Passivation mechanism and method of diamond cutter

A diamond tool and frame technology, applied in the field of precision cutting, can solve the problems of unsuitable diamond tools, high brittleness of diamond tools, blunt round edge chipping, etc., to prevent oxidation, high passivation efficiency, and low passivation cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

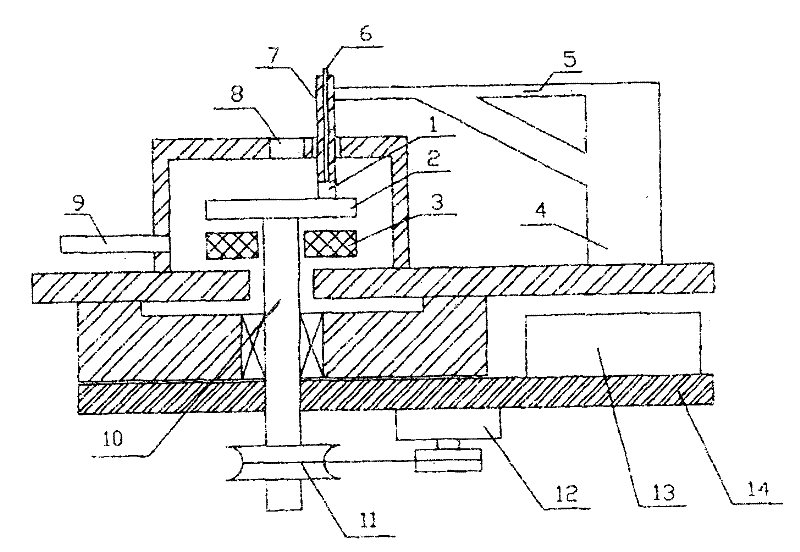

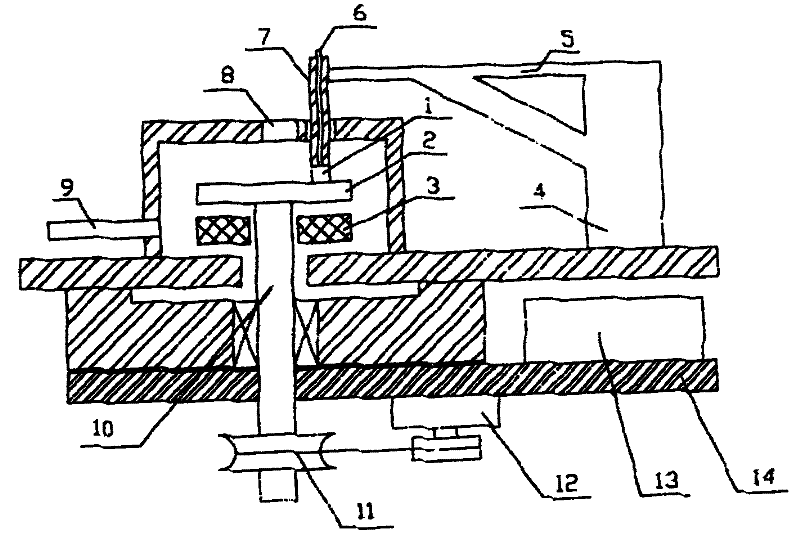

[0008] As shown in Figure 1, a diamond tool passivation mechanism includes a frame, a bracket, a grinding disc, a driving device composed of a motor and a pulley, a transmission device composed of a pulley and a transmission shaft, and a control device. The frame 14 is provided with a grinding cavity, and one side of the grinding cavity is provided with an air intake pipe 9, and the shaft end of the transmission shaft 10 fixed on the frame extends in the grinding cavity, and the shaft end of the transmission shaft is equipped with a grinding disc 2. A heater 3 is installed in the grinding chamber below the grinding disc. The upper end of the grinding disc can be in contact with the diamond tool 1 fixed by the bottom end of the fixture 7. The upper end of the fixture extends out of the grinding cavity, and is connected with the bracket 4 installed on one side of the frame. The force-measuring strain gauge 5 on the top is connected, and the optical fiber 6 connected with the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com