Saw blade with lateral buckles

A saw blade and circular technology, applied in the direction of manufacturing tools, metal sawing equipment, stone processing tools, etc., can solve the problems of imprecise cutting, high material cost, etc., and achieve the effect of cheap manufacturing, improved precision, and good sturdiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

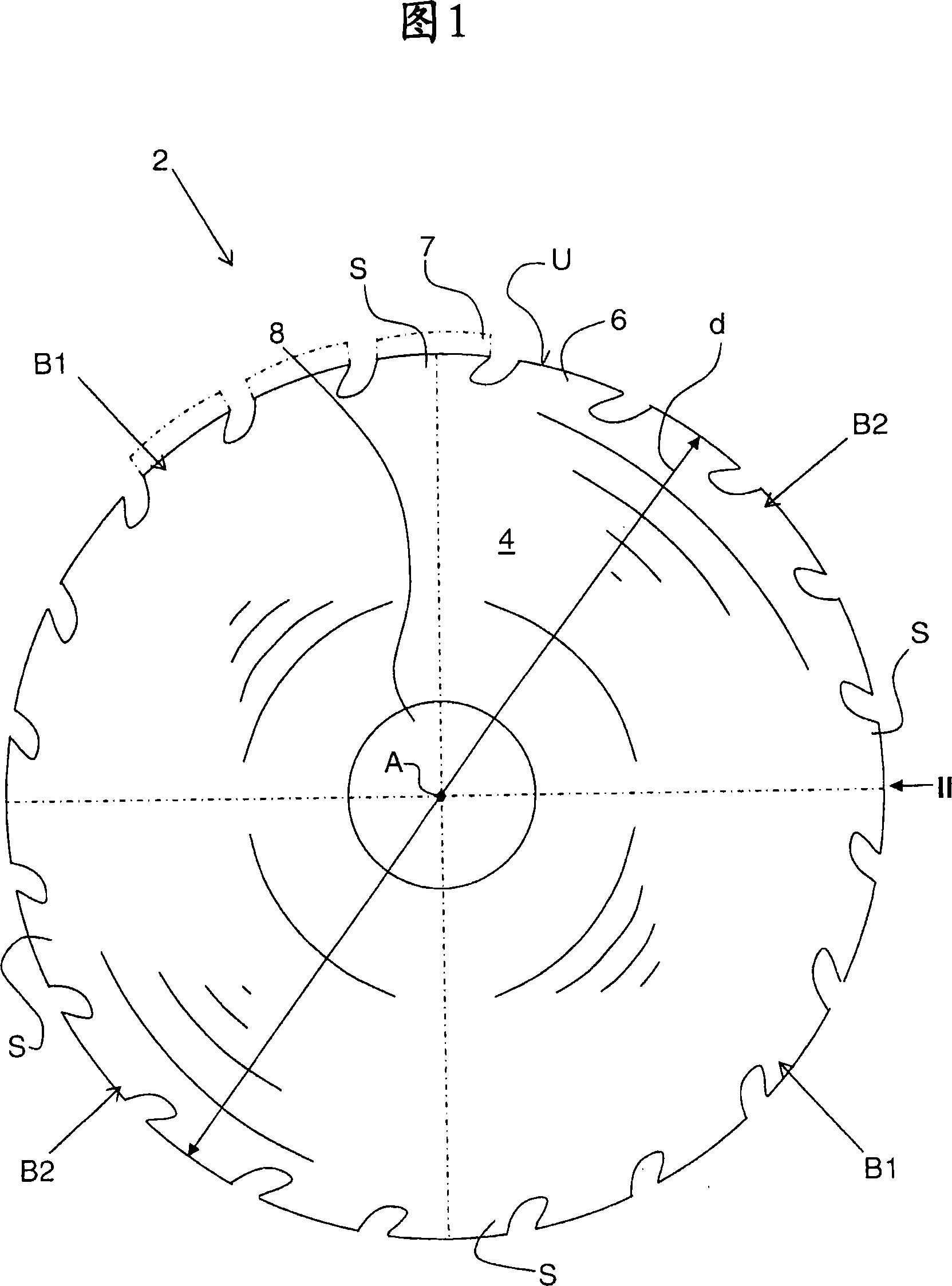

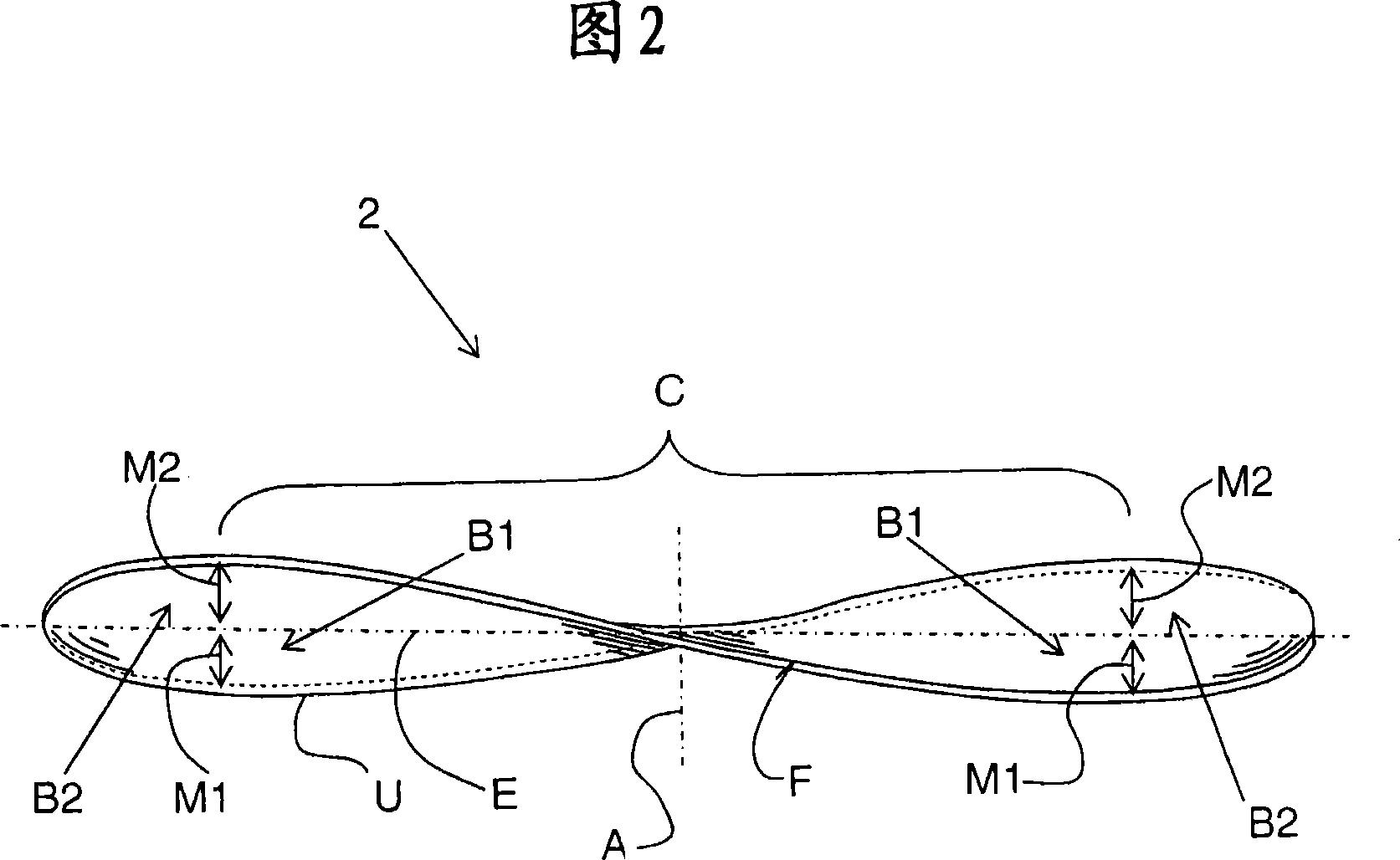

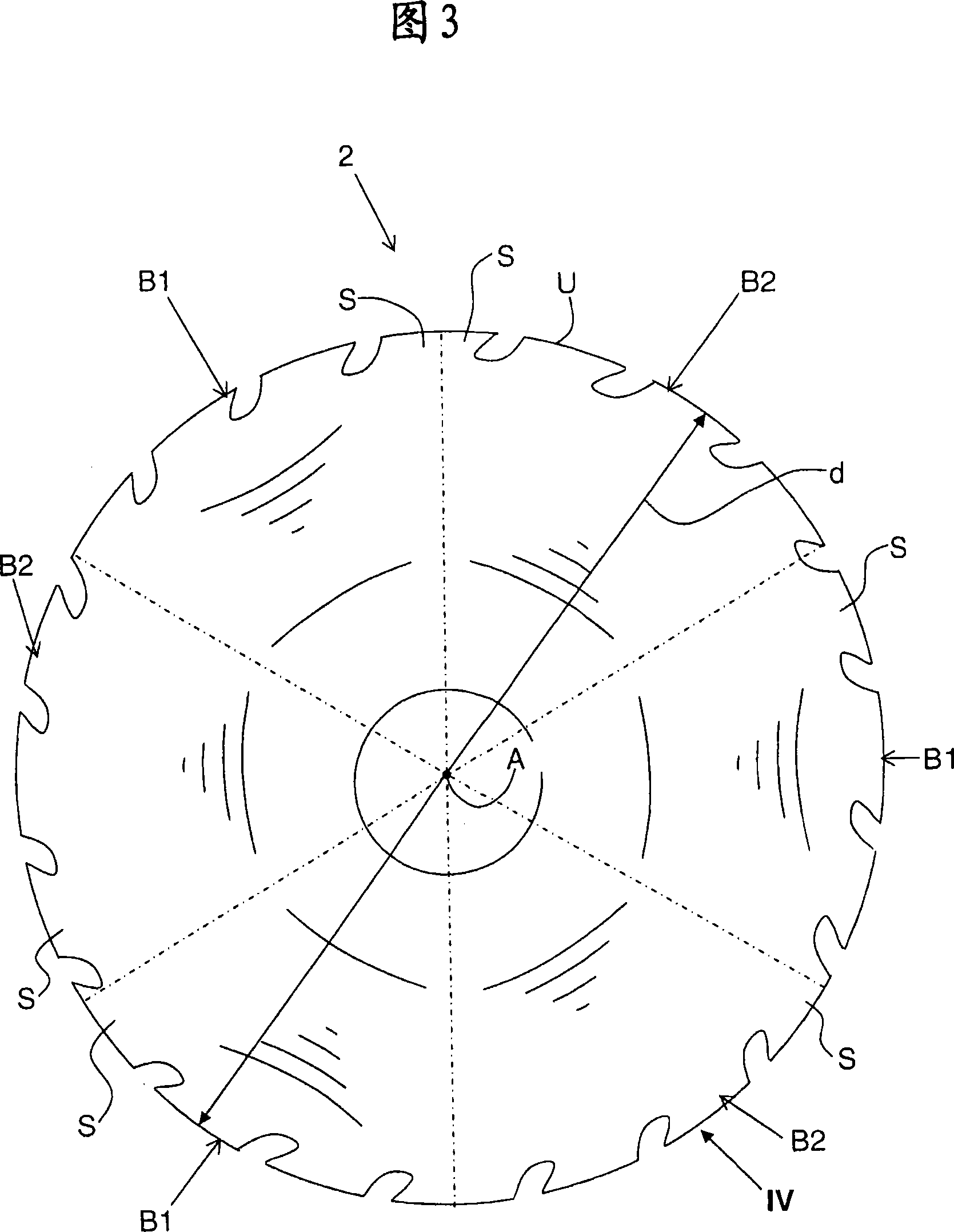

[0016] FIG. 1 shows a saw blade 2 for processing mineral material in the form of a wall saw blade with a diameter d of up to 800 mm. The saw blade has a main blade 4 , for example made of steel, on which processing means 6 in the form of cutting teeth are held. The cutting teeth can hereby be formed in one piece with the core piece 4 or at least partially consist of a special material which is applied to the core piece 4 . Instead of or in combination with the cutting teeth, diamond bodies can also be arranged on the circumference U of the saw blade 2 . In this case, diamond segments 7 can be arranged on a circumference U, for example, as indicated by dashed lines in FIG. 1 .

[0017] For fastening on a tool holder of a power tool not described, the power tool drives a saw blade 2 , which has a central bore 8 , in rotation about an axis A in the circumferential direction. In addition, the saw blade 2 is divided into four sectors S of equal size, each sector alternately havin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com