Patents

Literature

138results about How to "Reduce bad appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

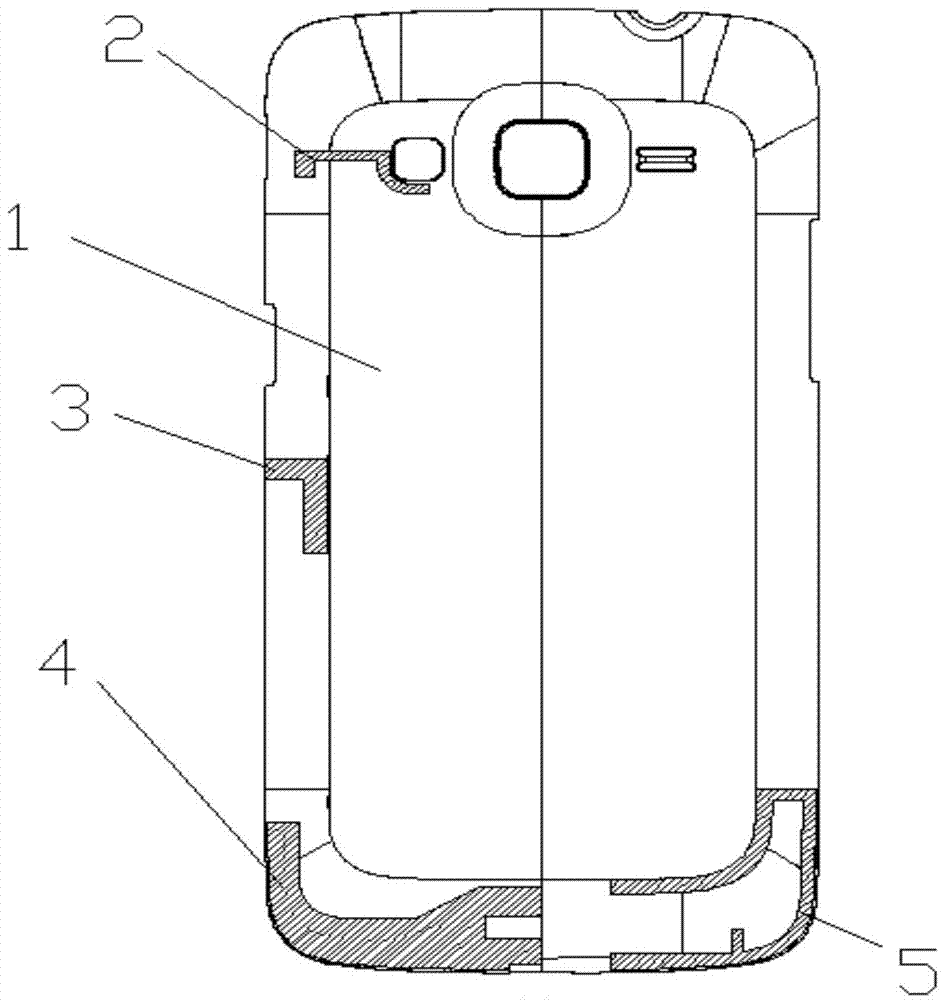

Method for manufacturing shell of electronic product

ActiveCN103702529ASimilar or consistent flatnessAvoid problems that affect appearanceElectrical apparatus casings/cabinets/drawersManufacturing cost reductionFile design

The invention discloses a method for manufacturing a shell of an electronic product. The method comprises the following steps of A, generating of 3D (Three-Dimensional) drawing file design of an injection mold: reserving an antenna groove by the injection mold when a mold opening 3D drawing file design is generated; B, injection mold processing: carrying out shape processing on the antenna groove when a mold core is processed so as to ensure the integrated forming of an antenna and the shell of the product when the antenna is subsequently processed, and enabling the shell of the product not to be subjected to poor appearance when surface processing is carried out; C, injection molding machine molding: completing the injection molding of the product by utilizing the injection mold, which is already designed and processed in a mold, of the antenna groove; D, mobile phone antenna processing: directly processing a mobile phone antenna in the antenna groove on the surface or the inner wall of a mobile phone plastic piece; E, mobile phone surface processing and coating. According to the method disclosed by the invention, the bottlenecks of a surface decoration technology that the surface of the product is rugged when the mobile phone antenna is assembled or printed on the surface of the product, and the surface of the product needs to be sanded when the mobile phone antenna is produced can be broken through, highly-textured appearance on the surface of the product can be generated, the manufacturing cost can be reduced, and the yield of the product can be increased.

