Filtering bottle

A filter bottle and bottle body technology, applied in the field of filter bottles that can replace the filter element, can solve the problems of matching special tools, inconvenient assembly and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

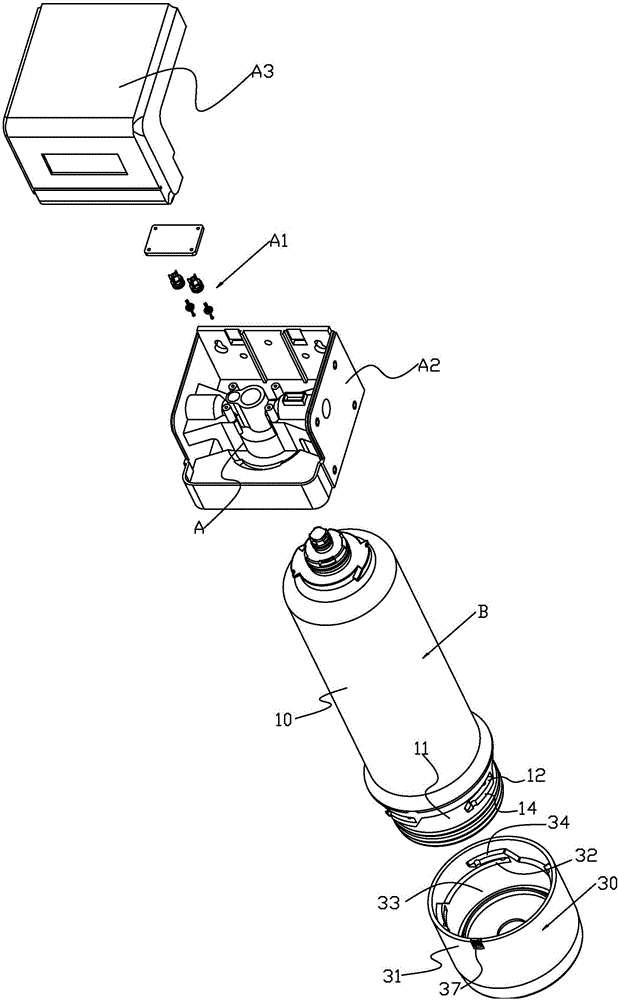

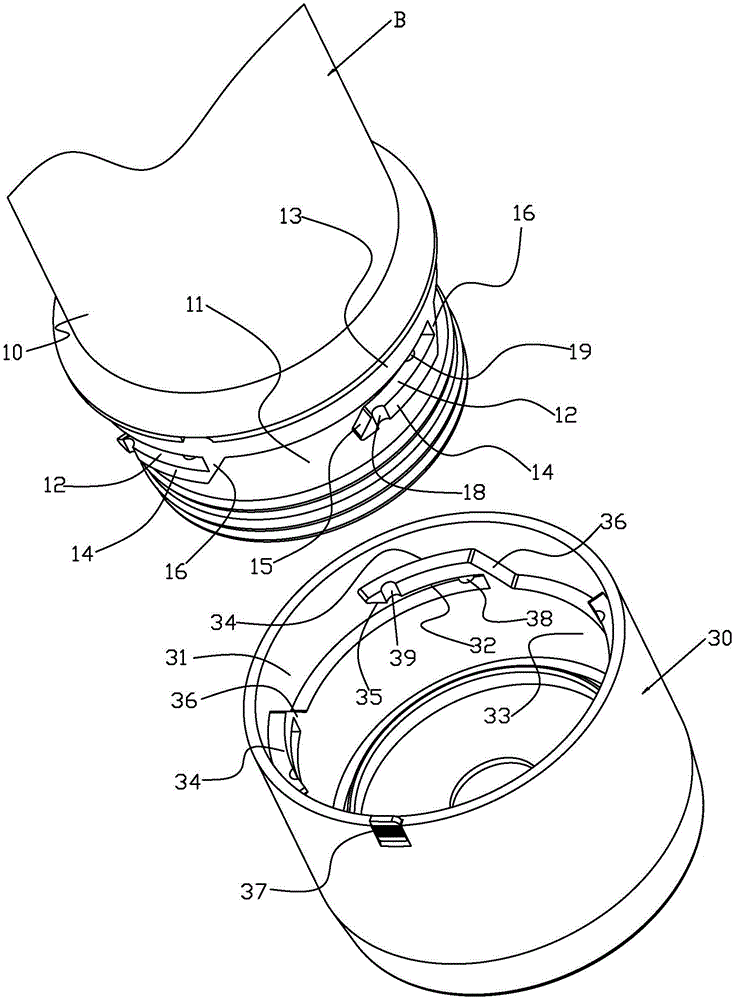

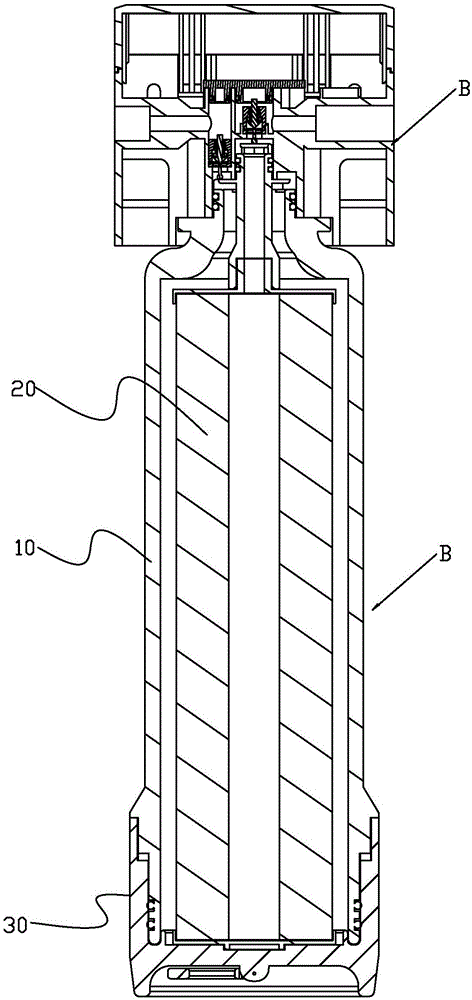

[0031] Please check figure 1 , figure 2 , image 3 and Figure 4 , The water purifier includes a base A and a filter bottle B. The filter bottle A includes a bottle body 10, a filter element 20 and a bottle cap 30. The bottle body 10 is provided with an accommodating space and a lower opening connected to the accommodating space. The filter element 20 is installed in the accommodating space of the bottle body 10. The bottle cap 30 is detachably attached to the bottle body 10 and closes the lower opening of the bottle body 10 ; the bottle body 10 is provided with a water inlet and a water outlet matching the filter element 20 . The base A is provided with two waterways that can respectively connect to external water sources and provide clean water to the outside. The machine base A and the filter bottle B are detachably connected together, and after assembly, the two waterways, the water inlet 11, and the water outlet 12 are respectively connected so that the water from th...

Embodiment 2

[0040] This embodiment differs from Embodiment 1 in that: Please refer to Figure 5 and Figure 6 , the bottle body 10 is provided with an accommodating space and an upper opening connected to the accommodating space, the filter element 20 is installed in the accommodating space of the bottle body 10, and the bottle cap 30 is detachably attached to the bottle body 10 and closed Bottle body 10 upper openings. The bottle cap 30 is provided with a water inlet and a water outlet matching the filter element 20 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com