Method for preparing arsenic-cadmium passivator, arsenic-cadmium passivator prepared through method and application

A passivator and activator technology, which is applied in the field of arsenic and cadmium passivators and the preparation of arsenic and cadmium passivators, can solve the problem that arsenic and cadmium cannot be passivated efficiently at the same time, achieve good curing stability, overcome easy loss, and achieve good results. long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation of embodiment 1 arsenic cadmium passivator

[0041] Mix 100g feldspar, 220g limestone, 12g ferric sulfate, 9g magnesite and 8g sodium sulfate and grind to 200 mesh, roast at 1200°C for 2.0h, cool and pulverize, roast clinker, K 2 FeO 4 and MnSO 4 Add water at a mass ratio of 7.3:0.9:1, adjust the pH of the system between 6 and 10, and react for 1.5 hours, then filter, and dry the obtained solid at 100°C to obtain a passivator.

[0042] In the prepared passivator, effective silicon is 25.5wt% (citrate soluble, with SiO 2 ), the available calcium is 42.8wt% (calculated as CaO), and the iron content is 4.21wt% (calculated as Fe 2 o 3 In terms of), the manganese content is 6.88% (as MnO 2 ), the contents of harmful elements Hg, As, Cd, Pb, and Cr are 0.5mg / kg, 3.26mg / kg, 2.14mg / kg, 10.35mg / kg, and 9.57mg / kg respectively, in line with the agricultural industry standard "NY 1110- 2010 Limit requirements for mercury, arsenic, cadmium, lead, and chromium i...

Embodiment 2

[0043] The preparation of embodiment 2 arsenic cadmium passivator

[0044] Mix 100g of illite, 200g of calcium carbonate, 15g of iron sulfate, 6g of magnesium sulfate and 7g of potassium sulfate and grind them to 250 mesh, roast at 1250°C for 1.5h, cool and pulverize, roast clinker, FeSO 4 ·7H 2 O and KMnO 4 Add water at a mass ratio of 30:5.2:1, adjust the pH of the system between 6 and 10, and react for 1.0 h, then filter, and dry the obtained solid at 102°C to obtain a passivator.

[0045] In the prepared passivator, effective silicon is 26.8wt% (citrate solubility, with SiO 2 ), the available calcium is 40.5wt% (calculated as CaO), and the iron content is 4.58wt% (calculated as Fe 2 o 3 In terms of), the manganese content is 1.66wt% (as MnO 2 ), the contents of harmful elements Hg, As, Cd, Pb, and Cr are 1.2mg / kg, 2.15mg / kg, 1.04mg / kg, 8.32mg / kg, and 10.85mg / kg respectively, in line with the agricultural industry standard "NY 1110- 2010 Limit requirements for mercury...

Embodiment 3

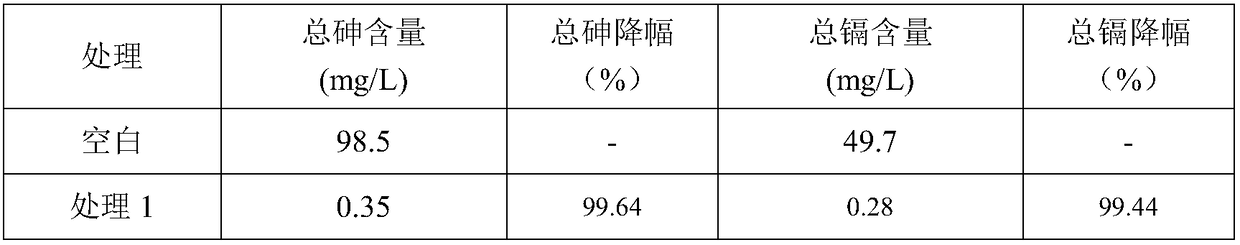

[0046] Embodiment 3 adopts passivating agent to control arsenic and cadmium composite polluted site soil

[0047] Soil for test: the soil of an arsenic and cadmium complex polluted site in Changde City, Hunan Province. The total arsenic content in the soil is 1017mg / kg, and the total cadmium content is 205mg / kg.

[0048] Passivator: the passivator prepared in Example 1.

[0049] The specific repair test method is as follows:

[0050] (1) Air-dry the arsenic-cadmium composite polluted soil, grind it through a 20-mesh sieve, take two parts of 100g of the under-sieve and place it in a beaker, and treat it as a blank control without adding a passivating agent. In the treatment 1, passivating agent / ( The mass ratio of As+Cd) is 150 to add passivating agent, fully mix;

[0051] (2) adding a pH regulator aqueous solution to adjust the pH to 6-9, and adding water to keep the soil moisture content at 32%;

[0052] (3) Seal with a plastic film, and set a plurality of small holes to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com