Patents

Literature

54results about How to "Improve cutting strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

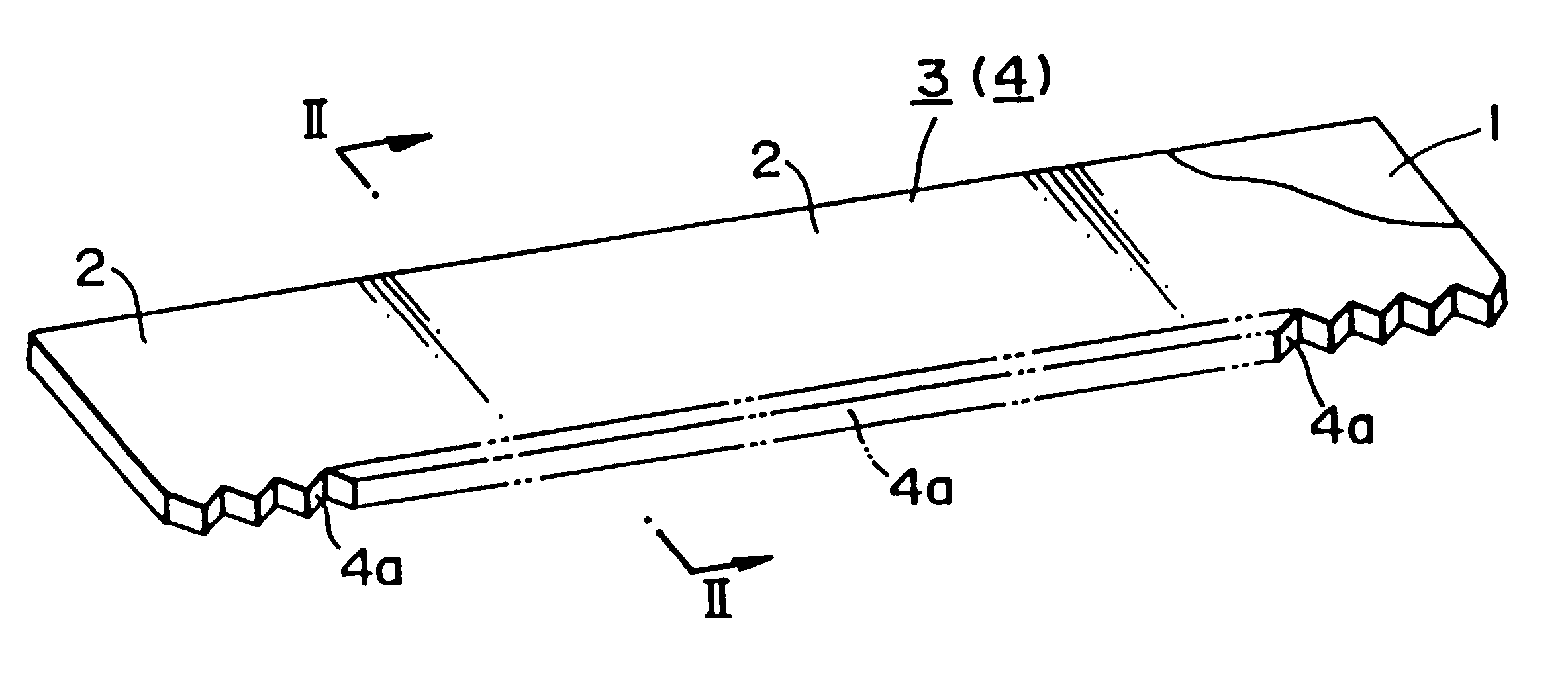

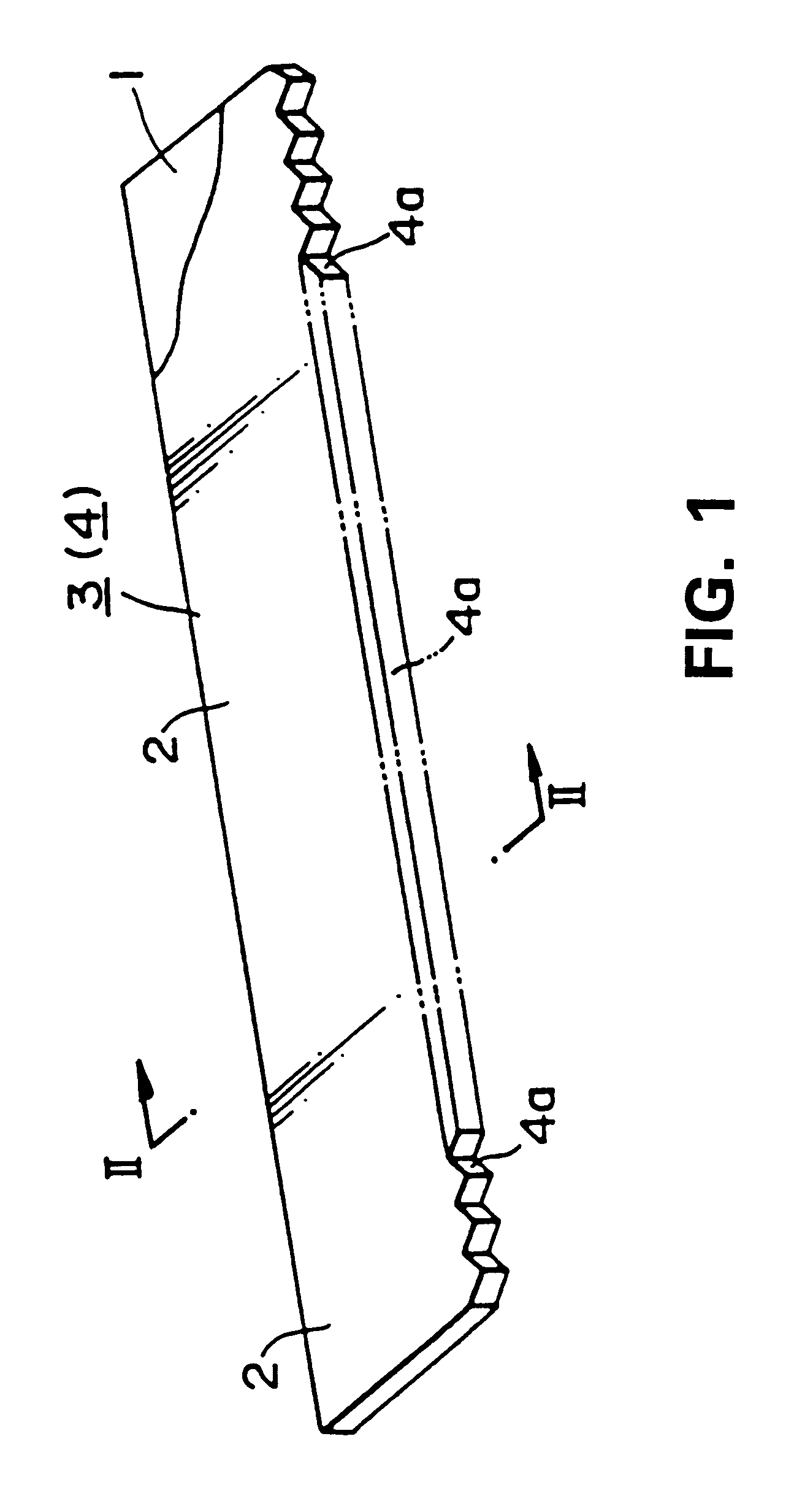

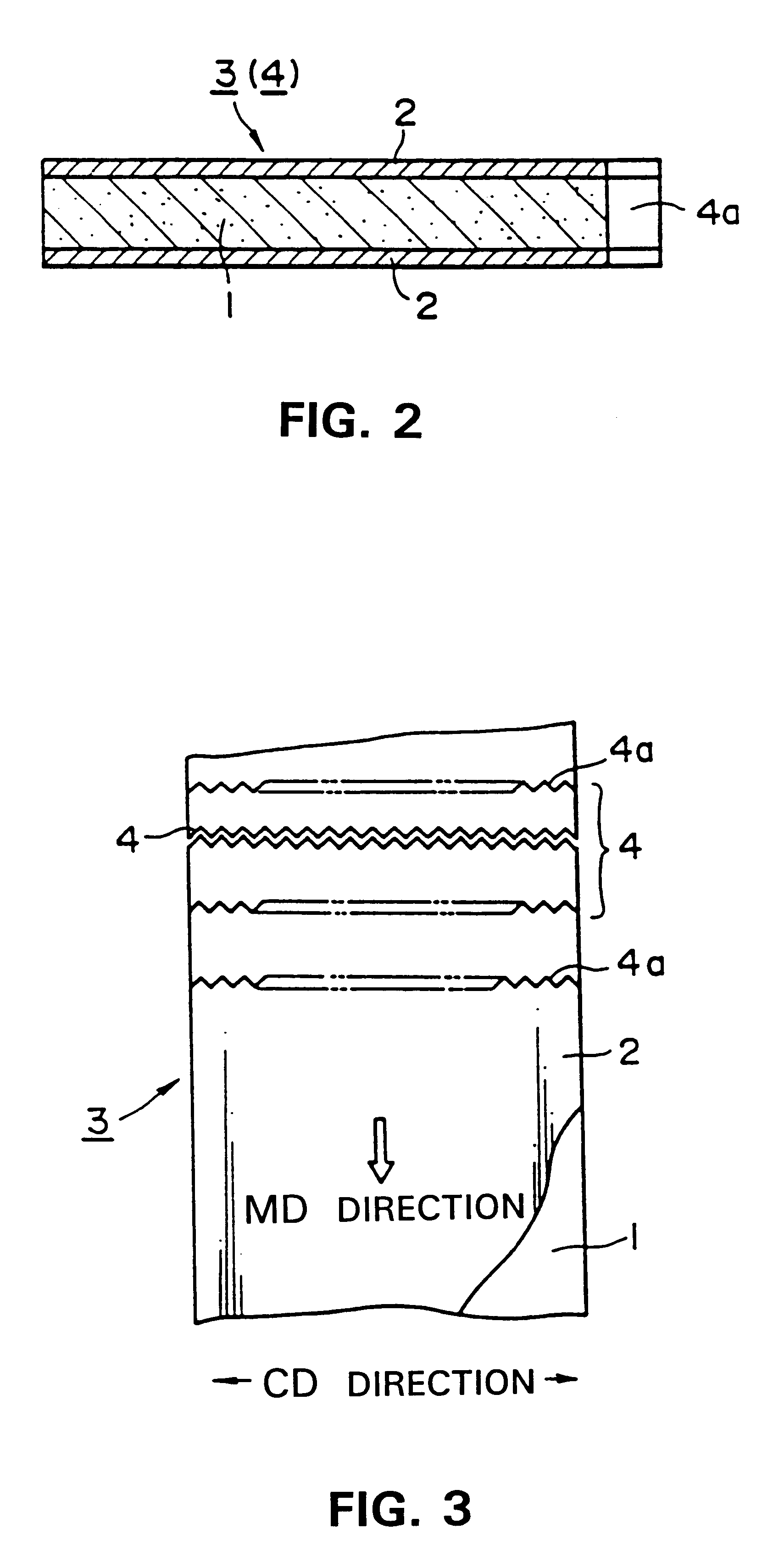

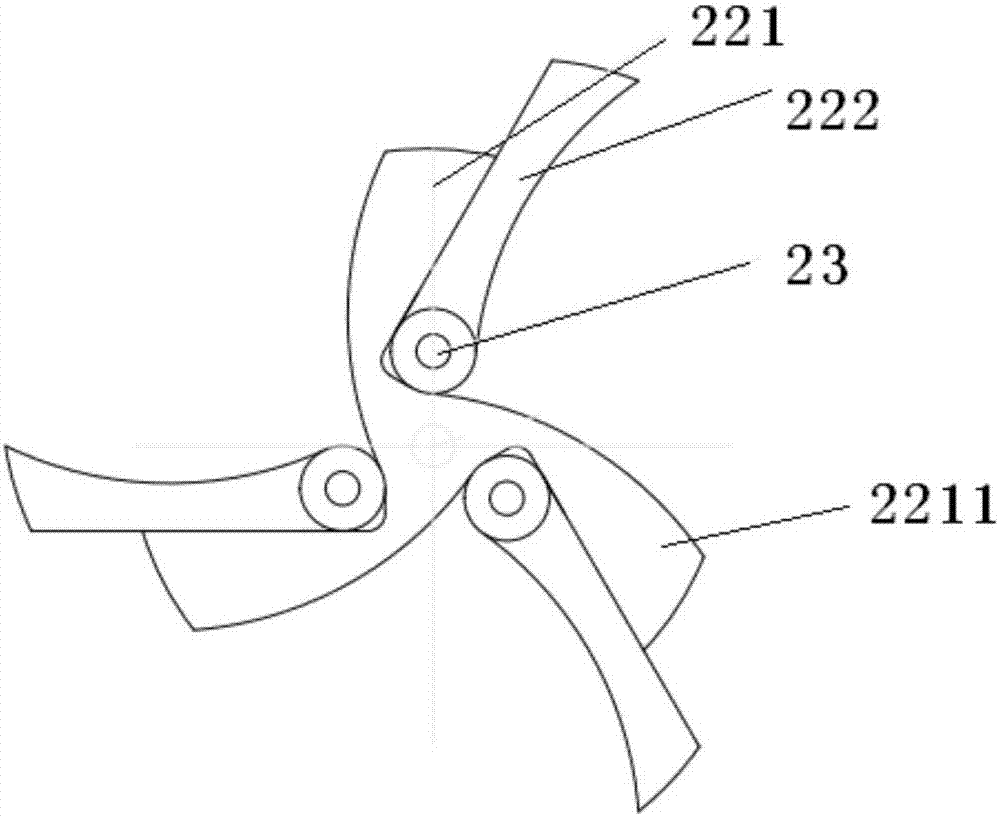

Vulcanized fiber sheet having a serrated cutting edge, a carton having said sheet adhered thereto, and a method of adhesion thereof

InactiveUS6173876B1Increase elasticityImprove rigidityBox making operationsFlat article dispensingMetallic foilFiber

The present invention is a sheet having a serrated cutting edge attached to a carton case containing a roll of a cooking sheet such as a synthetic resin film, paper sheet and metallic foil, the sheet having a serrated cutting edge used for cutting the cooking sheet. The sheet having a serrated cutting edge is made of a vulcanized fiber. A moisture-proof film of a synthetic resin is formed on the two surfaces of a vulcanized fiber blank in order to make the most of the rigidity and elasticity which are advantages of the vulcanized fiber and decreases moisture absorption which is a disadvantage thereof. The invention also is a carton to which the sheet having a serrated cutting edge is adhered to as well as to a method of adhering the sheet having a serrated cutting edge to the carton by utilizing the moisture-proof film and ultrasonic adhesion.

Owner:OJI PAPER CO LTD

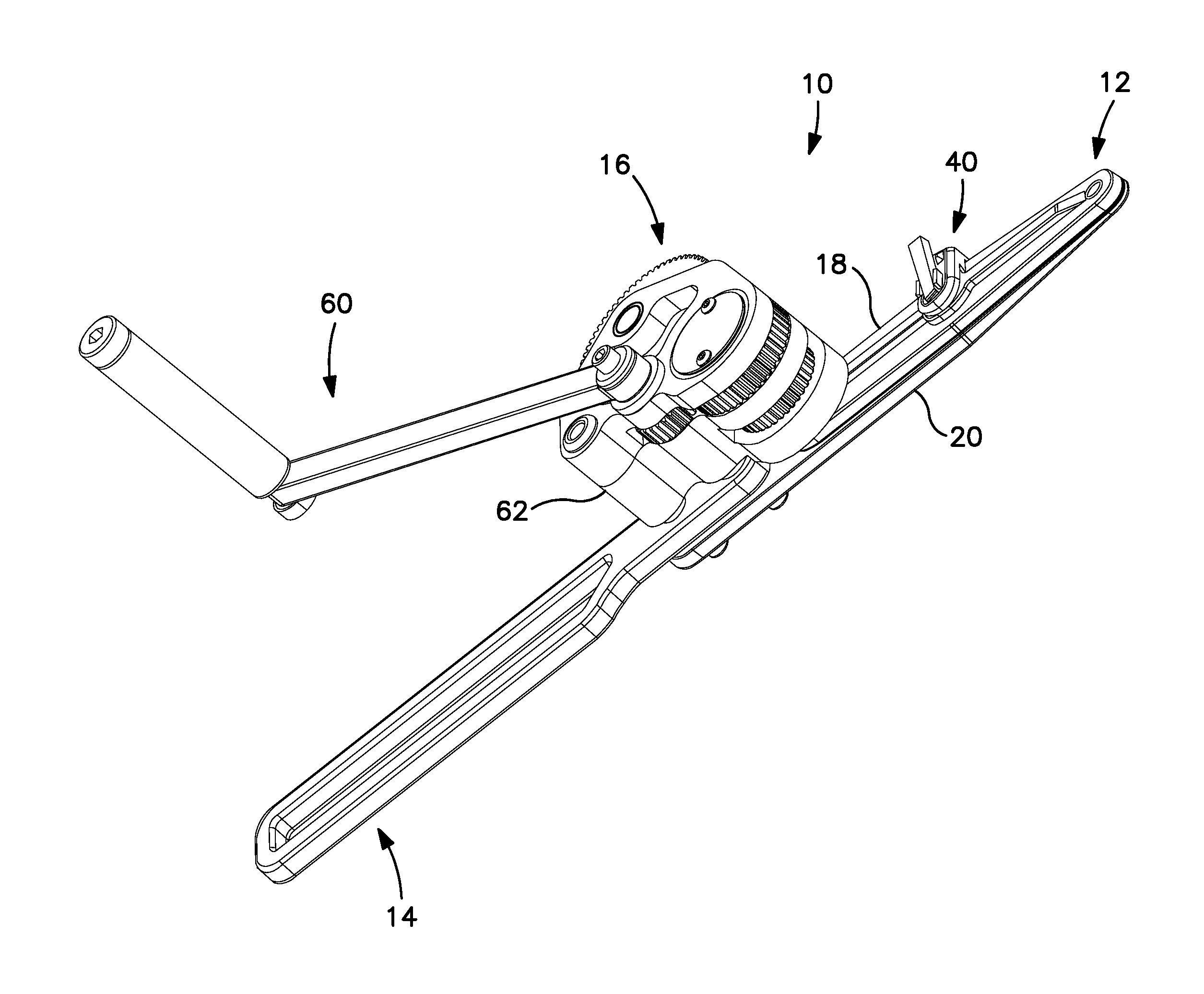

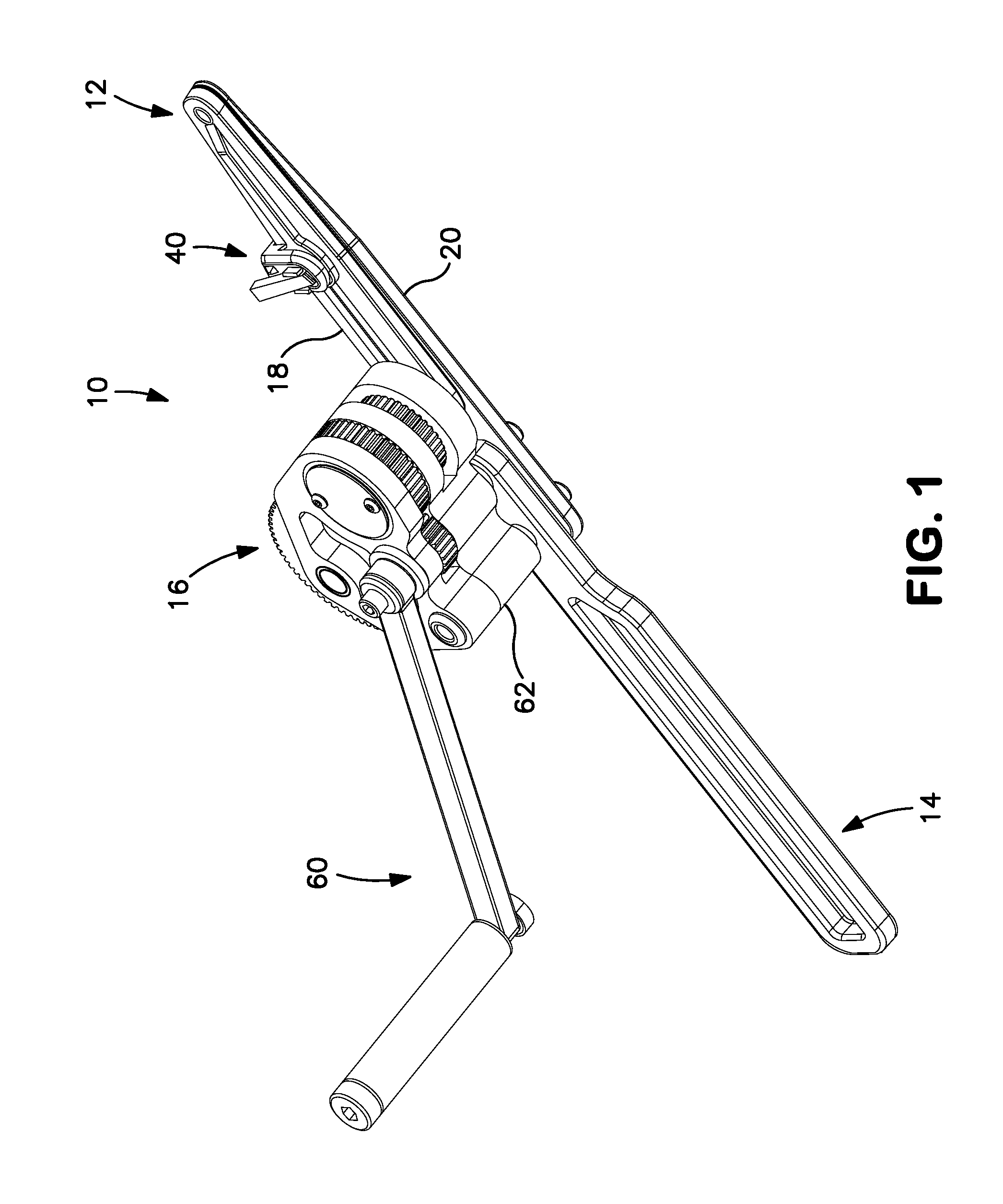

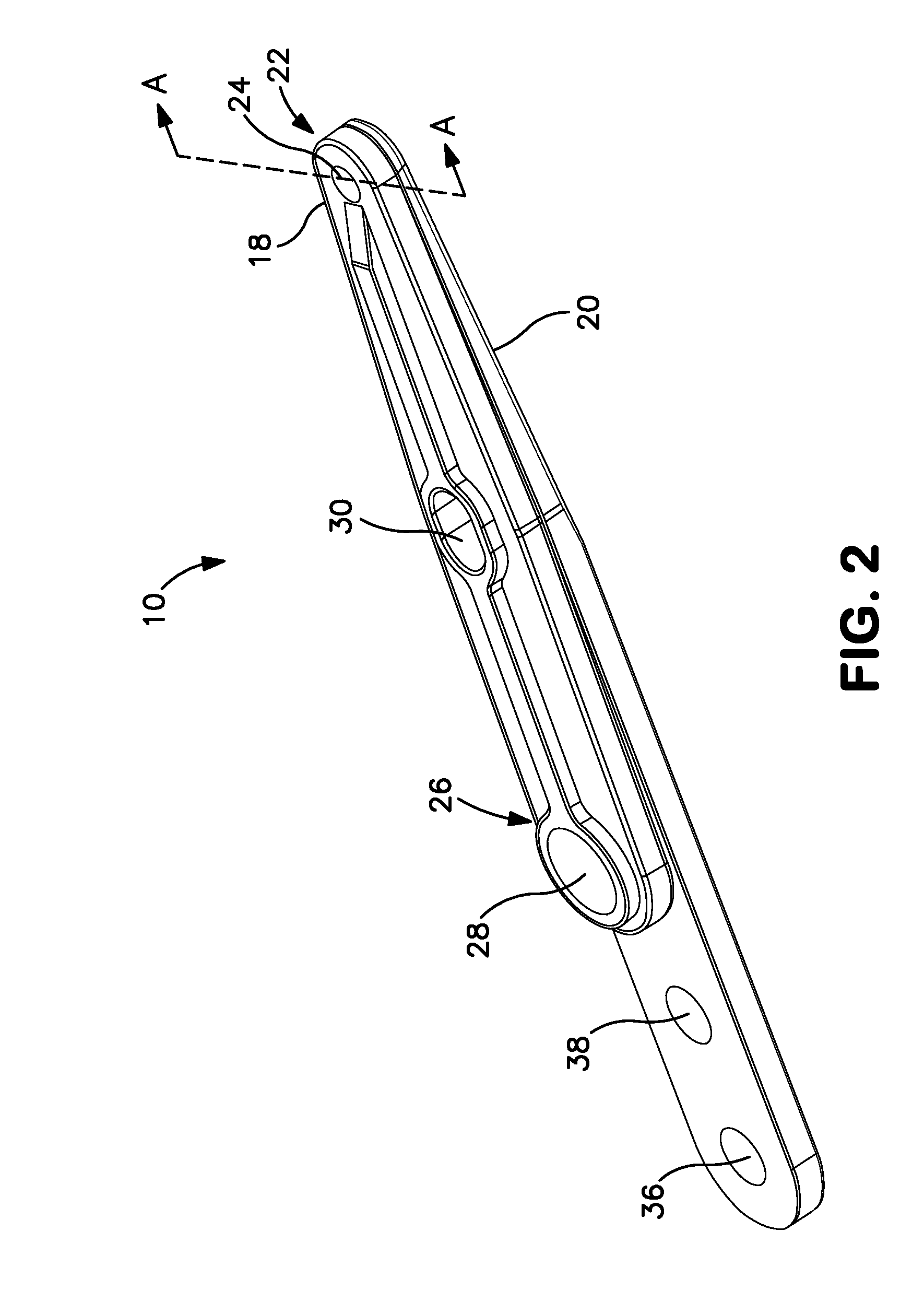

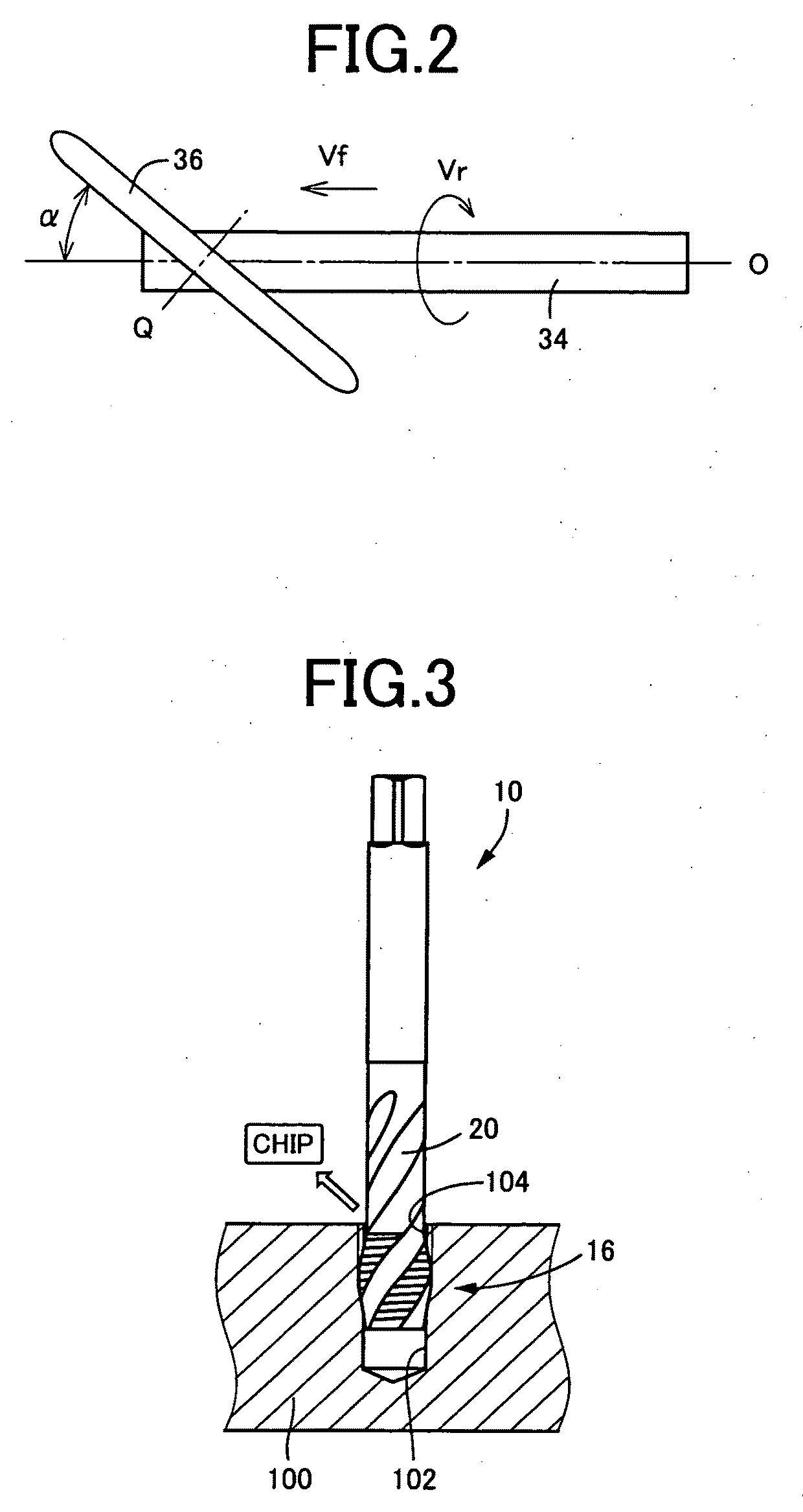

Oscillating rod cutter

InactiveUS20110107601A1Improve cutting strengthEasy to useTube shearing machinesPortable handheld shearing machinesEngineeringMechanical engineering

A rod cutter apparatus includes a rod holding plate having a rod opening for receiving a rod to be cut; a cutting member having a central opening defined by a cutting edge, the central opening being substantially aligned with the rod opening; and a drive assembly connected between the rod holding plate and the cutting member to cause oscillation of the cutting member relative to the rod holding plate, wherein oscillation of the cutting member relative to the rod holding plate cuts a rod in the rod opening.

Owner:VERMONT INSTR MAKERS

Method for cutting silicon wafer through 55-micrometer diamond wire

ActiveCN109808091AIncrease profitReduce processing timeWorking accessoriesFine working devicesMicrometerWire wheel

The invention relates to a method for cutting a silicon wafer through a 55-micrometer diamond wire. The method comprises the following steps that a cutting wire net is arranged in a cutting area between an upper wire wheel and a lower wire wheel, the wire net is in a Z shape, the distance between two wire guide wheels is M, the distance between the upper wire wheel and the lower wire wheel is N, and M is equal to M; tension and running speed of the cutting wire net, and the silicon bar motion speed are set; at the starting processing stage, the tension of the wire net is 8N, the workpiece motion speed is 2.3 to 2.4 mm / min, the diamond wire moving speed is 600m / min, and cooling liquid is prepared; in the continuous machining process, the tension of the wire net ranges from 9 to 10 N, the workpiece motion speed is 2.4 mm / min, and the motion speed of the diamond wire is 1500 m / min; at the finishing stage, the tension of the wire net is 12 N, the workpiece motion speed is 1.0 mm / min, and the diamond wire motion speed is 1300 to 1500 m / min; cooling liquid flow is set, wherein at the starting machining stage, the flow is 50 to 55 kg / min, at the continuous machining stage, the flow is 500kg / min, and at the finishing stage, the flow is 50 to 55 kg / min; and the wire arch of the cutting wire net and cutting strength of the extremely thin wire are matched, and the wire breaking problem is solved.

