Cutting saw for proximal surface sheet of fixed partial denture and processing method of cutting saw

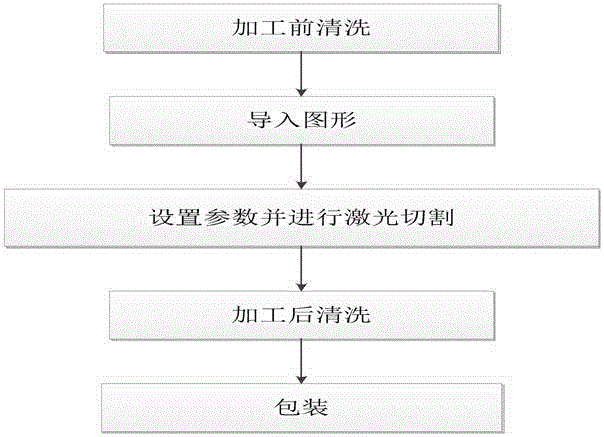

A technology for fixing dentures and processing methods, applied in dental saws, medical science, dentistry, etc., can solve the problems of inability to clean the contact area, insufficient floss strength, and difficult cleaning of adhesives, achieving excellent processing speed and convenient operation. , the effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing.

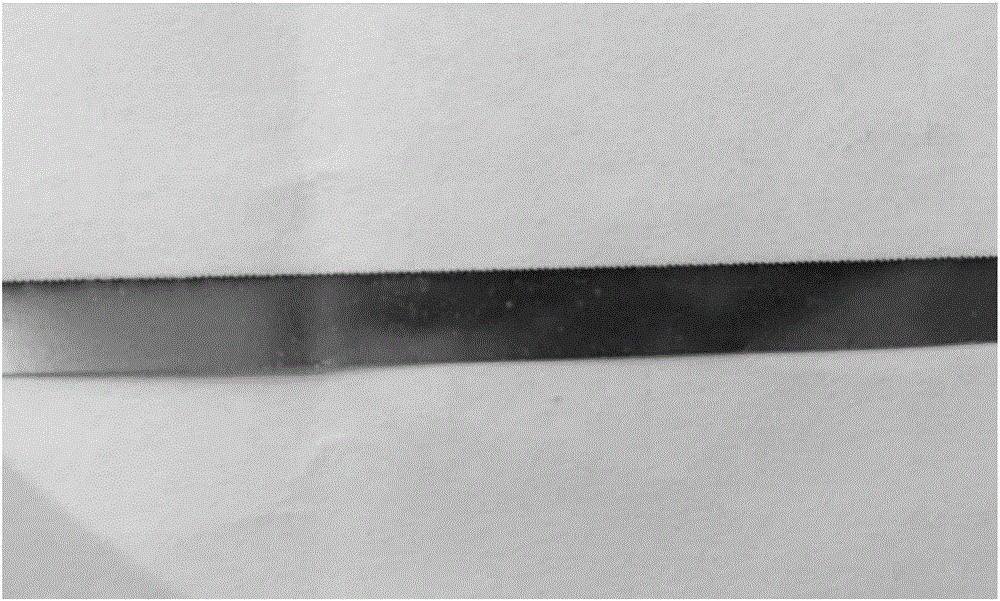

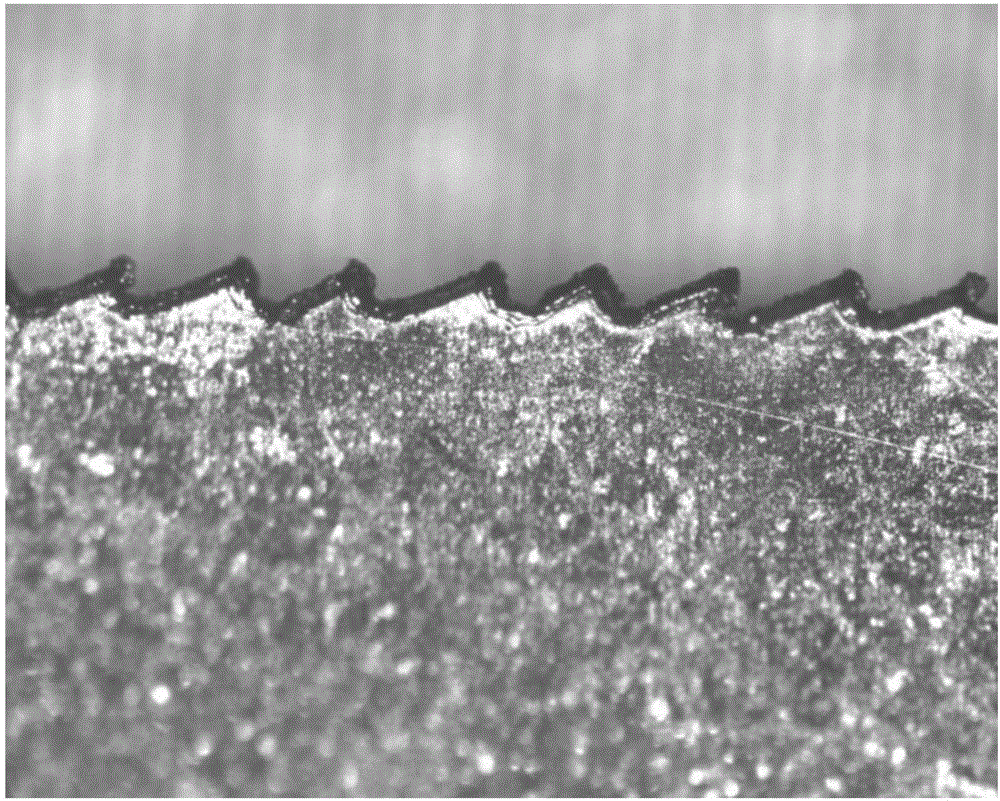

[0024] The utility model relates to a fixed denture adjacent surface cutting saw, which has a toothed structure, a tooth width of 10-20um, an addendum angle of 30°-60°, a total saw length of 50-150mm, a saw width of 2-10mm, and a thickness of 30-100um.

[0025] refer to figure 1 , figure 2 , image 3 , the sawtooth width of adjacent face slices is 10um, the tooth tip angle is 30°-60°, the total length of the saw is 50-150mm, the saw width is 2-10mm, and the thickness is 30-100um. The experimental results show that when the addendum angle is 30°, the cutting rate of light-curing resin is 200um / min, when the addendum angle increases to 45°, the cutting rate increases from 200um / min to 600um / min, and the addendum angle continues to increase to At 60°, the resection rate drops to 400um / min. The tooth width increases from 10um to 30um, and due to the low hardness of the light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com