Three-sharp wood drill

A woodworking drill and drill shank technology, which is applied to wood processing tools, wood drilling tools, wood turning tools, etc. Heart effect, long service life, and the effect of avoiding knife breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

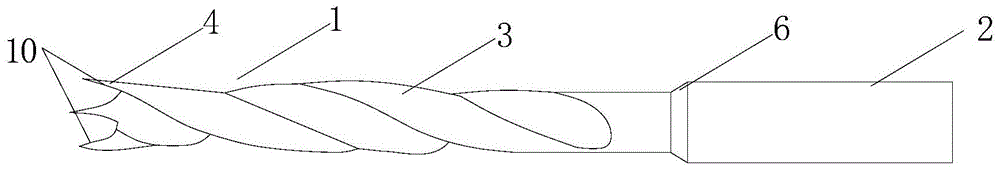

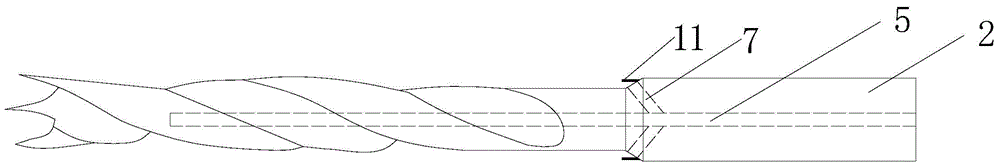

Embodiment 1

[0017] see Figure 1-Figure 3 As shown, the three-pointed woodworking drill includes a drill shank 2, a drill bit 1, and a drill neck 6 connecting the drill shank and the drill bit; the drill neck is tapered, and the drill neck and the drill shank are integrally formed. Shaped, tapered structure can bear the pressure, increase the strength of the joint between the drill shank and the drill bit, can effectively avoid the occurrence of broken tool and broken handle, and make the three-point woodworking drill have a longer service life; the peripheral surface of the drill bit Two helical cutting edges 3 are arranged on the top, and the edge and bottom of the cutting edge are cutting edges. Due to the use of two cutting edges, the cutting strength of the two cutting edges is high, which is convenient for use in high-speed cutting; the two cutting edges The junction of the edge of the cutting edge and the bottom cutting edge is provided with an outwardly protruding knife tip 4, and...

Embodiment 2

[0019] On the basis of the foregoing embodiment 1, the drill neck and the drill bit are welded. By adopting the welding form, different materials can be used for the drill shank and the drill bit, thereby saving manufacturing cost.

Embodiment 3

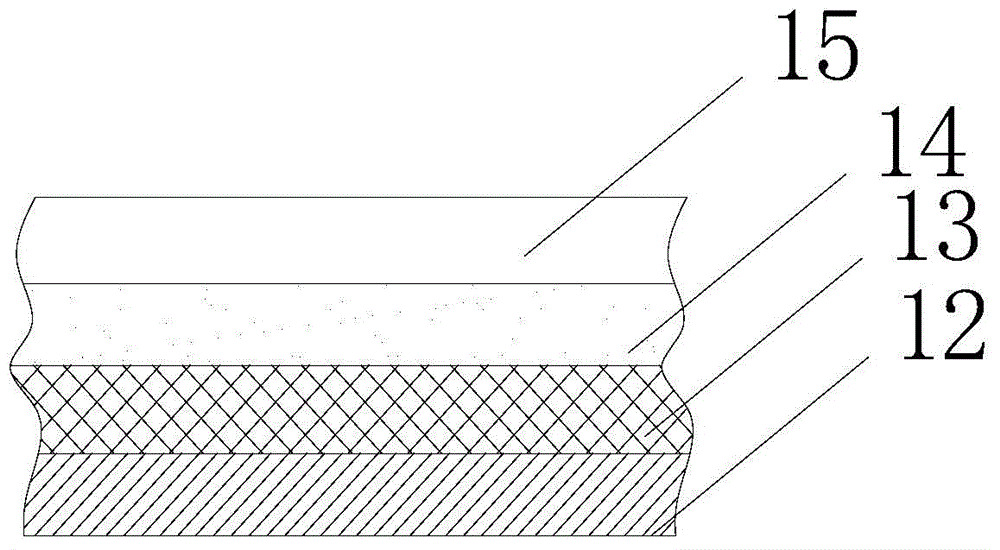

[0021] On the basis of the foregoing embodiment 2, the drill shank is made of No. 45 steel; the drill bit is made of cemented carbide. Tungsten carbide has high hardness and wear resistance, so that the drill bit can be used for a long time; and because the price of No. 45 steel is low, the manufacturing cost can be effectively reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com