Owner:WUXI ZHONGHUAN APPLIED MATERIALS CO LTD

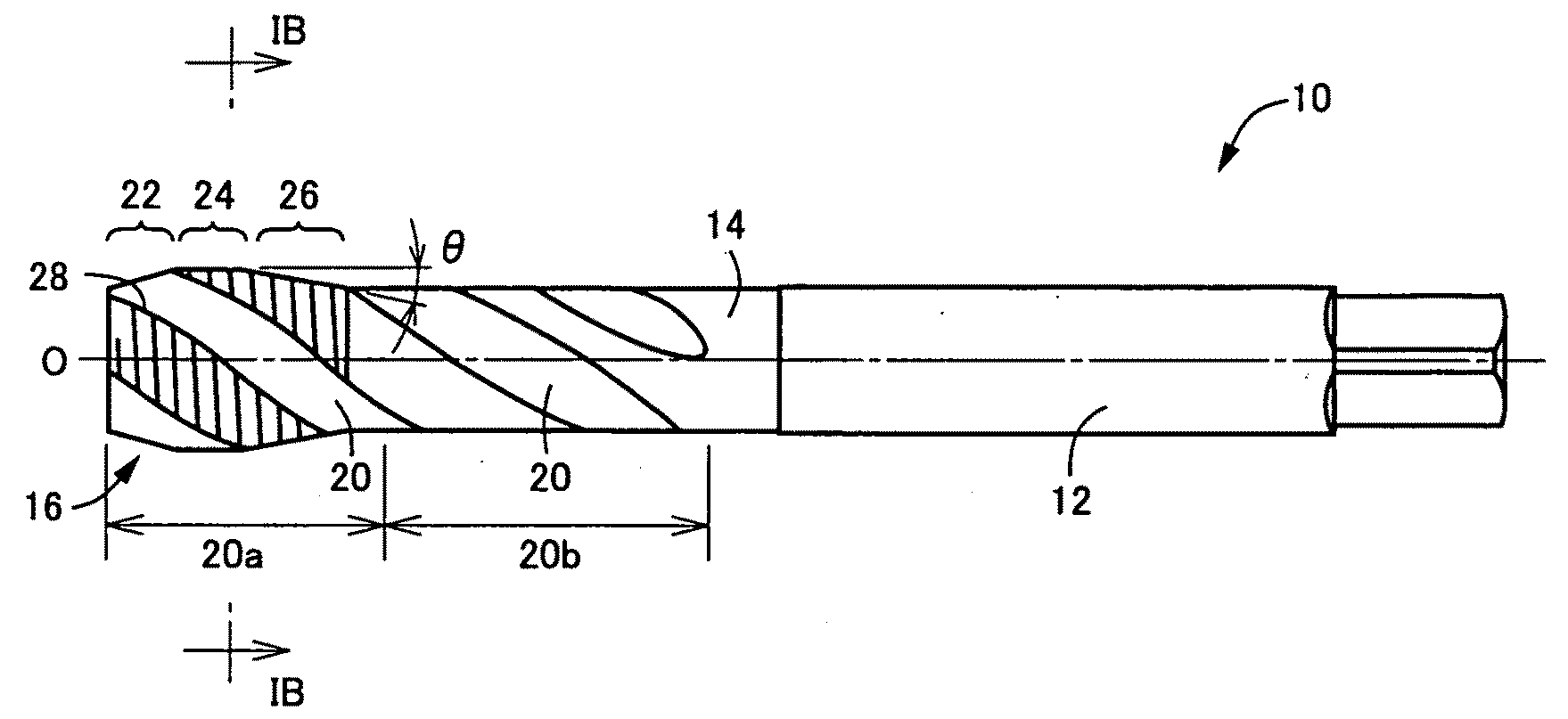

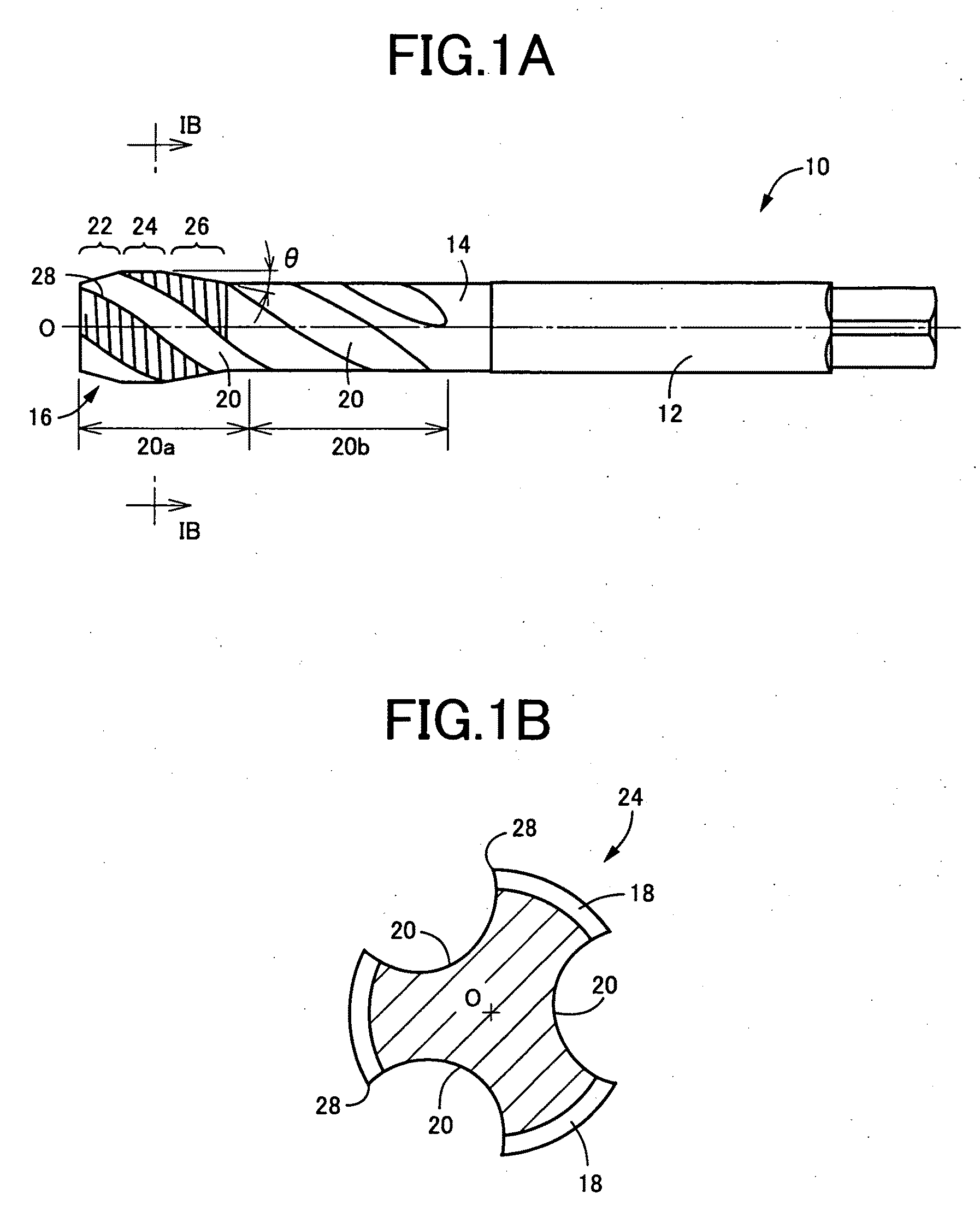

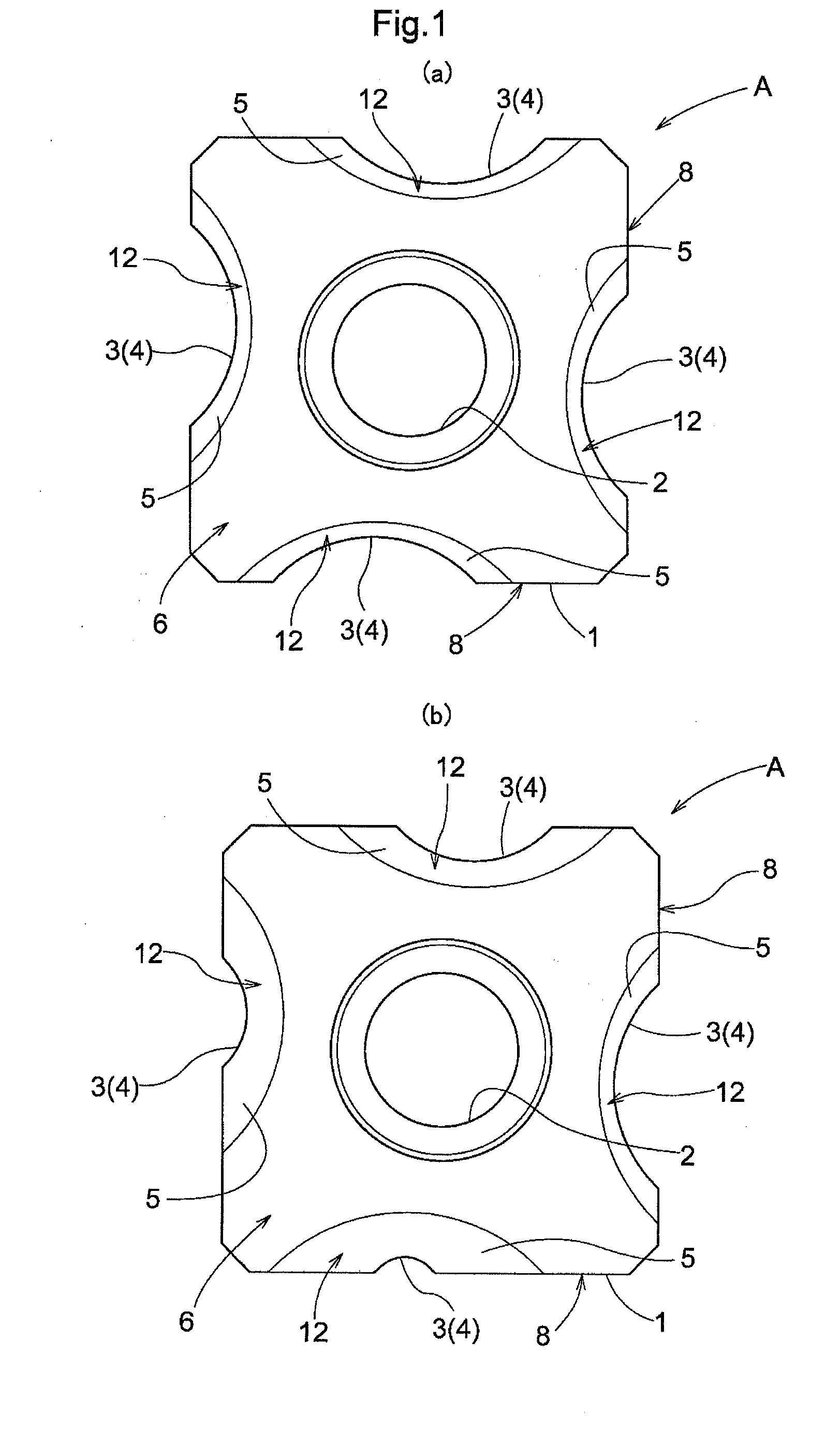

Spiral tap

ActiveUS20090214311A1Improve cutting performanceImprove cut qualityThread cutting toolsWood turning toolsFluteEngineering

As shown in FIG. 1, a helical flute has a constant lead part and a gradually increased lead part. The constant lead part has an axial length ranging from 0.3xLA to 1.2xLA and includes at least entirety of a leading part, so that the cutting performance of a cutting edge at the leading part and shape of chips (curled shape, etc.) are stable. In the constant lead part, because a lead is the smallest and a helix angle is large, a rake angle of the cutting edge is large, so that an excellent cutting quality is obtained and the chips become curled well. Meanwhile, in the gradually increased lead part, because of the lead gradually increased toward a shank, the chips are rapidly discharged toward the shank. Thus, the excellent cutting performance and the chip discharge performance rendered by the gradually increased lead are highly stabilized by the presence of the constant lead part. In this way, the durability is further improved.

Owner:OSG

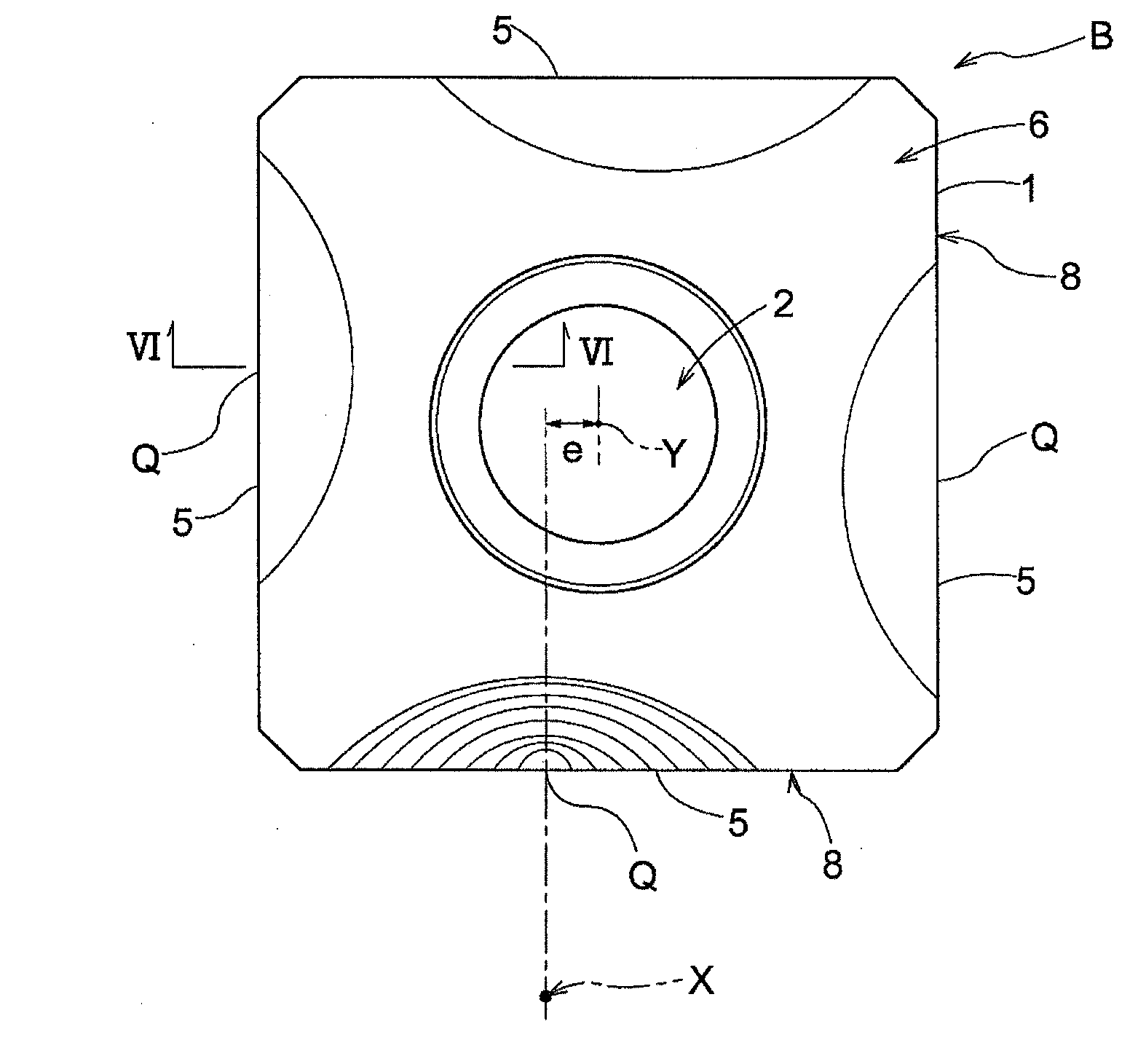

Insert

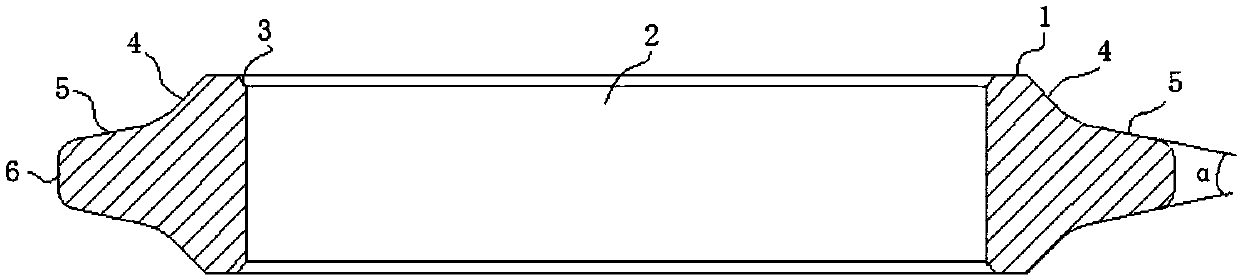

ActiveUS20130243537A1Improve cutting strengthHigh strengthTransportation and packagingMilling cuttersEngineeringHardness

An insert includes a rake angle set corresponding to the hardness of a material to be cut and that can suppress an increase in the material cost even when the strength of a cut edge section is increased. The insert has a polygonal shape and includes a cutting edge portion on at least one side of the polygonal shape. The cutting edge portion includes a rake face having a convex formed on one of opposite surfaces in the thickness direction, a flank face having a concave formed on a surface intersecting with the one surface in the thickness direction and a concave cutting edge that is formed between the rake face and the flank face.

Owner:DAISHOWA SEIKI CO LTD

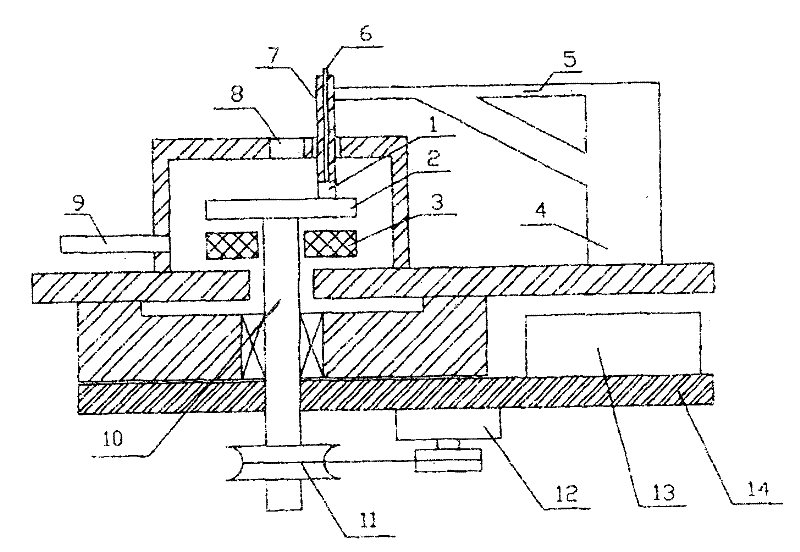

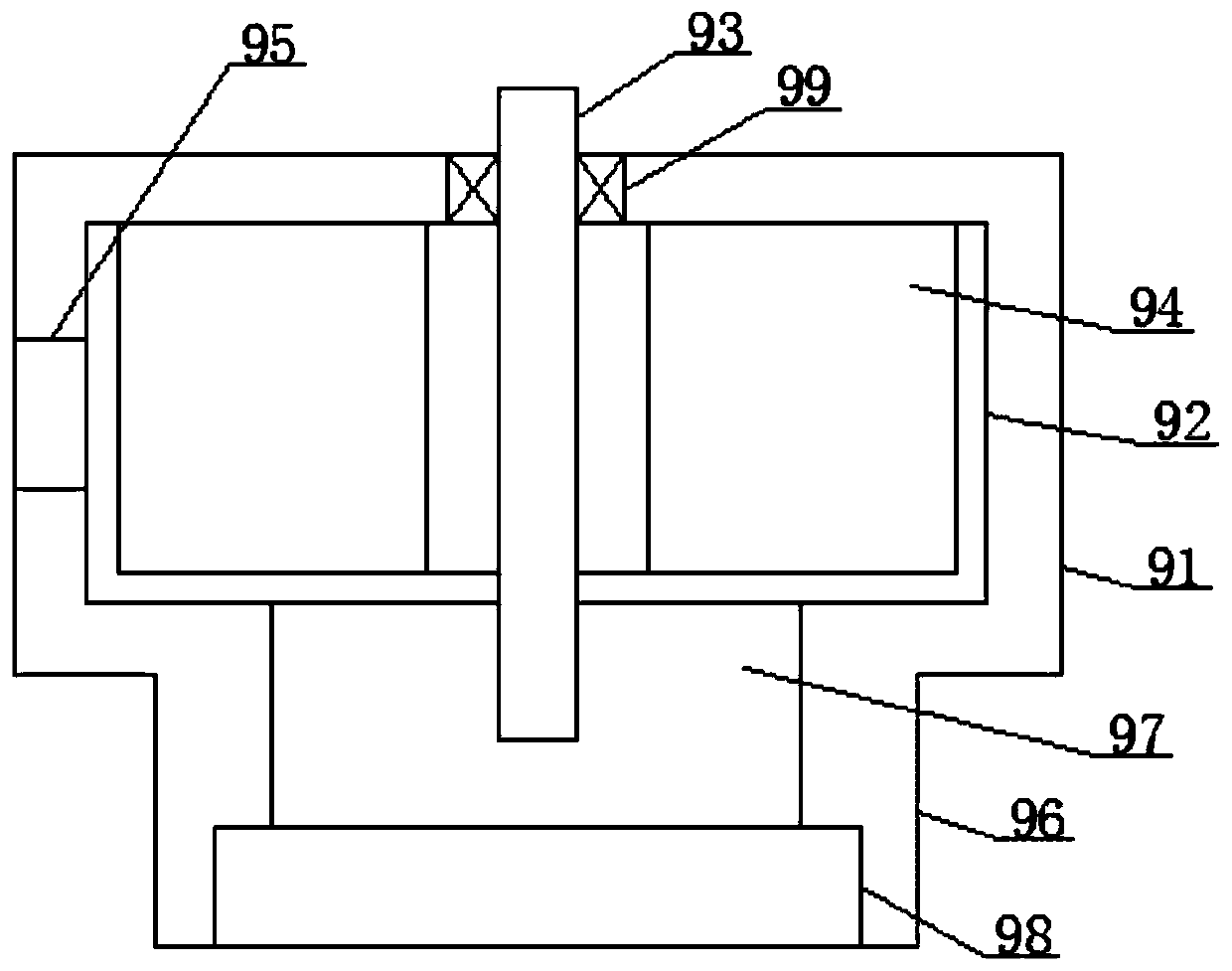

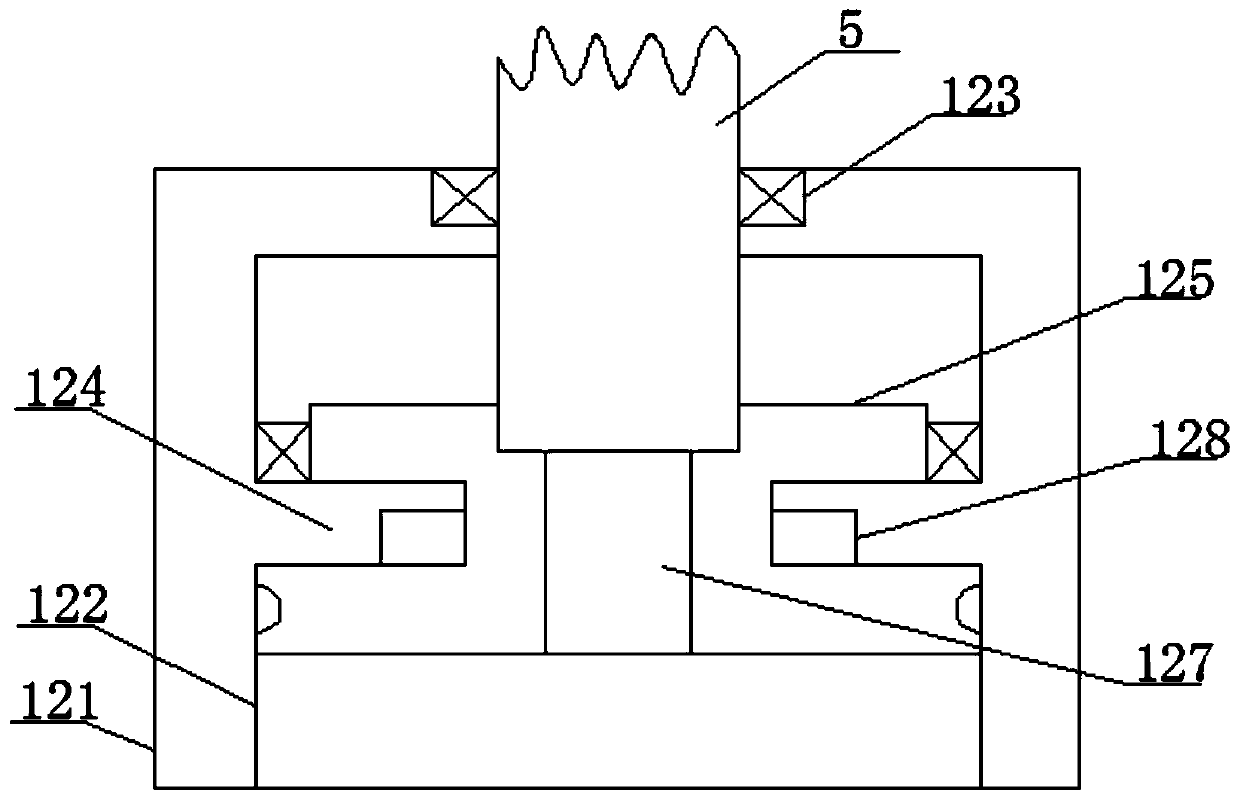

Passivation mechanism and method of diamond cutter

InactiveCN102343530APrevent oxidationExtended service lifeOther manufacturing equipments/toolsHydrogenDrive shaft

The invention discloses a passivation mechanism and method of a diamond cutter. The passivation mechanism comprises a frame, a bracket, a grinding disc, a driving device, a transmission device and a control device, wherein the driving device consists of a motor and a belt pulley; the transmission device consists of a belt pulley and a transmission shaft; a grinding cavity is arranged on the frame (14); an air inlet pipe (9) is arranged on the grinding cavity; the shaft end of the transmission shaft (10), which is fixedly connected with the grinding disc (2), is arranged in the grinding cavity in an extending way; a heater (3) is arranged below the grinding disc; the upper end of the grinding disc can be in contact with the diamond cutter (1) at the bottom end of a clamp (7); the upper end of the clamp extends out of the grinding cavity and is connected with a dynamometric strain gauge (5) arranged on the bracket (4); and optical fiber (6) which is connected with the control device (13) is arranged in the clamp. When the diamond cutter is passivated, the temperature of the grinding disc is 700-900 DEG C; under the atmosphere condition of hydrogen, the rotation speed of the motor is 20-200r / min and the grinding time is 3-20s, and a 3-50mum blade arc can be obtained; and the passivation mechanism and method disclosed by the invention have the advantages of high passivation efficiency, good effect and low cost.

Owner:常州卓铸精艺精密工具有限公司

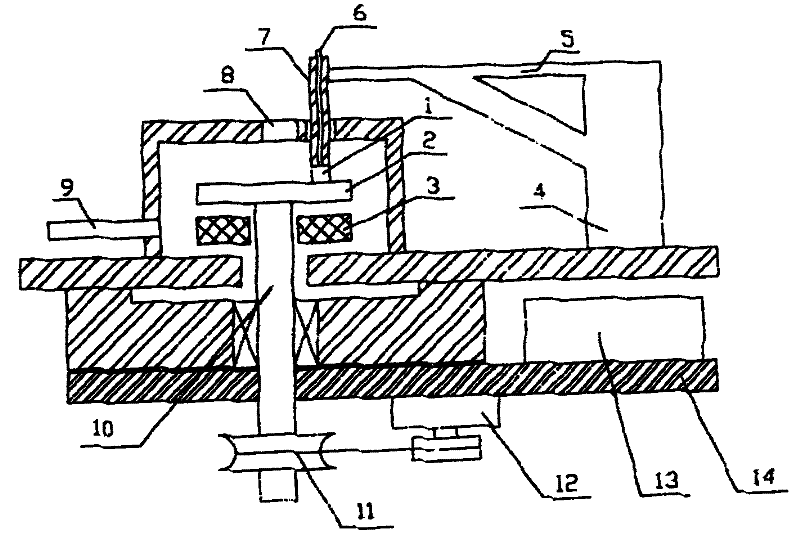

High-uniformity full-screen light guide plate and preparation method thereof

InactiveCN108044705AImprove the display effectImprove uniformityMetal working apparatusLaser beam welding apparatusLight guidePulp and paper industry

The invention provides a high-uniformity full-screen light guide plate and a preparation method thereof. The preparation method comprises the following steps that S1, injection molding is carried outwith a light guide plate production mould to form a rectangular light guide plate body, the light guide plate body is provided with a lamp socket slot at one end and a cutting line at the other end, both ends of the cutting line are correspondingly connected with the edges of the light guide plate body, the cutting line is arc-shaped, and an area surrounded by the cutting line is the area to be cut; S2, the light guide plate body is suspended by using a clamps, a support plate is used for supporting the area to be cut, and the support plate is away from the cutting line; and S3, finally a cutting fixture is used for cutting along the cutting line, so that the area to be cut is separated from the light guide plate body to form a notch. According to the high-uniformity full-screen light guide plate and the preparation method thereof, the uniformity of injection molding materials in the notch of a light guide plate is good, no bright line or dark line defects are formed, and the full screen display effect is good.

