ALuminium plate with envelope and electronic equipment parts using the same

A film and aluminum plate technology, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., can solve problems such as cracks and peeling of resin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

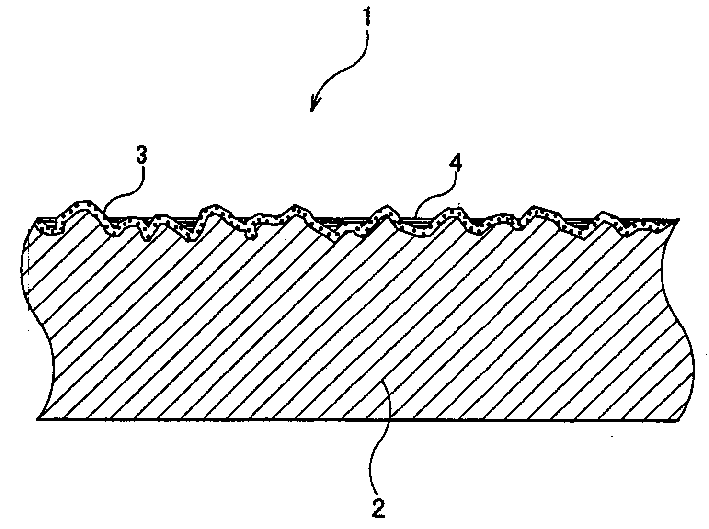

[0087] In Comparative Example 8 in which the amount of lubricant is less than the lower limit of the specified range of the present invention, the friction coefficient becomes large (0.77), and after the bending test, obvious cracks (peeling) in the resin film can be seen, that is, the moldability is deteriorated. On the other hand, in Comparative Example 9 in which the amount of lubricant exceeds the upper limit, scratch resistance deteriorates. (The influence of the amount of colloidal silica added)

[0088] In Comparative Example 10 in which the addition amount of colloidal silica exceeded the upper limit of the specified range of the present invention, the bending workability deteriorated, and therefore, very slight cracks were seen in the resin film.

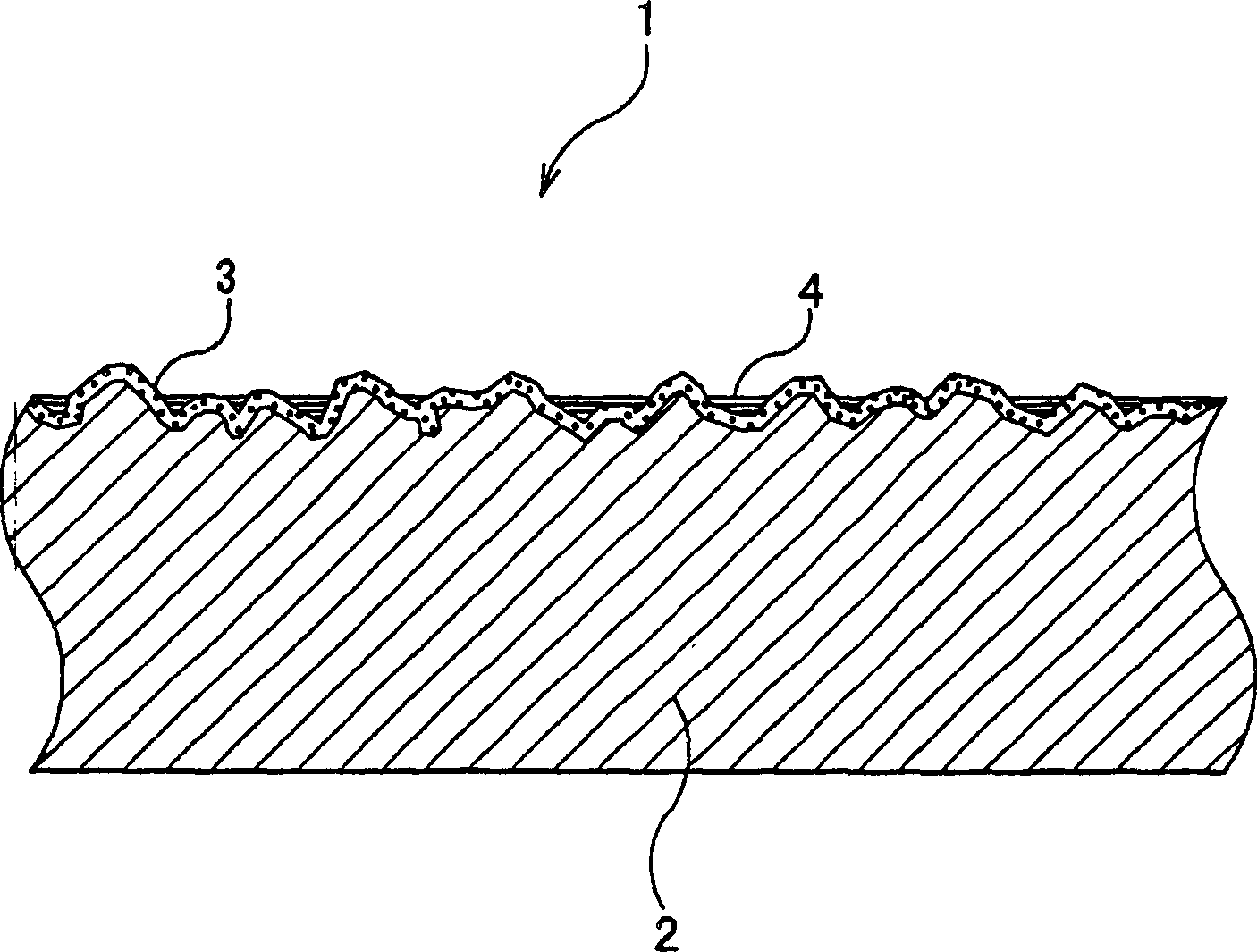

[0089] On the other hand, it was confirmed that the surface roughness (center line average roughness Ra) of the aluminum sheet, the adhesion amount of the corrosion-resistant coating, the type and thickness of the resin coating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com