Owner:KUNSHAN RUIXIANG XUNTONG COMM TECHCO

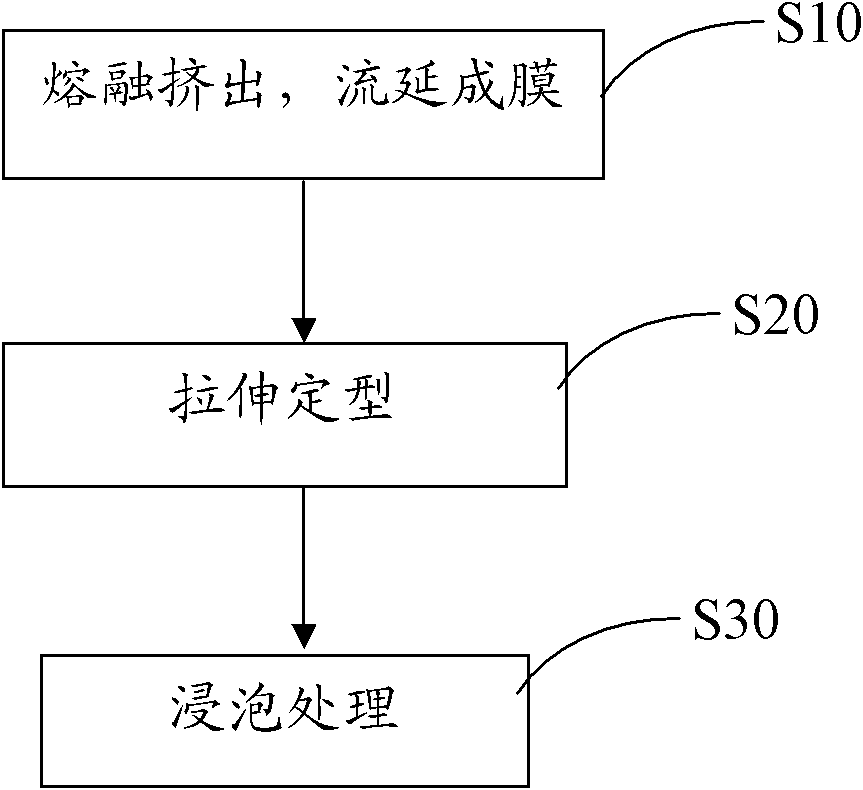

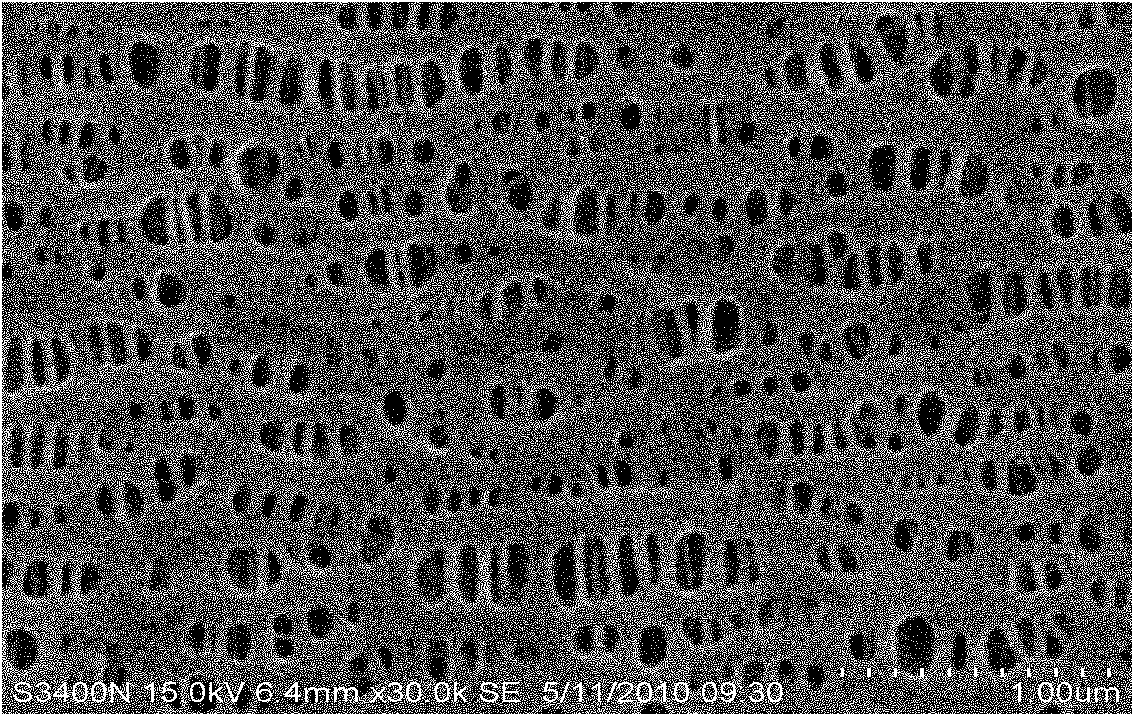

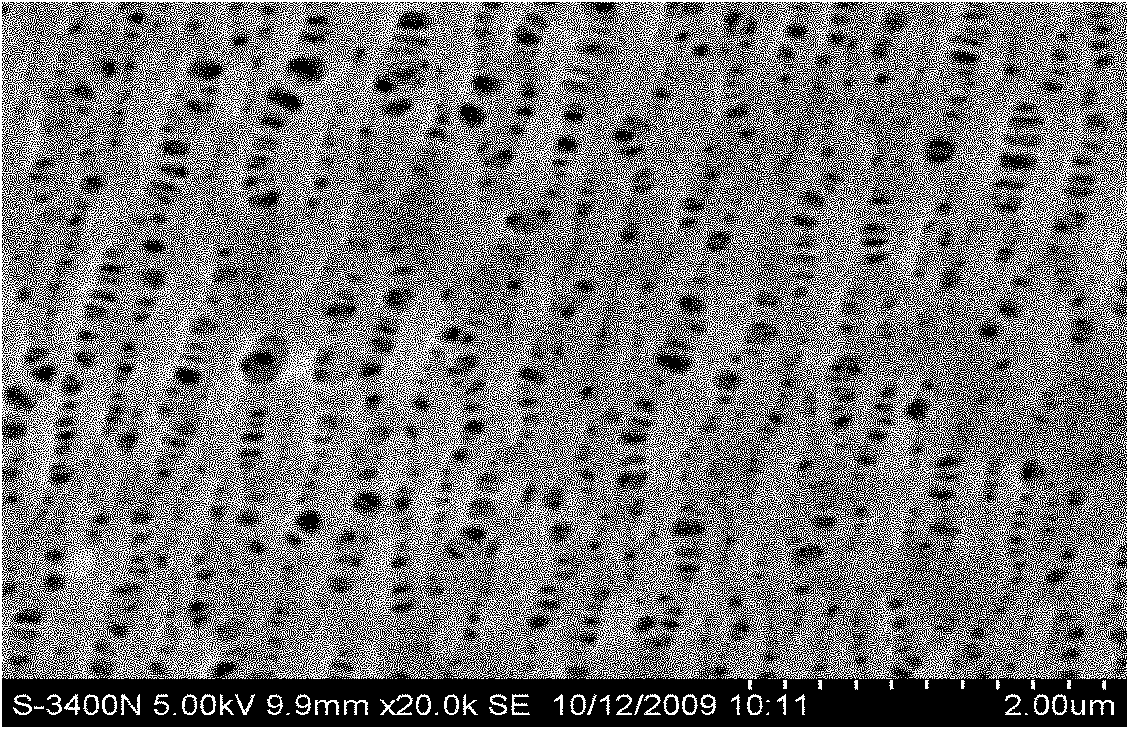

Polyolefin microporous membrane preparation method and use

ActiveCN102153771AImprove breathabilityUniform performance distributionSecondary cellsCell component detailsPolyolefinPolymer science

The invention provides a polyolefin microporous membrane preparation method, which comprises the following steps: subjecting polyolefin to melt extrusion at 180 to 260 DEG C, and casting a membrane to obtain polyolefin cast base membrane; drawing the polyolefin cast base membrane, and performing heat setting treatment to obtain a preformed polyolefin microporous membrane; and soaking the preformed polyolefin microporous membrane in an organic solvent with a surface tension less than 30mN / m, soaking, removing the organic solvent and obtaining the polyolefin microporous membrane. The invention also provides the use of the polyolefin microporous membrane preparation method in the preparation of diaphragm or lithium ion batteries. In the preparation method, the preformed polyolefin microporous membrane formed by drawing and heat setting is soaked in the organic solvent with the surface tension less than 30mN / m, so the obtained polyolefin microporous membrane has rounder and bigger holes, the breathability is uniformly distributed along the transverse direction of the microporous membrane, and thus, the breathability of the microporous membrane is improved.

Owner:SHENZHEN SENIOR TECH MATERIAL

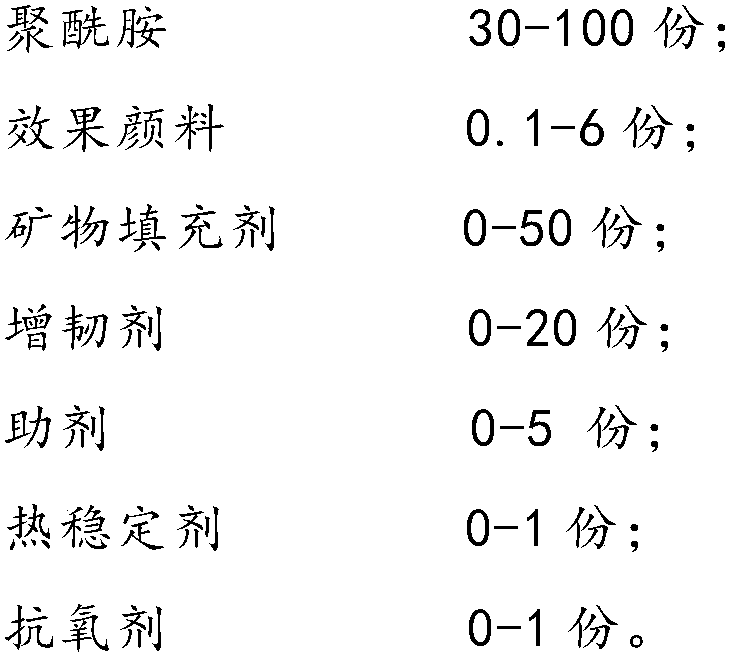

Low-smell high-gloss free-spraying polyamide composition and preparation method thereof

The invention discloses a low-smell high-gloss free-spraying polyamide composition which comprises, by weight, 30-100 parts of polyamide, 0.1-6 parts of effect pigments, 0-50 parts of mineral fillers,0-20 parts of flexibilizers, 0-5 parts of auxiliaries, 0-1 part of heat stabilizers and 0-1 part of antioxidants. Monomers and low-polymer components remaining in the production process of polyamideare eliminated by reaction in the preparation process, and the smell of a low-smell nylon composition is improved. Besides, surface defects of free-spraying workpieces are decreased, brightness is improved, the free-spraying workpieces are closer to appearance effects of painted parts, the smell of the nylon composition is further removed by a smell removal process, and glossiness and tensile strength are further improved by introducing the mineral fillers and the flexibilizers.