Owner:JIANGXI HOLITECH TECH

Processing technology of shield tunneling machine hobbing cutter ring with high wear resistance

ActiveCN108044317AReduced edge wearImprove wear resistance and service lifeTunnelsShield tunnelingAlloy

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

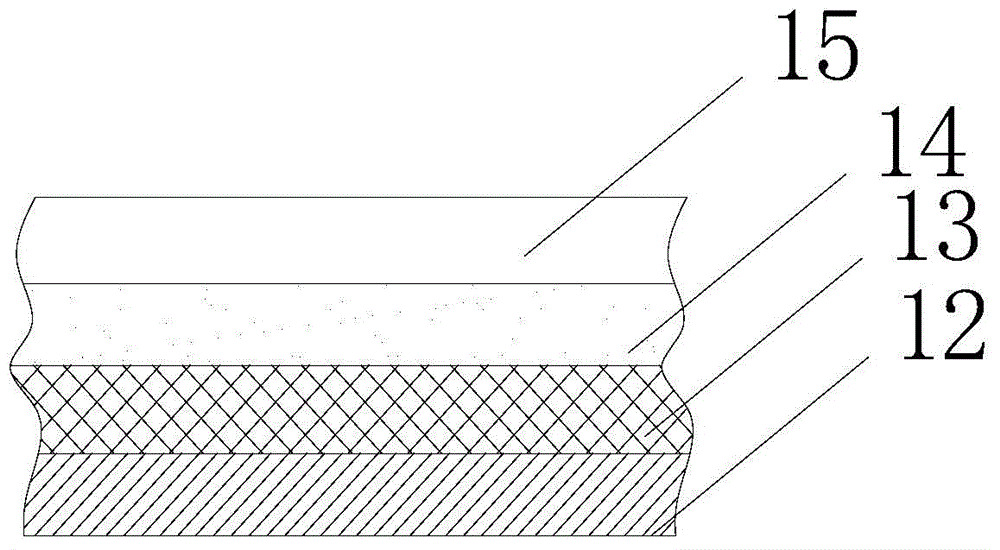

Novel material with high light shading property and high buffering capability

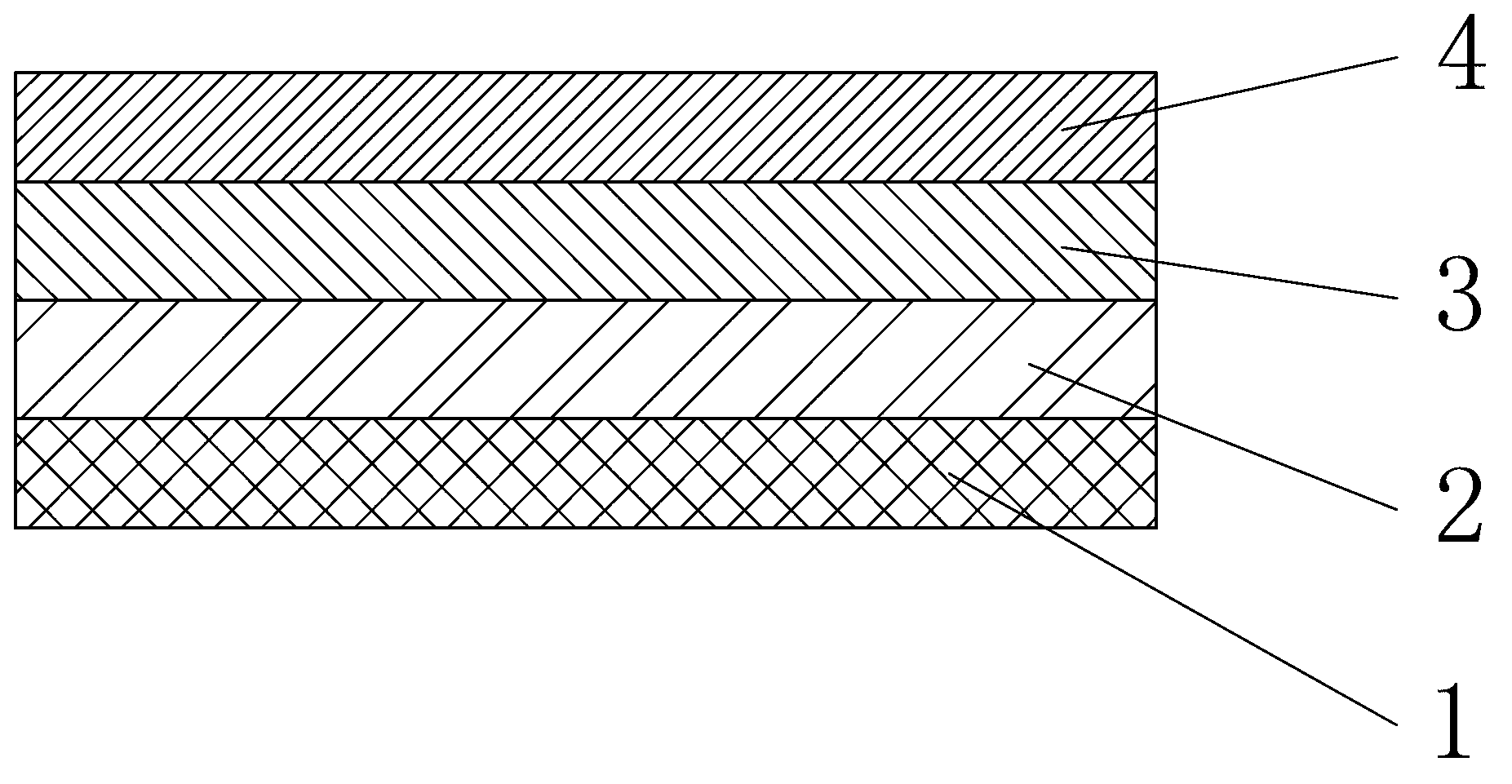

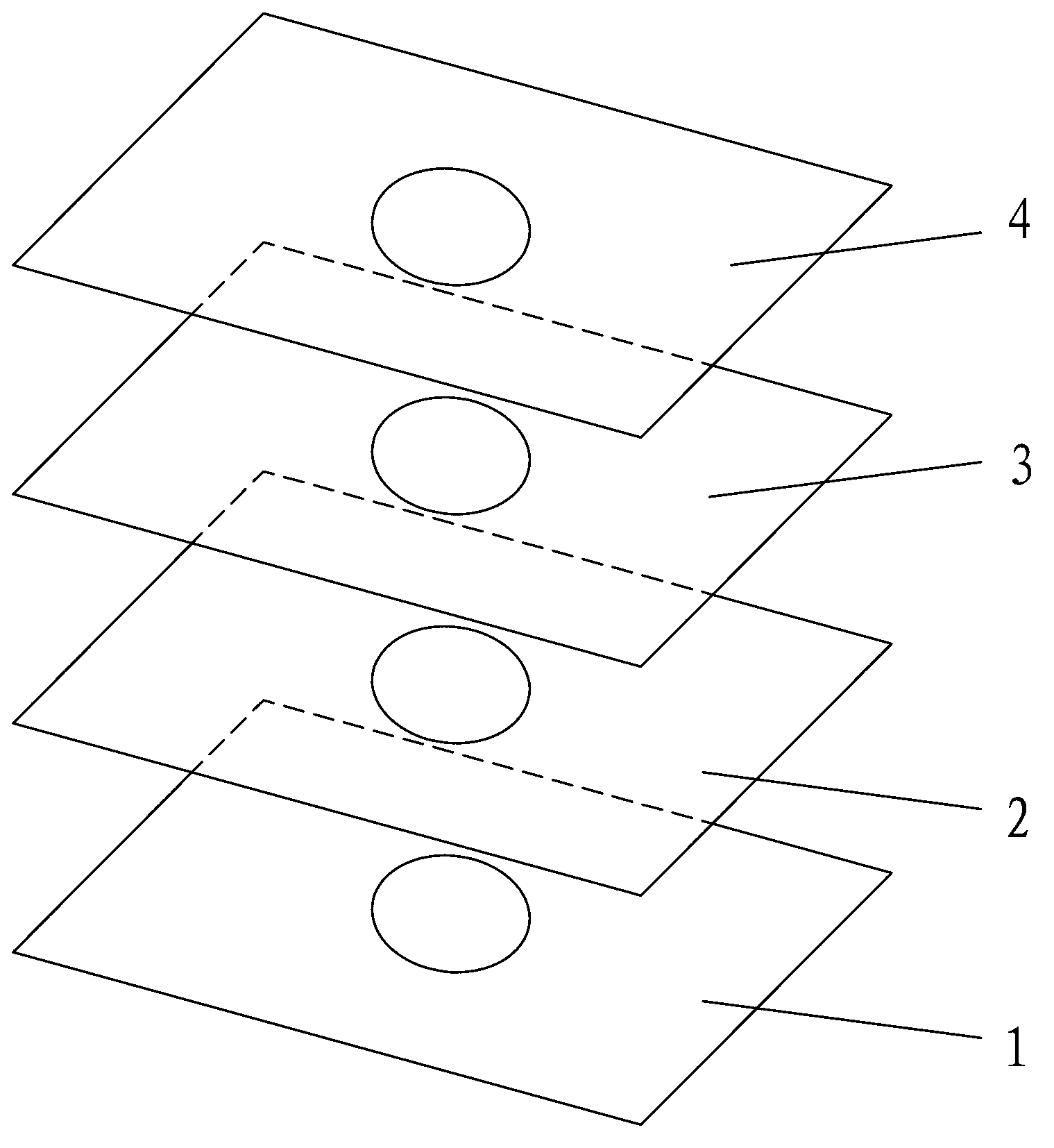

InactiveCN103013376AAccurate thicknessUniform thicknessFilm/foil adhesivesSynthetic resin layered productsPolyethylene glycolUltimate tensile strength

The invention discloses a novel material with a high light shading property and a high buffering capability. The novel material comprises an adhesive layer and a light shading layer which are fixed by adhesion, wherein the other side surface of the light shading layer is provided with an ink layer; the light shading layer comprises a polyurethane foaming layer and a PET (polyethylene glycol terephthalate) layer; the polyurethane foaming layer is positioned between the adhesive layer and the PET layer; and the ink layer is printed and applied on the surface. By the manner, the novel material can play roles of fixation, buffering and light shading and has an accurate thickness and excellent machinability; and the novel material can be cut to accurate die-cut shapes due to high cutting strength.

Owner:SUZHOU ANJIE TECH

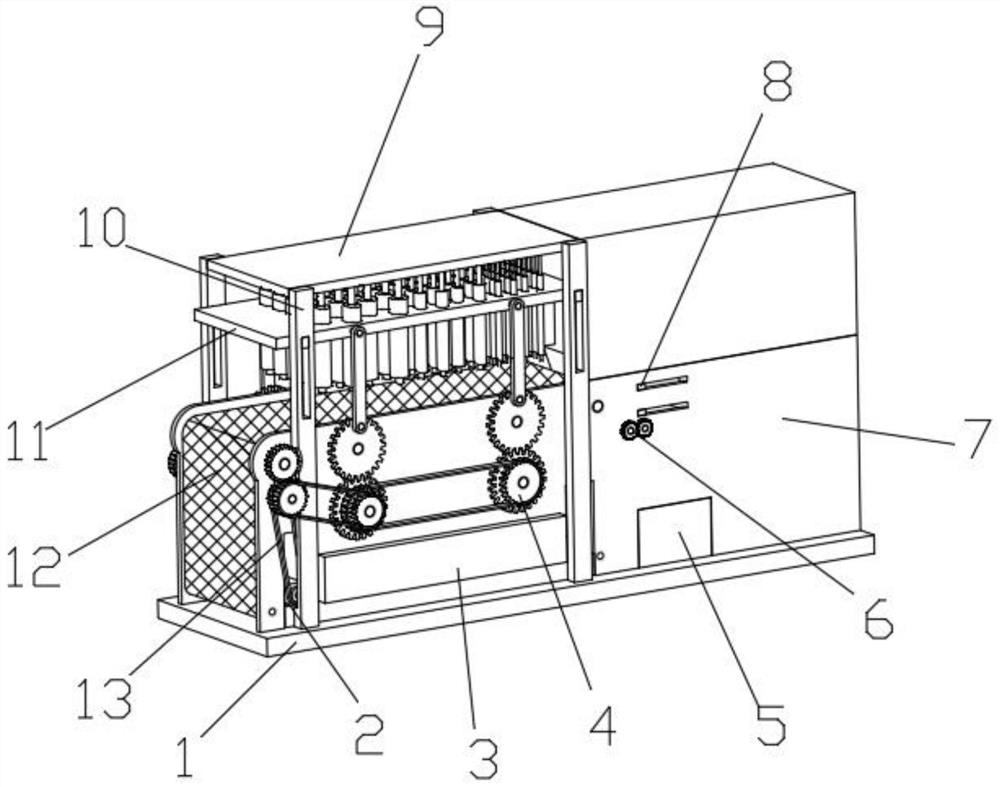

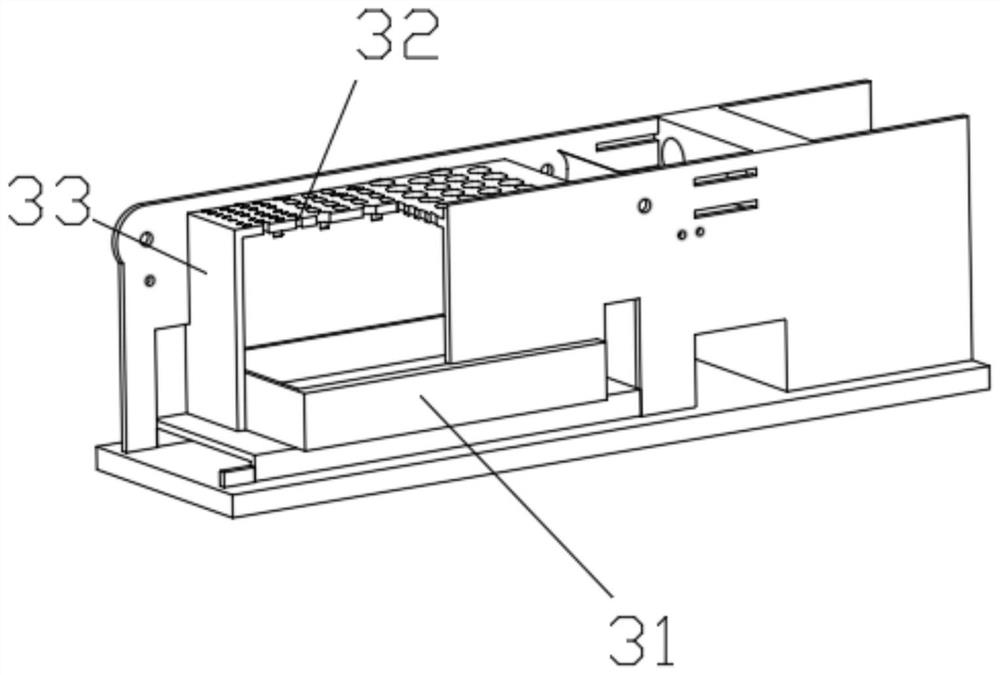

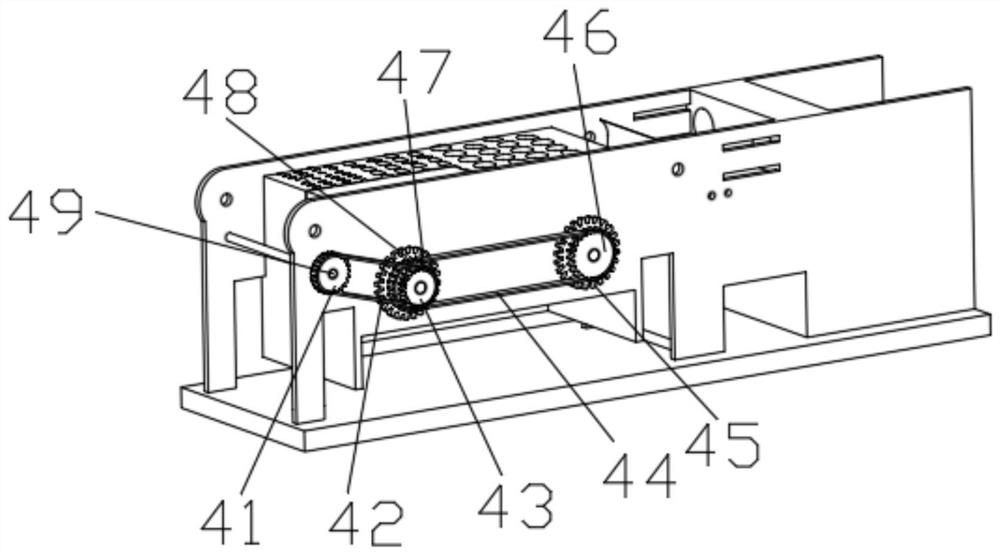

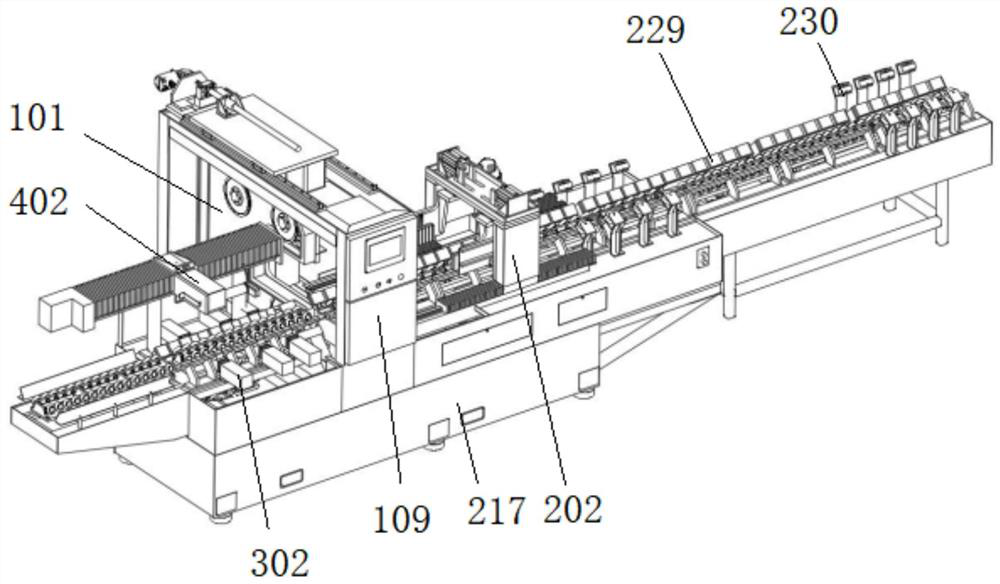

Metal lead and zinc recovery equipment

The invention discloses metal lead and zinc recovery equipment in the technical field of recovery processing equipment. The metal lead and zinc recovery equipment adopts a tube-pressing cutting mode to cut waste materials, so that the materials are uniformly cut and crushed more thoroughly, adopts a transportation mode of moving, stopping and moving, and is linked with a cutting mechanism adoptinga vertical cutting mode, so that when a blade cuts the material, a net-shaped conveyor belt is in a stop state, the stress of the blade in the conveying direction is reduced, burden of the blade is reduced, damages are avoided, the service life of the blade is prolonged, cutting strength and cutting smoothness are improved through vertical cutting, the materials are easily cut, abrasion loss andburden of the blade are reduced, and the blade is protected; a crushing and leading-in device is arranged to preliminarily crush the cutting excess materials and lead the crushed materials into a crushing mechanism; the crushed materials are thoroughly crushed through the crushing mechanism, so that treatment efficiency of the equipment on the materials is improved, a contact area of the crushed materials during reaction extraction is larger, and efficiency is higher.

Owner:尤梦宇

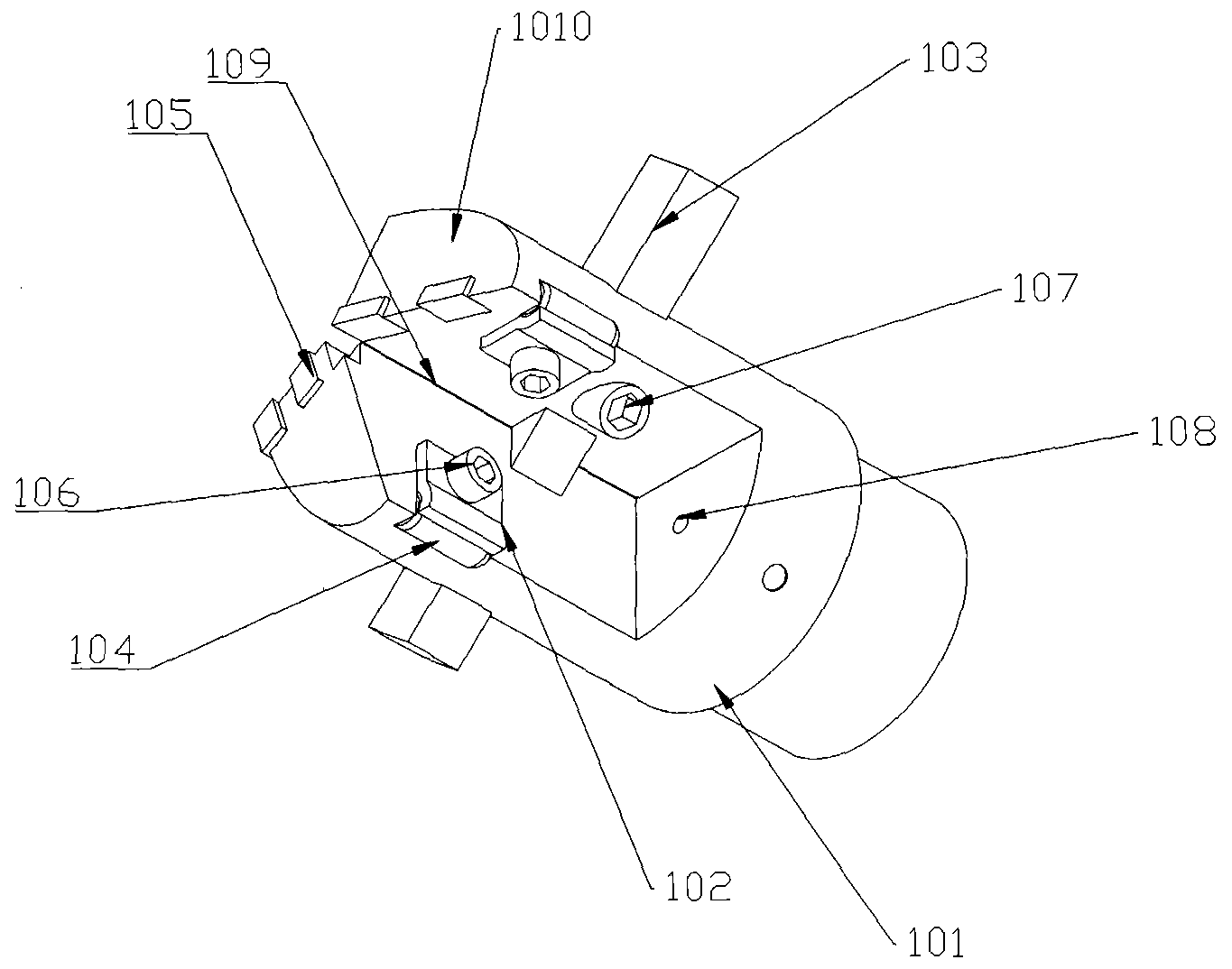

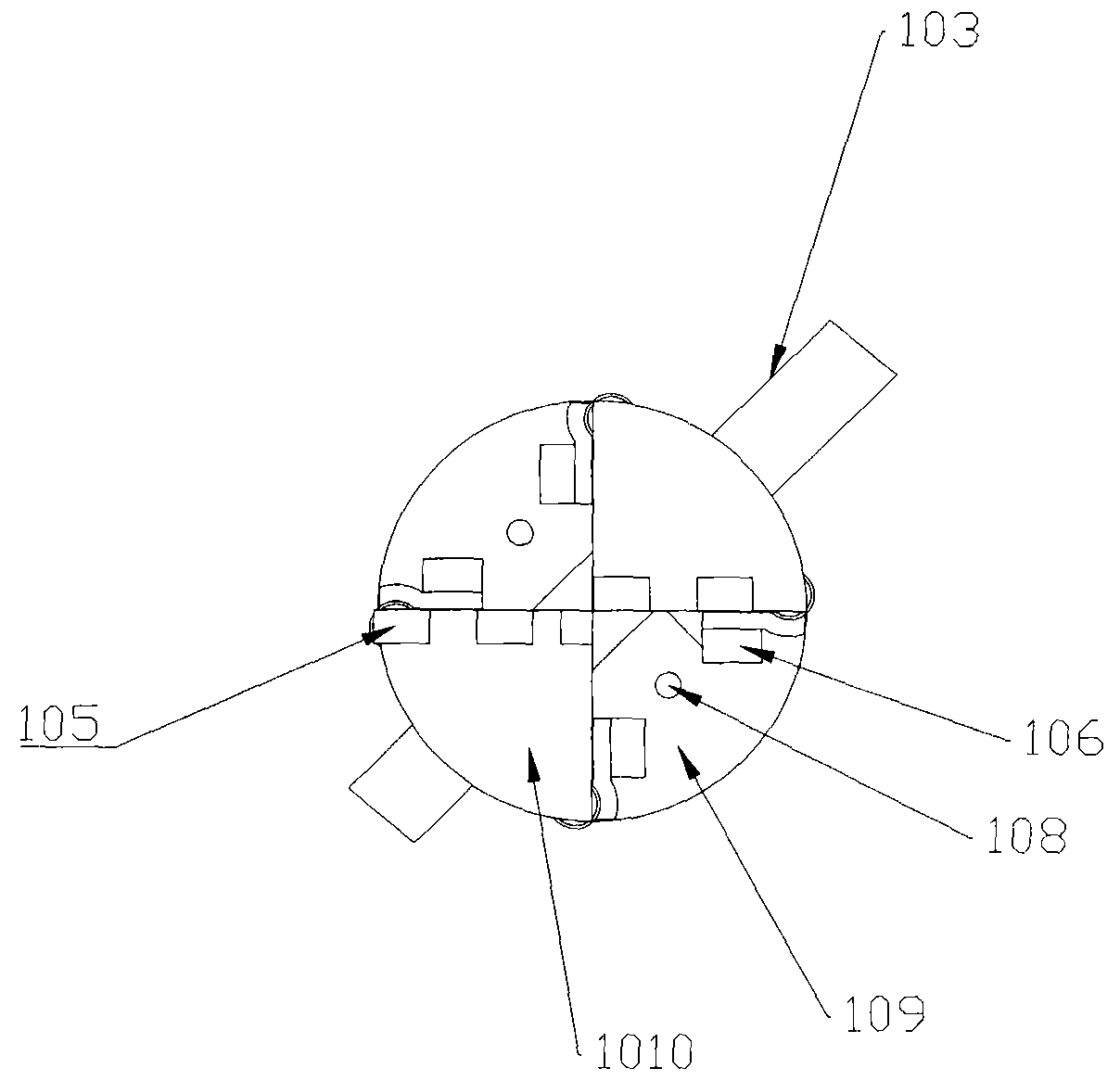

Drill bit for deep and large hole drilling

InactiveCN104384572AGood axial movementEffectively fixedTransportation and packagingTrepanning drillsTool bitAlloy

The invention belongs to the technical field of mechanical machining equipment, and particularly relates to a drill bit for deep and large hole drilling. The drill bit comprises a tool bit body, a roller pressing plate, a white steel knife strip, a supporting roller, a hard alloy blade, a roller pressing plate fixing screw and a white steel knife fixing screw. A drilling chip removal area which is arranged in an X crossing manner is machined on a drill bit body; a cutting liquid spraying hole is formed in the bottom of the drill bit body; and automatic chip removal in the machining process is achieved. The drill bit is special for deep and large hole machining and has the beneficial effects that the drilling efficiency is high, the supporting force in the drilling process is large, the blade is not prone to collapsing, and the service life of the drill bit is long.

