Laser drilling and mechanical grinding matching device and drilling method

A technology of mechanical grinding and matching device, applied in drilling equipment and methods, drilling equipment, wellbore/well components, etc., can solve problems such as single work of laser drilling or mechanical grinding technology, achieve simple drilling method and reduce tripping Drilling time, the effect of saving drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

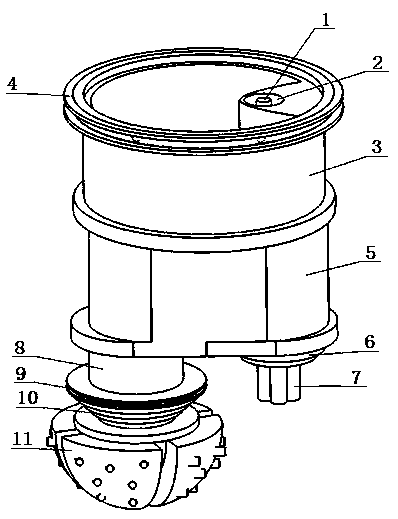

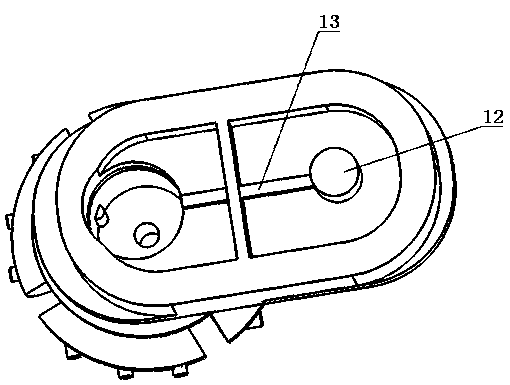

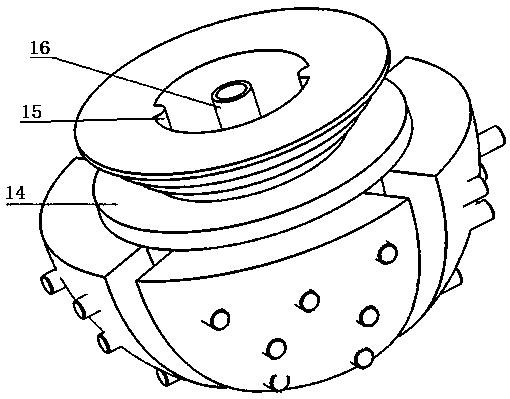

[0021] The present invention will be further described in conjunction with accompanying drawing below:

[0022] combine figure 1 , figure 2 , image 3 As shown, this matching device for laser drilling and mechanical grinding includes a drill pipe 3, a double-chamber connecting chamber 5, a laser transmitter 7, a drill bit 11, a signal transmission system 13, a pressure sensing device 15, and the inner chamber of the double-chamber connecting chamber 5 It is divided into a left chamber and a right chamber. A laser generator 12 is installed in the right chamber. The upper end of the double-cavity connection chamber 5 is connected to the drill pipe 3. The top of the drill pipe 3 is equipped with a first turntable 4. The inner wall of the drill pipe 3 There is a cable groove 2, the cable 1 passes through the cable groove 2 and is connected to the laser generator 12 in the right chamber of the double-cavity connecting chamber 5, and the inner wall of the drill pipe 3 is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com