Owner:SHANGHAI KINGFA SCI & TECH +2

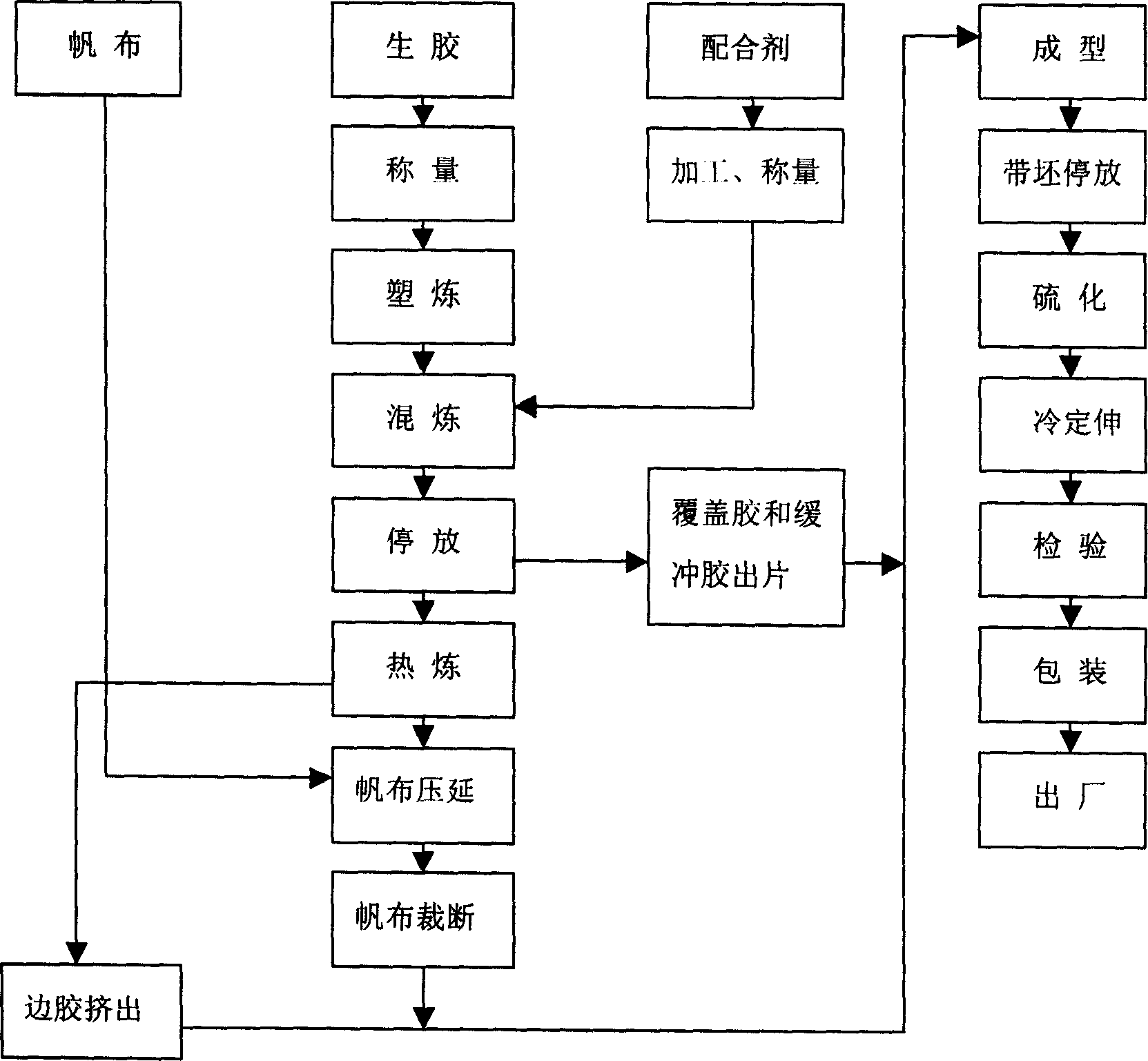

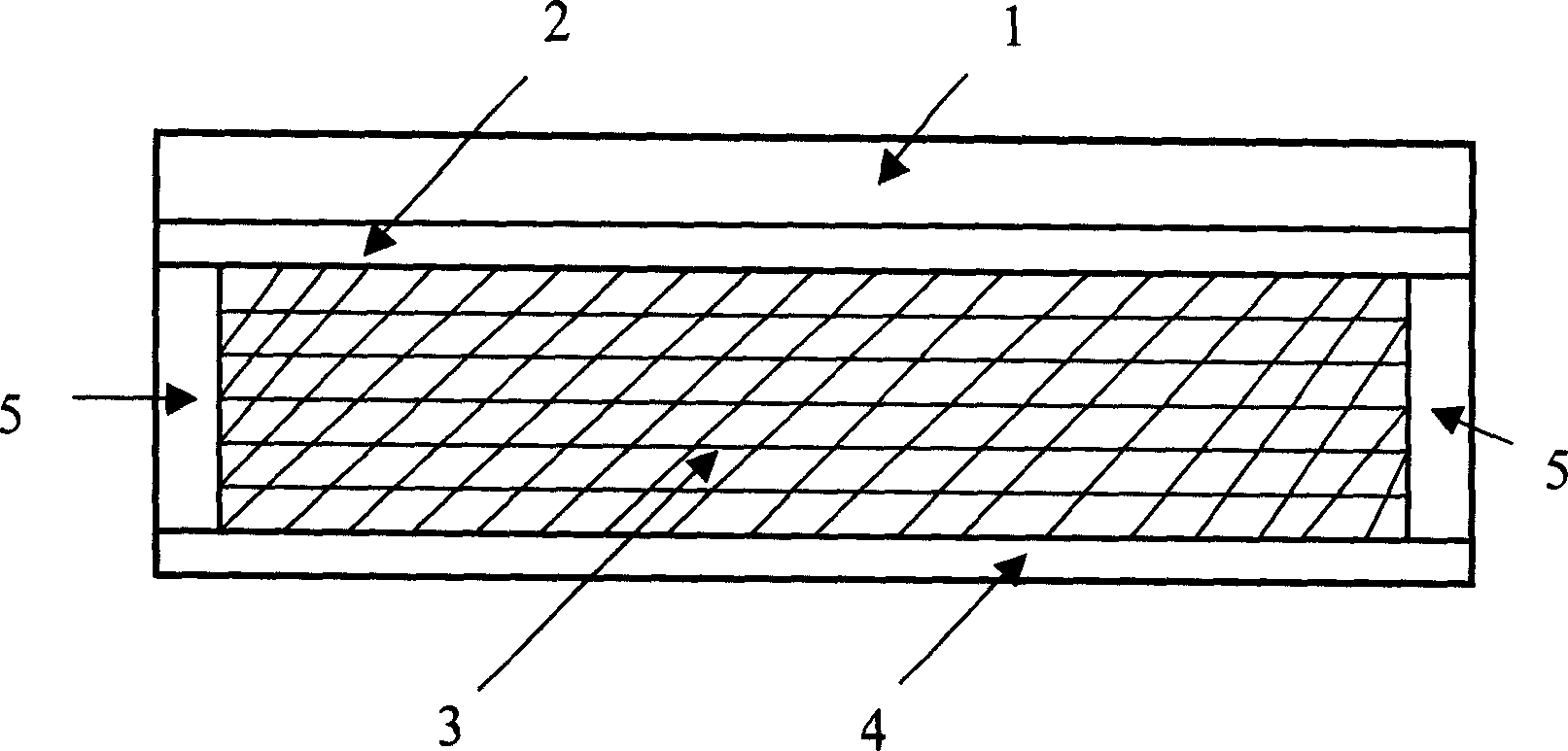

Impact resistance high wearing-proof conveyer belt

An anti-impact and anti-wear conveying belt features that the rubber layer covered on its surface is proportionally prepared from natural rubber, synthetic rubber, sulfur, zinc oxide, stearic acid, promoter, reinforcing agent, softening agent and anti-ageing agent.

