Cutter for machining Fresnel patterns and manufacture method of cutter

A manufacturing method and pattern technology are applied to the tool for processing Fresnel pattern and its manufacturing field, which can solve the problems of high processing difficulty, low processing efficiency, difficult burden, etc., and achieve the improvement of the sharpness of the blade, the improvement of the quality of the pattern, and the improvement of fineness. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

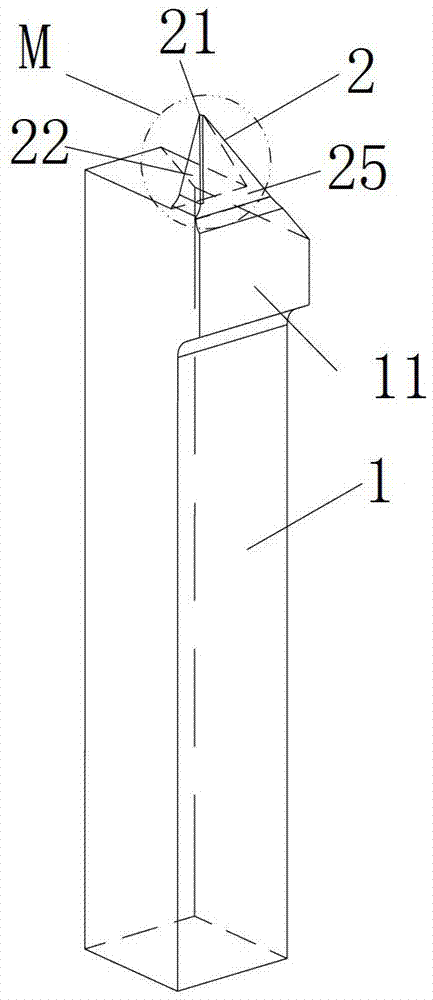

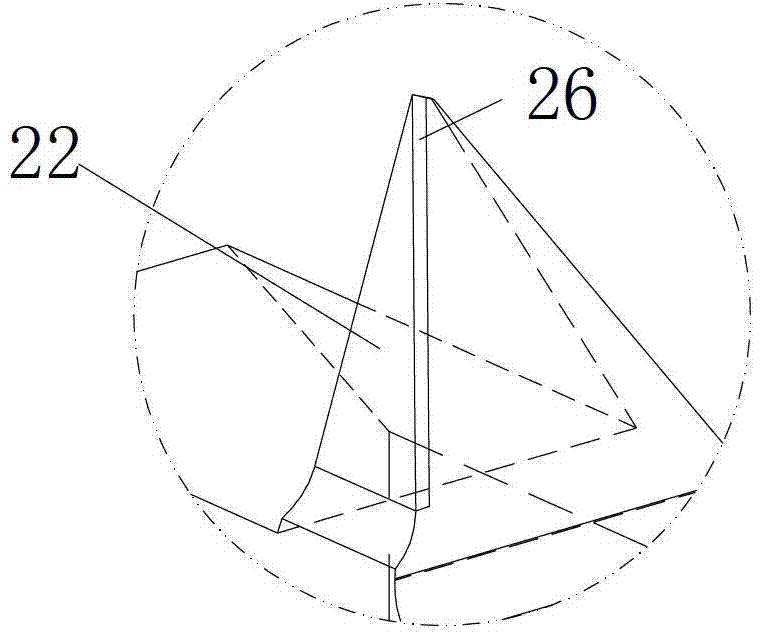

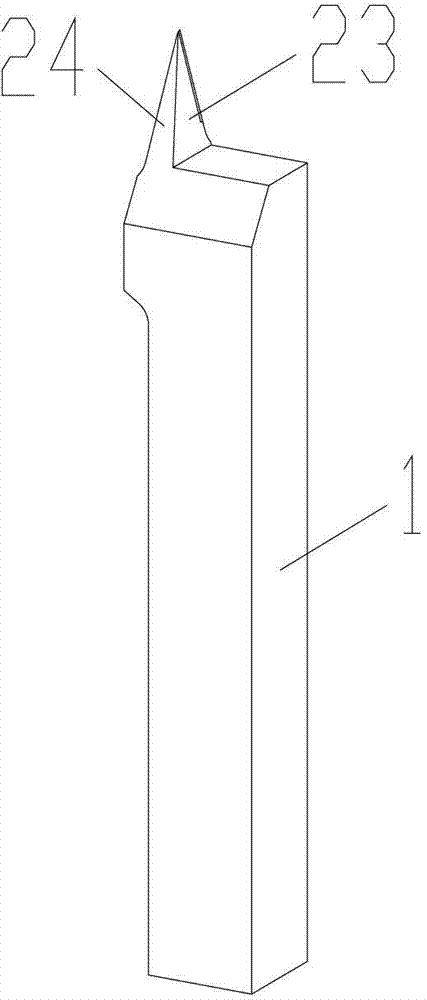

[0035] Embodiments of the present invention provide a tool for processing Fresnel patterns, such as Figure 1 to Figure 7Shown, comprise cutter bar 1 and be located at the cutter head 2 above cutter bar 1, described cutter head 2 is the cone with four sidewalls, and this cone apex is the cutter tip 21 of cutter head, and the cutter head 2 of this cone The four side walls are respectively the rake face 22, the flank face 23, the auxiliary flank face 24 and the side cutter face 25 of the cutter head, the rake face 22 is facing the auxiliary flank face 24, and the flank face 23 is facing the side cutter Surface 25; the surface of the rake face 22 is inlaid with a layer of diamond 26 with a thickness of 0.2 mm to 0.8 mm. In the embodiment of the present invention, the thickness of the diamond is 0.5 mm, so that the cost of the cutter head and the hardness of the cutter head are optimized. Diamonds can be natural diamonds and artificial diamonds. From the perspective of enhancing p...

Embodiment 2

[0057] An embodiment of the present invention provides a method for manufacturing a tool for processing a Fresnel pattern to realize the manufacturing of the tool described in Embodiment 1 above, and the method includes the following steps.

[0058] Step 100: Obtain the parameter r of the Fresnel pattern to be processed min , R min , A max and alpha min . In this step, according to the parameters of the Fresnel pattern to be processed, a limit tooth space is assumed, and the limit tooth space contains the above-mentioned parameter r min , R min , A max and alpha min , so as to facilitate the later trimming design and processing.

[0059] Step 101: Machining a cylinder blank. In this step, the raw material of the tool is preliminarily processed, and the raw material is processed into a cylinder blank, which can be a cylinder or a square column. In order to facilitate later operations, the raw material is processed into a square cylinder blank in the embodiment of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com