mechanical seal

A technology of mechanical sealing device and sealing ring, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of sealing gap leakage, mechanical sealing device failure, etc., to reduce leakage rate, improve axial movement, improve shaft The effect of direction following performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

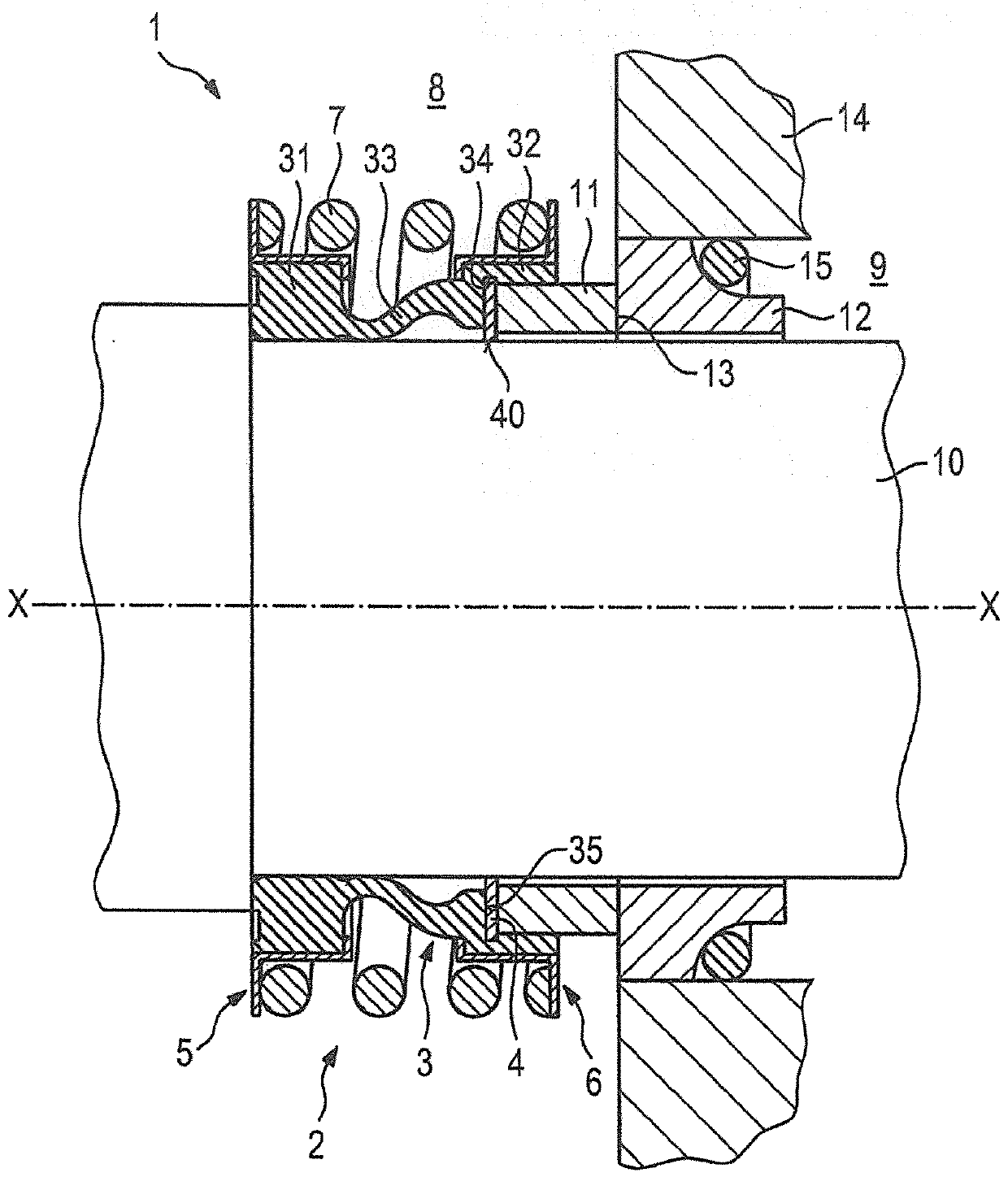

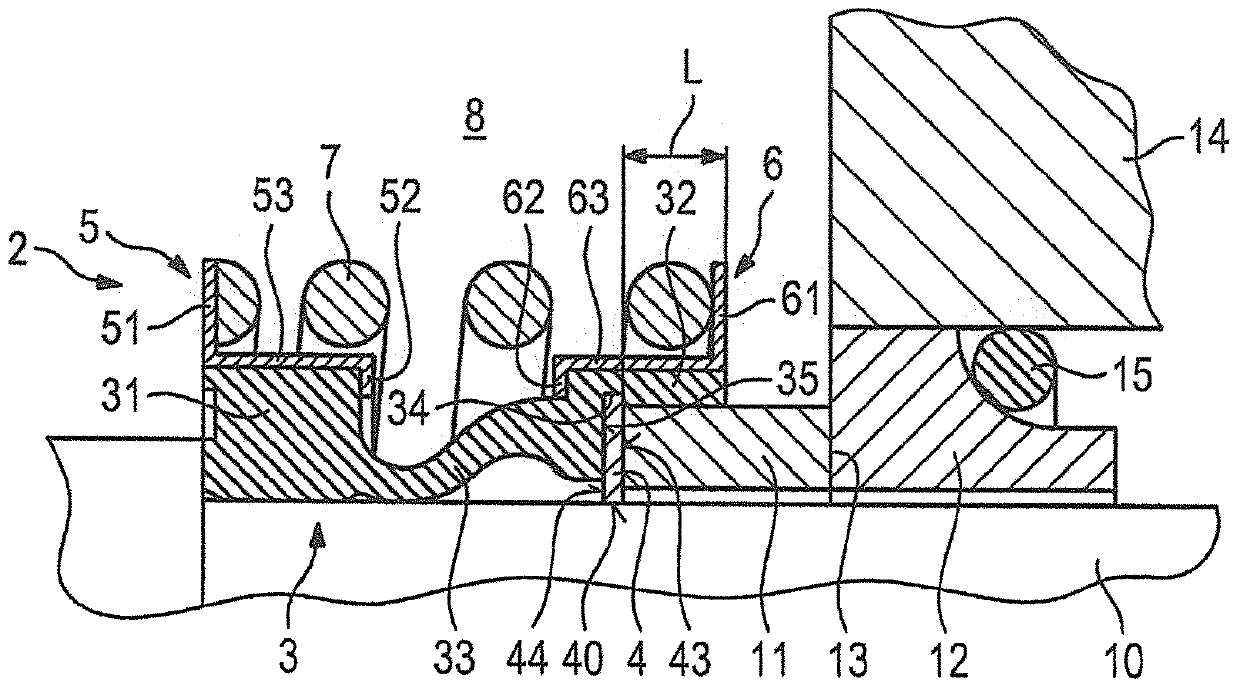

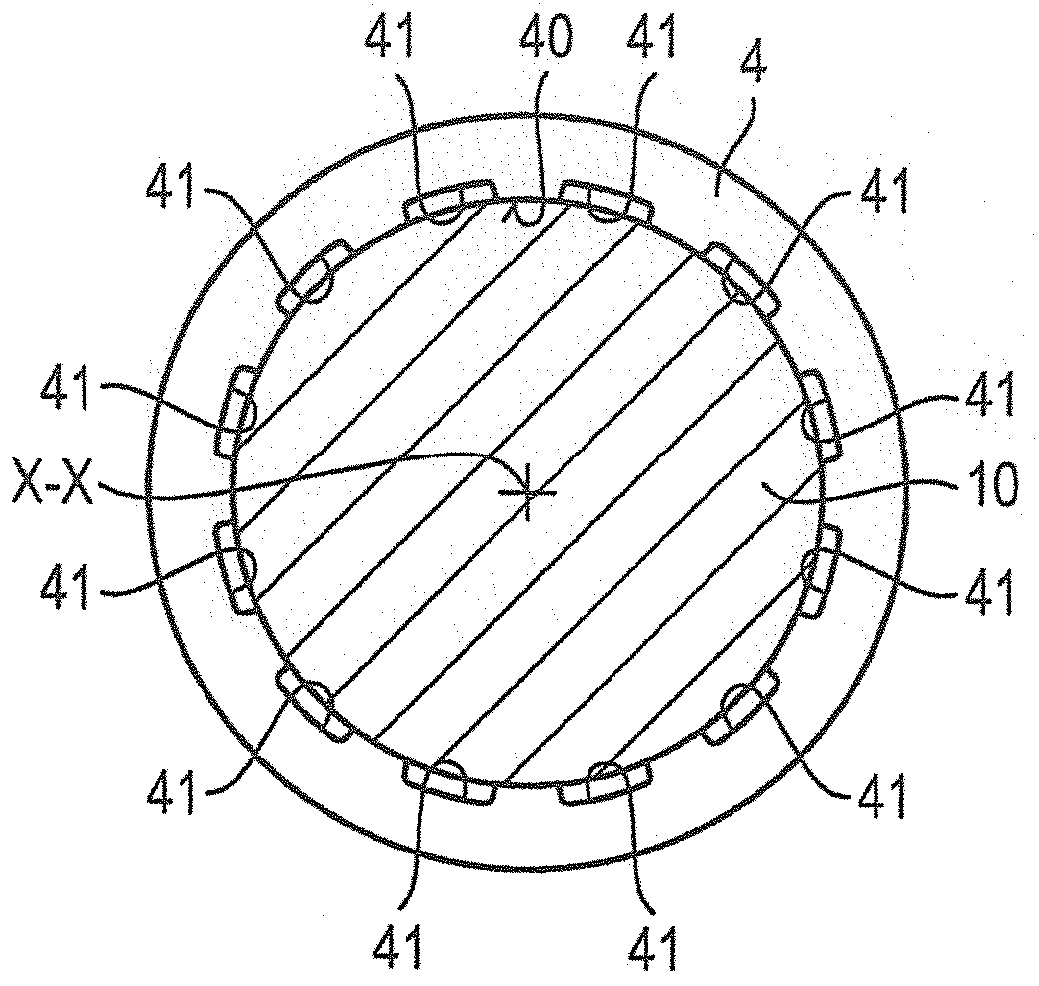

[0033] Refer to the following Figures 1 to 3 The mechanical seal device 1 according to the first embodiment of the present invention has been described in detail.

[0034] Such as figure 1 It is clear that the mechanical seal arrangement 1 comprises a rotating sealing ring 11 and a stationary sealing ring 12 which define a sealing gap 13 between them in a known manner. The mechanical sealing device 1 is used for sealing the first space 8 and the second space 9 .

[0035] The rotary sealing ring 11 is connected to and rotates with a rotating member 10 , which in this embodiment is a shaft. The stationary sealing ring 12 is connected to a stationary housing 14 . Reference numeral 15 denotes an auxiliary seal for sealingly fixing the sealing ring 12 relative to the housing 14 .

[0036] The mechanical seal arrangement 1 also comprises a bellows unit 2 which establishes the connection between the rotary seal ring 11 and the rotary component 10 . The bellows unit 2 comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com