Drill bit for deep and large hole drilling

A drill bit, deep and large technology, applied in the field of drill bits for deep and large hole drilling processing, can solve the problems of low cutting efficiency, easy chipping inserts, limited processing aperture and depth, etc., and achieve high cutting strength and easy chip removal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

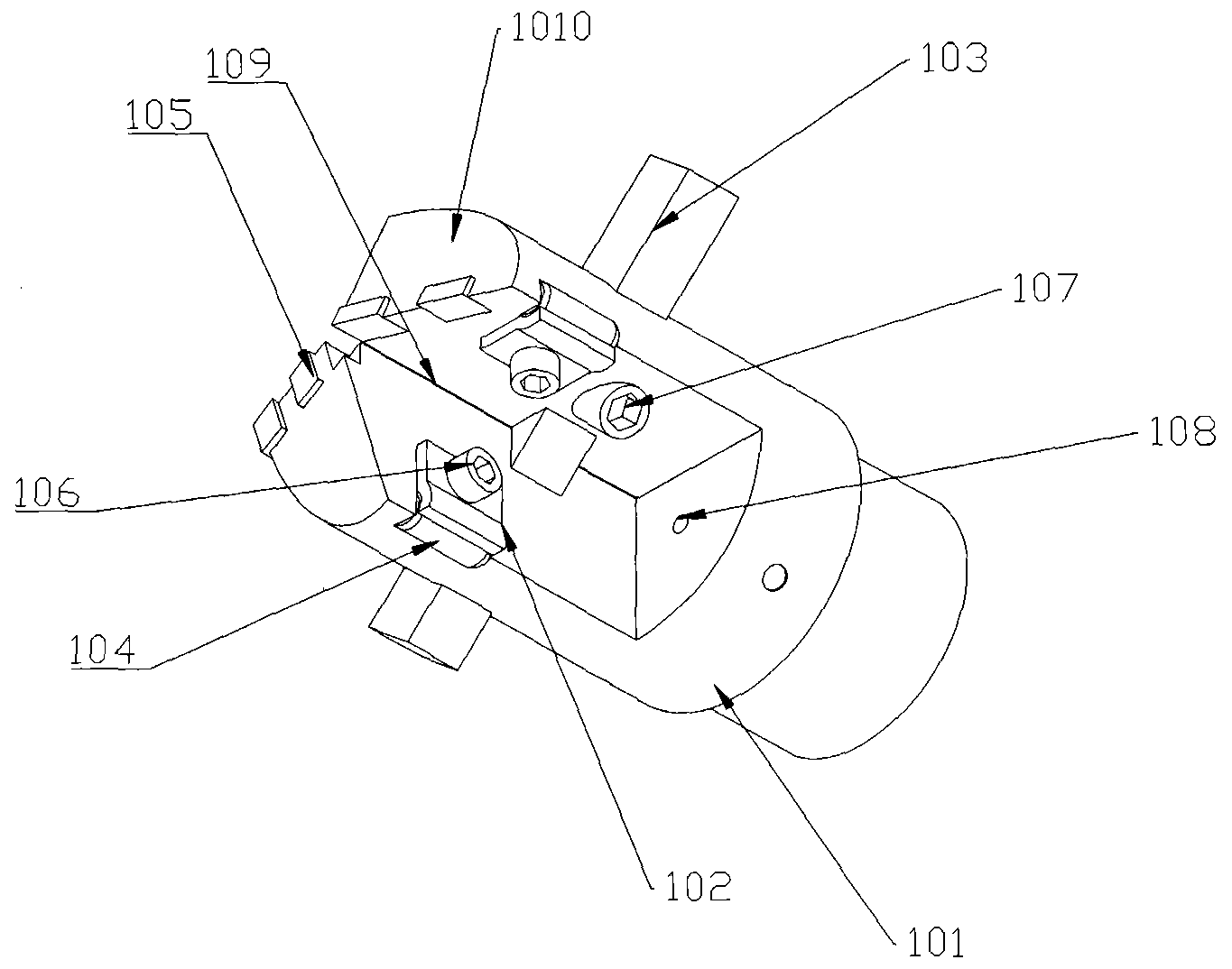

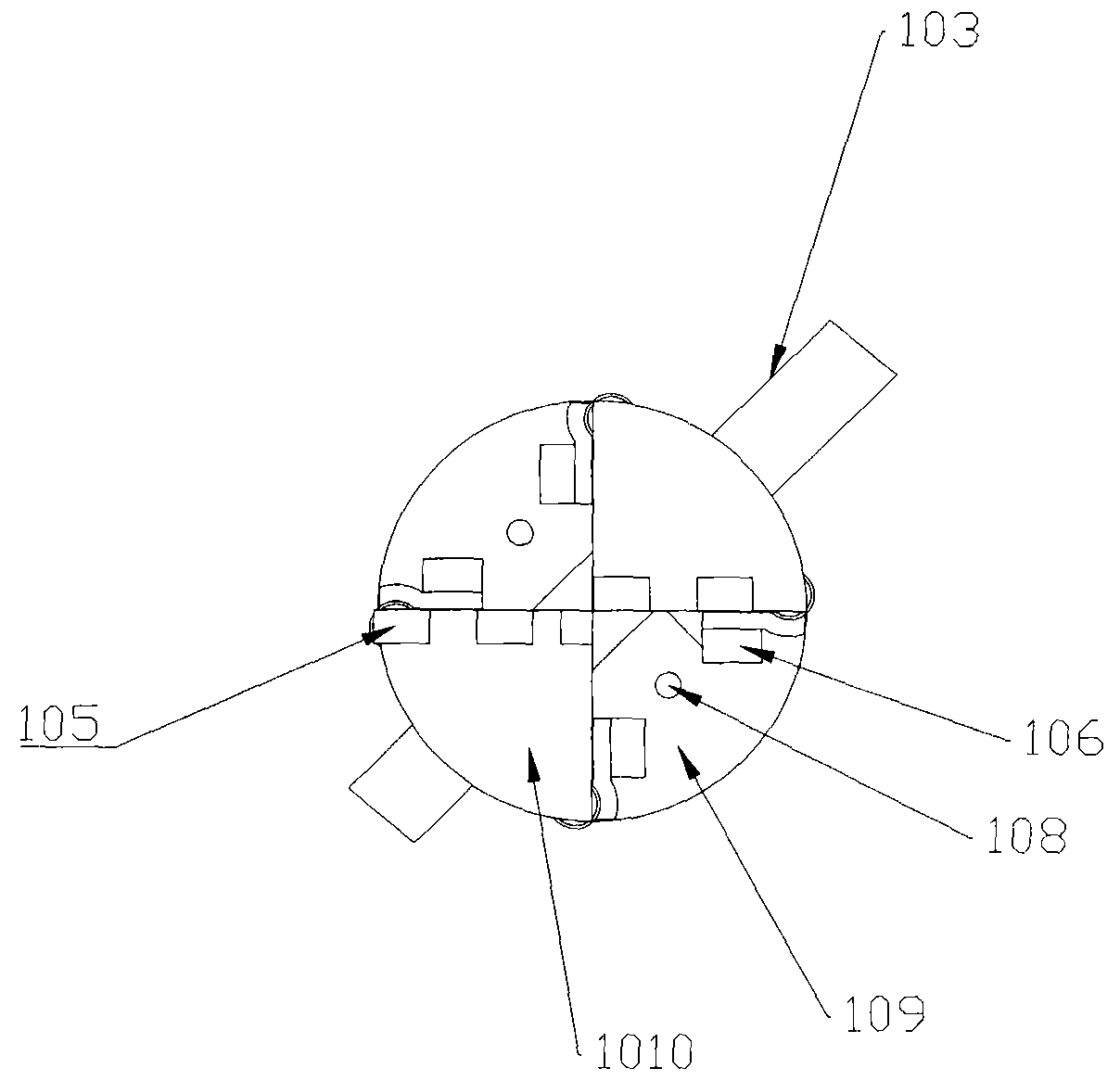

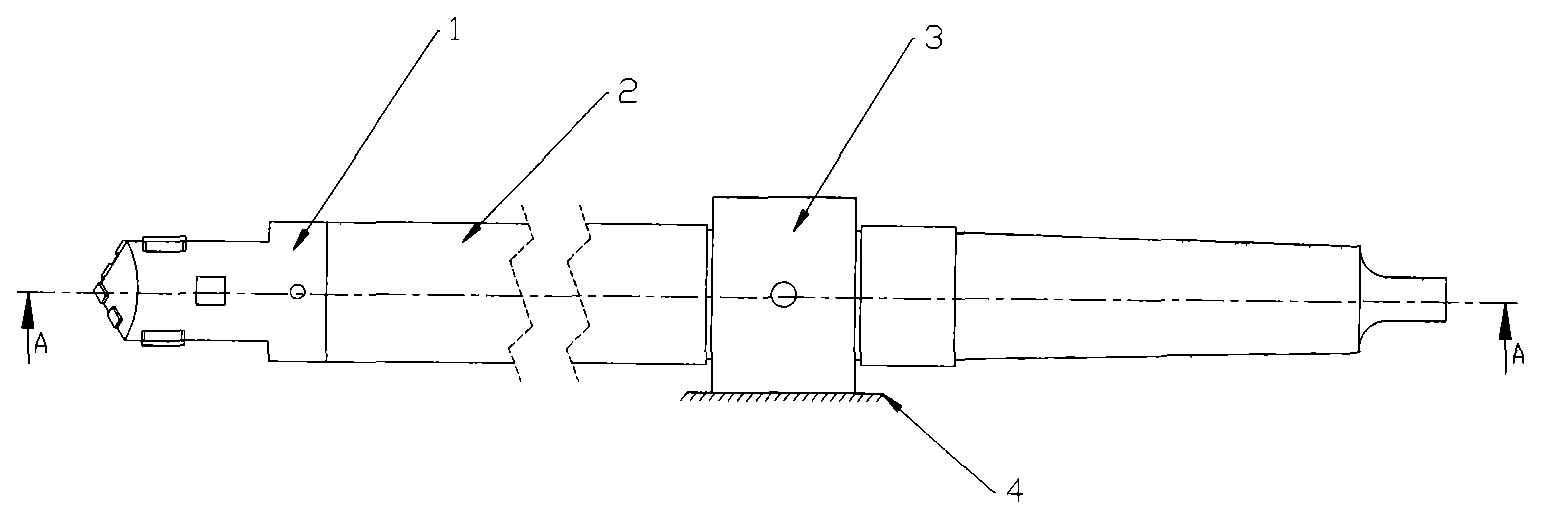

[0027] A drill bit for deep and large holes, such as figure 1 As shown, it includes a cutter head body 101, a roller pressing plate 102, a white steel blade 103, a support roller 104, a hard alloy blade 105, a roller pressing plate fixing screw 106, and a white steel knife fixing screw 107. The cutter head body is provided with a drilling