Chrome-free fingerprint resistant water-based paint

A water-based paint and fingerprint-resistant technology, applied in the field of paint, can solve the problems of chromate pollution, poor electrical conductivity, insufficient corrosion resistance, etc., and achieve the effects of scratch resistance, blackening resistance, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

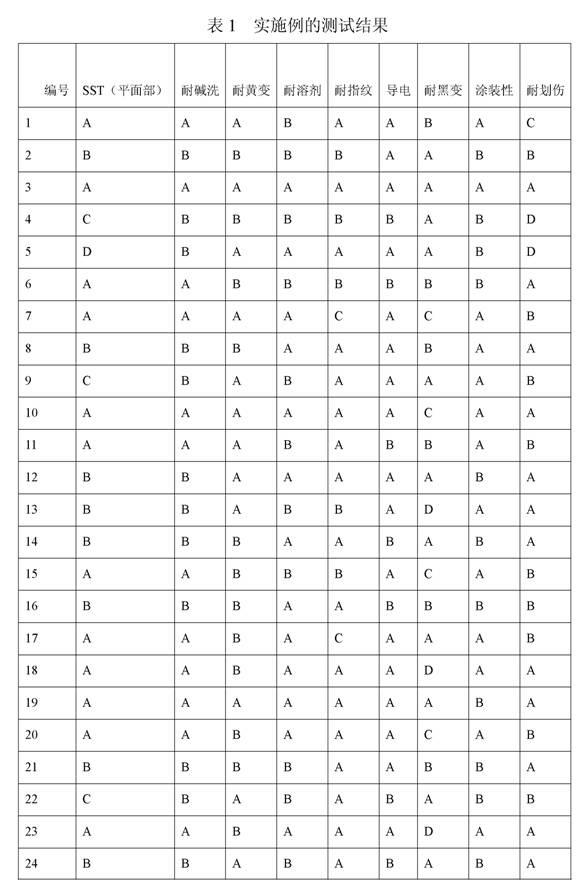

Examples

Embodiment 1

[0025] The preparation steps of a chromium-free fingerprint-resistant water-based coating of the present invention are as follows: the formula ratio is by weight:

[0026] (1) Preparation of nano-oxide concentrated slurry: Mix 1 part of silicon dioxide, 0.1 part of modifier silane coupling agent and 98 parts of water, then perform high-speed shear dispersion, stir at 500r / min for 2 hours to prepare nano-oxide Concentrated slurry.

[0027] (2) Mixing preparation: take 5 parts of nano-oxide concentrated slurry prepared in step (1), 30 parts of water-based polyurethane emulsion, 0.2 parts of zirconium ions, 0.3 parts of titanium ions, 0.05 parts of phosphoric acid and 1 part of wax, and mix well Adjust the pH to 7 to obtain the product chrome-free anti-fingerprint water-based paint.

[0028] The role of the main components of the chromium-free fingerprint-resistant water-based paint of the present invention:

[0029] Water-based polyurethane emulsion is the main film former, wh...

Embodiment 2

[0035] The preparation steps of a chromium-free fingerprint-resistant water-based coating of the present invention are as follows: the formula ratio is by weight:

[0036] (1) Preparation of nano-oxide concentrated slurry: Mix 30 parts of zinc oxide, 15 parts of modifier silane coupling agent and 55 parts of water, then perform high-speed shear dispersion, and stir at 3500r / min for 0.5h to prepare nano-oxide Concentrated slurry.

[0037] (2) Mixing preparation: Take 80 parts of nano-oxide concentrated slurry prepared in step (1), 75 parts of water-based polyurethane emulsion, 1 part of molybdate ion, 2 parts of vanadate ion, 2 parts of tungstate ion, phosphate antirust 5 parts of pigment and 5 parts of wax are fully mixed and adjusted to pH 8 to obtain the product chrome-free anti-fingerprint water-based paint.

Embodiment 3

[0039] The preparation steps of a chromium-free fingerprint-resistant water-based coating of the present invention are as follows: the formula ratio is by weight:

[0040] (1) Preparation of nano-oxide concentrated slurry: Mix 15 parts of titanium dioxide, 10 parts of modifier silane coupling agent and 80 parts of water, then perform high-speed shear dispersion, stir at 2000r / min for 1h to prepare concentrated nano-oxide pulp.

[0041] (2) Mixing preparation: Take 60 parts of nano-oxide concentrated slurry prepared in step (1), 50 parts of water-based polyurethane emulsion, 1 part of titanium ion, 2 parts of molybdate ion, 1 part of phosphate, amino trimethylene phosphonic acid 2 parts of ATMP and 3 parts of wax, mix well and adjust the pH to 9 to obtain the product chrome-free anti-fingerprint water-based coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com