Owner:CHANGSHA XINGXIN MACHINERY EQUIP

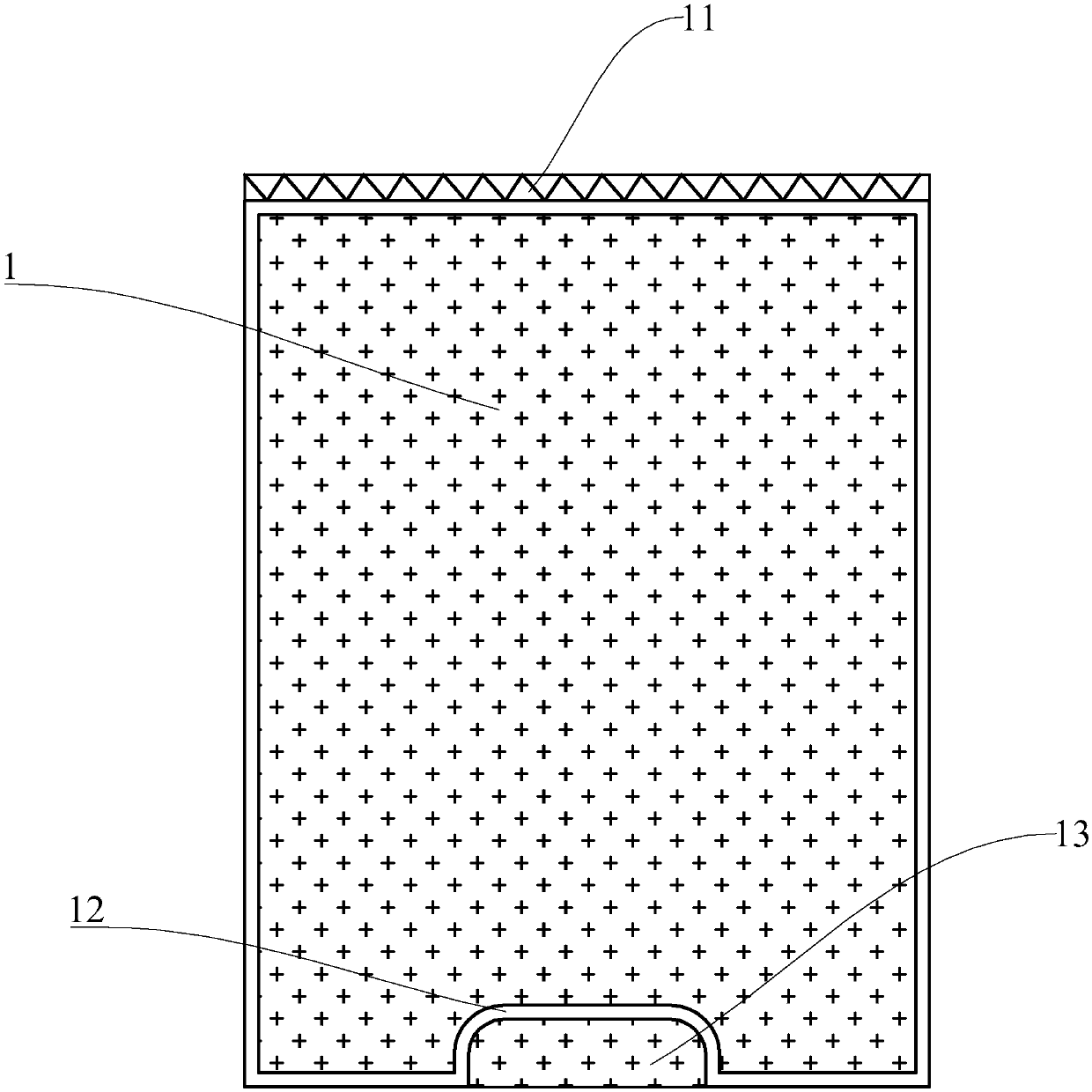

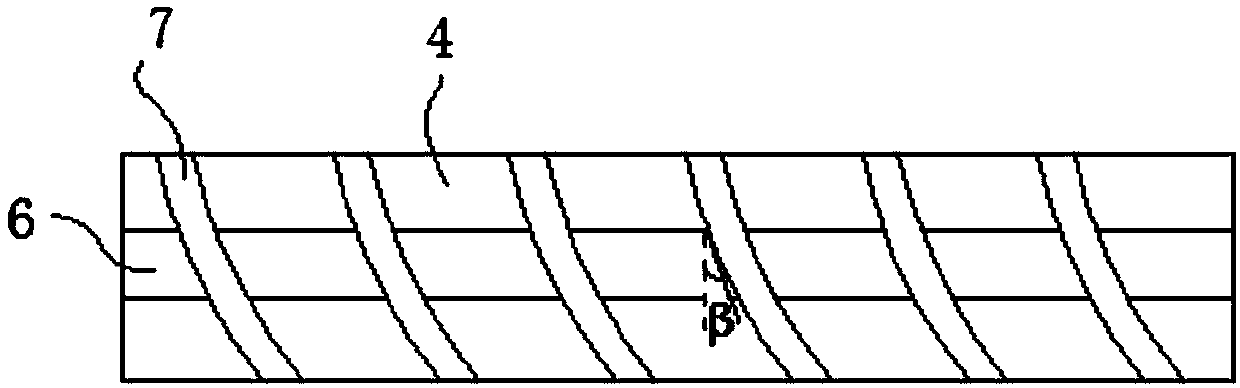

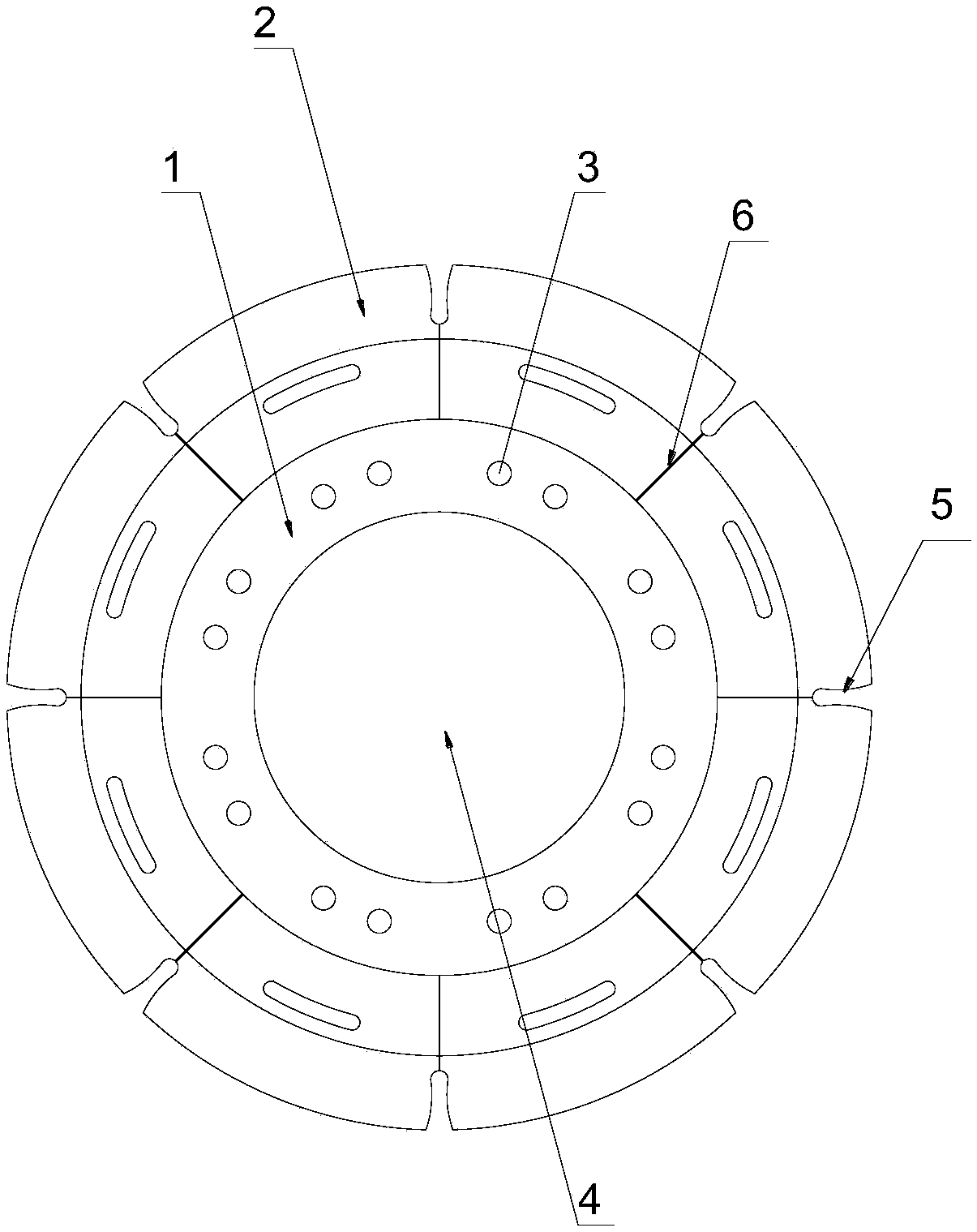

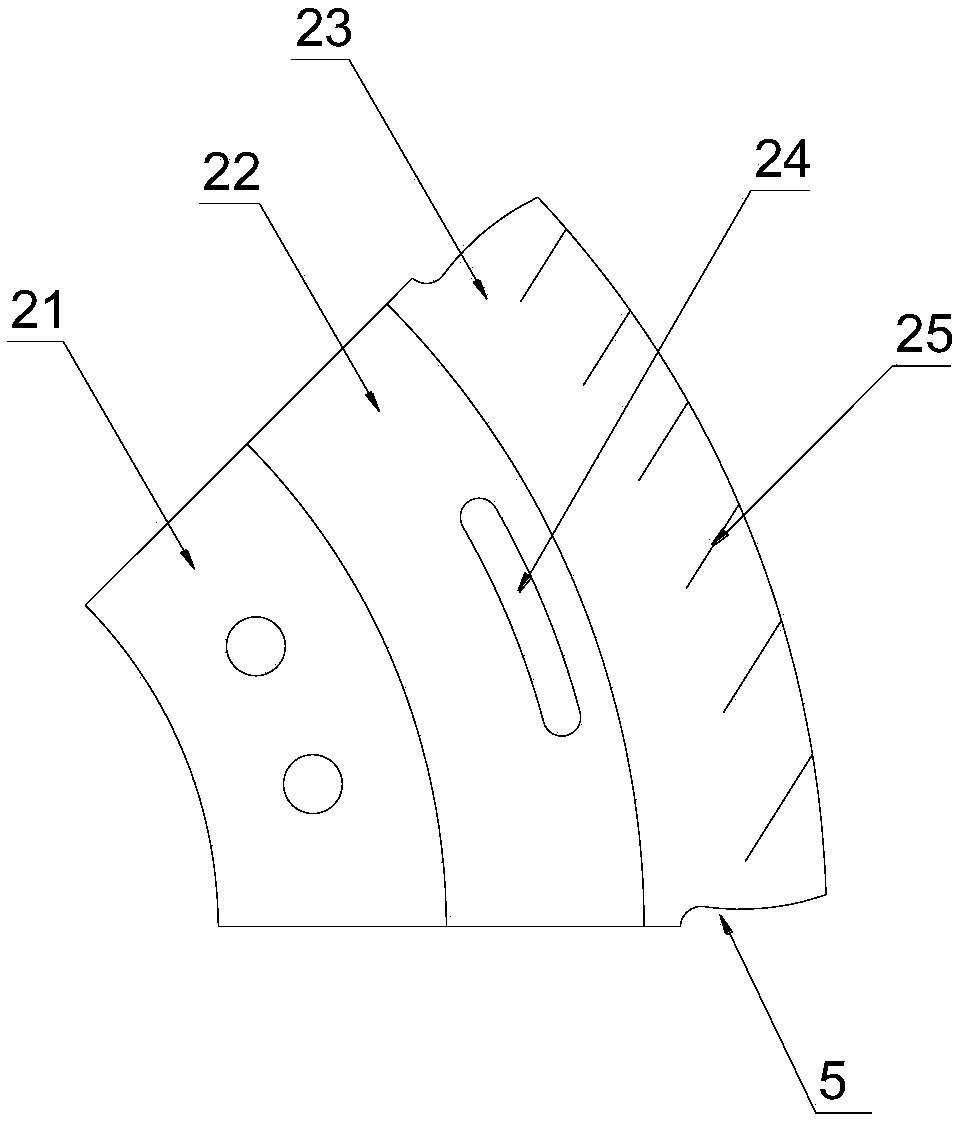

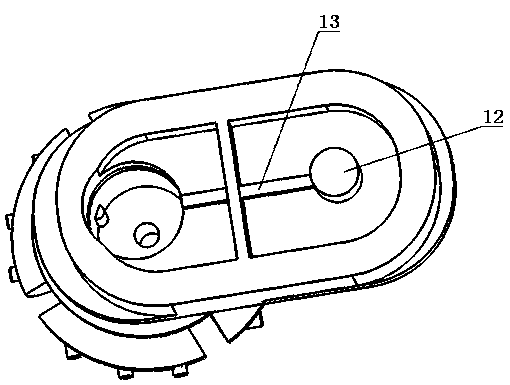

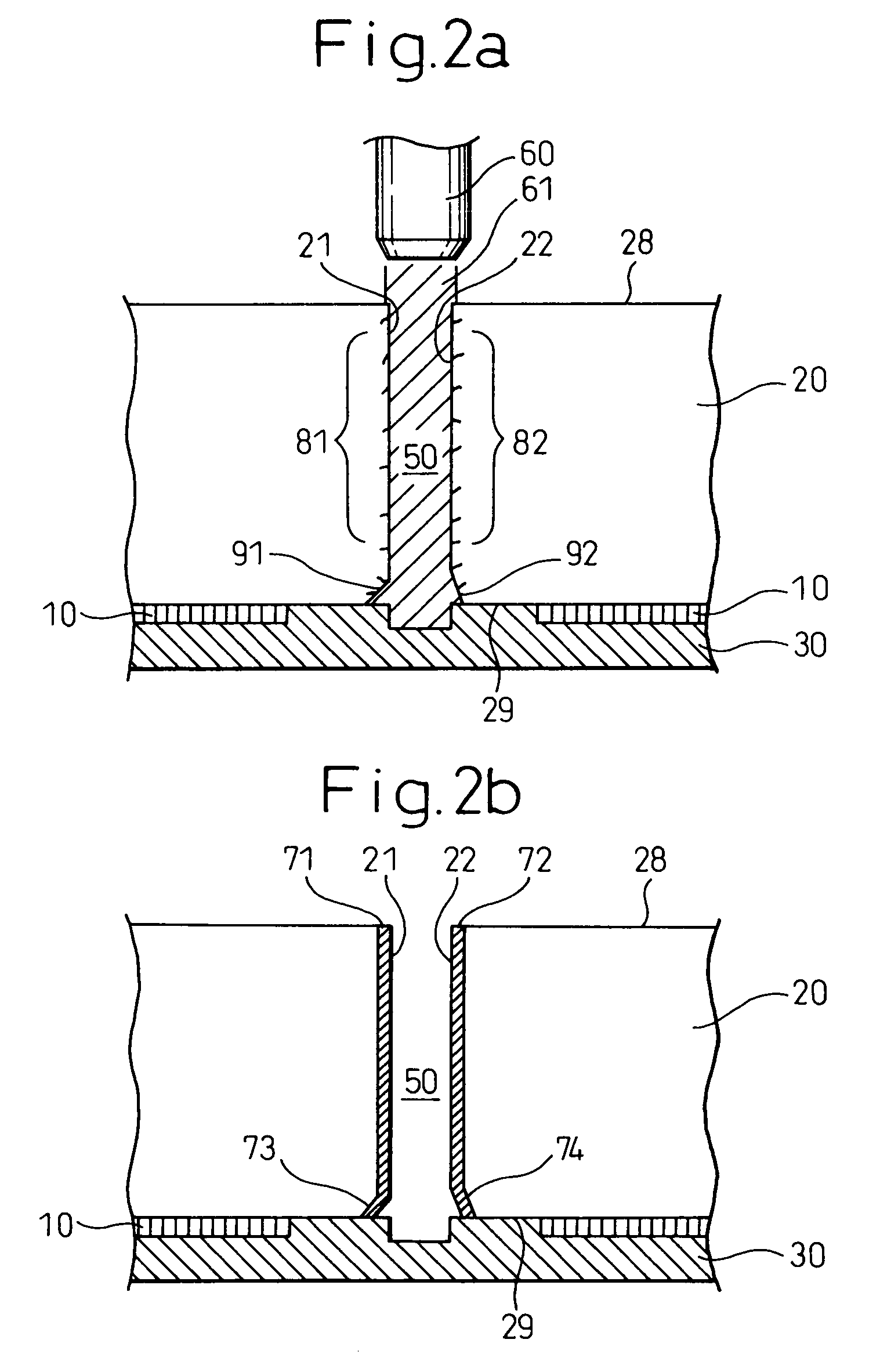

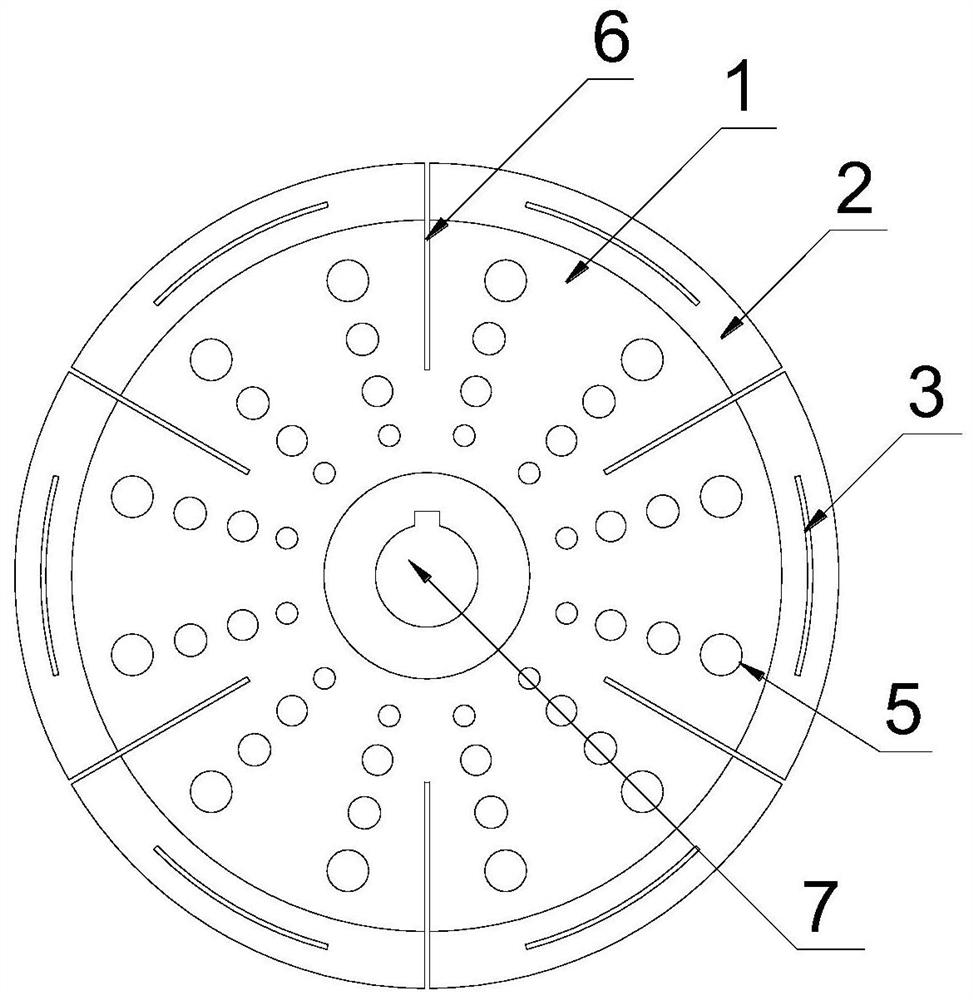

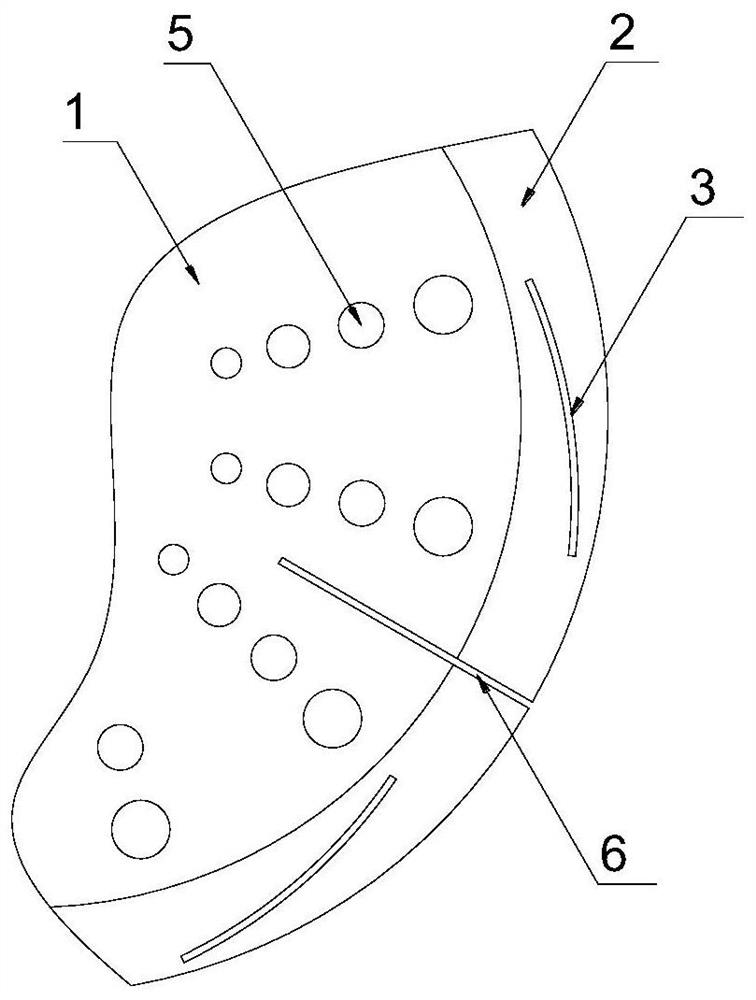

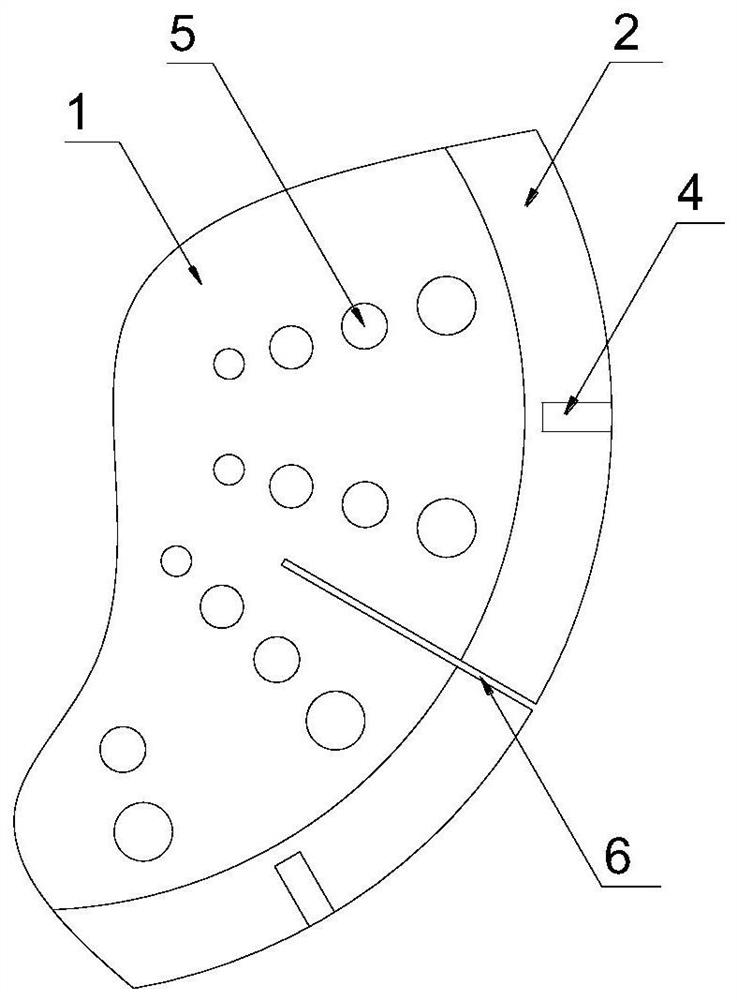

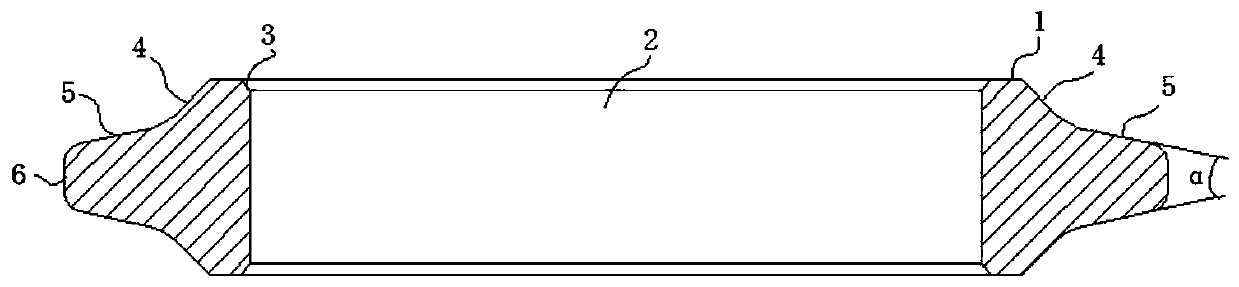

Dismountable diamond saw blade assembly

InactiveCN108544667AAvoid shakingAvoid breakingMetal sawing toolsWorking accessoriesEngineeringMechanical engineering

The invention discloses a dismountable diamond saw blade assembly. The dismountable diamond saw blade assembly comprises a first fixing part, a second fixing part, a mounting part, a plurality of sawblades and a bolt assembly, wherein the saw blades are sectorial, and each saw blade comprises a mounting part, a connecting part and a cutter body; the first fixing part, the second fixing part and the mounting part are circular and are concentrically arranged; the mounting part is fixedly arranged between the first fixing part and the second fixing part; the diameter of the mounting part is lessthan the diameter of the first fixing part and the diameter of the second fixing part; a mounting space is formed between the first fixing part and the second fixing part; the mounting parts of the saw blades are inserted into the mounting space in a fitting manner; the plurality of saw blades are annularly arranged along the outer circumference of the mounting part, and connecting parts of the saw blades are positioned between the mounting parts and the cutter bodies; discharging gaps are formed in two ends of the cutter bodies; a plurality of saw kerfs are formed in the cutter bodies; and aheat dissipating space is formed between every two adjacent saw blades. According to the dismountable diamond saw blade assembly, the saw blades are conveniently dismounted and replaced, and the damage caused by expanding in heat can be avoided; the device cutting quality is high; and the working efficiency is high.

Owner:WUHU CHANGLING DIAMOND TOOL CO LTD

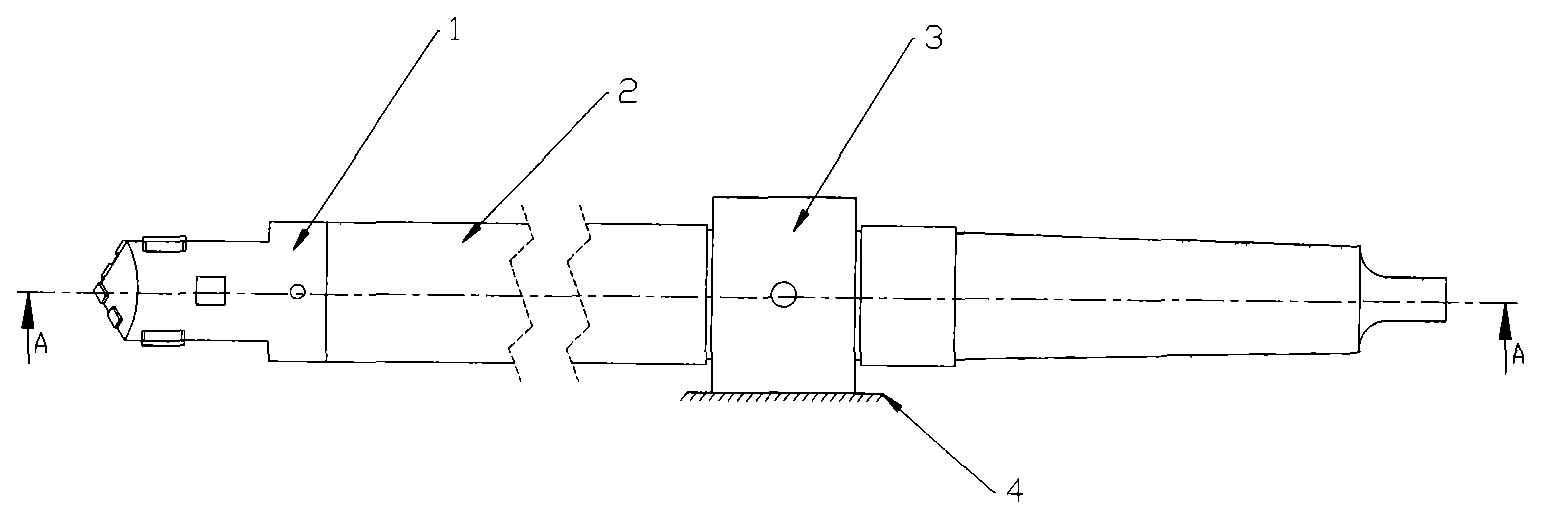

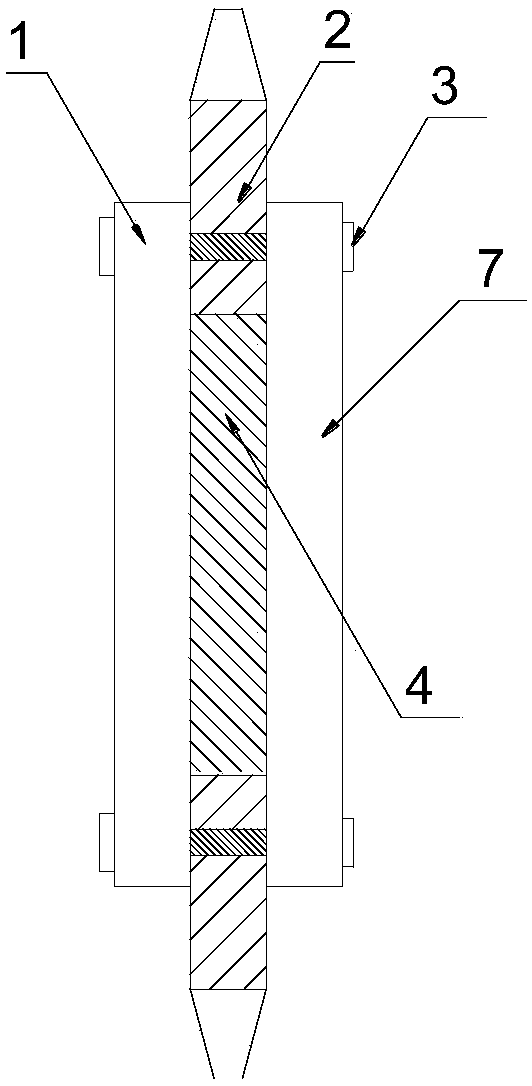

Laser drilling and mechanical grinding matching device and drilling method

InactiveCN108612475AReduce wearIncrease drilling speedSurveyDrilling rodsLaser transmitterWell drilling

The invention relates to a drilling method for a laser drilling and mechanical grinding matching device, wherein an inner cavity of a double-cavity connecting chamber used for the laser drilling and mechanical grinding matching device is divided into a left chamber and a right chamber, a laser generator is installed in the right chamber, a laser transmitter is connected below the laser generator through a first connecting device, and a signal transmission system is installed in the inner cavity of the double-cavity connecting chamber; the laser generator is connected to the right end of the signal transmission system, and a pressure sensing device is connected to the left end of the signal transmission system; a drill rod and a first rotary disc are sequentially connected to the upper endof the double-cavity connecting chamber, a cable groove is formed in the inner wall of the drill rod, and a cable penetrates through the cable groove and is connected with the laser generator in the right chamber; and the laser transmitter and a second rotary disc are correspondingly connected to the lower end of the double-cavity connecting chamber through the first connecting device and a secondconnecting device, the second rotary disc is sequentially connected with a pressure disc group and the drill bit, and a water hole is formed in the center position of the drill bit. According to thedrilling method for the laser drilling and mechanical grinding matching device, drilling is carried out in a mode of laser cutting and mechanical grinding matching, so that the drilling speed is improved.

