A high wear resistance shield machine hob ring

A high wear resistance, shield machine technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of hard alloy block wear, uneven hob wear, hard alloy block loosening, etc. Achieve the effects of improving wear resistance and service life, enhancing overall service life, and enhancing overall wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

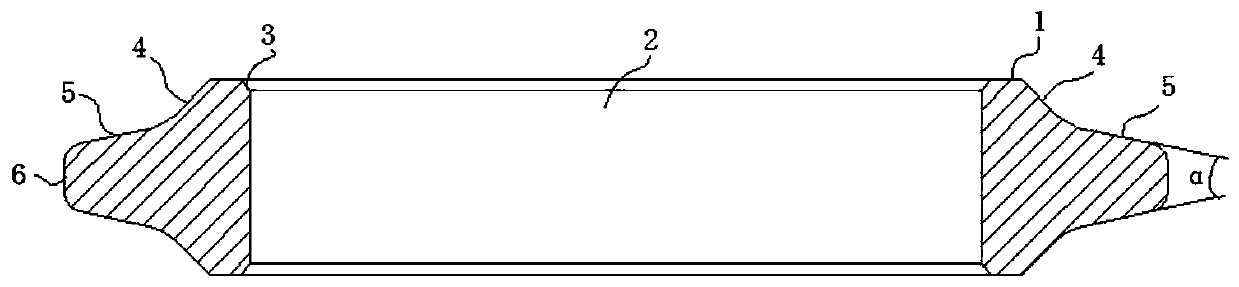

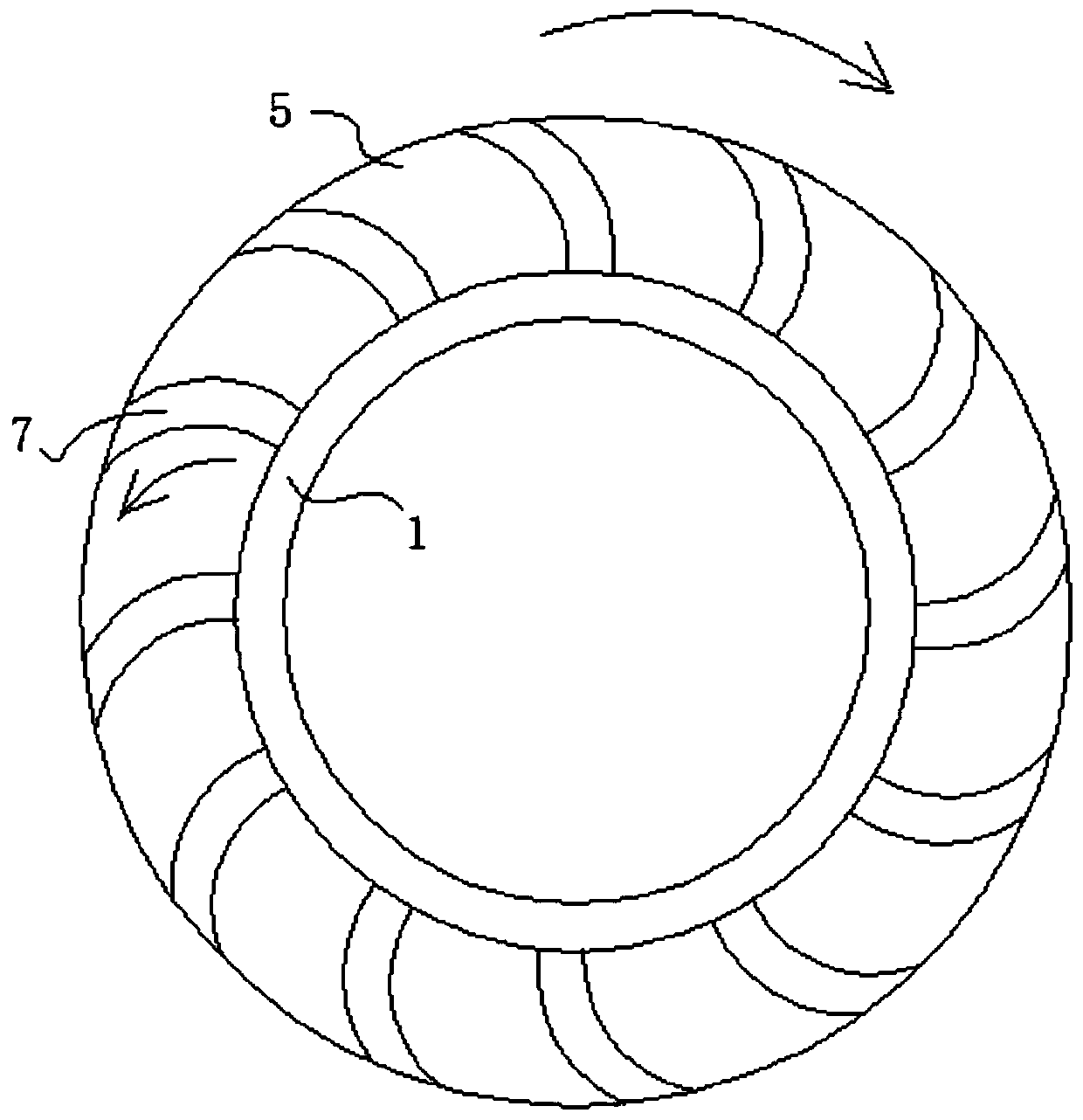

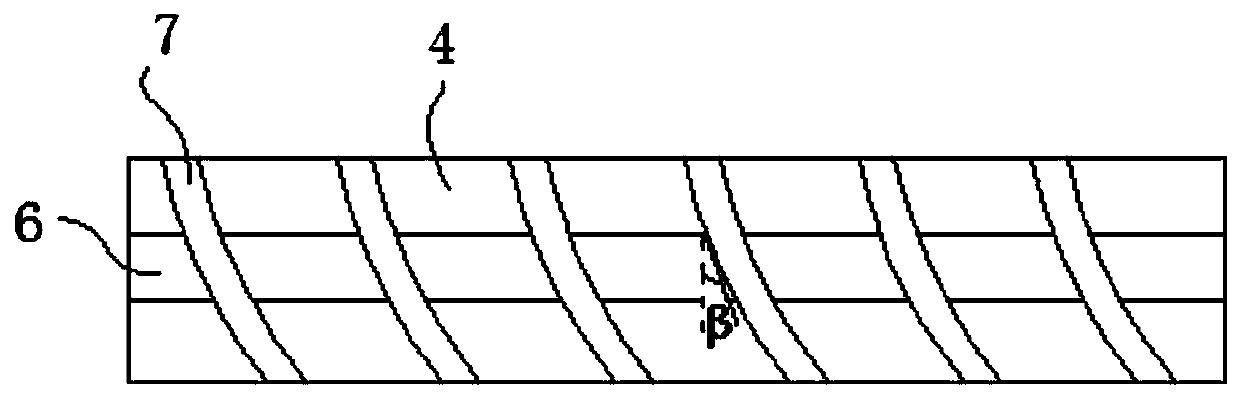

[0037] like Figure 1-Figure 3 As shown, a hob ring of a shield machine with high wear resistance in this embodiment includes a cutter ring body 1, and an installation cavity 2 is opened in the cutter ring body 1, and the hob ring is installed through the installation cavity 2 in actual use. On the central power shaft, it is used to drive the rotation and feed of the hob ring, and the first and last ends of the installation cavity 2 are provided with inclined inner walls 3 with openings gradually enclosing outwards along the circumferential direction, such as figure 1 As shown, the setting of the inclined inner wall 3 facilitates the installation and positioning of the hob ring and the central power shaft. Further, the inner wall of the installation cavity 2 is an inclined inner wall, and the included angle with the vertical direction is 1°-2° ( figure 1 (not marked in the middle), form the slope fit between the installation cavity 2 and the central power shaft, improve the fi...

Embodiment 2

[0048] A high wear resistance shield machine hob ring in this embodiment is basically the same as in Embodiment 1, the difference is that the thickness of the hard alloy in this embodiment is 4mm, and the surface of the hard alloy is respectively higher than the longitudinal transition Section 4, the transverse transition section 5 and the surface 1mm of the frontal area 6; the angle α between the tangents of the transverse transitional section 5 on both sides of the frontal area 6 is 24° in the present embodiment, and the arc-shaped cemented carbide is in the frontal area 6 The angle β between the tangent line at its top and the vertical plane is 15°.

Embodiment 3

[0050] A high wear resistance shield machine hob in this embodiment is basically the same as in Embodiment 1, the difference is that the thickness of the hard alloy in this embodiment is 3.5mm, and the surface of the hard alloy is respectively higher than the longitudinal The surface of the transition section 4, the transverse transition section 5, and the front area 6 is 0.5mm; in this embodiment, the angle α between the tangents of the transverse transition section 5 on both sides of the front area 6 is 26°, and the arc-shaped hard alloy is on the front side The angle β between the tangent line at the top of the area 6 and the vertical plane is 20°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com