Owner:阳江市北山胶化有限公司

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

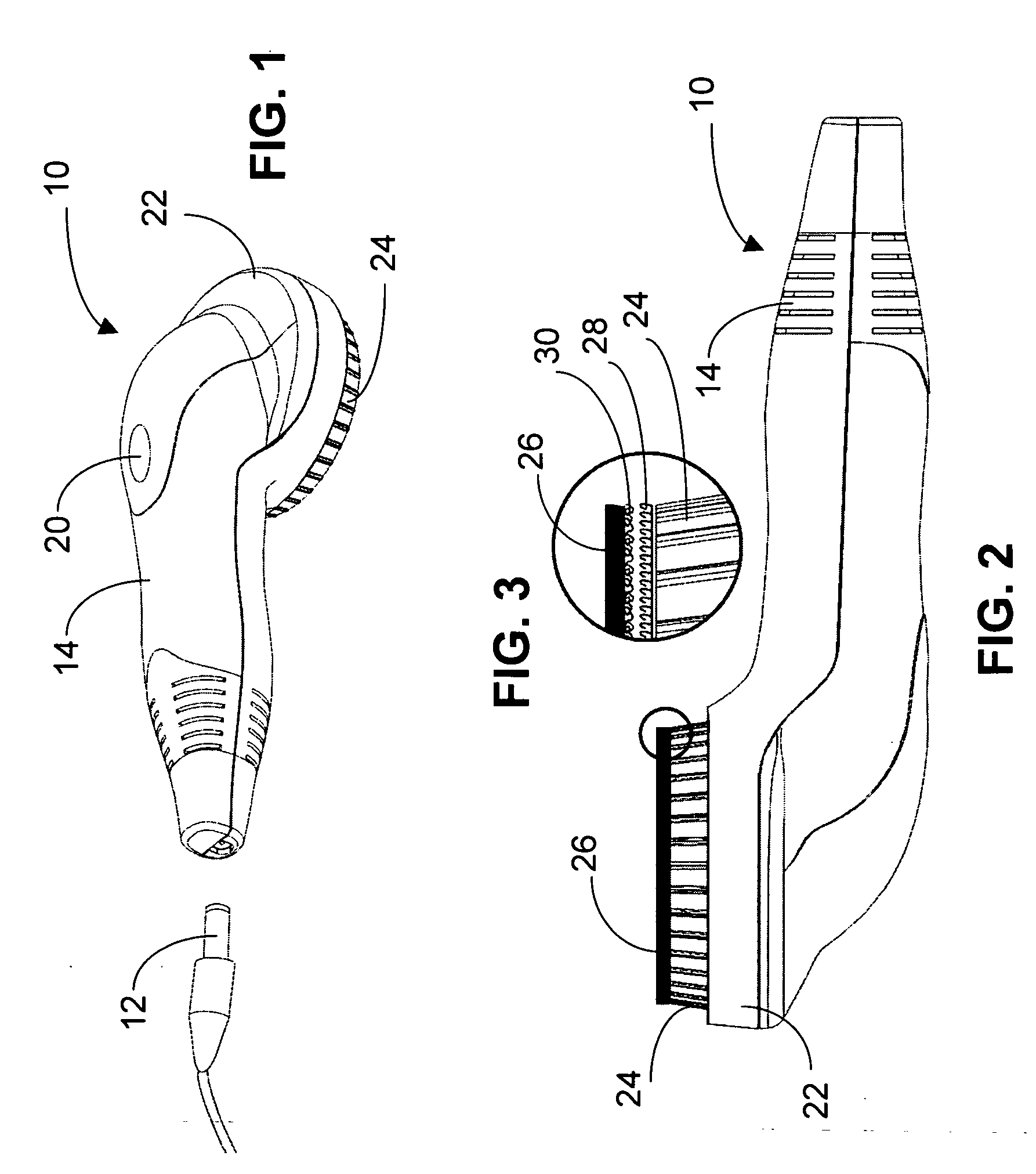

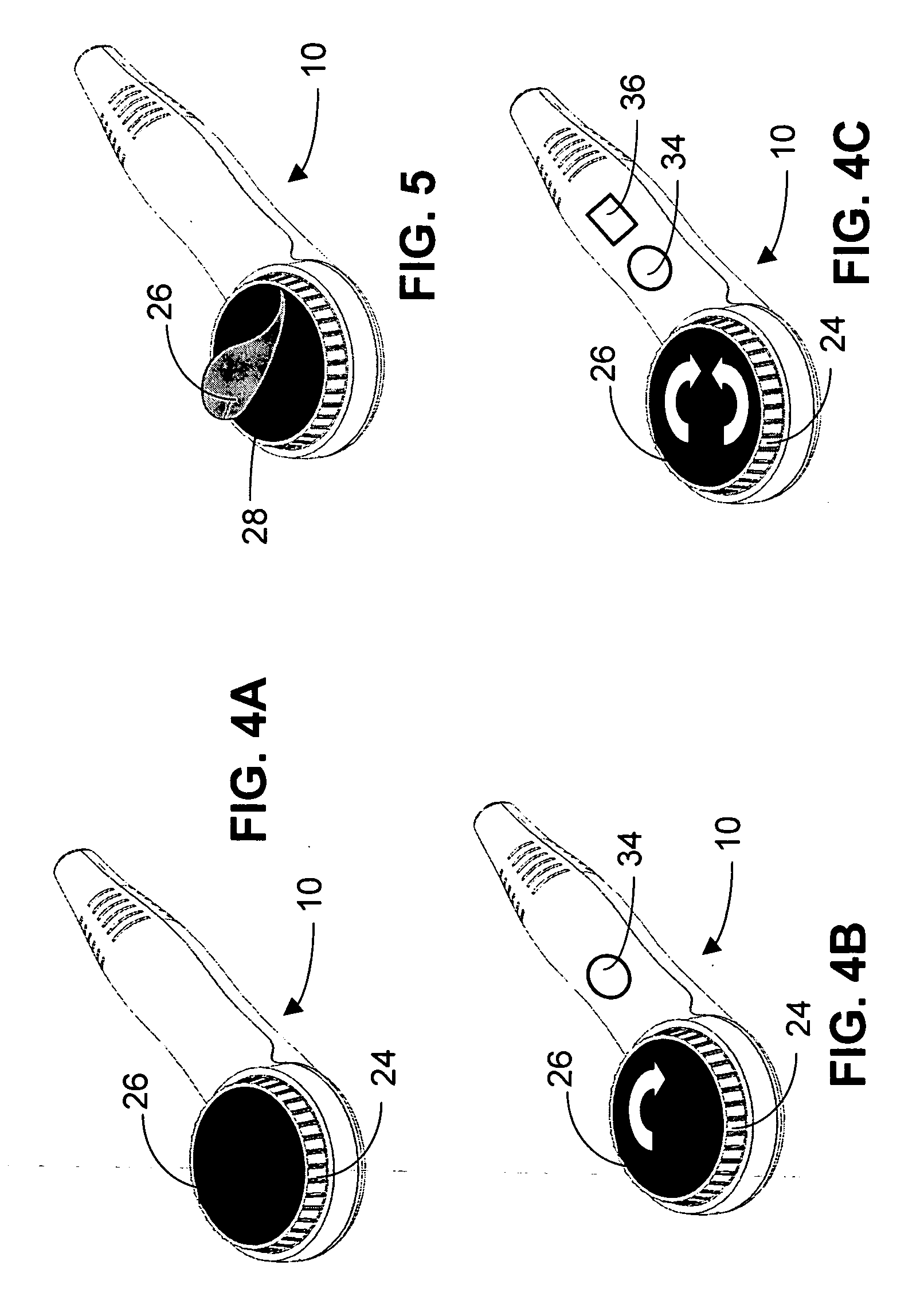

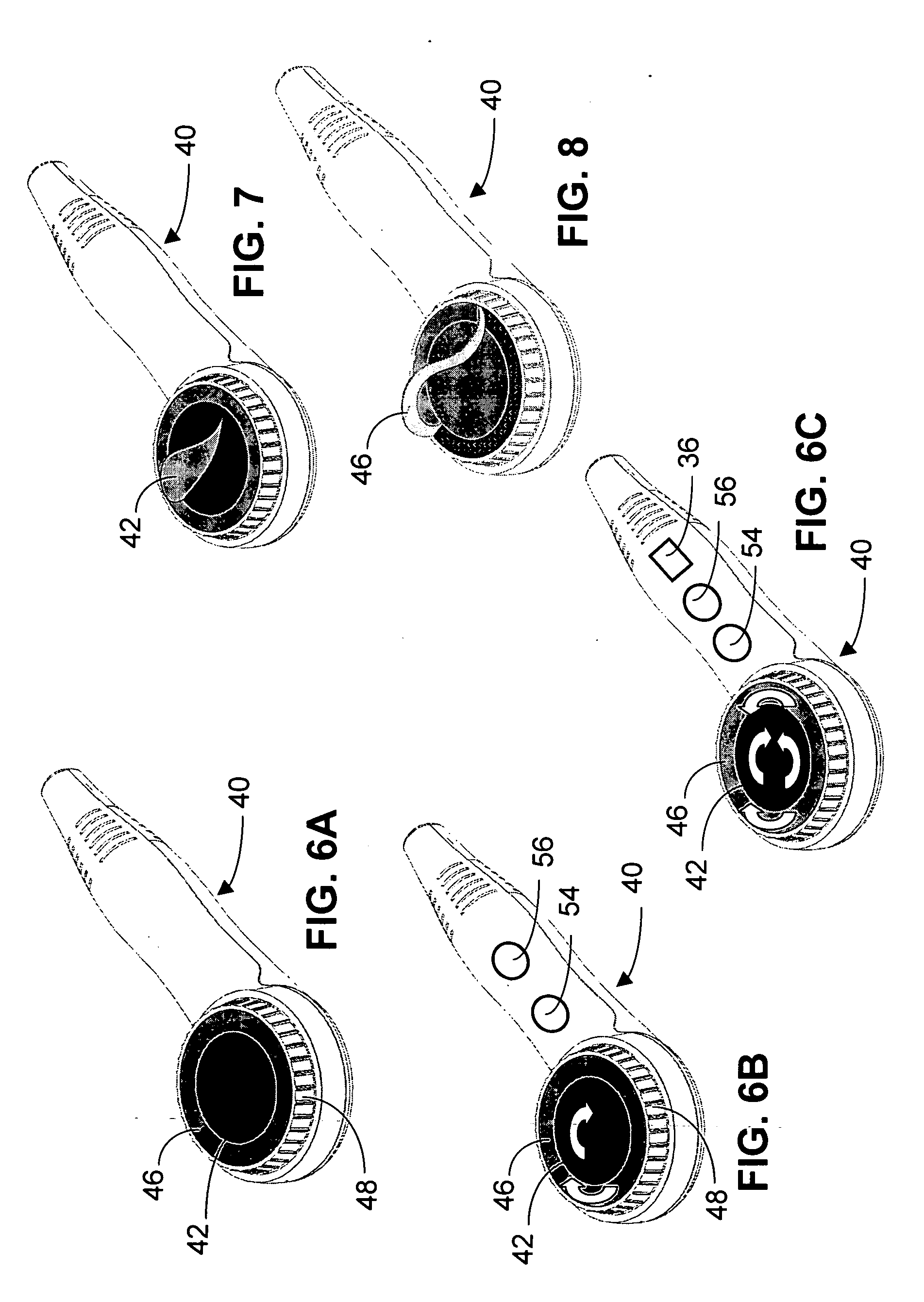

Electrical hair remover

InactiveUS20060130335A1Reduce thicknessReduce visibilityHair-singeingMetal working apparatusSkin lossHairy skin

An electrical device removes body and facial hair and dead skin cells by buffing and abrading by rotating motion. The electrical hair removing device has one, two or three abrasive surfaces for pressing against hairy skin to exfoliate the skin and abrade the hair by automatic and continual electronically controlled rotational movement in the same direction. Hooks and loops removably attach each abrasive surface to a circular base driven in rotation. The two or three abrasive surfaces can be controlled to rotate at different speeds. The two or three abrasive surfaces can also be controlled to rotate in alternating directions and at different speeds.

Owner:SUEN CHI MING

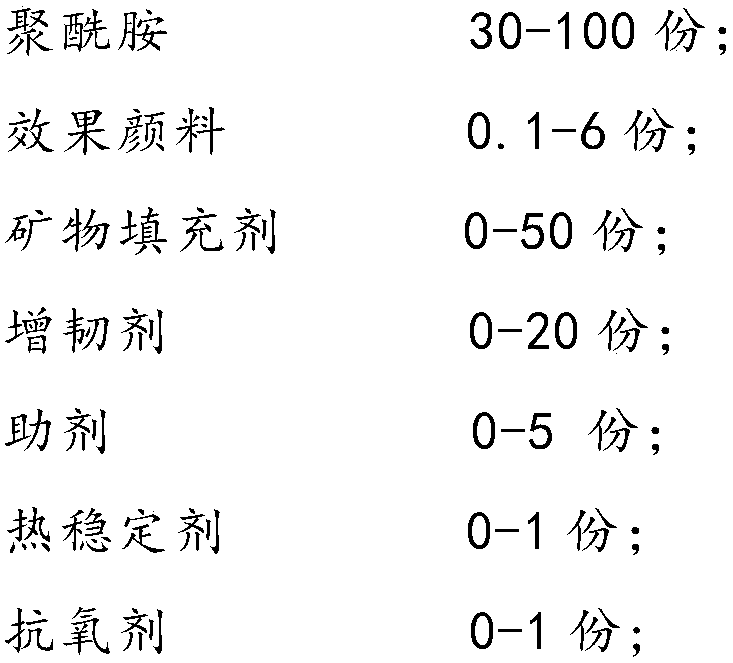

Environment-friendly low-smell and spraying-free polyamide composition and preparation method thereof

The invention discloses an environment-friendly low-smell and spraying-free polyamide composition. The environment-friendly low-smell and spraying-free polyamide composition comprises the following components in parts by weight: 95-100 parts of polyamide, 0.01-5 parts of metal compound, and 0.1-6 parts of effect pigment. According to the environment-friendly low-smell and spraying-free polyamide composition, smell produced in the production process and / or formation process of nylon materials can be extremely reduced; the appearance defects, caused by smell, on spraying-free products, in particular the products emphasizing on appearance and surface aesthetic effects, can be extremely reduced. According to the abovementioned technical scheme, the metal compound is introduced, and the post-processing technology is carried out, so that the surface brightness of the spraying-free polyamide composition is greatly improved.

Owner:SHANGHAI KINGFA SCI & TECH +2

Filled polypropylene composite material applied to rapid forming component

The invention discloses a filled polypropylene composite material applied to a rapid forming component, comprising the following ingredients in parts by weight: 60-88 parts of polypropylene, 1-25 parts of a toughener, 10-30 parts of a mineral powder filler, 1-5 parts of nanofiller master batches, 0.3-0.5 part of a nucleator, 0.1-1.0 part of heat stabilizer DSTP, 0.1-1.0 part of antioxidant 1010, and 0.1-0.5 part of antioxidant 168. The filled polypropylene composite material applied to a rapid forming component provided by the invention has the advantages of being good in material flowability, low in shrinking rate, good in dimensional stability, and capable of reducing apparent defects such as tiger skin strips; and moreover, a process for preparing the filled polypropylene composite material applied to a rapid forming component is simple and low in cost.

