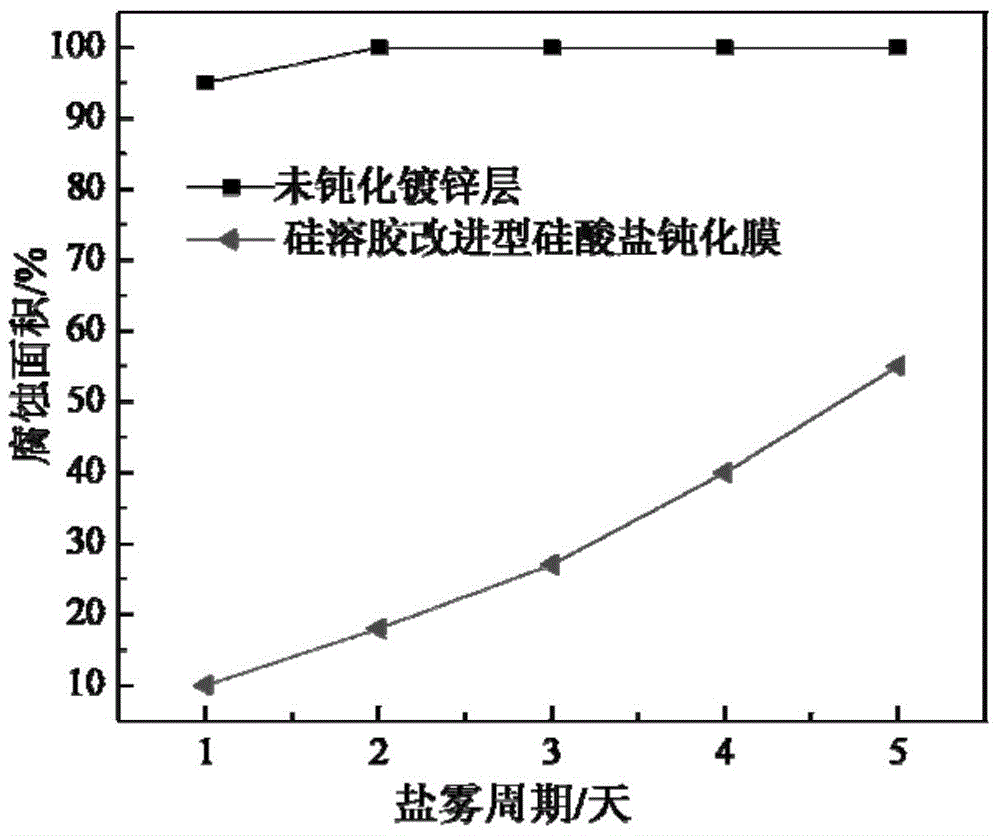

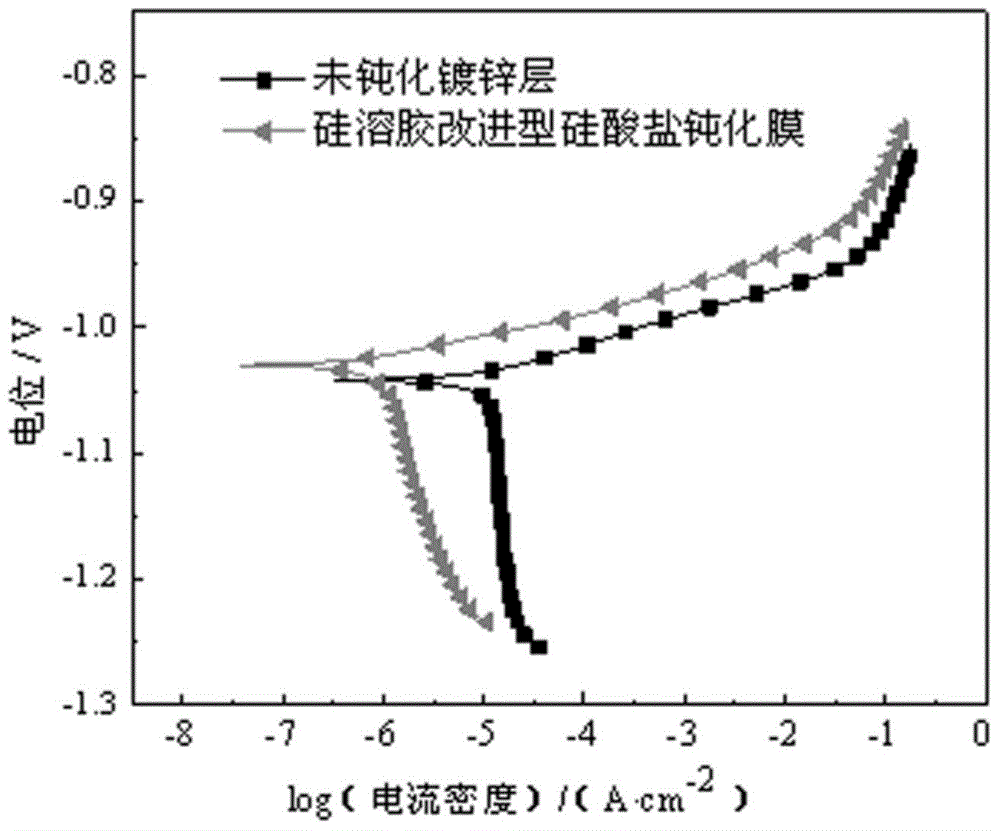

[0032] After the steel workpiece is galvanized, the workpiece is placed in the environmentally friendly galvanized silicate passivation solution for 1 minute by constant temperature dipping method, then taken out, and dried naturally at a passivation temperature of 60°C; the composition of the silicate passivation solution is Sodium hydroxide is 14g / L, silicon dioxide is 30g / L, silica sol is 17ml / L, the pH value of the passivation solution is 10.5, and the rest is water.

[0033] The specific method of silicate passivation solution configuration is:

[0034] (1) In a 1000mL beaker, dissolve 14g of sodium hydroxide with 100mL of distilled water and stir until the sodium hydrox...

Embodiment 2

[0048] Hot-dip galvanizing of steel plates, the process is as follows: degreasing in hot alkaline bath → hot water washing → pickling and rust removal → cold water washing → plating flux aid → drying → hot dipping → water cooling.

[0049] Silicate solution and treatment process:

[0050] After the steel workpiece is galvanized, the workpiece is placed in the silicate passivation solution for 1 minute by constant temperature dipping, then taken out, and dried naturally at a passivation temperature of 60°C; the composition of the silicate passivation solution includes sodium hydroxide 20g / L, silicon dioxide 30g / L, silica sol 70ml / L, and the pH value of the passivation solution is 10.0.

[0051] The specific method of silicate passivation solution configuration is:

[0052] (1) In a 1000mL beaker, dissolve 20g of sodium hydroxide with 100mL of distilled water and stir until the sodium hydroxide is completely dissolved;

[0053] (2) Slowly add 30g of silicon dioxide, and stir ...

Embodiment 3

[0060] Hot-dip galvanizing of steel plates, the process is as follows: degreasing in hot alkaline bath → hot water washing → pickling and rust removal → cold water washing → plating flux aid → drying → hot dipping → water cooling.

[0061] Silicate solution and treatment process:

[0062] After the steel workpiece is galvanized, the workpiece is placed in the silicate passivation solution for 3 minutes by constant temperature dipping, then taken out, and dried naturally at a passivation temperature of 40°C; the composition of the silicate passivation solution includes sodium hydroxide 20g / L, silicon dioxide 30g / L, silica sol 70ml / L, and the pH value of the passivation solution is 10.0.

[0063] The specific method of silicate passivation solution configuration is:

[0064] (1) In a 1000mL beaker, dissolve 20g of sodium hydroxide with 100mL of distilled water and stir until the sodium hydroxide is completely dissolved;

[0065] (2) Slowly add 30g of silicon dioxide, and stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com