Owner:NORTHEAST GASOLINEEUM UNIV

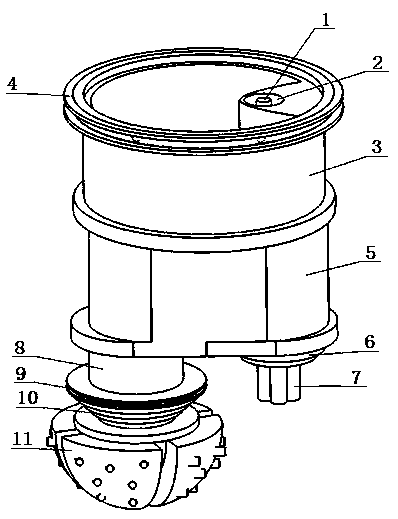

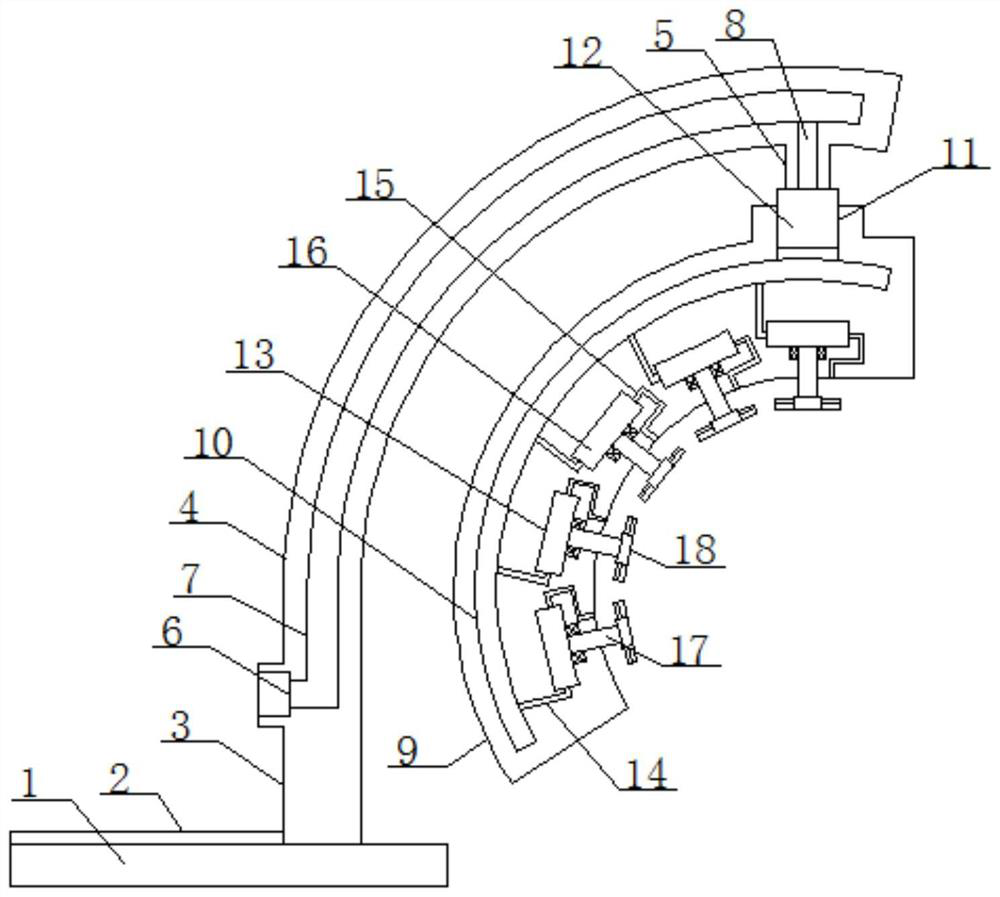

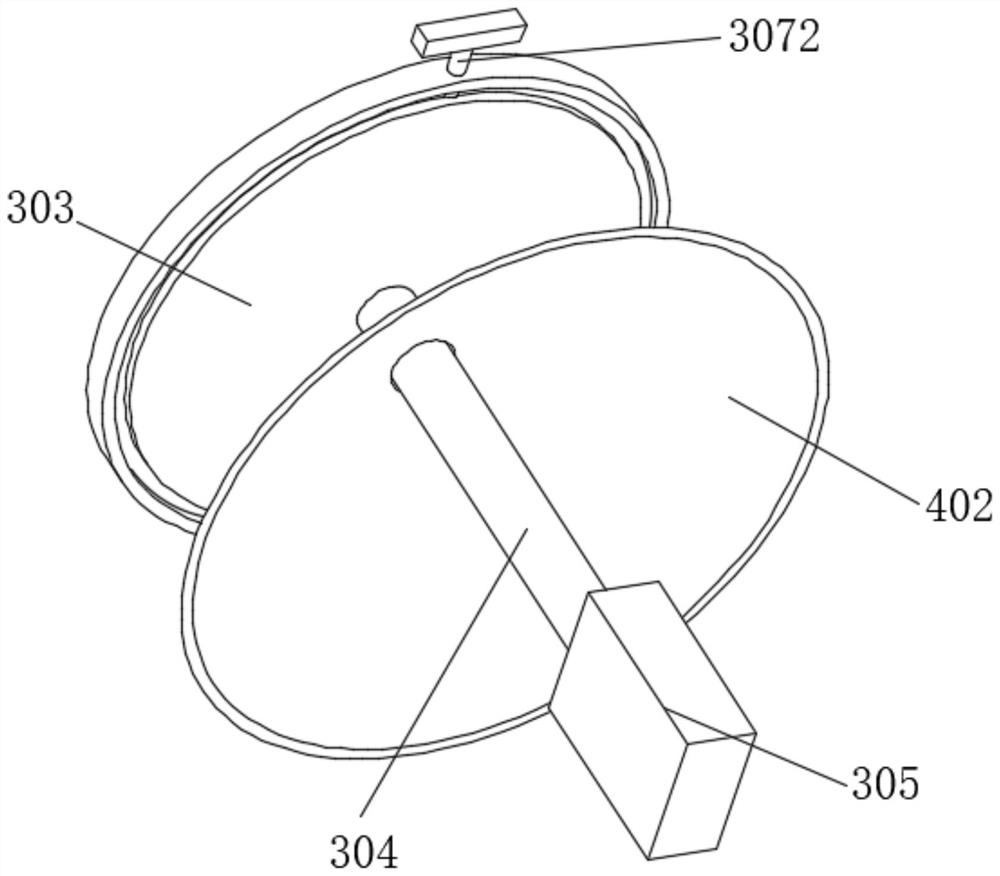

Ball-shaped trimmer for ball-shaped plants

ActiveCN111567257AImprove cutting strengthIncrease profitCuttersCutting implementsHuskAgricultural engineering

The invention discloses a ball-shaped trimmer for ball-shaped plants. The trimmer includes a bottom installation base plate and a sub-semi-annular shell; an installation plate and a main longitudinalsupporting rod are installed on the upper surface of the bottom installation base plate; the top of the main longitudinal supporting rod is provided with a main semi-annular shell in an integrated structure; and the bottom on the top end of the main semi-annular shell is provided with a main longitudinal discharging pipeline in an integrated structure. Through the utilization of the kinetic energygenerated by high pressure air, each rotating blade can be driven to rotate, and surface blowing and cleaning can be performed on trimmed leaves, so that the utilization rate of the kinetic energy can be enhanced; when the blades are rotated by the device, through a turbine technology, the middle part that air flows can drive the main rotation force to blow the leaves; and when the trimming is raised again, the cutting strength of the blades can further increase the utilization rate of air kinetic energy, and the efficiency and effects during trimming can be enhanced.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

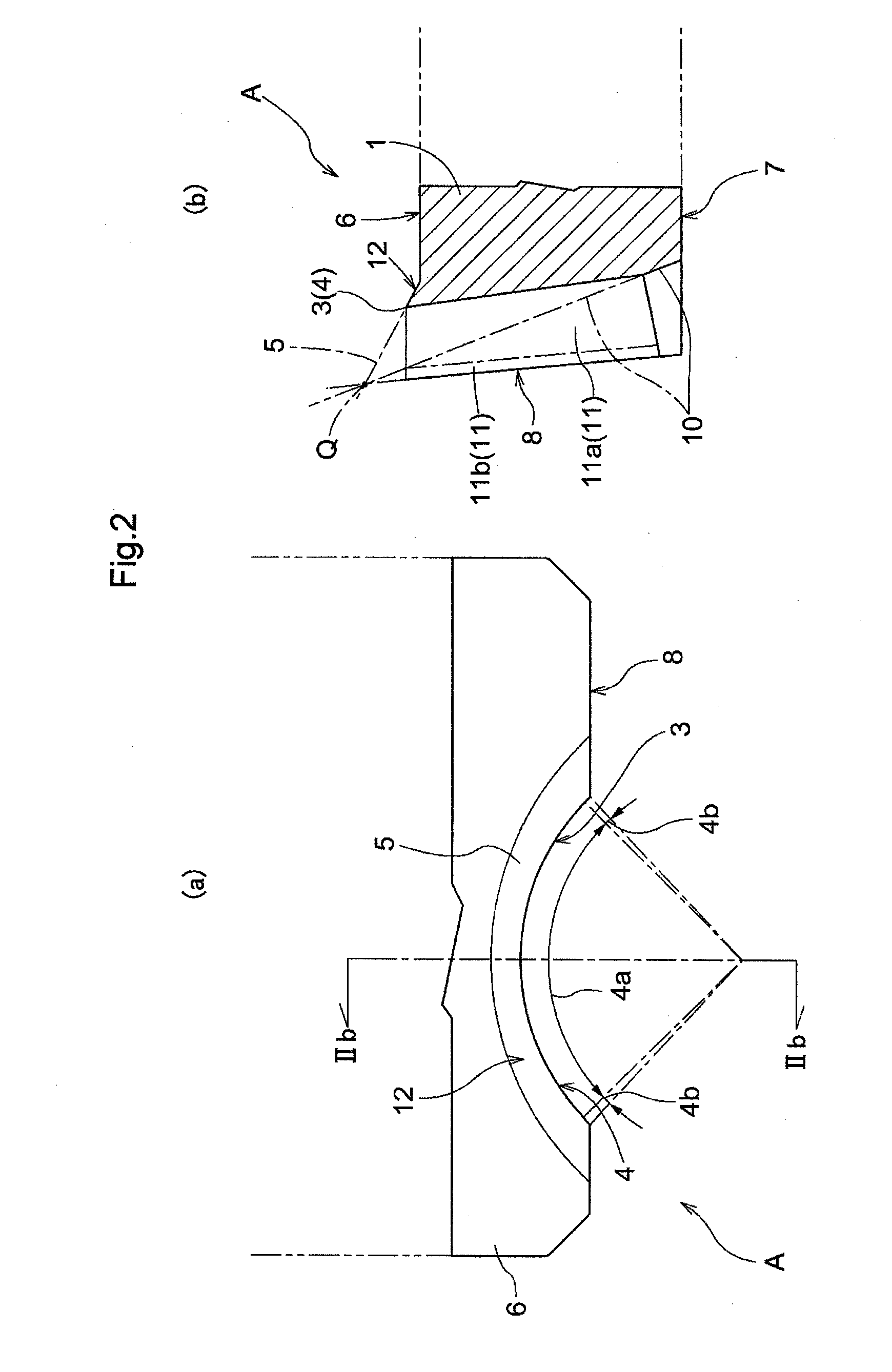

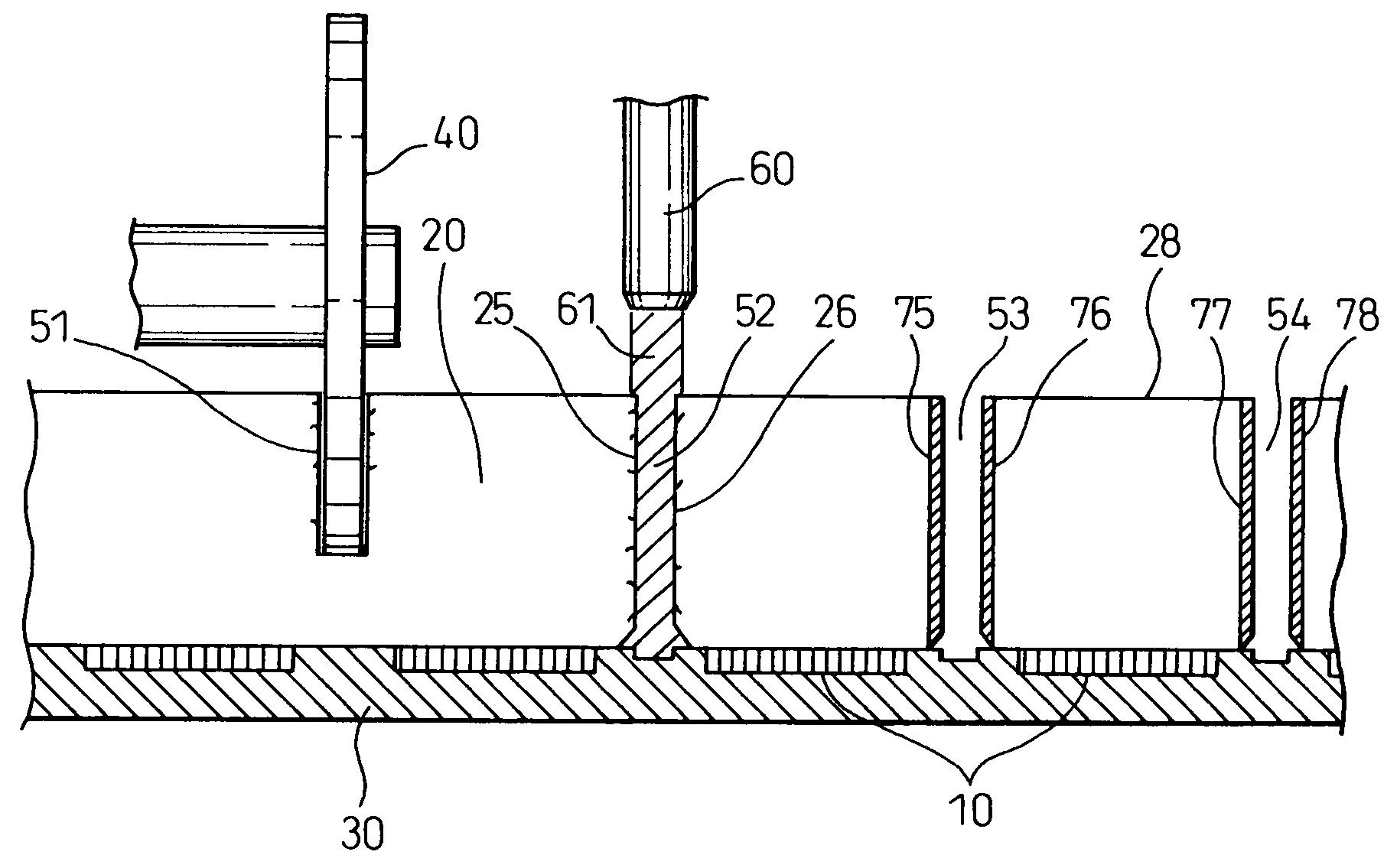

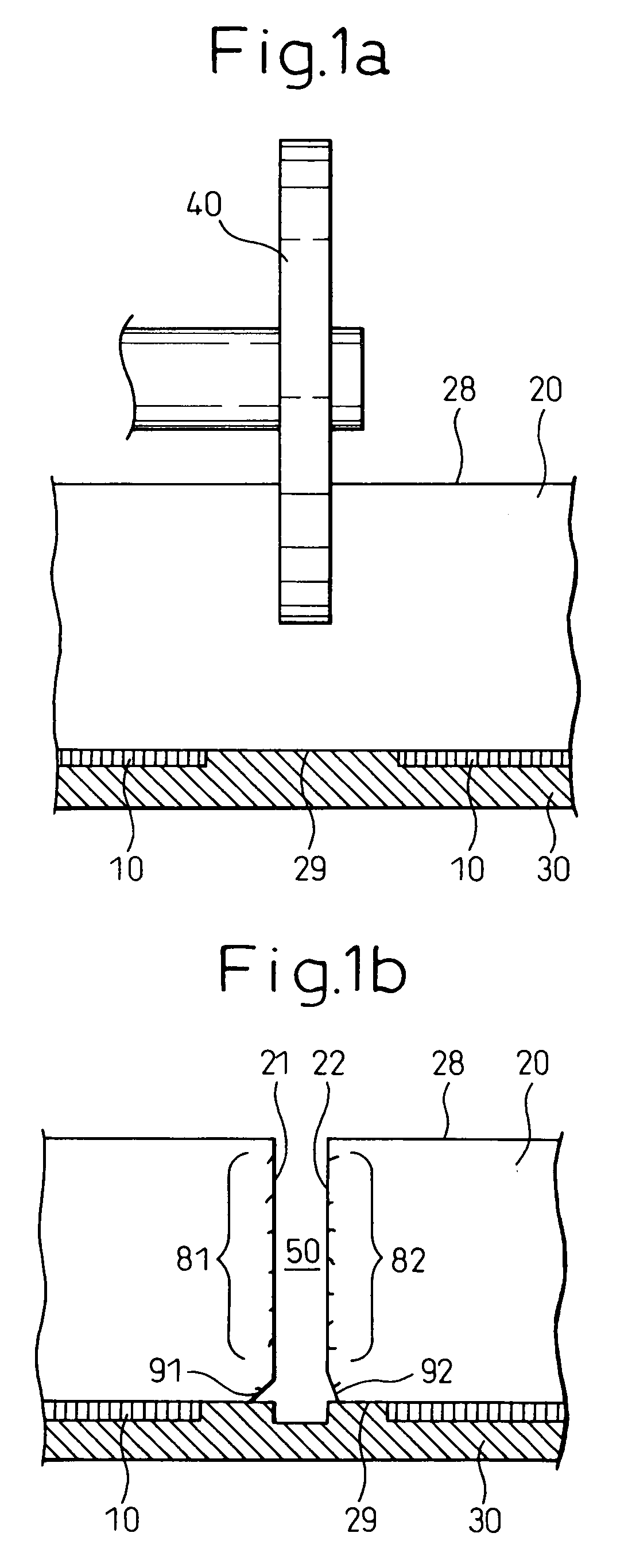

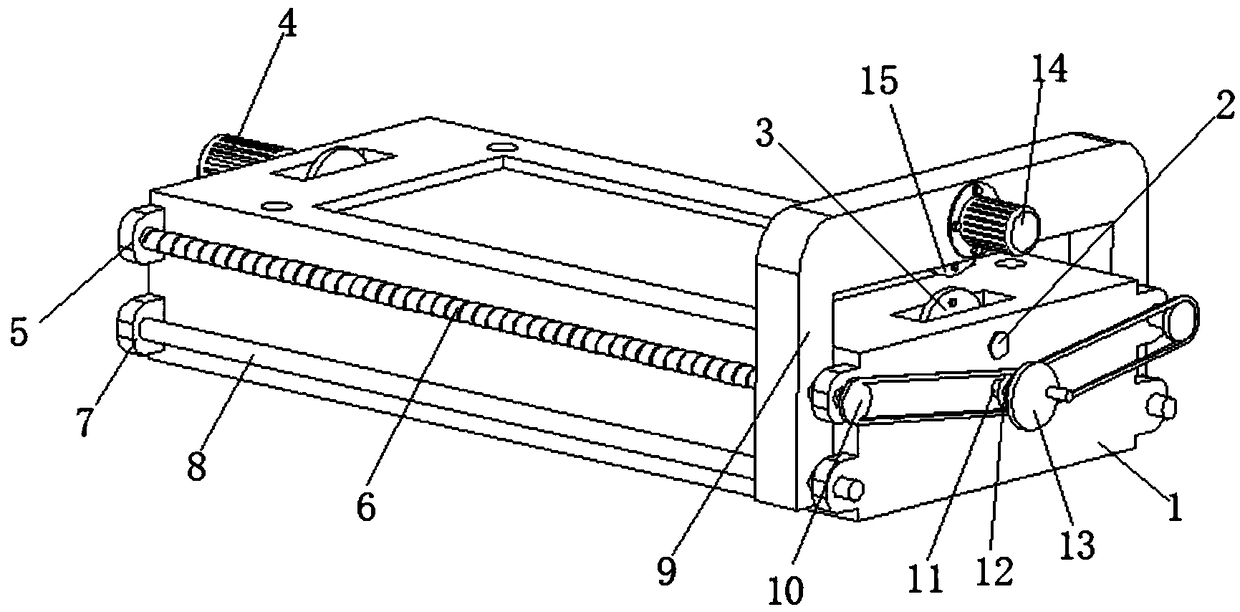

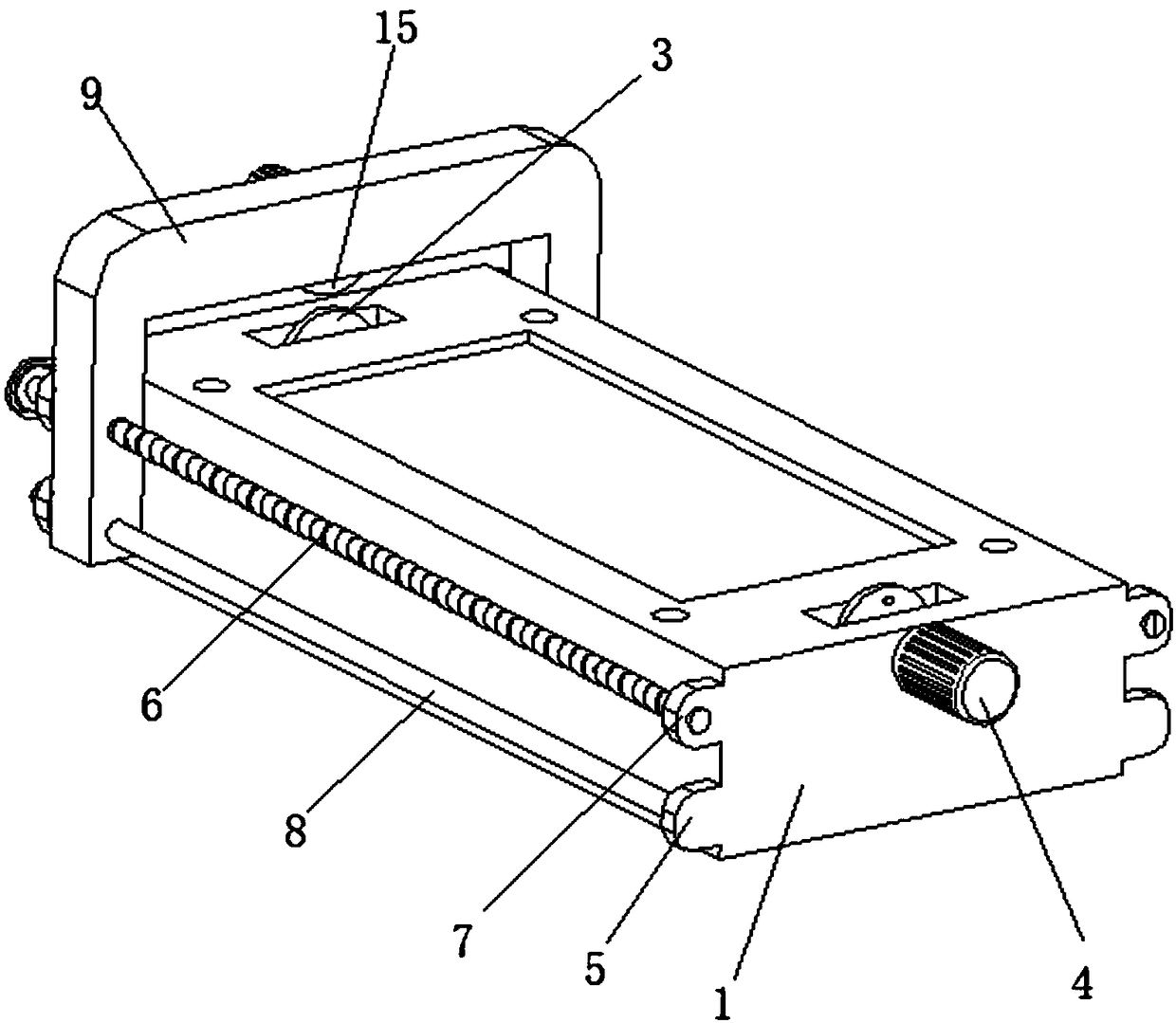

Method and apparatus for machining substrate

InactiveUS7098118B2Improve cutting strengthImprove overall strengthSemiconductor/solid-state device manufacturingFine working devicesLaser lightEngineering

In a substrate machining method for machining a substrate, there are provided a substrate machining method in which a disk-like blade is rotated to cut the substrate from its one surface, and the cut surfaces of the substrate, which are positioned in the vicinity of the other surface of the substrate, are irradiated with laser light; and a substrate machining apparatus which carries out the substrate machining method. The entirety of the cut surfaces of the substrate may be irradiated with the laser light. The laser may be a YAG laser or a CO2 laser. Further, a dicing tape may be adhered to the other surface of the substrate, and the laser light may be irradiated after cutting only the substrate and expanding the dicing tape. Modified layers are formed by an irradiation of the laser light, so that dice are prevented from being broken in an assembling operation of the dice.

Owner:TOKYO SEIMITSU

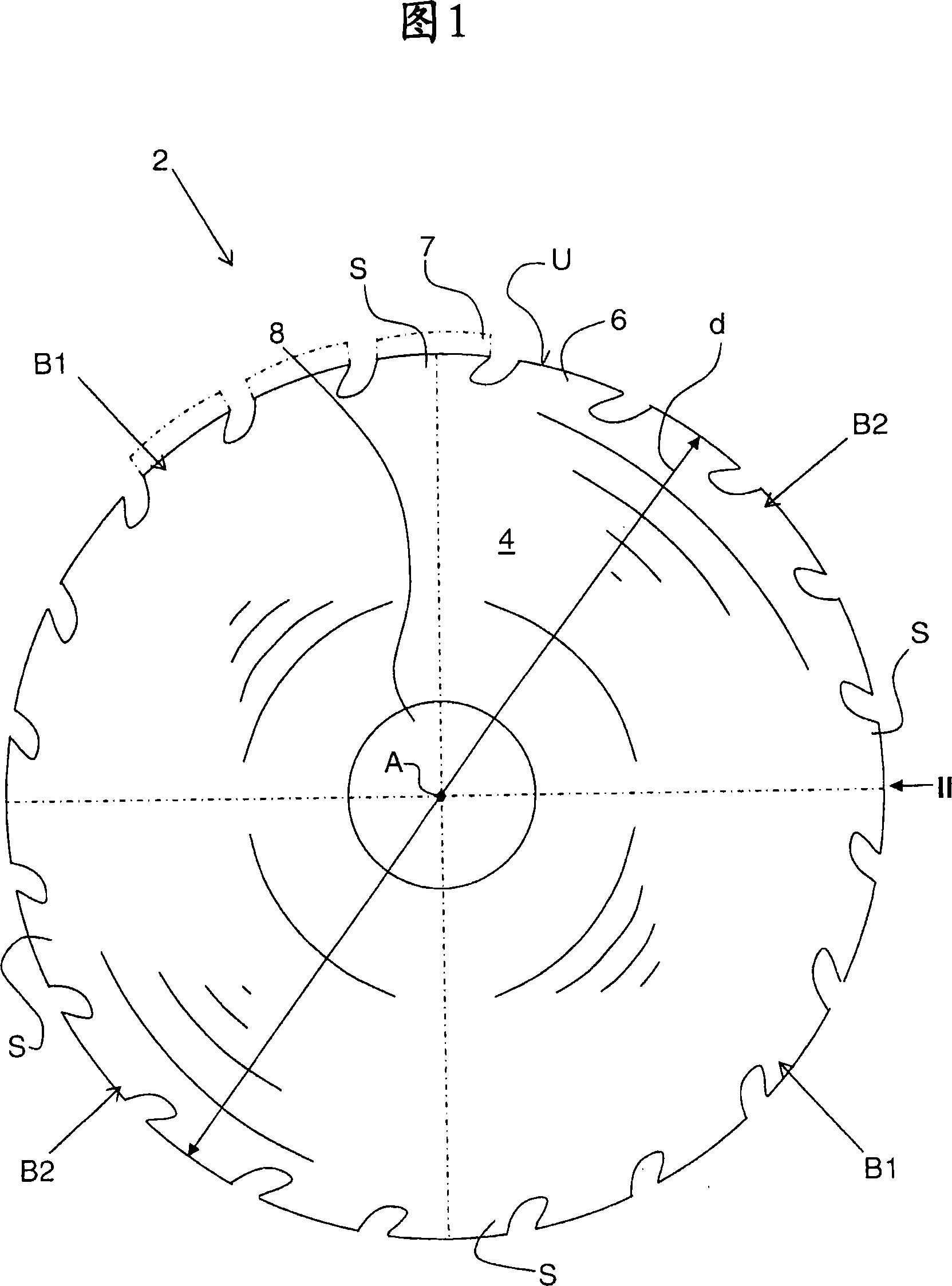

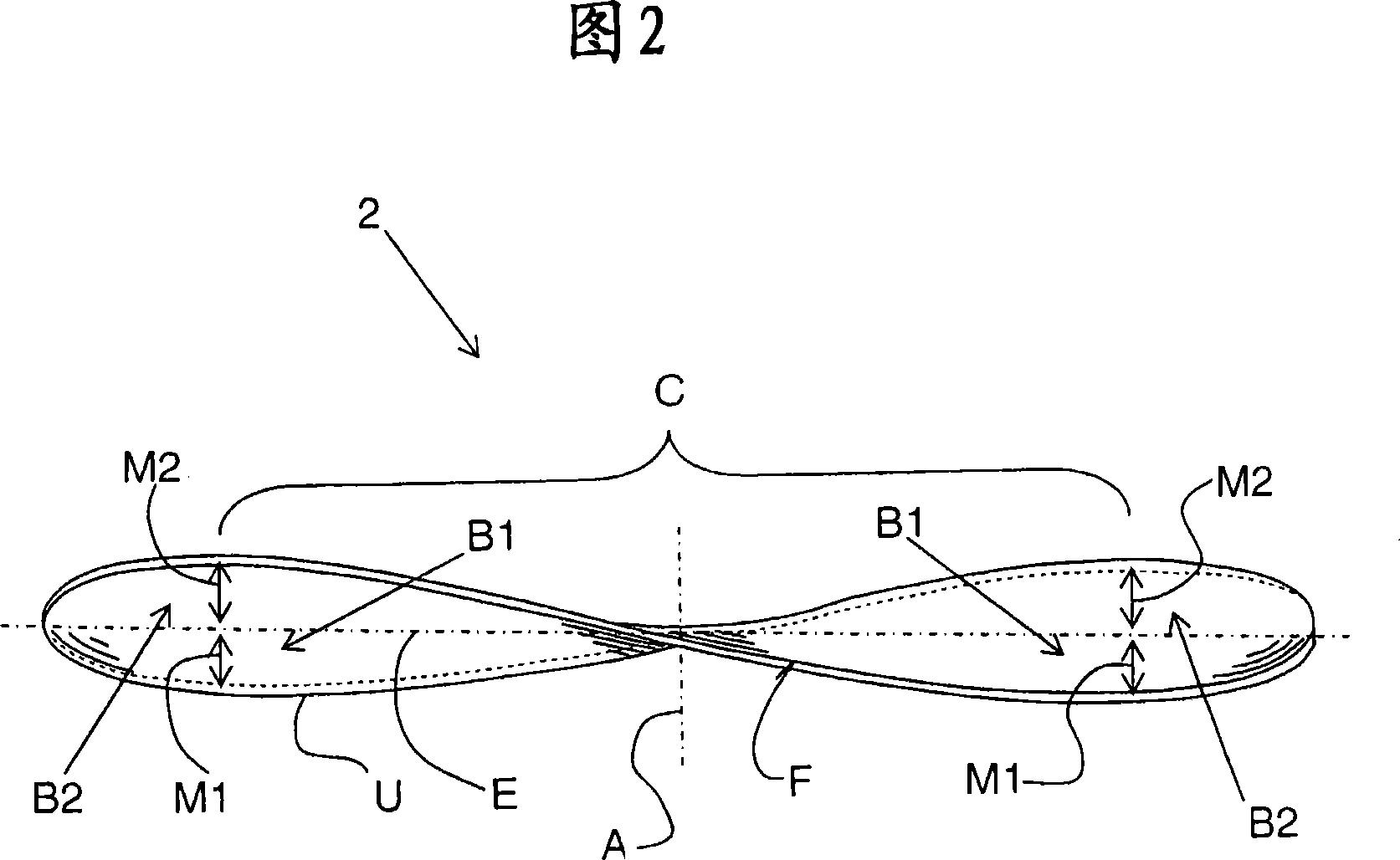

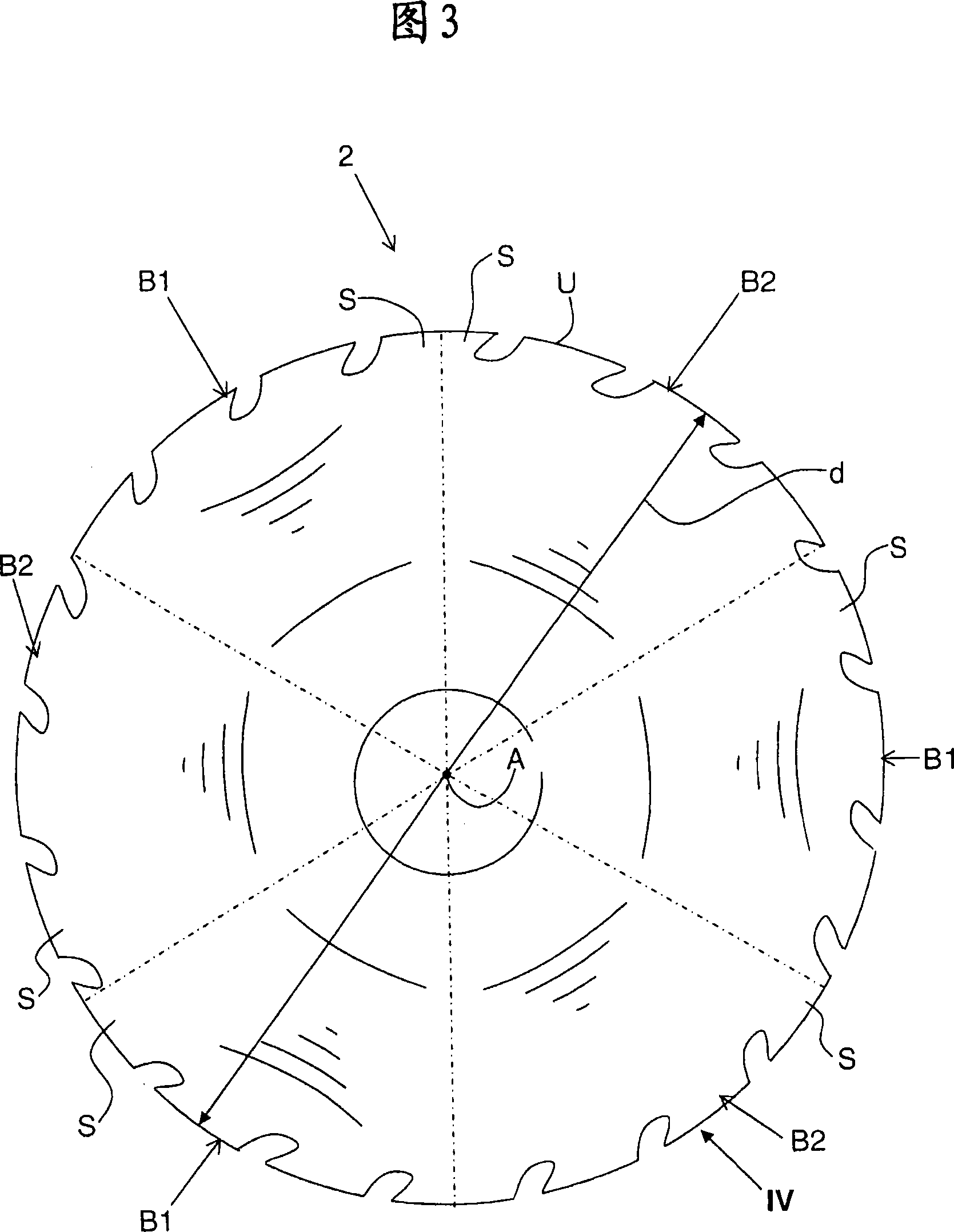

Saw blade with lateral buckles

InactiveCN101096116AGuaranteed sturdinessGreat lateral stabilityMetal sawing toolsStone-like material working toolsCircular sawMiddle plane