chip removal area 109 in an X-shaped cross arrangement, and the drilling side surface 1010 on the cutter head body and the drilling chip removal area are symmetrically arranged on the cylinder where the cutter head body is located, and the drilling side surface 1010 Carbide blades 105 are cross-distributed on the cylindrical diameter position along the cutter head body, such as figure 2 shown. An arc hole for placing a cylindrical support roller 104 is machined on the axial side of the drilling chip removal area 109, and the support roller 104 is embedded in the arc hole, and the roller clamp 102 is fixed on the On the cutter head body, th...

Embodiment 2

[0029] A drill bit for deep and large holes, such as figure 1 As shown, it includes a cutter head body 101, a roller pressing plate 102, a white steel blade 103, a support roller 104, a hard alloy blade 105, a roller pressing plate fixing screw 106, and a white steel knife fixing screw 107. The cutter head body is provided with a drilling chip removal area 109 in an X-shaped cross arrangement, and the drilling side surface 1010 on the cutter head body and the drilling chip removal area are symmetrically arranged on the cylinder where the cutter head body is located, and the drilling side surface 1010 Carbide blades 105 are cross-distributed on the cylindrical diameter position along the cutter head body, such as figure 2shown. The circular arc holes for placing the cylindrical support rollers 104 are machined on the inner axial side of the drilling chip removal area 109, the support rollers 104 are embedded in the arc holes, and the roller clamp 102 is fixed by the roller cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com