Owner:SUZHOU RUNJIA ENGINEER PLASTIC

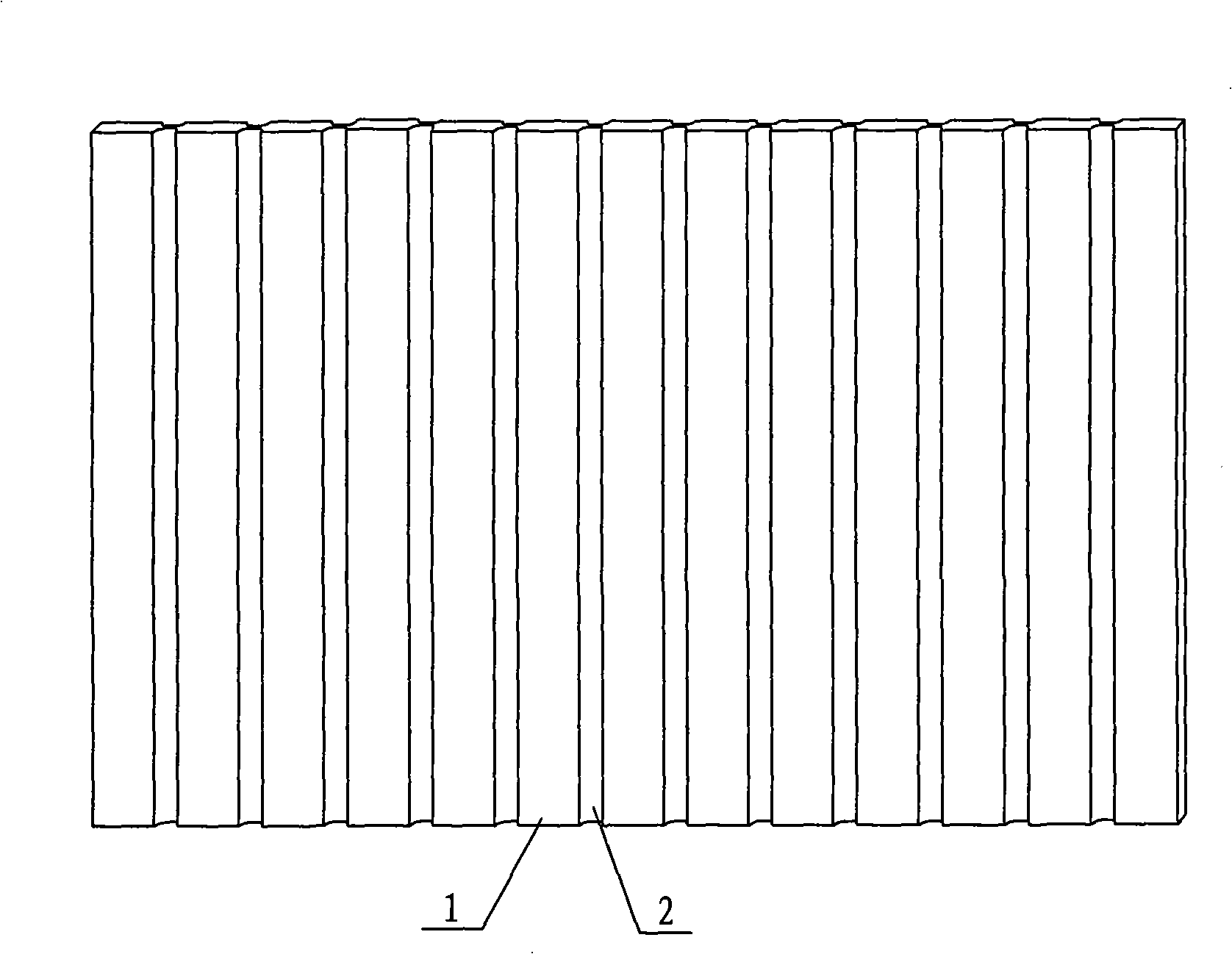

Conveniently folding window curtain

ActiveCN101307671AAvoid patternsAvoid the problem of pattern misalignmentDoor/window protective devicesCurtainsEngineeringLinear density

The invention discloses a curtain which is convenient for folding, comprising a curtain body, wherein, the curtain body is formed by a plurality of thick textile fabric sections and a plurality of thin textile fabric sections which are mutually spaced; a lockstitch structure is arranged on a joint of a thick textile fabric section and a thin textile fabric section which are adjacent to each other; the linear density of warp threads used for weaving the curtain body is less than or equal to 22.2 texes; the linear density of weft threads used for weaving the thick textile fabric sections is between 66 and 333 texes; the linear density of weft threads used for weaving the thin textile fabric sections is less than or equal to 22.2 texes; the density ratio of the thick textile fabric sections to the thin textile fabric sections is 1.5-3 to 1; and each edge lockstitch structure used for weaving the curtain body is woven by 2 to 4 lock lines and warp threads of the curtain body by means of tabby weave. The curtain is convenient to process, has smooth appearance and is convenient for surface treatment.

Owner:游龙

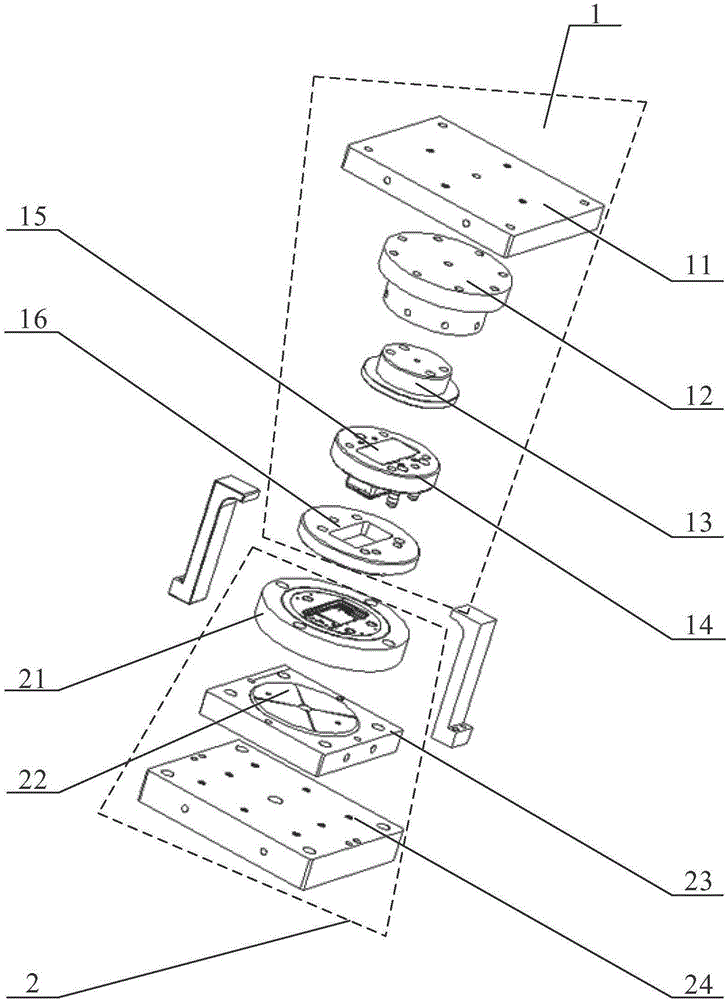

Processing system of mobile equipment shells

InactiveCN106734842AShorten processing timeMeet product appearance and size performance requirementsForging/hammering/pressing machinesEngine componentsMachine toolMachining time

The invention discloses a processing system of mobile equipment shells. The processing system comprises a forging mould and a numerically-controlled machine tool, wherein the forging mould is used for roughly machining a preprocessed plate to obtain a rough base with the size being larger than the preset allowance of a product, the forging mould comprises an upper mould component and a lower mould component, a mould core for forging the plate is mounted on the upper mould component, and the lower mould component is provided with a cavity allowing the plate to be placed in; the numerically-controlled machine tool used for finely machining the rough base to remove the preset allowance to obtain the product. The processing system has the advantages that the plate can be roughly machined by the forging mould before the numerically-controlled machining to form the rough base, the machining quantity of the numerically-controlled machining is reduced, only the preset allowance needs to be removed, about half of CNC machining time can be reduced, the product structure and product size cannot be changed, product machining efficiency can be increased effectively, product machining cost and company resource cost are lowered evidently, and product appearance, size and performance requirements are satisfied.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

ALuminium plate with envelope and electronic equipment parts using the same

InactiveCN1454046ACrack suppressionExcellent fingerprint resistanceCasings/cabinets/drawers detailsSpecial surfacesCorrosion resistantAluminium

Owner:KOBE STEEL LTD

Thermal shrinked thin-membrane with polyvinyl chloride and production thereof

InactiveCN1817621AImprove thickness uniformityExcellent thermal shrinkage uniformityThin membranePolyvinyl chloride

A thermoshrinking PVC film with high uniformity and quality is prepared through mixing PVC resin, assistant and modifier, stirring, cooling, extruding, calendering or doctor blading to obtain thick sheet, cooling, pre-heating to 50-100 deg.C, monodirectional or bidirectional drawing by 2-5 times, and cooling for fixating its shape.