Owner:HILTI AG

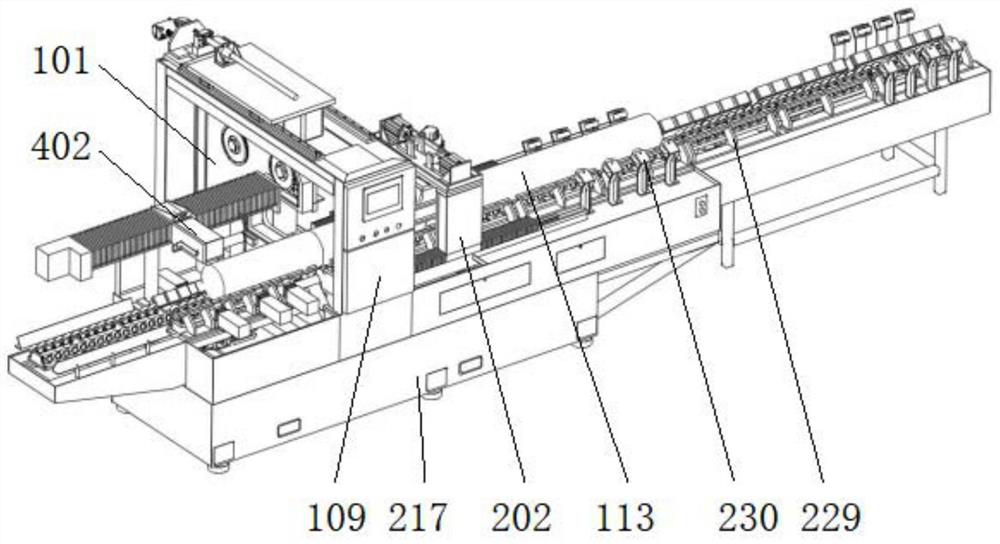

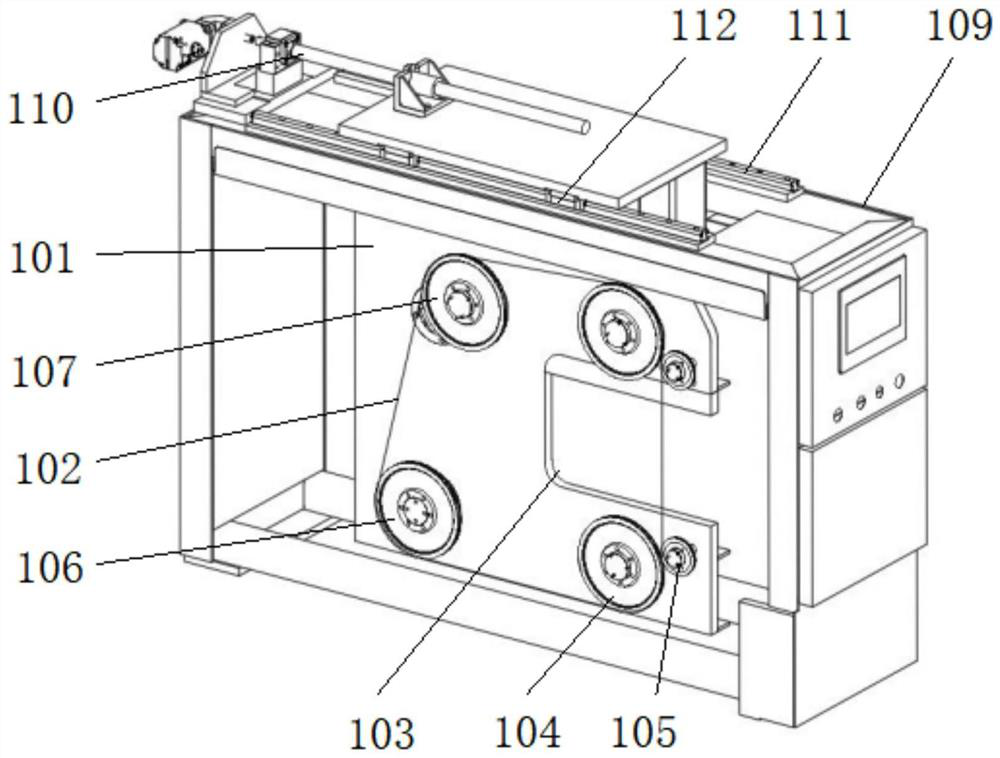

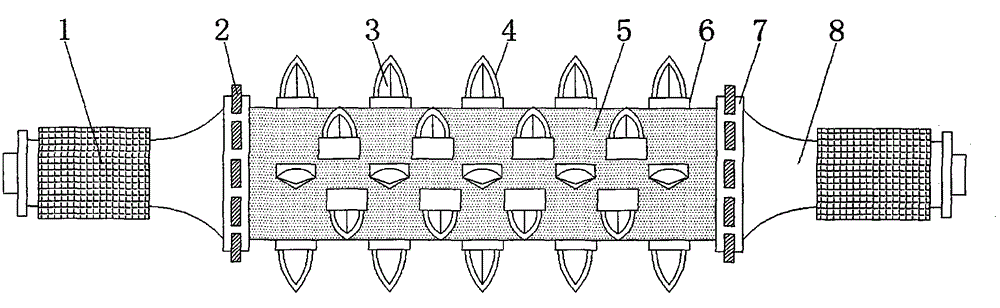

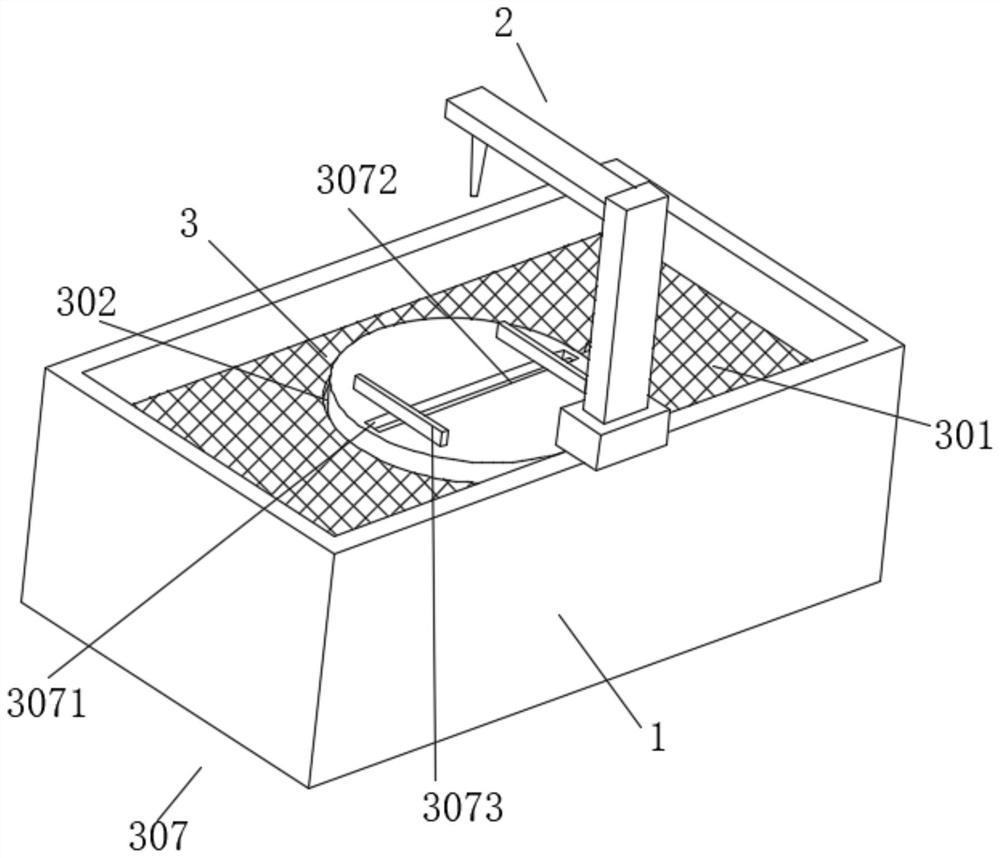

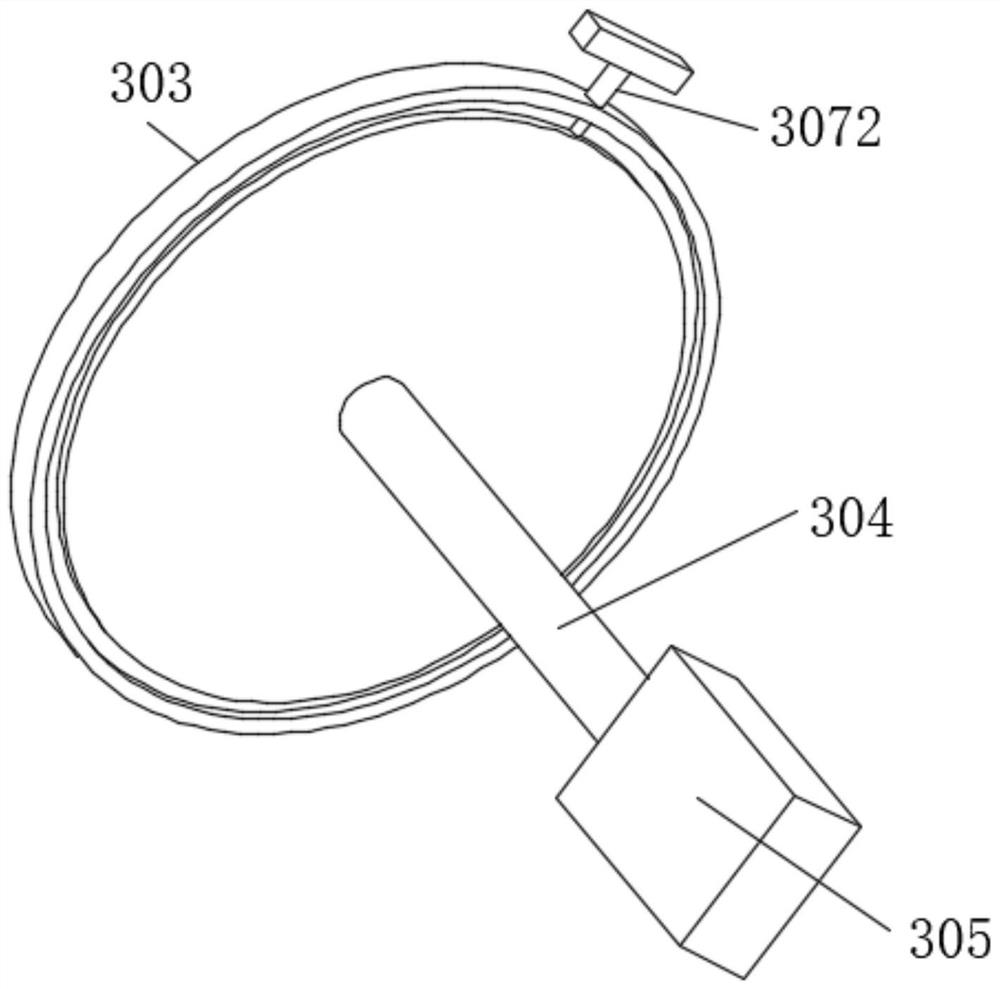

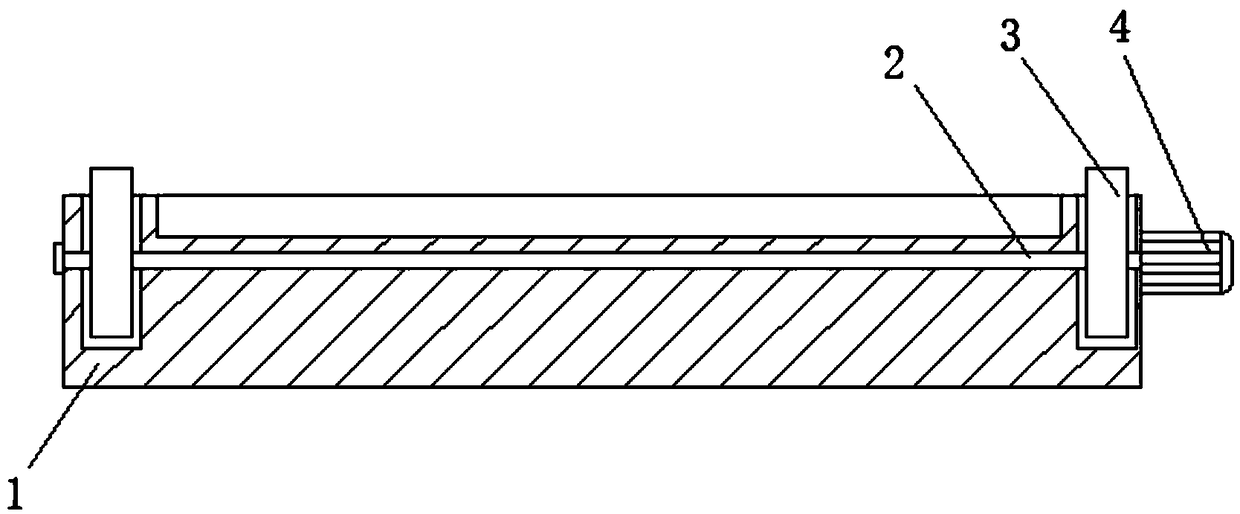

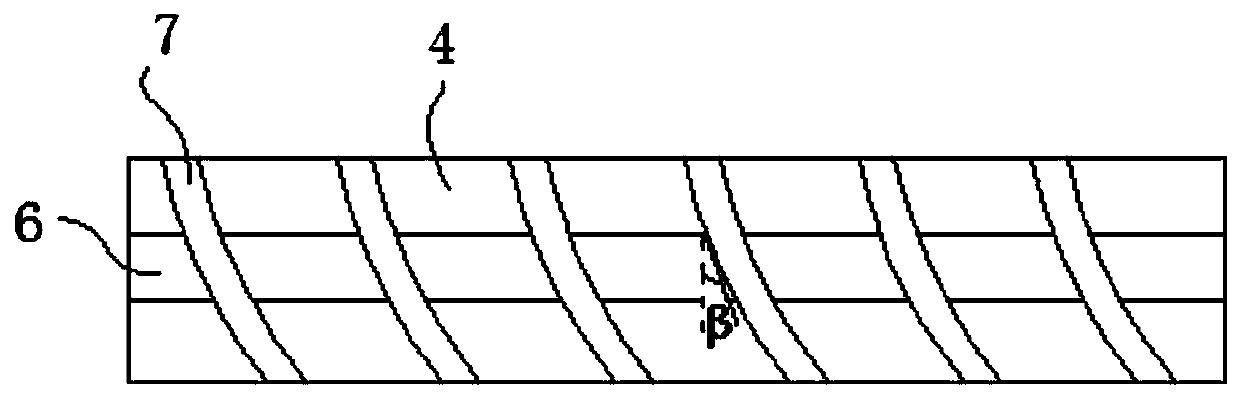

Reciprocating cutting machine through diamond wire

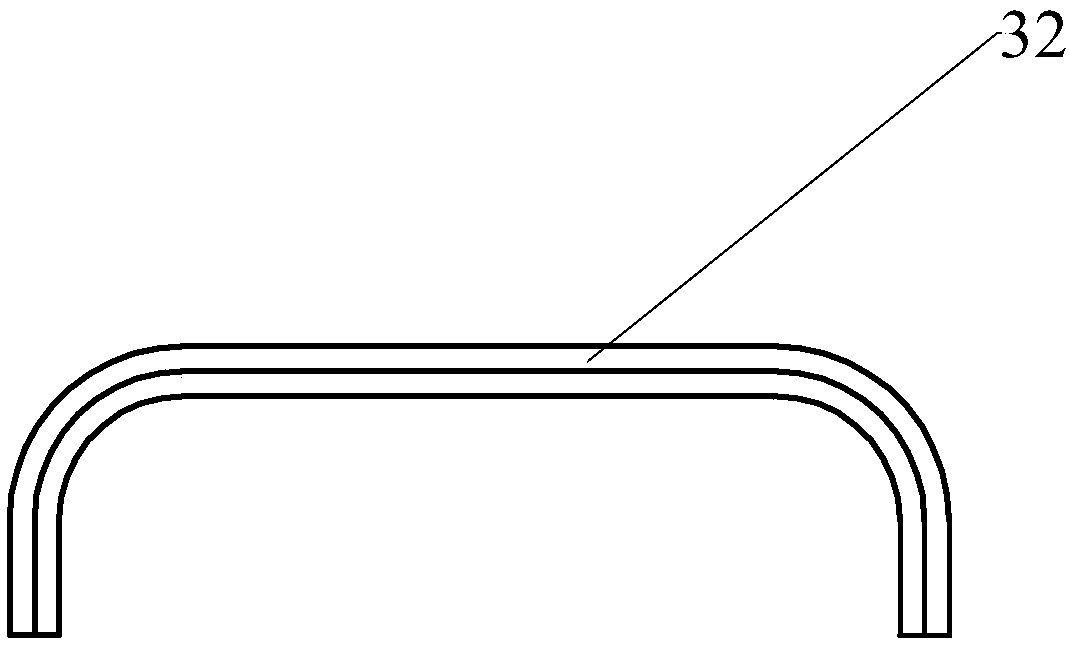

PendingCN112078042AStable cutting lengthImprove cutting strengthWorking accessoriesFine working devicesEngineeringSupport point

The invention discloses a reciprocating cutting machine through a diamond wire. The reciprocating cutting machine comprises a base frame, the diamond wire which is arranged on the base frame and usedfor cutting a silicon rod and a limiting assembly which is used for achieving reciprocating cutting of the diamond wire, and the diamond wire is wound in the limiting assembly to form a reciprocatingcutting position. According to the reciprocating cutting machine through the diamond wire, the limiting assembly is arranged to limit the diamond wire to always have a short stress supporting point atthe reciprocating cutting position, so that the cutting length of the diamond wire at the reciprocating cutting position is kept stable as much as possible, the size of a wire bow in the cutting process is controlled, the cutting strength of the diamond wire at the reciprocating cutting position is improved, reduction of the cutting efficiency due to overlarge wire bow caused by reversing cuttingis avoided, reciprocating cutting is carried out on the silicon rod at the reciprocating cutting position, the tool retracting process in multi-section cutting of the silicon rod is omitted, the cutting speed is increased, and the production efficiency is improved.

Owner:QINGDAO GAOCE TECH CO LTD

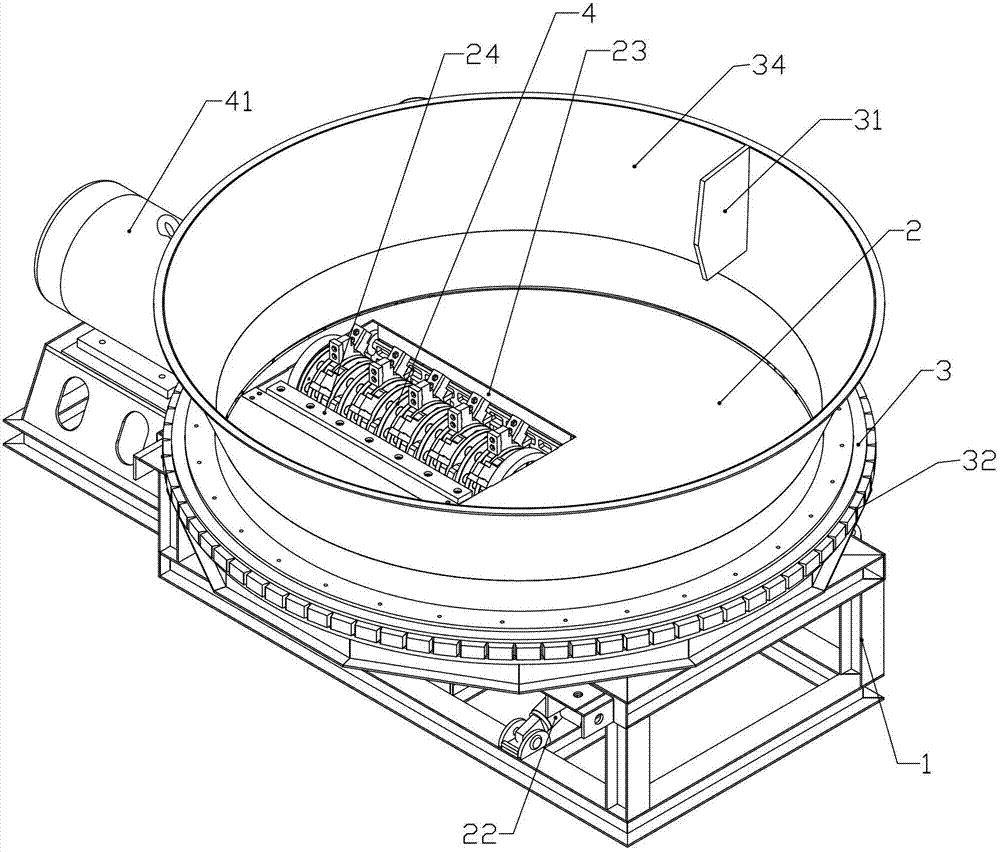

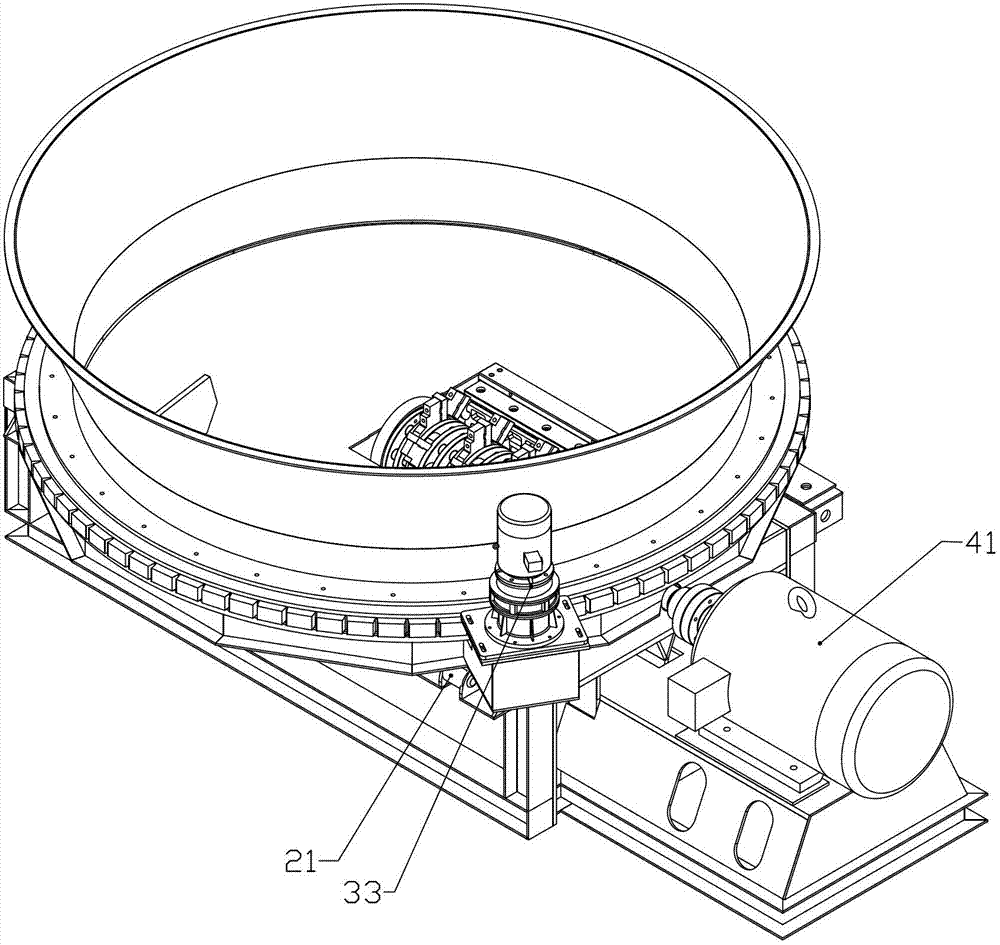

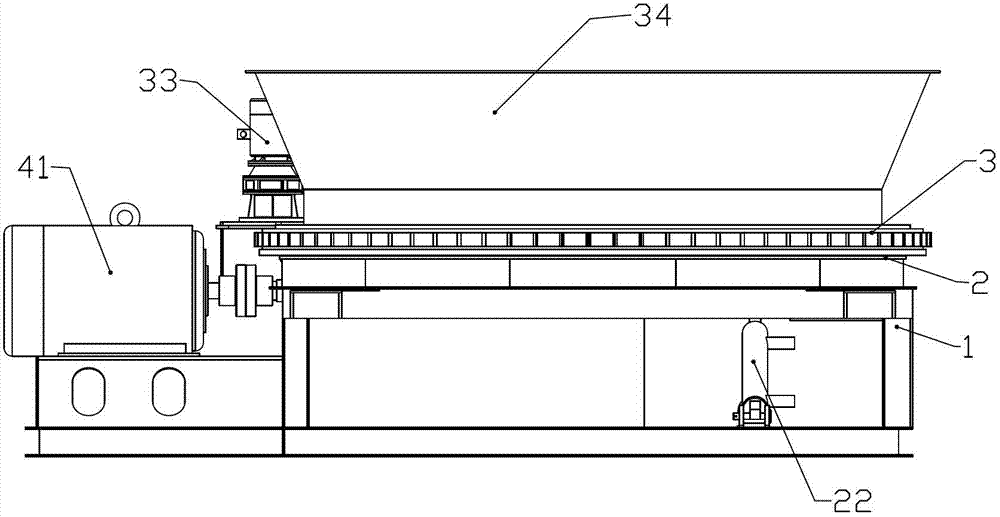

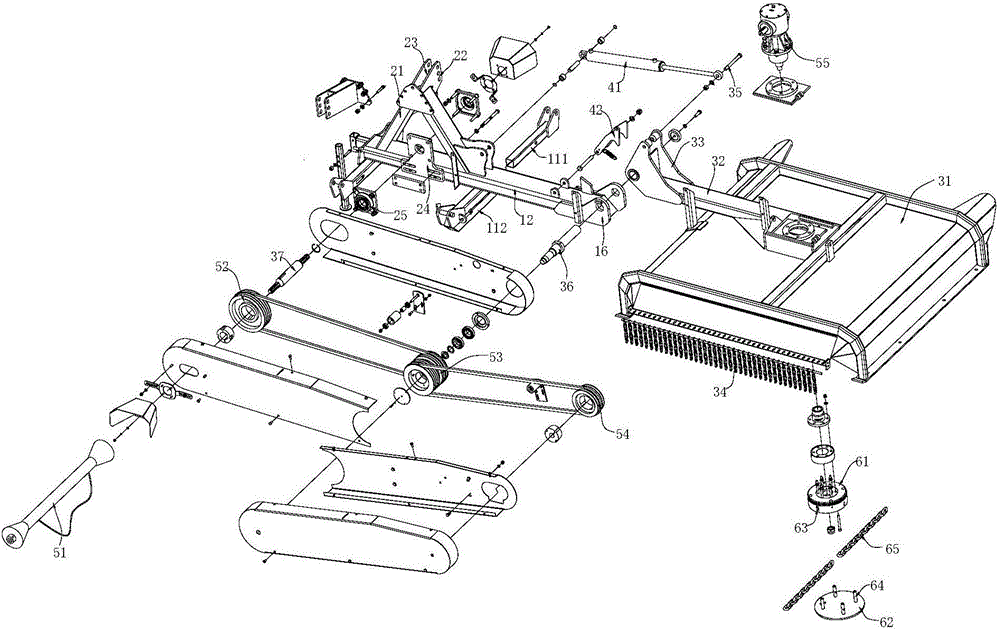

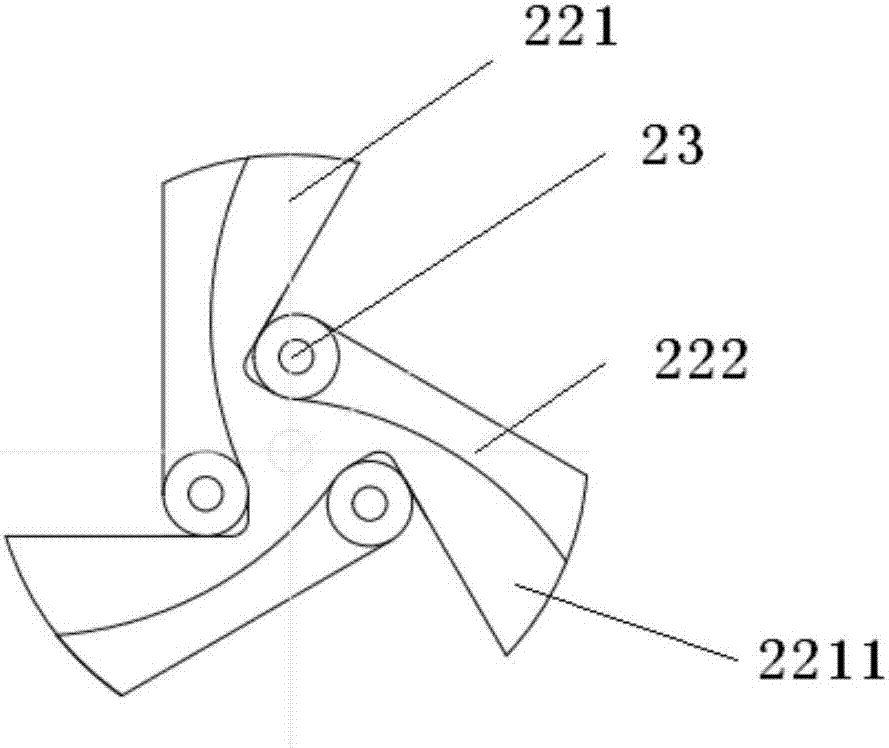

Rotary cutter for straw bales

A rotary cutter for straw bales relates to a smashing device and comprises a machine frame and a cutting-up roller, a flat plate is arranged on the upper side of the machine frame, a rotatable turnplate is movably installed on the flat plate of the machine frame, a conical-barrel-shaped bin is fixed on the turnplate, a driving mechanism is arranged between the turnplate and the flat plate, the cutting-up roller is arranged on the lower side of the flat plate of the machine frame, the position of the flat plate corresponding to the cutting-up roller is provided with a feeding port, a fixed knife with a knife edge is arranged on one side of the feeding port, an arc-shaped screen mesh is arranged below the cutting-up roller, and a blanking port is arranged below the screen mesh. When the rotary cutter is in use, a smashed object is bales of straw in a compaction state, slicing and smashing are integrated, branches and stems with diameters of 1-20 cm can also be chipped, the rotary cutter can also be used for chipping of fiber straw-shaped materials such as bamboos, thatch, cornstalk and sorghum stalk, and the cutting efficiency is high.

