High-uniformity full-screen light guide plate and preparation method thereof

A technology of light guide plate and uniformity, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of dark area, poor light uniformity, affecting the full-screen display effect, etc., and achieve good uniformity and display effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] like Figures 1 to 5 As shown, a method for preparing a high-uniformity full-screen light guide plate includes the following steps:

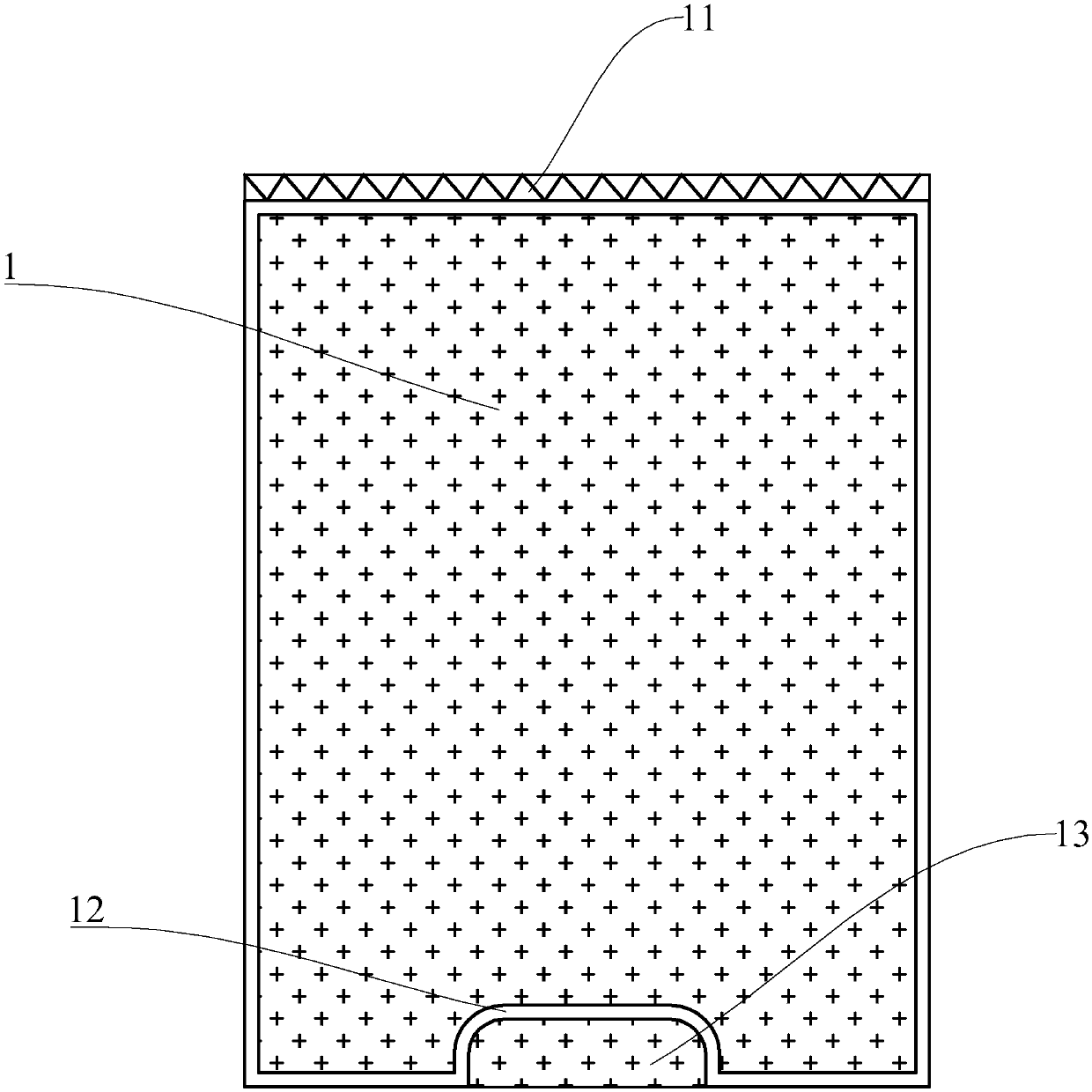

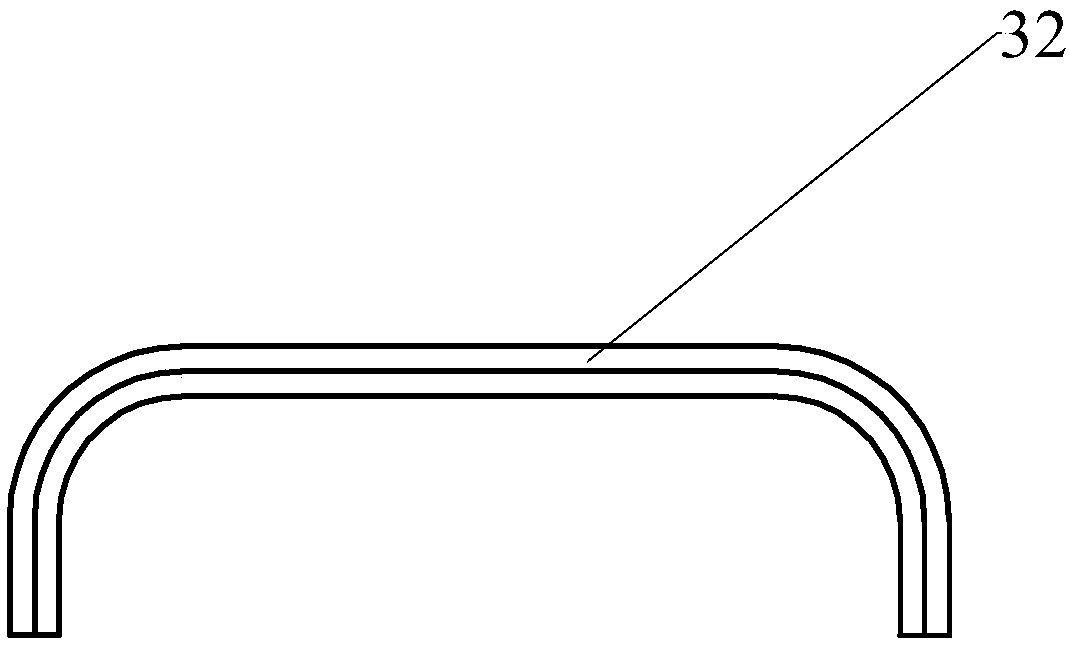

[0026] S1. Use the light guide plate production mold to form a rectangular light guide plate body 1 by injection molding. The light guide plate body 1 is provided with dots. One end