Owner:FSPG HI TECH

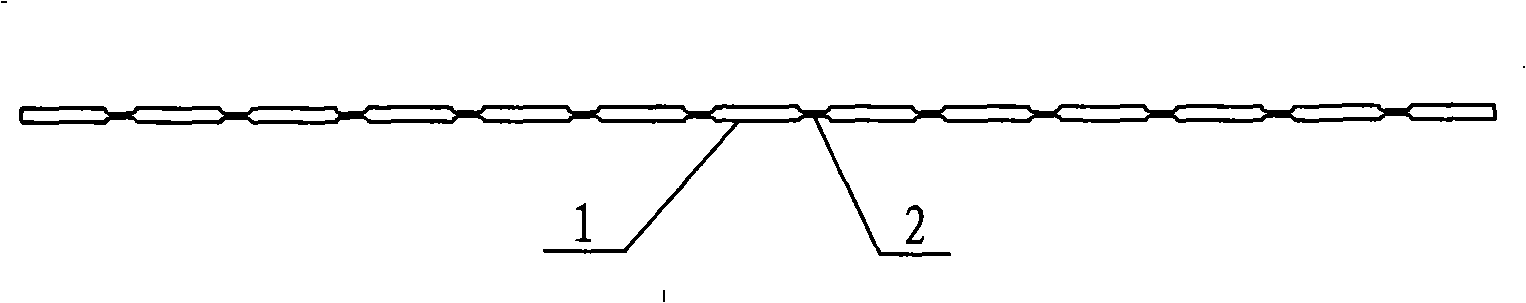

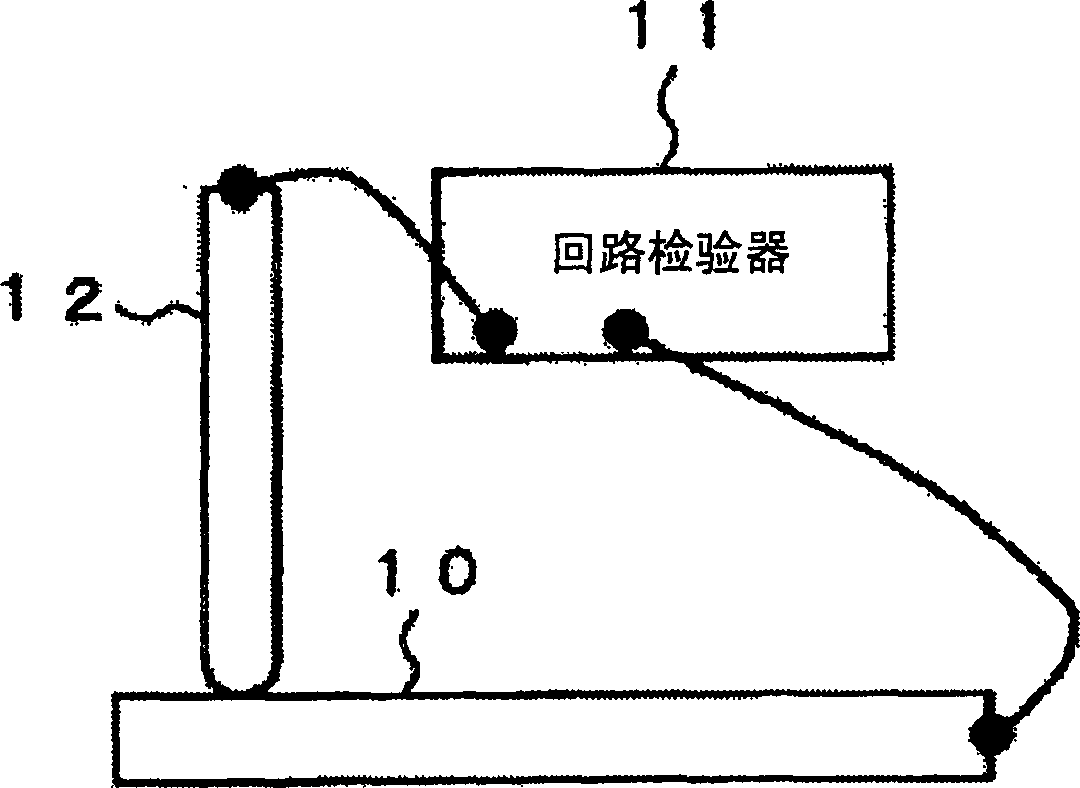

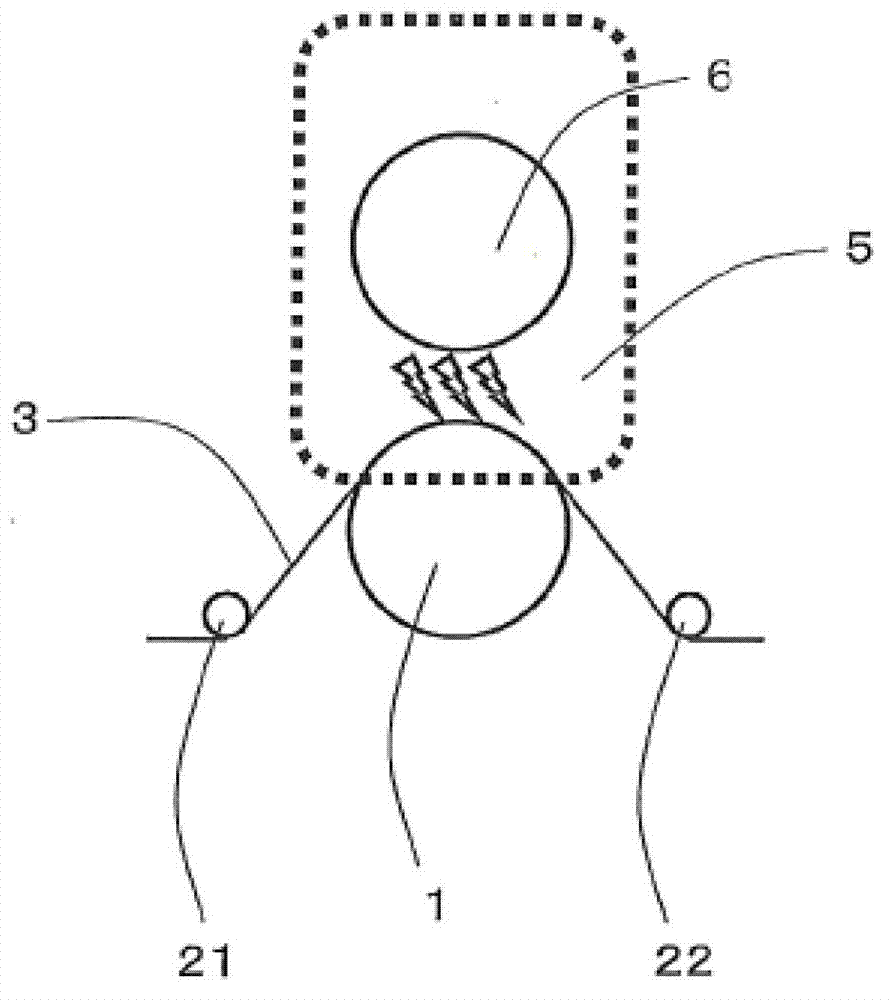

Lithium ion battery pole piece processing method

InactiveCN102694144AHigh surface energyImprove wettabilityElectrode manufacturing processesSurface energyCurrent collector

The invention belongs to the technical field of lithium ion batteries and particularly relates to a lithium ion battery pole piece processing method. A pole piece comprises a current collector and a membrane arranged on the surface of the current collector, and the pole piece is subjected to corona treatment after cold-pressing process of the pole piece and before reeling or laminating process of a battery cell. Compared with the prior art, as the single sides or both sides of both a cathodal pole piece and an anodal pole piece are subjected to corona treatment, the surface energy of the pole pieces can be increased, generation of a hydrophilic atom set or functional group on the surfaces of the pole pieces is promoted, and accordingly, the purposes of improving the wettability of an electrolyte to the pole pieces and improving the imbibition performance of the battery cell are achieved. Therefore, the stewing time after liquid charging and before formation is shortened, the production period of a battery is shortened, and the manufacturing cost is lowered eventually; a stable solid electrolyte interphase (SEI) interface can be formed in the formation procedure, so that the performance of the battery cell is ensured; and the liquid rise of the battery cell is reduced, products with damaged appearance are reduced and the product acceptance rate is improved.