Owner:山东宇龙机械有限公司

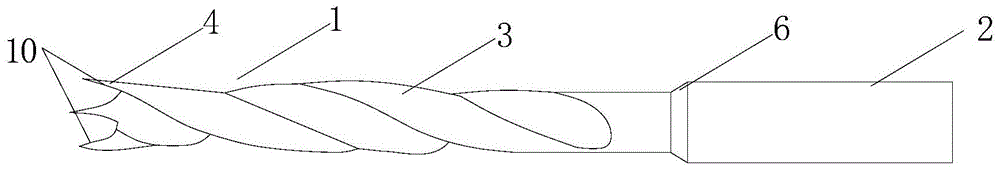

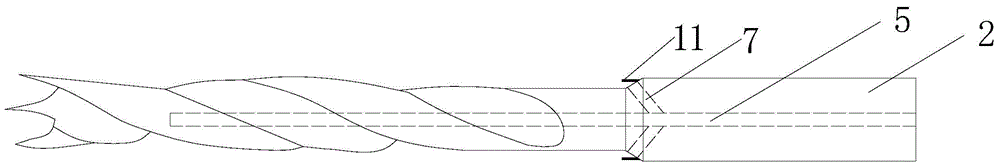

Three-sharp wood drill

InactiveCN104354197AHigh strengthExtended service lifeWood turning toolsWood boring toolsDrill bit shankEngineering

The invention relates to the technical field of cutting tools, in particular to a three-sharp wood drill. The three-sharp wood drill comprises a drill shank, a drill bit, and a drill neck for connecting the drill shank with the drill bit, wherein the drill neck is cone-shaped, and the drill neck and the drill shank are integrally formed; two spiral cutting edges are arranged on the circumference surface of the drill shank, and edge points are respectively arranged at the edges and the bottoms of the cutting edges; outwards projecting tool noses are respectively arranged at the joints of the edge points at the edges and the bottoms of the cutting edges, and the inner tool faces of the two tool noses respectively extend towards two opposite directions. The three-sharp wood drill is stable in centering, a tool and a handle are hardly broken, and the production cost is low.

Owner:常州华尔澜工具有限公司

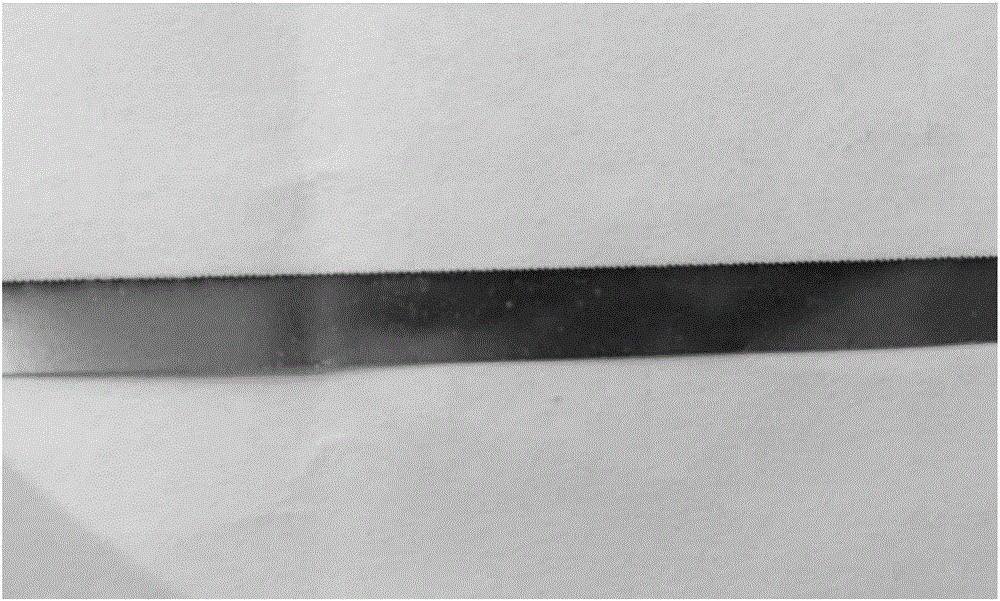

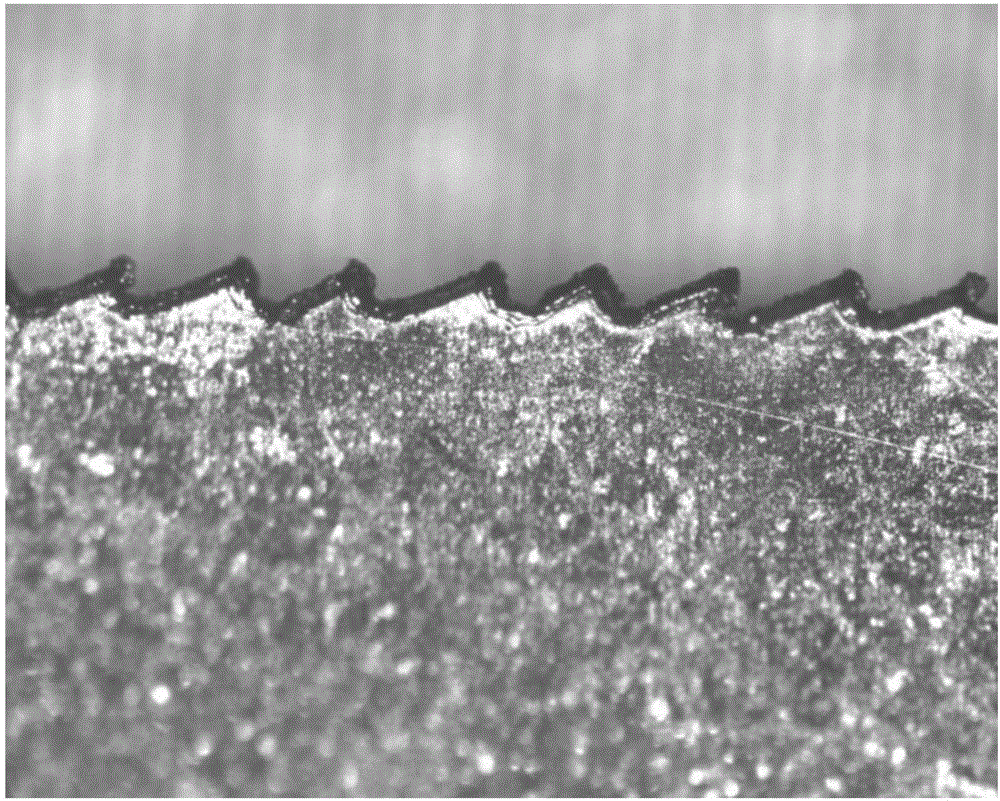

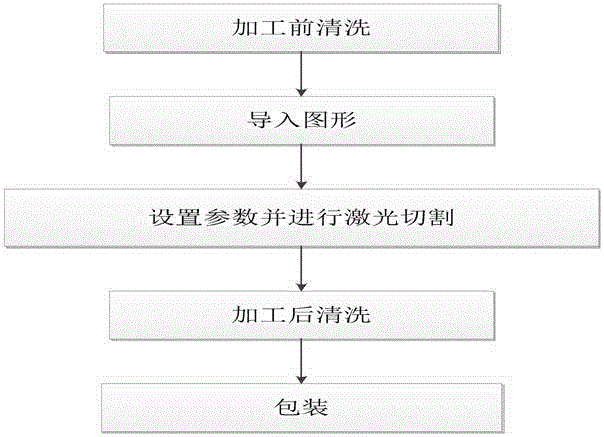

Cutting saw for proximal surface sheet of fixed partial denture and processing method of cutting saw

The invention discloses a cutting saw for a proximal surface sheet of fixed partial denture and a processing method of the cutting saw. The cutting saw is of a toothed structure; the width of teeth is 10mu m, the apex angle of the teeth is 30 to 60 degrees, the total length of the saw is 50 to 150mm, the width of the saw is 2 to 10mm, and thickness of the saw is 30 to 100mu m; during processing, a cleaned stainless steel sheet is putted on a laser cutting machine by adopting a laser cutting method, and parameters of the laser cutting machine are adjusted for micro processing; during use, the current of a laser power supply is 10 to 20A, and the scribing speed is 1 to 3mm / s; finally, edges are deburred and cleaned again. The cutting saw disclosed by the invention can be used for quickly removing a residual bonding agent of the proximal surface of the teeth and polishing the surface; compared with other cutting saws for the proximal surface, the process disclosed by the invention has the advantages of high microprocessing precision, excellent processing speed, higher rate of finished product and good removing effect on the proximal surface; the product can be repeatedly used, the working efficiency can be improved, and the use cost is reduced.

Owner:XI AN JIAOTONG UNIV

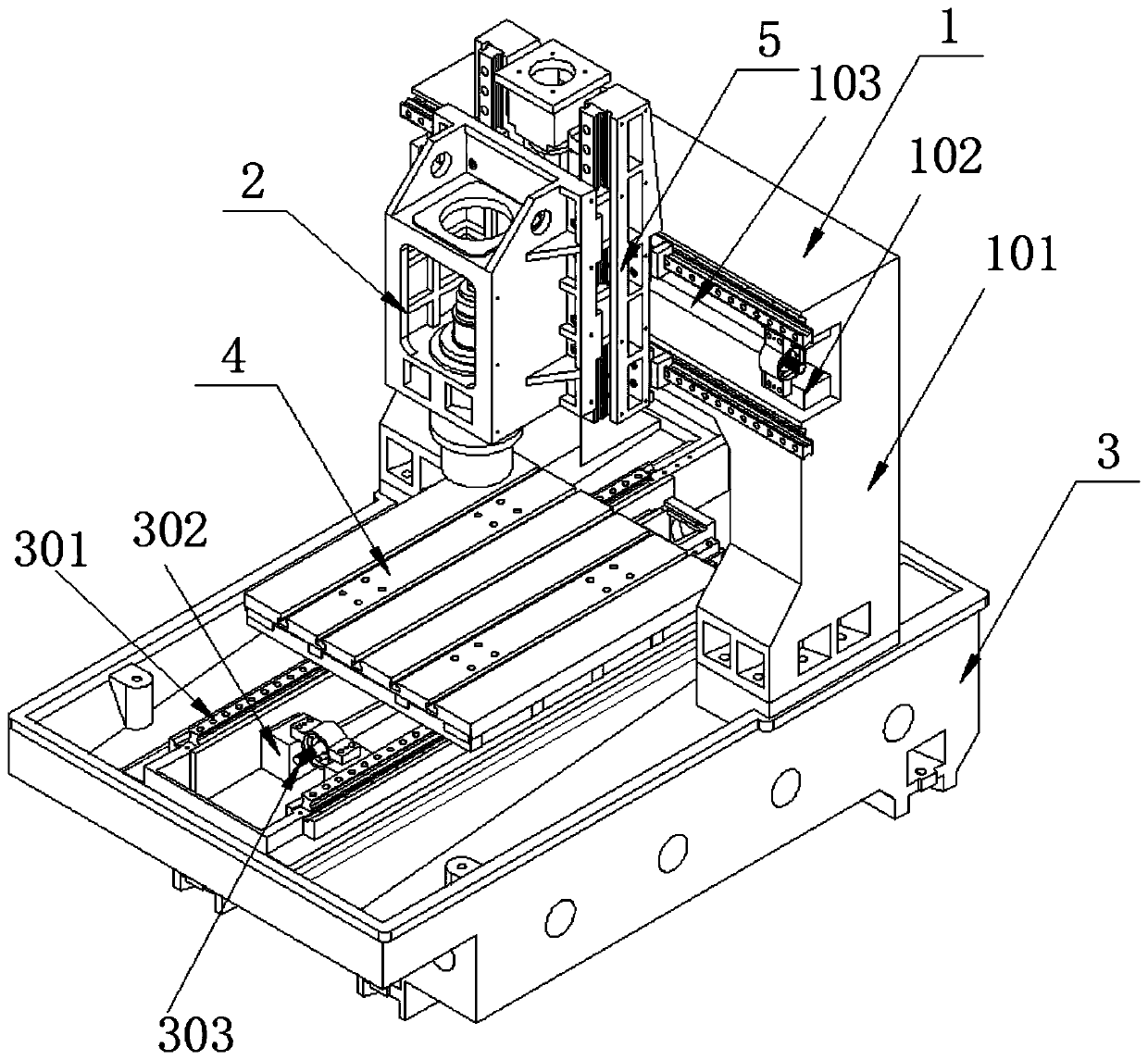

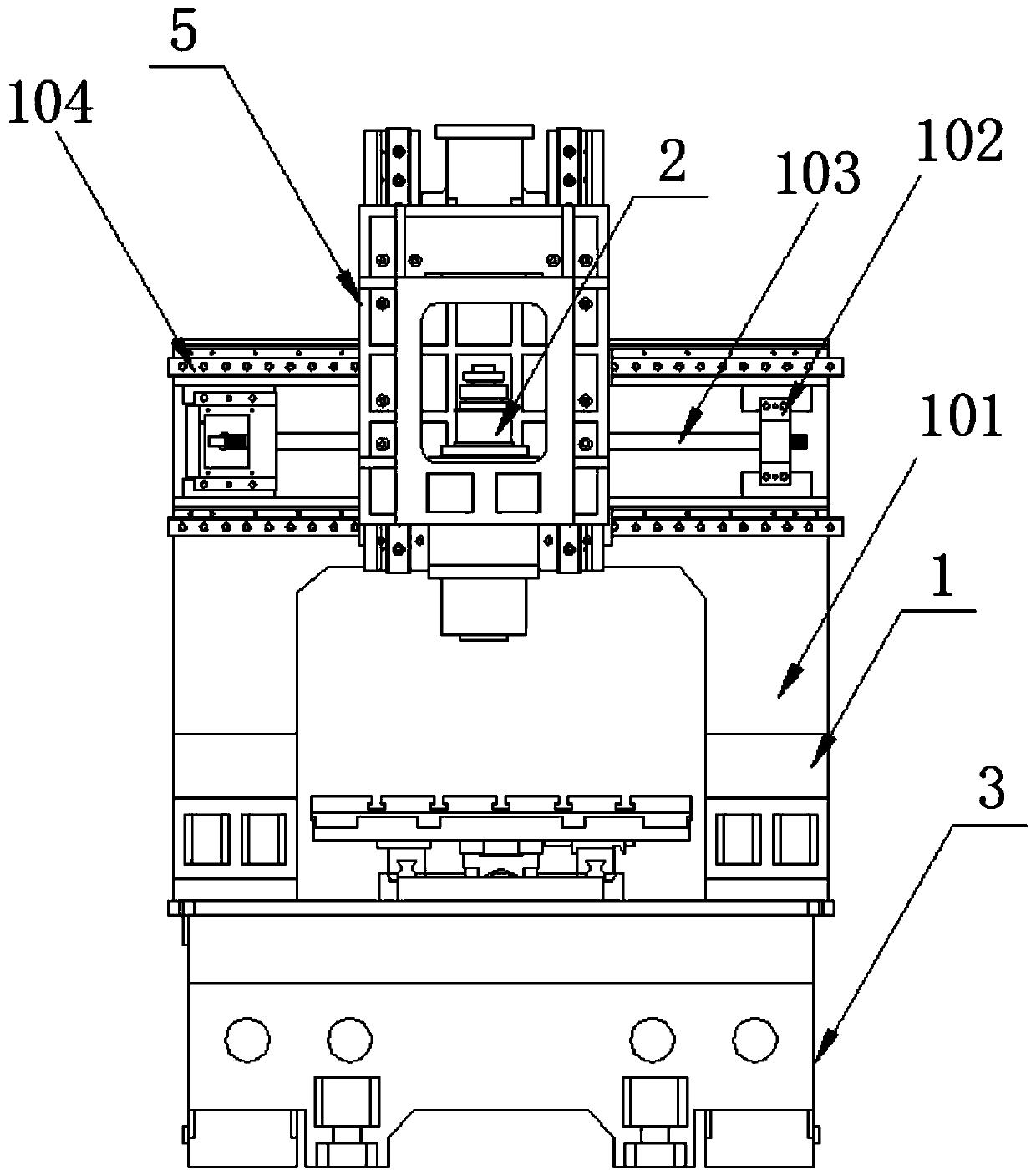

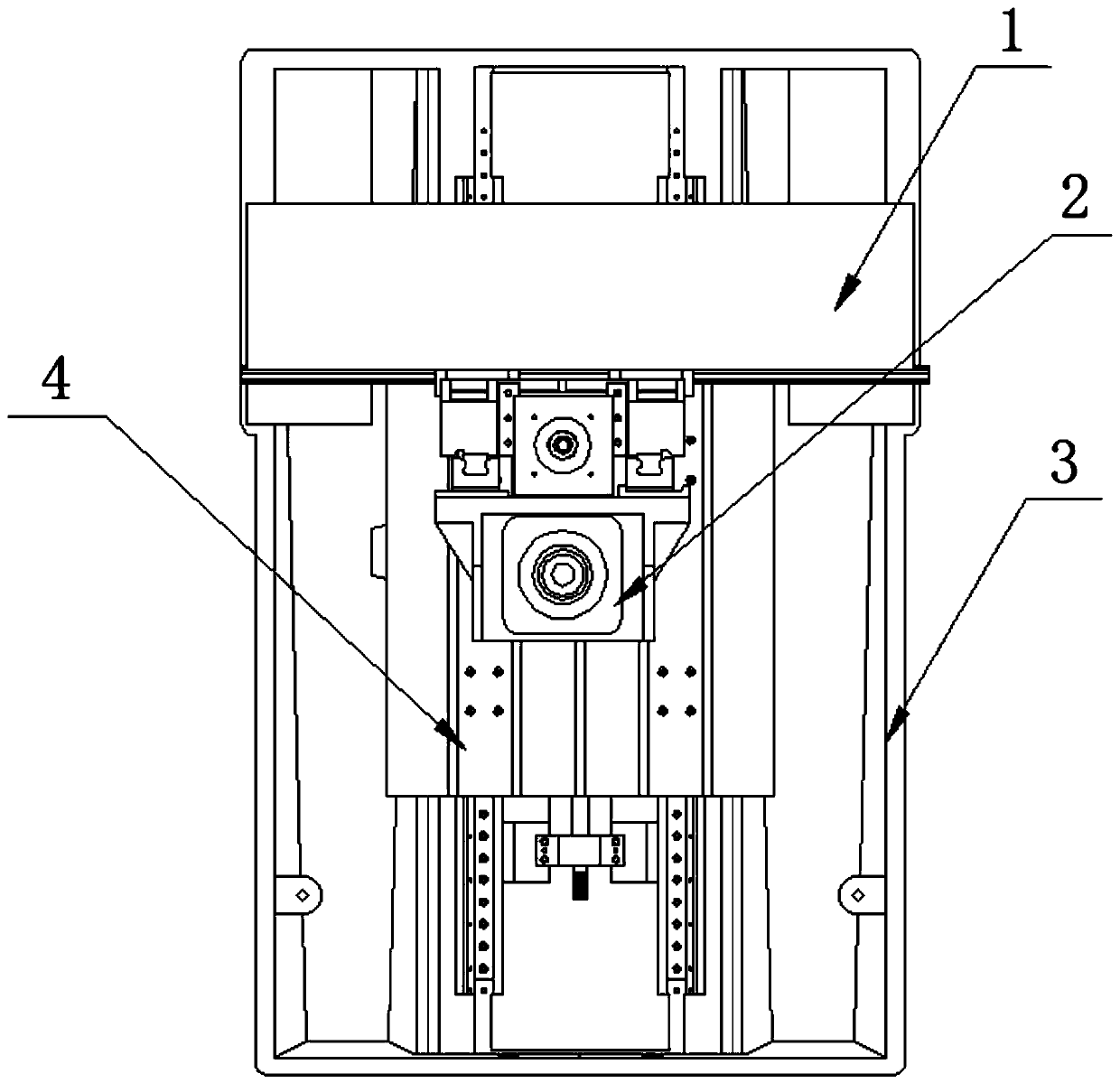

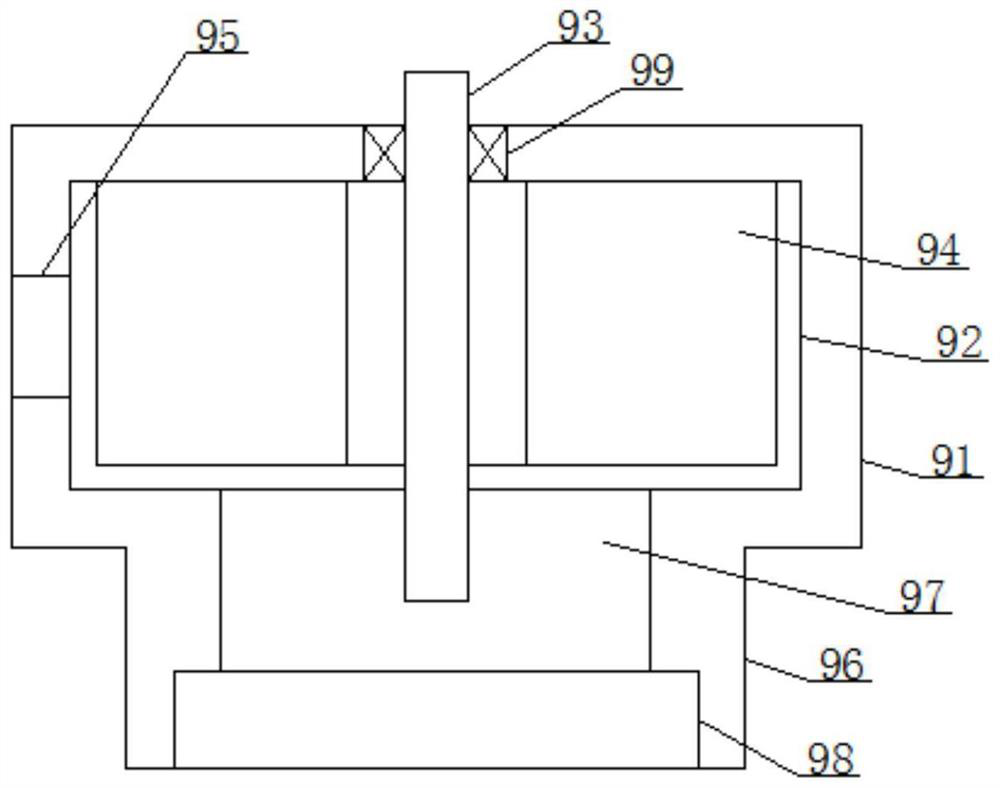

TC860 gantry machining machine tool

InactiveCN109746700AImprove machining accuracyImprove cutting strengthFeeding apparatusLarge fixed membersEngineeringMachine tool

The invention discloses a TC860 gantry machining machine tool. The TC860 gantry machining machine tool comprises a base, an upright column and a dragging plate, wherein the upright column is fixed toone side of the upper end surface of the base, and the dragging plate is mounted on the upright column to realize X-axis movement. A machine head for realizing Z-axis movement is mounted on the dragging plate. The base is provided with a workbench for realizing Y-axis movement. The upright column comprises a column body, two groups of X-axis limiting blocks, an X-axis lead screw and two groups ofsymmetrically arranged X-axis guide rails, wherein the column body is arranged on the base; the two groups of X-axis limiting blocks arranged on the upper side wall of the column body; the X-axis leadscrew is rotatably connected between the X-axis limiting blocks; the two groups of symmetrically arranged X-axis guide rails are arranged on two sides of the X-axis lead screw in a threaded mode; andone end of the X-axis lead screw is driven to rotate by an X-axis motor, and the X-axis motor is installed on the column body. When the TC860 gantry machining machine tool is compared with a verticalmachine tool, during X-axis machining, a workpiece is kept static, the machine head and a cutter are driven by the dragging plate to do cutting left and right, and the workpiece machining precision is high.

Owner:东莞市台川数控科技有限公司

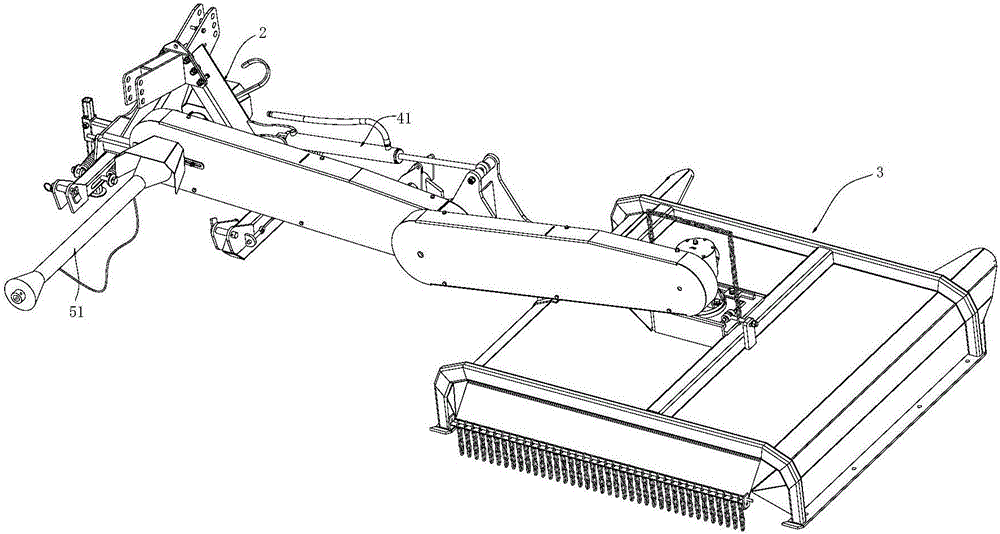

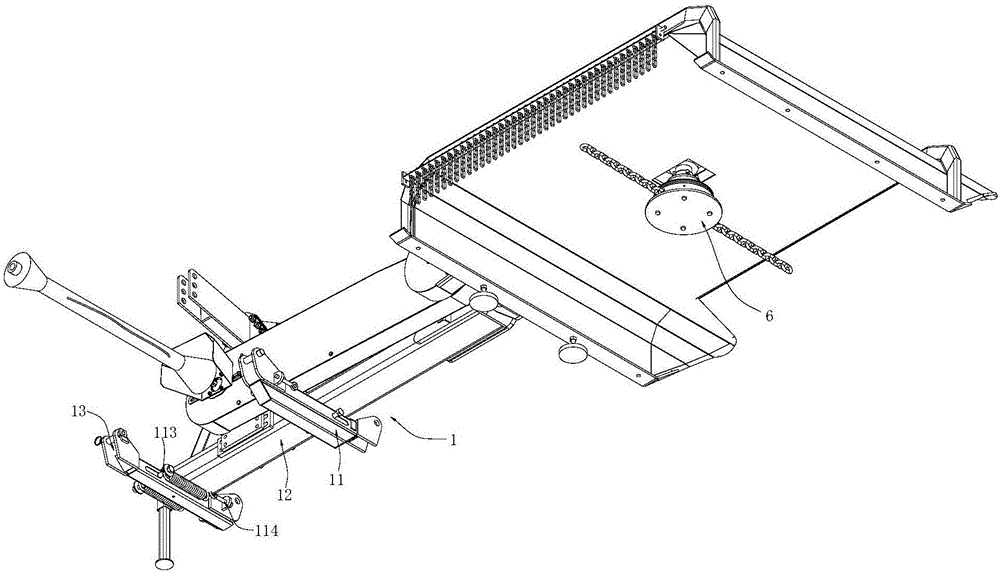

Transverse trimming machine

The invention relates to the field of agricultural machinery, and particularly relates to a transverse trimming machine. The trimming machine comprises a rack, and a transmission component and a cutting component which are arranged on the rack, wherein the rack comprises a roller assembly, an upper frame arranged on the roller assembly, and a shell assembly connected to the end part of the roller assembly. The transverse trimming machine has a novel structure, on one hand, the floor area of the machine can be reduced by folding the rack, so that storage and maintenance can be facilitated; on the other hand, the cutting part is improved, so that the machine is adaptive to high-strength cutting.