of the light guide plate body is provided with a lamp slot 11, and the other end is provided with a cutting line 12. The two sides of the cutting line The ends are respectively connected to the edge of the light guide plate body, the cutting line is arc-shaped, and the area surrounded by the cutting line is the area to be cut 13;

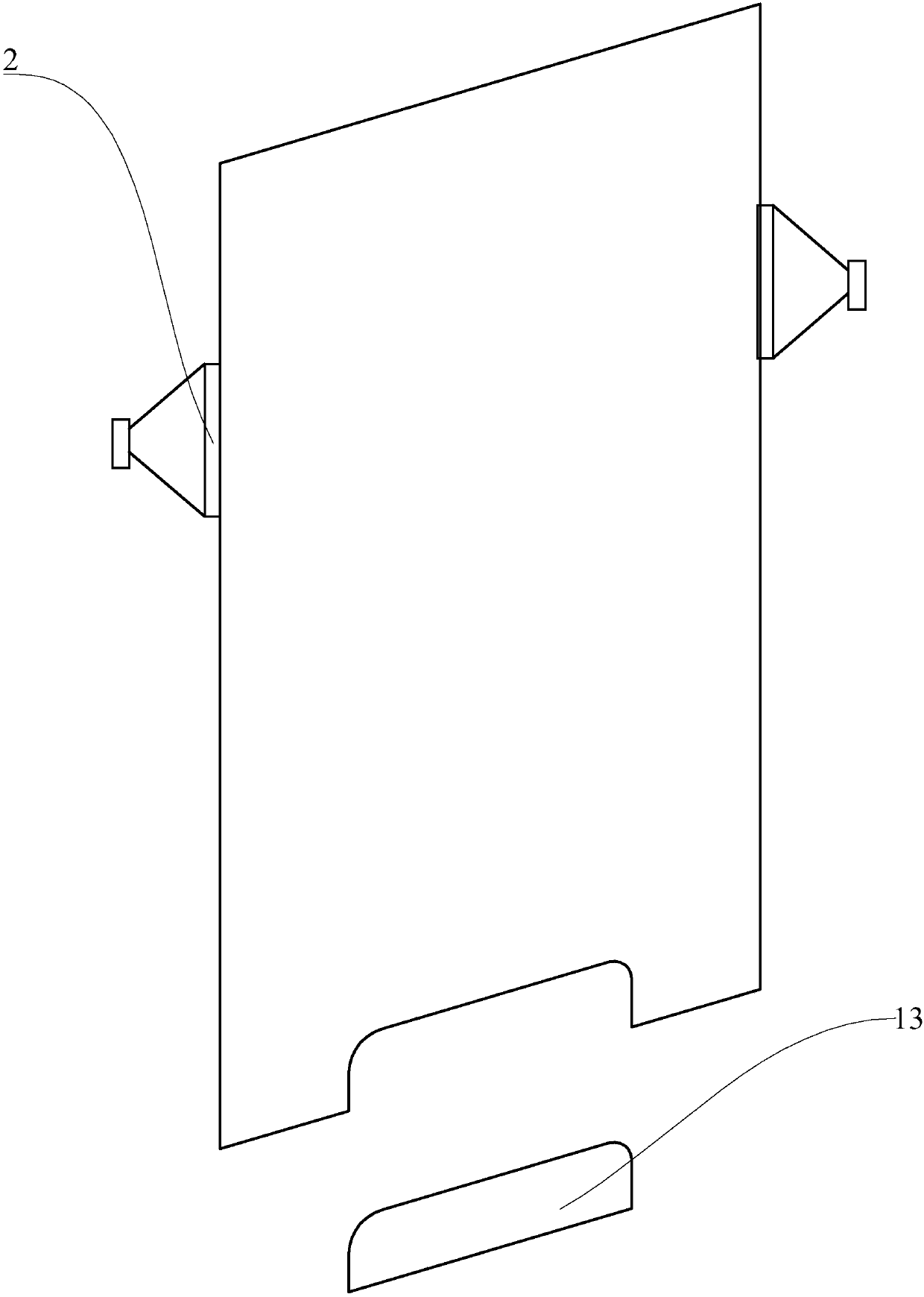

[0027] S2. Use the clamp 2 to clamp the non-dot area on the edge of the light guide plate, and place the light guide plate body 1 in the air, which can prevent the dots on the light guide plate from being worn, and then use the support plate to support it in the area to be cut. The support plate is far away from the Cutting line; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com