Owner:DONGGUAN AMPEREX TECH +1

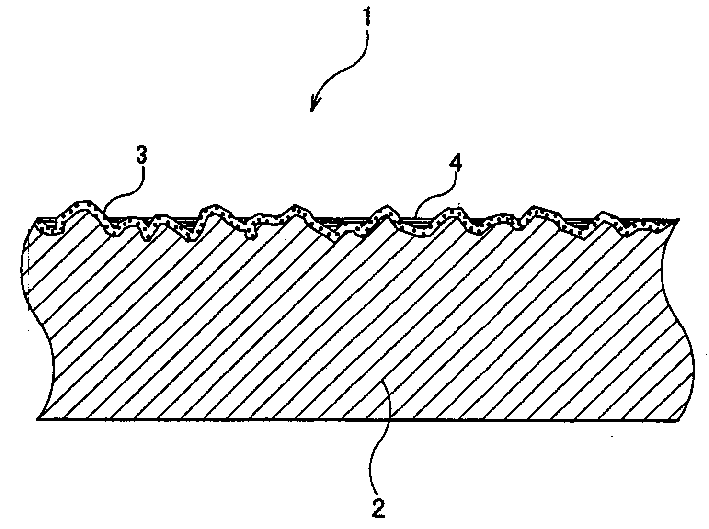

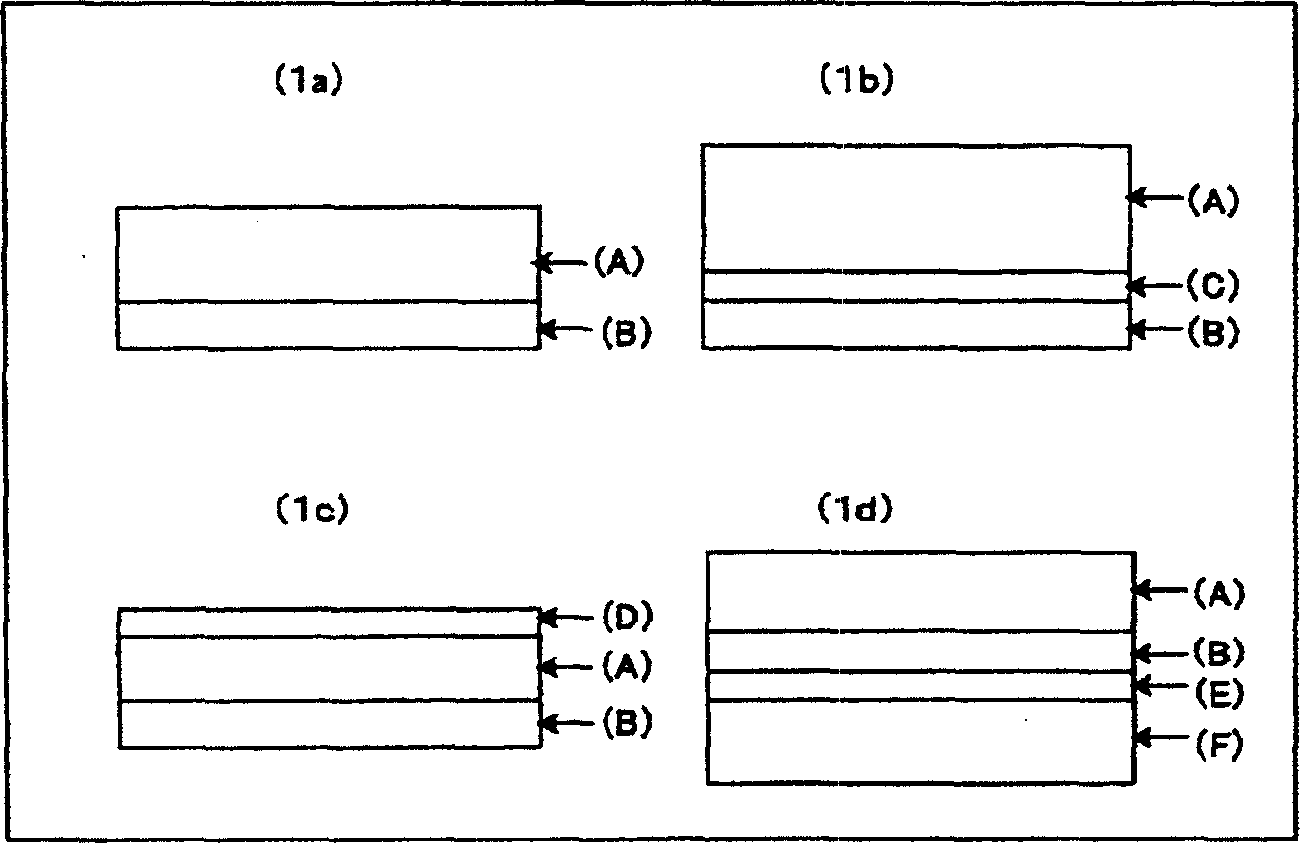

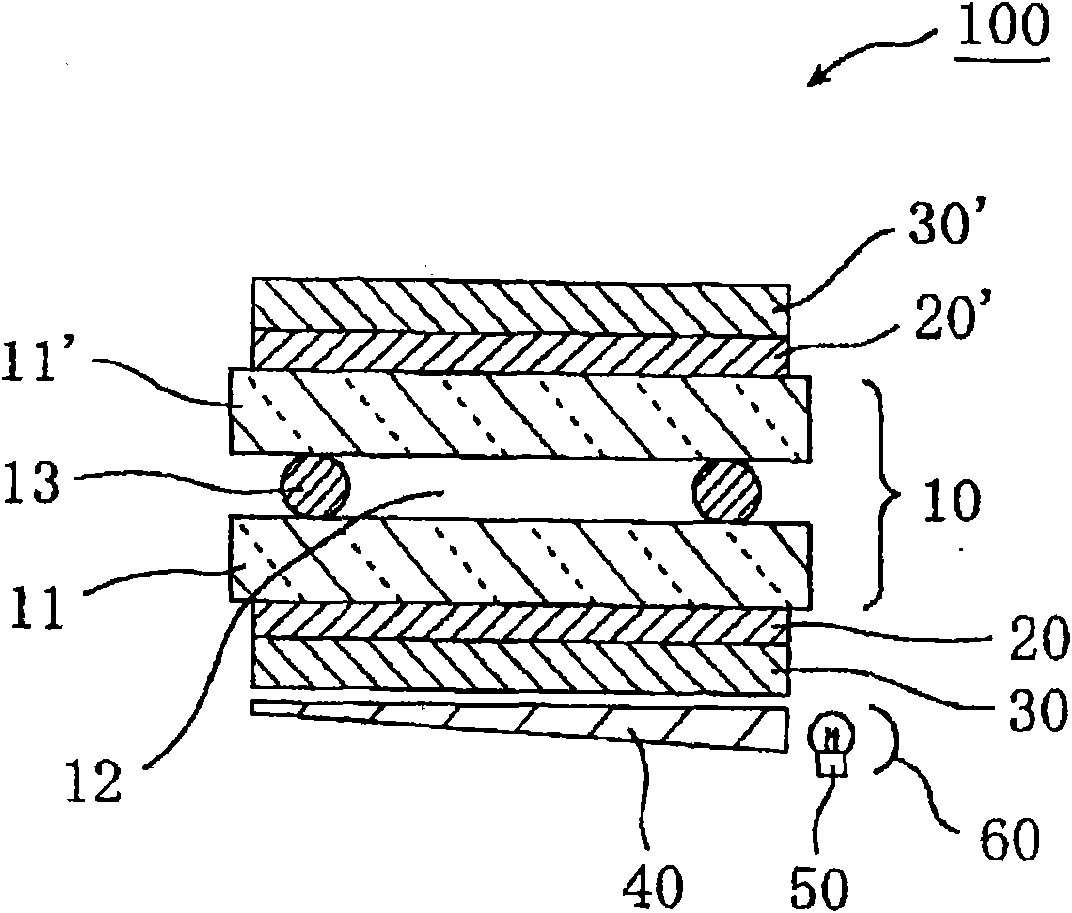

Activating treatment method for optical film, method for producing optical laminated-film, optical laminated-film, and image display device

InactiveCN103487850AAvoid Cosmetic DefectsGood adhesionLaminationPolarising elementsPolarizerOptical thin film

An activating treatment method for an optical film includes feeding the optical film along a roll, and subjecting the optical film to the activating treatment from a side of the optical film that is opposite to a side of the optical film at which the roll is located. The activating treatment is conducted while the roll is cooled.

Owner:NITTO DENKO CORP

Filled polybutylene composite material used in fast-forming parts, and preparation method thereof

The invention discloses a filled polybutylene composite material used in fast-forming parts. The material comprises, by weight, 61-86 parts of polybutene, 1-25 parts of a toughening agent, 5-29 parts of a mineral powder filling material, 1-5 parts of modified nano-grade filling material masterbatch, 0.3-0.5 parts of a nucleating agent, 0.1-1.0 parts of a heat stabilizer DSTP, 0.1-1.0 parts of an antioxidant 1010, and 0.1-0.5 parts of an antioxidant 168. The invention also discloses a preparation method of the filled polybutylene composite material used in fast-forming parts. The method comprises the following steps: (1) the modified nano-grade filling material masterbatch is prepared; (2) the raw materials are weighed; (3) mixing is carried out, wherein the raw materials weighed in the step (2) are subjected to dry mixing in a high-speed mixer for 3-5min; and (4) extrusion and granulation are carried out, wherein the mixed raw material is subjected to melt extrusion and granulation in a double-screw machine.