Owner:ZHEJIANG LEKELAI MACHINERY

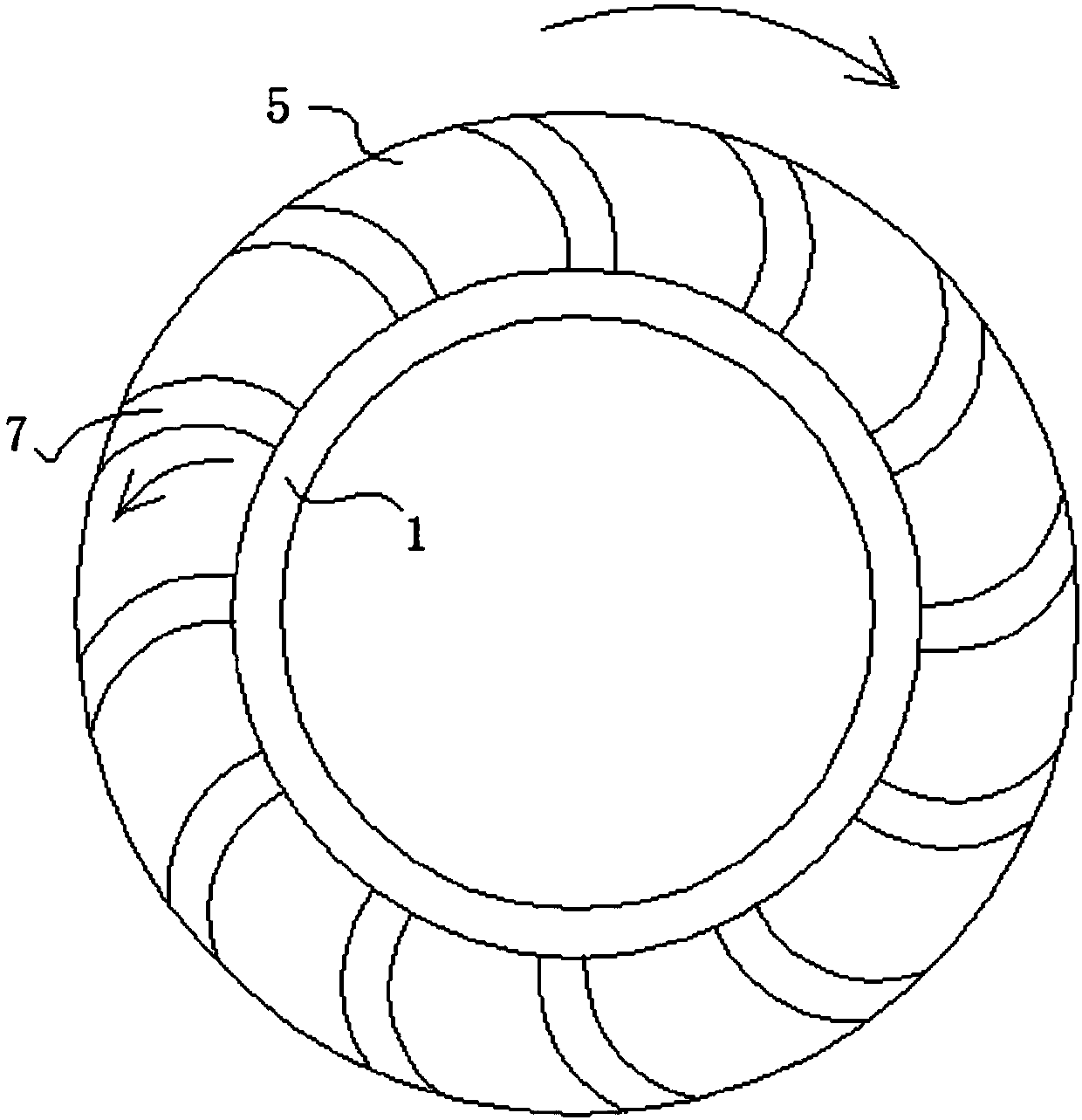

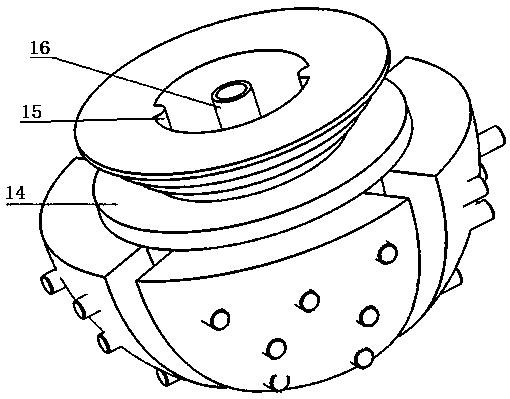

A high-efficiency cutting diamond saw blade

ActiveCN108748708BImprove cutting effectImprove cutting strengthMetal sawing toolsStone-like material working toolsStructural engineeringMechanical engineering

The invention discloses a high-efficiency cutting diamond saw blade comprising a base body, a cutter, an indication tank and a discharging tank. Diamond particles are arranged on the cutter in a brazing mode; a mounting hole is formed in the center of the base body; a key groove is formed in the inner periphery of the mounting hole; the base body is provided with a plurality of heat dissipation silencing holes; the cutter is arranged on the outer periphery of the base body; saw kerfs are arranged on the base body and the cutter in the radius direction and extend to the circumferential face ofthe cutter from the middle of the base body to form an opening in the circumferential face of the cutter; the multiple saw kerfs are evenly distributed with the circle center of the base body as the base point; the arc-shaped indication tank is formed in the front face of the cutter; the extending lines of the two ends of the indication tank are tangential with the inner periphery and the outer periphery of the cutter respectively; and the discharging tank is arranged on the back face of the cutter. The saw blade heat dissipation effect is good, the cuttings discharging effect is good, the cutting quality is good, the cutting efficiency is high, and the wearing conditions of the saw blade are convenient to observe.

Owner:WUHU CHANGLING DIAMOND TOOL CO LTD

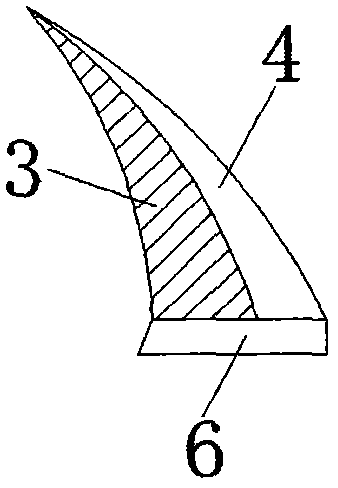

Cutting roller used for mining

The invention discloses a cutting roller used for mining. The cutting roller comprises cutting chain wheels, cutting teeth, a guide roller body, material blocking plates and a roller shaft, the roller shaft is sleeved with the guide roller body, the cutting chain wheels are arranged at the two ends of the roller shaft, the material blocking plates are connected with the two ends of the guide roller body, extended blocking pieces are fixed on each material blocking plate through bolts, multiple tool aprons are welded to the surface of the roller shaft, one cutting tooth is fixed on each tool apron, and a cutting edge is arranged at the front end of each cutting tooth. According to the cutting roller used for mining, the structure is simple, the installation, detachment and replacement are convenient, the tool aprons are arrayed in a straight line and staggered mode integrally, the cutting intensity is high, the cutting effect is good, each cutting edge is of a V-shaped structure, the structural strength is increased, the cutting efficiency of mining is high, the grinding effect is good, meanwhile, the extended blocking pieces on the material blocking plates are easy to adjust, mineral aggregate is prevented from being scattered and spattered, the cutting roller is easy to transport, and safety accidents are effectively prevented.

Owner:姚旺东

A spherical pruner for spherical plants

ActiveCN111567257BImprove cutting strengthIncrease profitCuttersCutting implementsStructural engineeringTurbine

The invention discloses a spherical trimmer for spherical plants, which comprises a bottom installation base plate and a sub-semi-annular shell, an installation plate and a main longitudinal support bar are installed on the upper surface of the bottom installation base plate, and the top of the main longitudinal support bar is provided with a There is a main semi-annular casing with an integrated structure, and a main longitudinal discharge pipe with an integrated structure is arranged at the top and bottom of the main semi-annular casing. The invention utilizes the kinetic energy generated by the high-pressure air, which can not only drive the rotating blades to rotate, but also blow and clean the surface of the trimmed fallen leaves, which improves the utilization rate of the kinetic energy. When the device is providing the rotation of the blades, it can The middle part of the air flow uses the turbine technology to drive the main rotation force. When the air is discharged, the blowing performance of the blade is improved again when trimming. The cutting strength of the blade further improves the utilization rate of the kinetic energy of the air, and at the same time Improved efficiency and effectiveness when pruning.

Owner:WEIFANG ENG VOCATIONAL COLLEGE

Adjustable high-pressure water cutting equipment

InactiveCN114714255AAdjustable cutting angleEasy to adjustAbrasive machine appurtenancesAbrasive blasting machinesEngineeringHigh pressure water

The invention relates to the technical field of water cutting, and discloses adjustable high-pressure water cutting equipment which comprises a cutting table and a water cutting tool body, a turning mechanism is arranged at the top of the water cutting tool body, a waterproof mechanism is arranged in the cutting table, and the turning mechanism comprises a grating steel frame. A circular cavity groove is formed in the top of the grating steel frame, a rotating frame is installed in the circular cavity groove, a rotating rod is installed at the bottom of the rotating frame, a servo motor is coaxially and fixedly connected to the bottom of the rotating rod, a sliding assisting piece is arranged between the circular cavity groove and the rotating frame, and a clamping piece is arranged at the top of the rotating frame. The adjustable high-pressure water cutting equipment has the advantages of being convenient to fix, capable of adjusting the cutting angle and the like, and solves the problems that a table top of existing water cutting equipment is not fixed, and adjustment is troublesome due to no cutting angle.

Owner:陈涛

Plastic mold with edge material cutting device

The invention relates to the technical field of plastic molds, in particular to a plastic mold with an edge material cutting device. The plastic mold comprises a lower die; a rotating shaft is arranged in the lower die; first cutters are arranged at both ends of the rotating shaft; a first motor is arranged at one end of the lower die; first ear seats are arranged on the two sides of the lower die; a threaded rod is arranged between the two first ear seats; second ear seats are arranged under the first ear seats; a guide rod is arranged between the two second ear seats; a sliding support seatis arranged on the threaded rod; a first driving wheel is arranged at one end of the threaded rod; a coupling shaft is arranged on the side wall of the low die; a second driving wheel is arranged on the coupling shaft; a hand wheel is arranged at one end of the coupling shaft; a second motor is arranged on the side wall of the sliding support seat; a second cutter is arranged at the interior partof the sliding support seat; and the output shaft of the second motor passes through the side wall of the sliding support seat and is fixedly connected with the second cutter. The plastic mold has strong practicability and is worth popularizing.

Owner:HUANGSHAN MINGSHENG DIE MATERIAL CO LTD

Cutter for machining Fresnel patterns and manufacture method of cutter

ActiveCN103302344BHigh strengthIncrease the level of detailMilling cuttersEngineeringMachining process

The invention discloses a cutter for machining Fresnel patterns and a manufacture method of the cutter. A cutter bit of the cutter is a cone with four side walls, a diamond layer with the thickness of 0.2-0.8mm is embedded on the surface of a front cutter face, the front cutter face and side cutter faces incline towards the inner side of the cutter bit from top to bottom to respectively form a first negative deflection angle and a second negative deflection angle together with a vertical line passing through the cutter bit; an auxiliary rear cutter face is formed by linking a first incline and a second incline with different slopes from the cutter bit to the root part of the cutter bit; and the bottom edge of a rear cutter face inclines towards the side cutter faces from the front cutter face to the auxiliary rear cutter face to form a rear cutter face inclination angle. According to the cutter, the strength of the cutter bit is greatly improved, the front cutter face and the side cutter faces incline towards the inner side for a certain angle, the negative deflection angle of the front cutter face is capable of well discharging cuttings, the negative deflection angles of the side cutter faces are capable of avoiding a machining material, thus the refining degree of machined patterns is improved; and the auxiliary rear cutter face is capable of ensuring that a machined face of a workpiece is not touched in a machining process, and thus the quality of the machined patterns is further improved.

Owner:DATAMATIC GUANGZHOU INJECTION MOLD

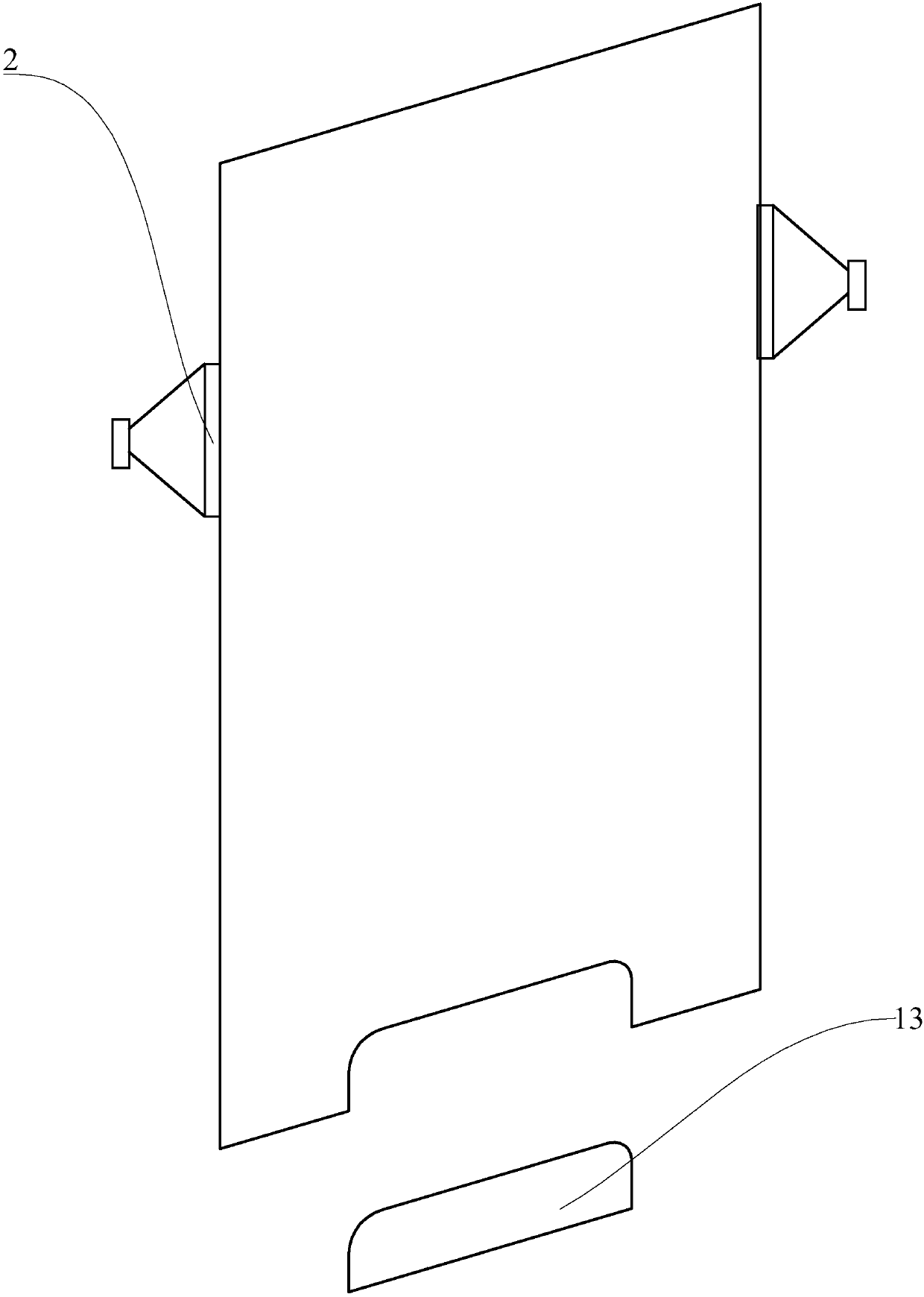

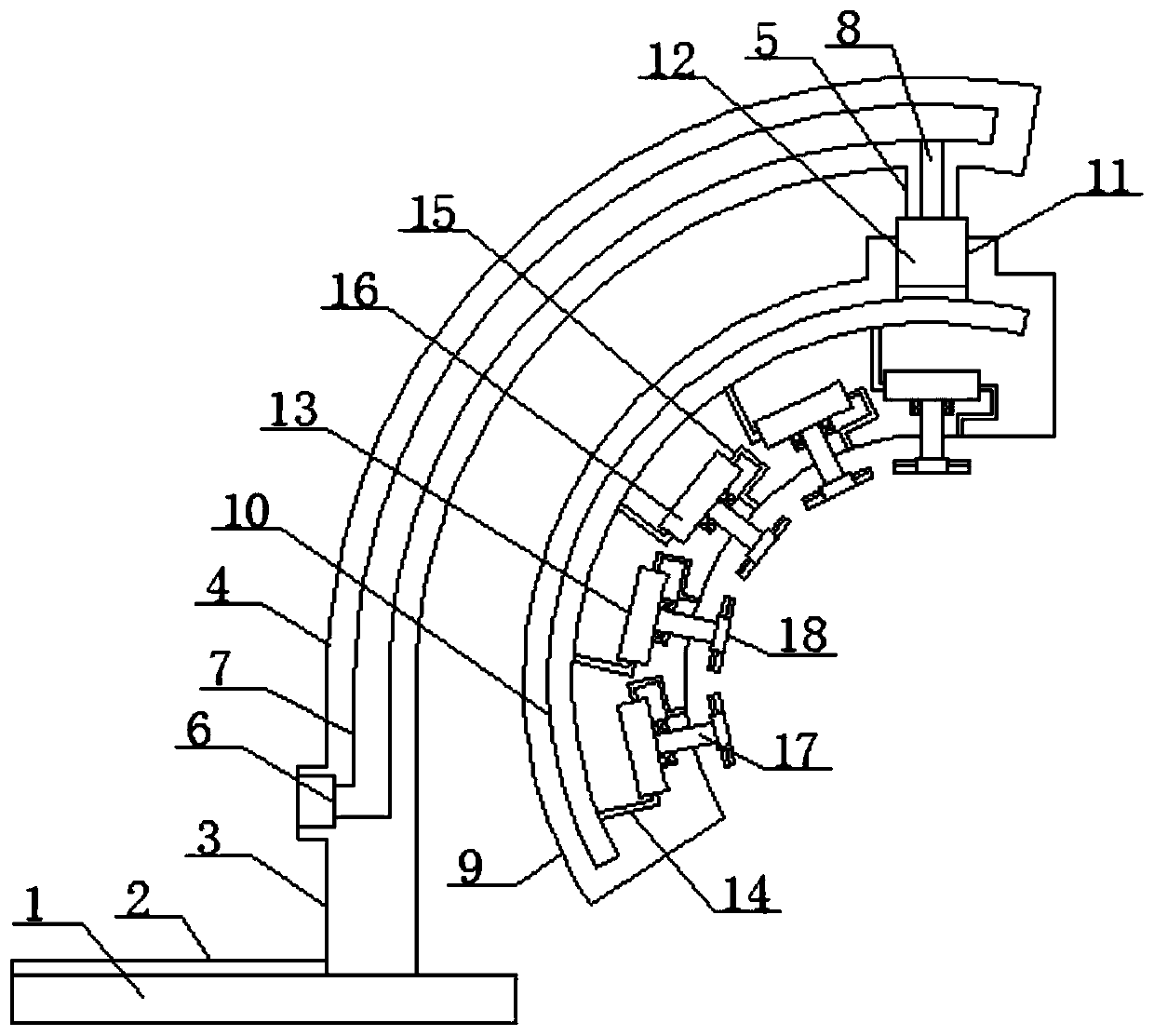

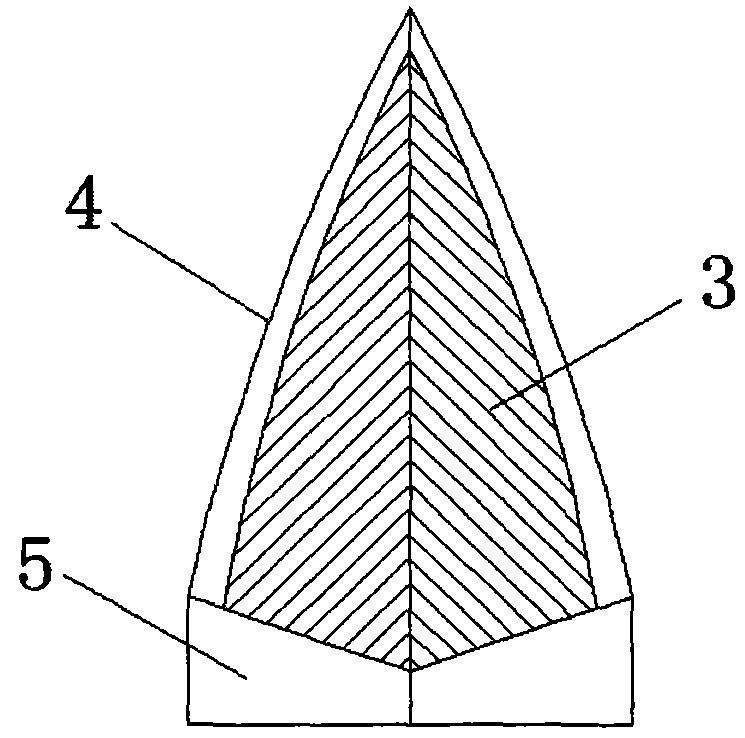

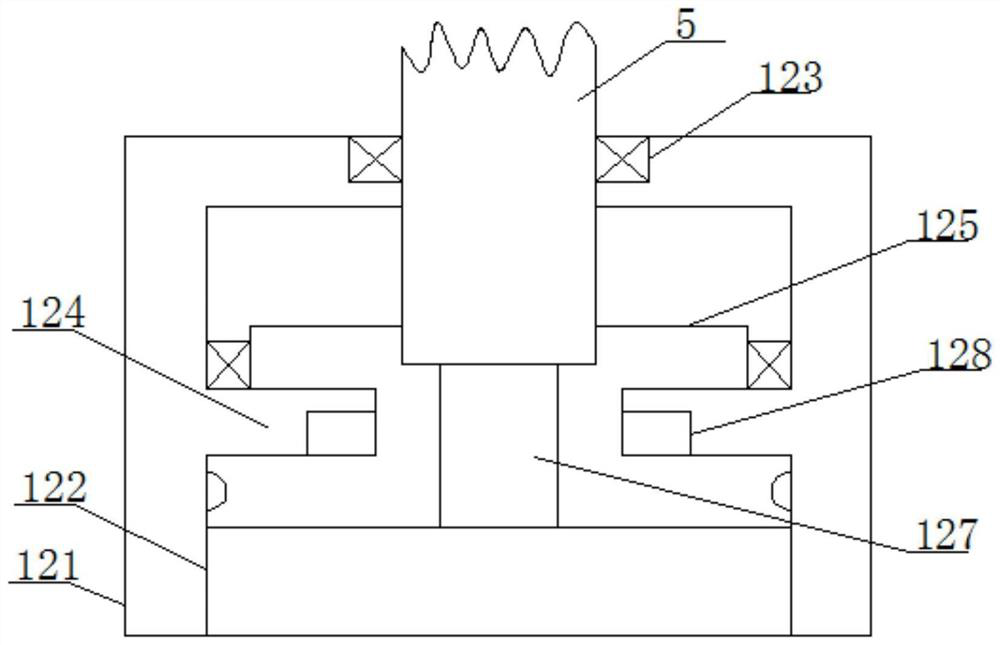

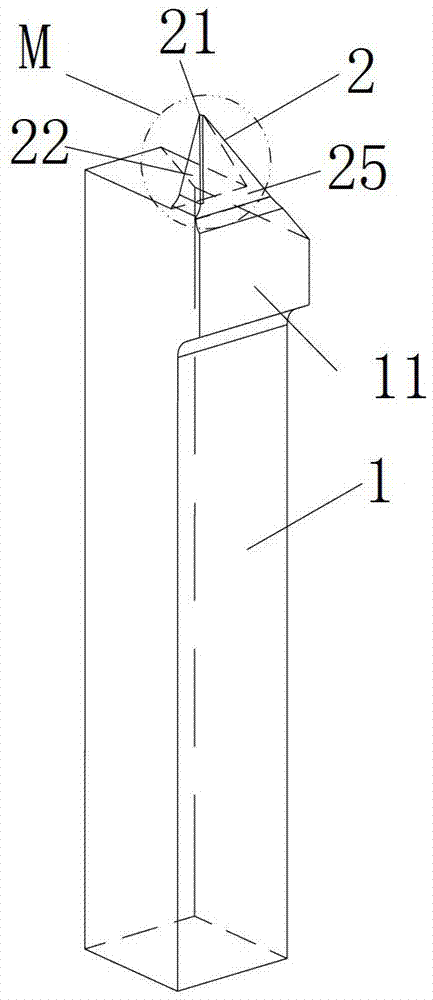

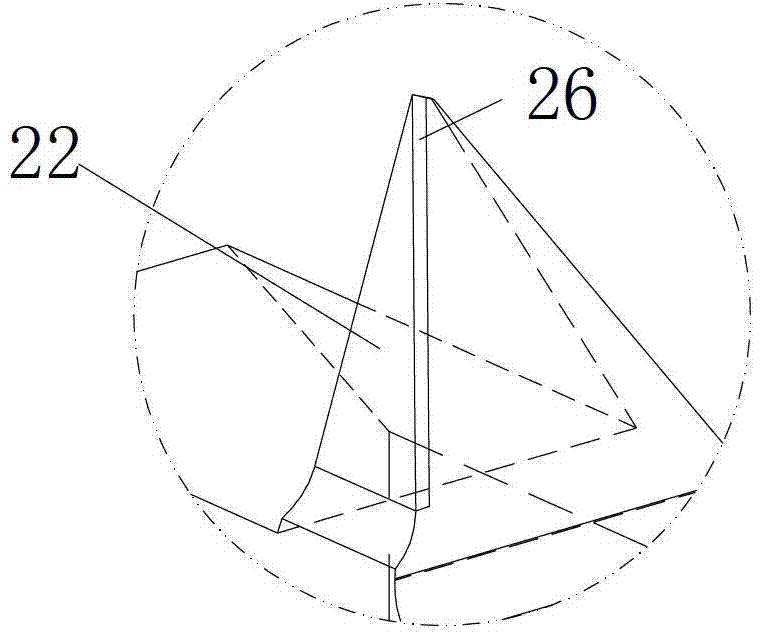

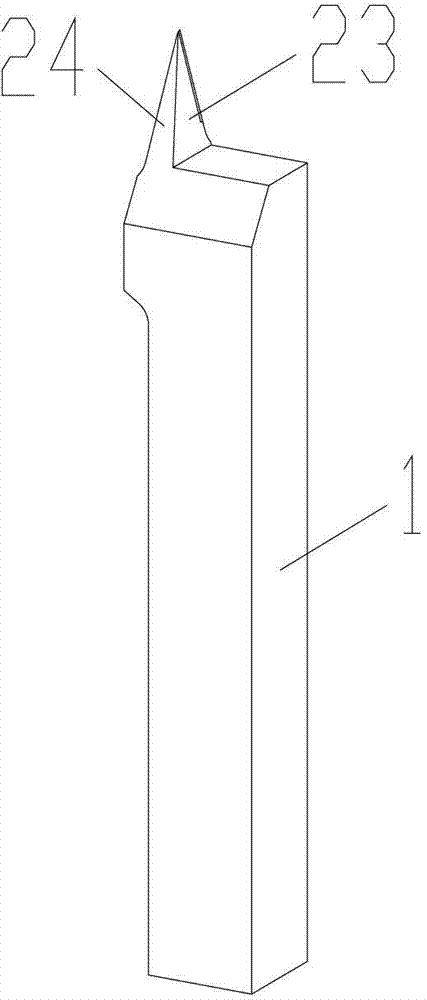

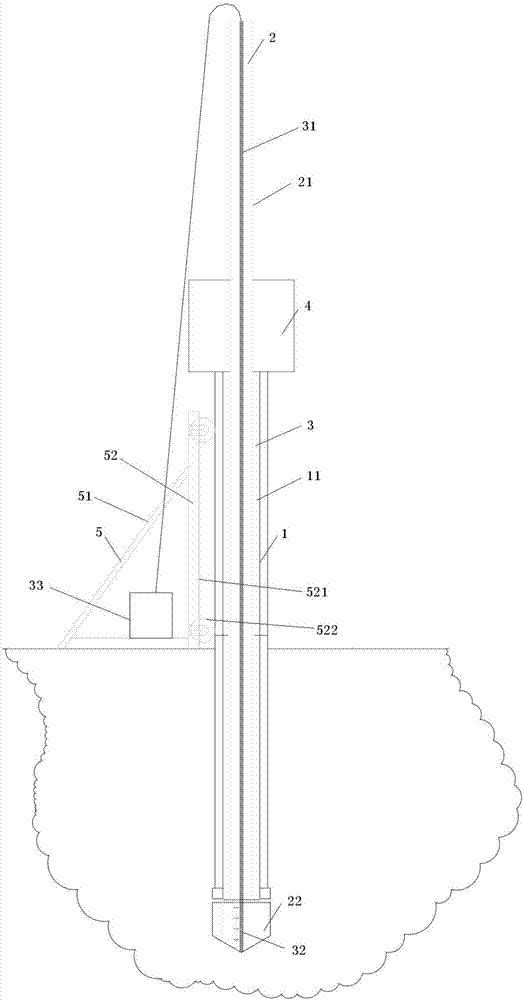

Sinking construction device of underground building

PendingCN107386295AGuaranteed cutting and crushing strengthSinking smoothlyDrill bitsDrilling with mechanical conveyingEngineeringBuilding construction

The invention relates to the technical field of underground construction, in particular to a sinking construction device of an underground building. The sinking construction device of the underground building comprises an excavation mechanism (2), a conveying mechanism (3) and a drive mechanism (4). The excavation mechanism (2) is detachably connected with a prefabricated outer wall board (1) buried in advance and excavates earth and stone under the buried prefabricated outer wall board (1). The conveying mechanism (3) conveys the earth and stone excavated by the excavation mechanism (2) to the ground. The drive mechanism (4) is used for driving the excavation mechanism (2) and the conveying mechanism (3). The excavation mechanism (2) is a blade assembly used for cutting earth and stone. In the excavation process, the sinking construction device of the underground building has a great cutting and breaking function on the earth and stone and can guarantee that a wall smoothly goes down.

Owner:NENGCHENG GRP

A high wear resistance shield machine hob ring

The invention discloses a high abrasion resistance shield tunneling machine rolling cutter ring, and belongs to the field of shield tools. The high abrasion resistance shield tunneling machine rollingcutter ring comprises a cutter ring body, a mounting cavity is formed in the cutter ring body, and a front side area protruding outwards is arranged in the middle of the outer side of the cutter ringbody in the circumferential direction in a surrounding mode; annularly-distributed transverse transition sections are symmetrically arranged on the upper side and the lower side of the front side area, the transverse transition sections are connected with the cutter ring body through annularly-distributed longitudinal transition sections, fixing grooves are evenly formed in the annular side wallsof the longitudinal transition sections, and the transverse transition sections and the front side area at intervals correspondingly; and the fixing grooves in the longitudinal transition sections, the transverse transition sections and the front side area are connected in a one-to-one correspondence mode, and the fixing grooves are internally provided with hard alloys. According to the high abrasion resistance shield tunneling machine rolling cutter ring, by reasonably arranging the hard alloys on the outer side of the shield cutter ring, abrasion resistance of the cutter ring is effectivelyenhanced, the service life of the shield cutter ring is prolonged, the production cost is reduced, and the production loss is reduced.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com