Owner:SUZHOU EXCELLENCE ENG PLASTICS

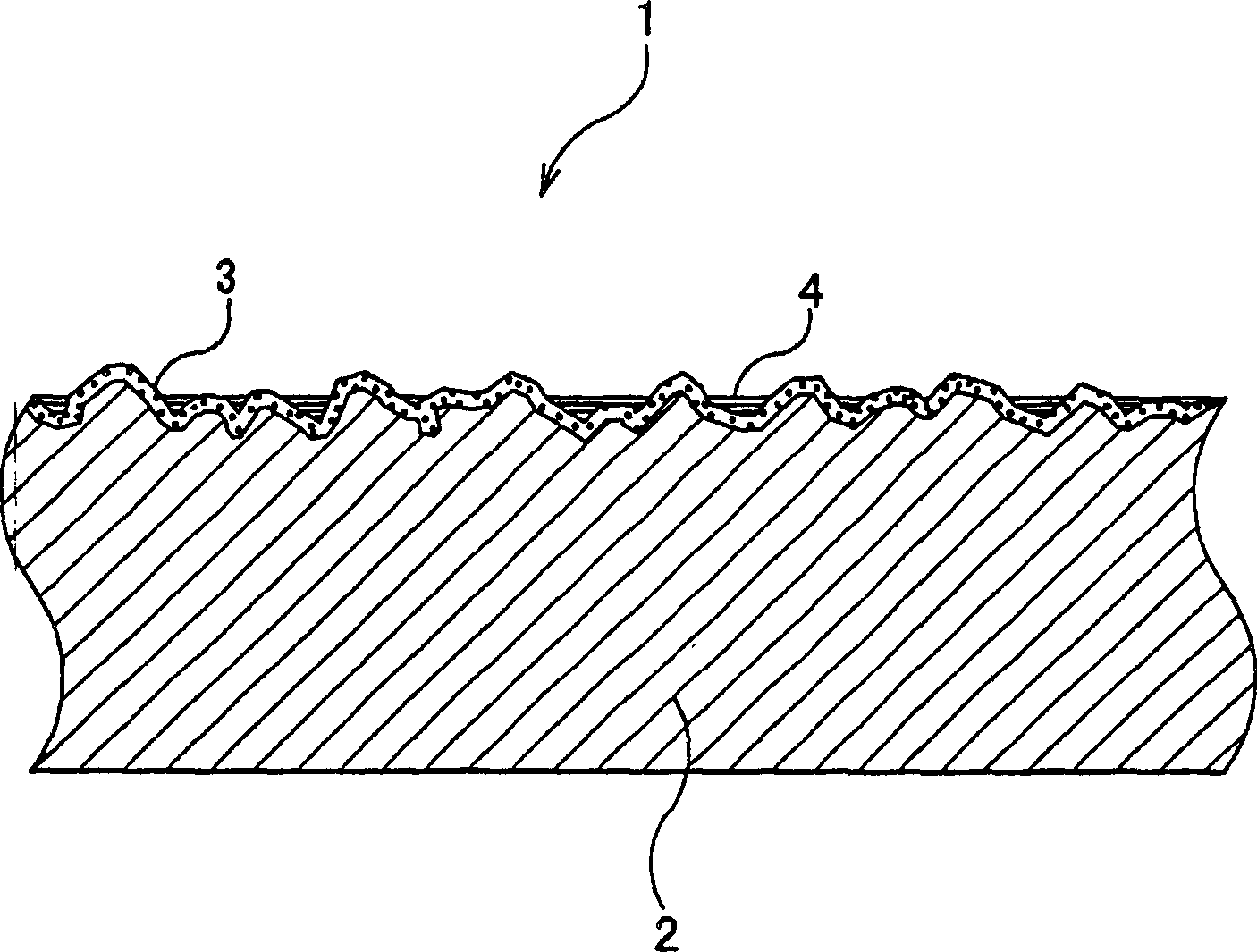

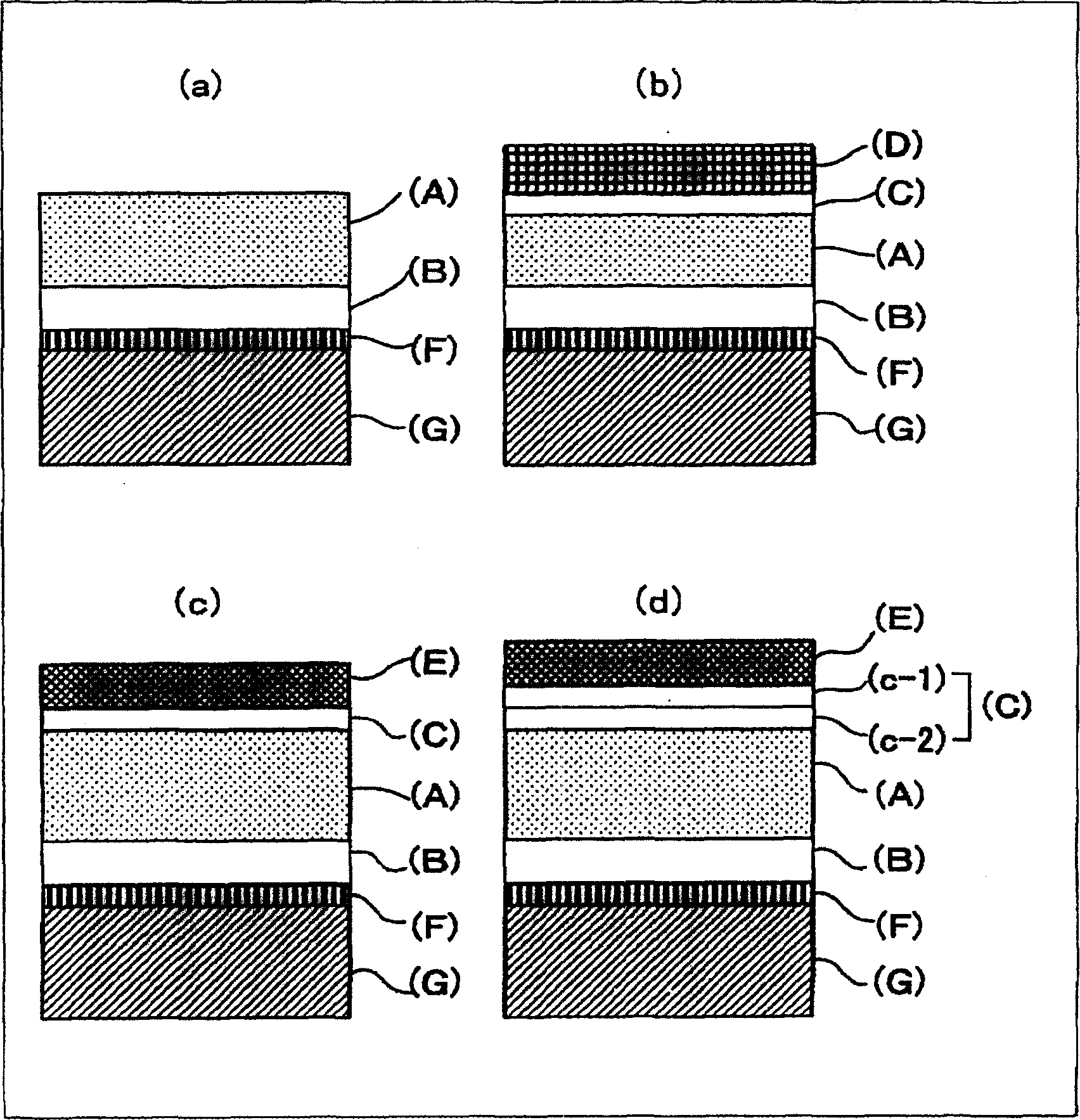

Resin-covered metal sheet, pattern sheet for resin -covered metal sheet, and process for the production of resin-covered metal sheet

InactiveCN1692015AMaintain physical propertiesSuppresses the phenomenon of molecular weight decreaseLayered productsAdhesivePolyester resin

A resin-covered metal sheet excellent in durability (resistance to moist heat) which is obtained by laminating a metal sheet with a laminated sheet consisting of at least two unstretched layers (layers A and B) made mainly of a polyester resin via an adhesive with the layer B side employed as the adhesive surface, wherein the laminated sheet has a total thickness of 65 to 300mum and a pigment for coloring and hiding is incorporated mainly into the layer A, with the layers A and B having thicknesses of 50 to 250mum and 15 to 80mum respectively and with the amount of the pigment component contained in the layer B being limited to at most 10 parts by weight per 100 parts by weight of the resin component. Further, resin-covered metal sheets having good embossed appearance can be provided by the use of a current embossing machine used in embossing flexible PVC sheets.

Owner:MITSUBISHI PLASTICS INC

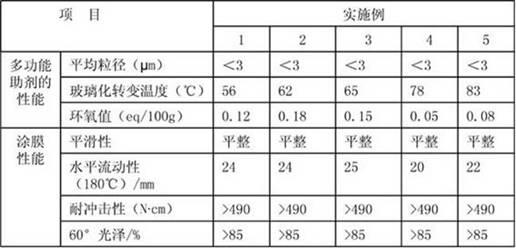

Method for preparing multifunctional power coating additive with core-shell structure

InactiveCN102060955AGood storage stabilityImprove the level ofPowdery paintsSodium bicarbonateGlycidyl methacrylate

The invention relates to a method for preparing a multifunctional power coating additive with a core-shell structure. The method comprises the steps of: A. uniformly mixing butyl methacrylate (BMA), methyl methacrylate (MMA) and lauryl mercaptan as a core monomer; B. uniformly mixing butyl methacrylate (BMA), methyl methacrylate (MMA), glycidyl methacrylate (GMA) and lauryl mercaptan as a shell monomer; C. adding water, lauryl sodium sulfate and sodium bicarbonate in a reactor, uniformly stirring to raise temperature, dripping the core monomer and ammonium persulfate, and maintaining the temperature; dripping the shell monomer and ammonium persulfate, and maintaining the temperature; cooling and filtering to obtain white acrylic ester core-shell polymer latex, wherein the solid content in the latex is 40-50%, and the conversion rate of the monomer is higher than 90%; and D. adding a calcium chloride aqueous solution, separating, washing with water, and drying to obtain a white powdery solid product. The additive is used for power coatings without being molten and granulated, can be added directly for use, and has the environmentally friendly characteristic.

Owner:HEFEI UNIV OF TECH

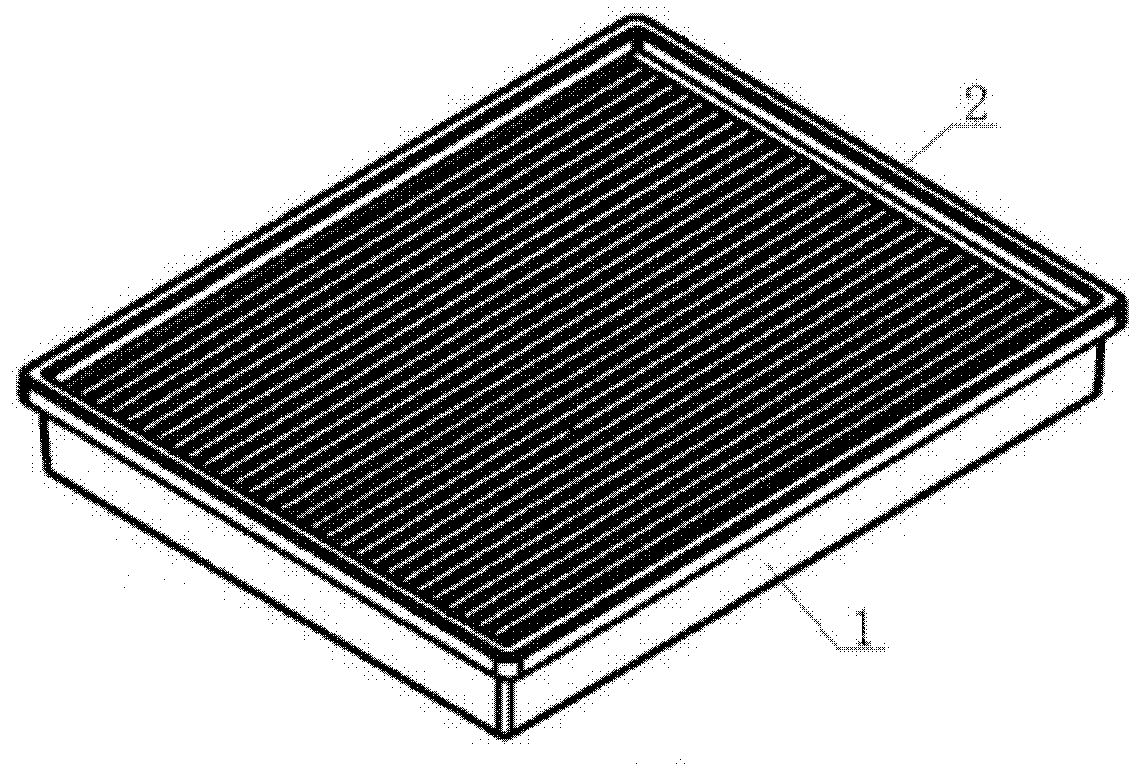

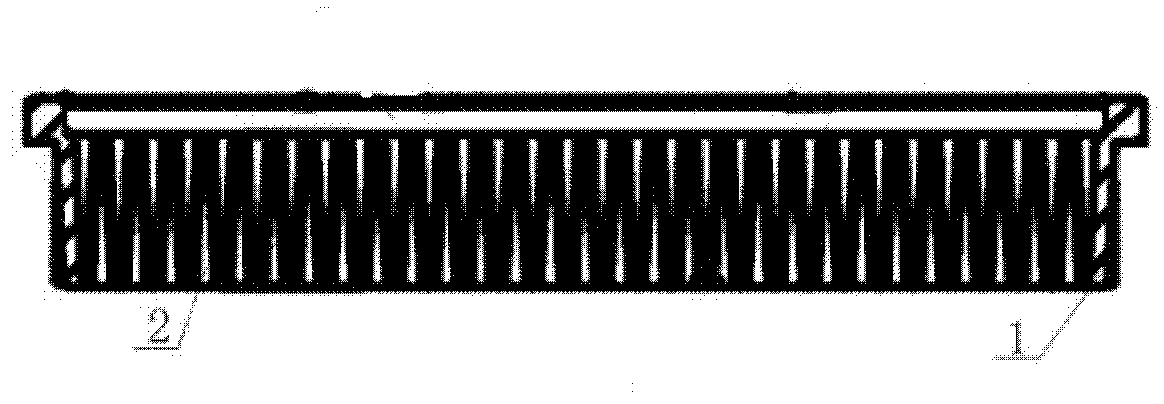

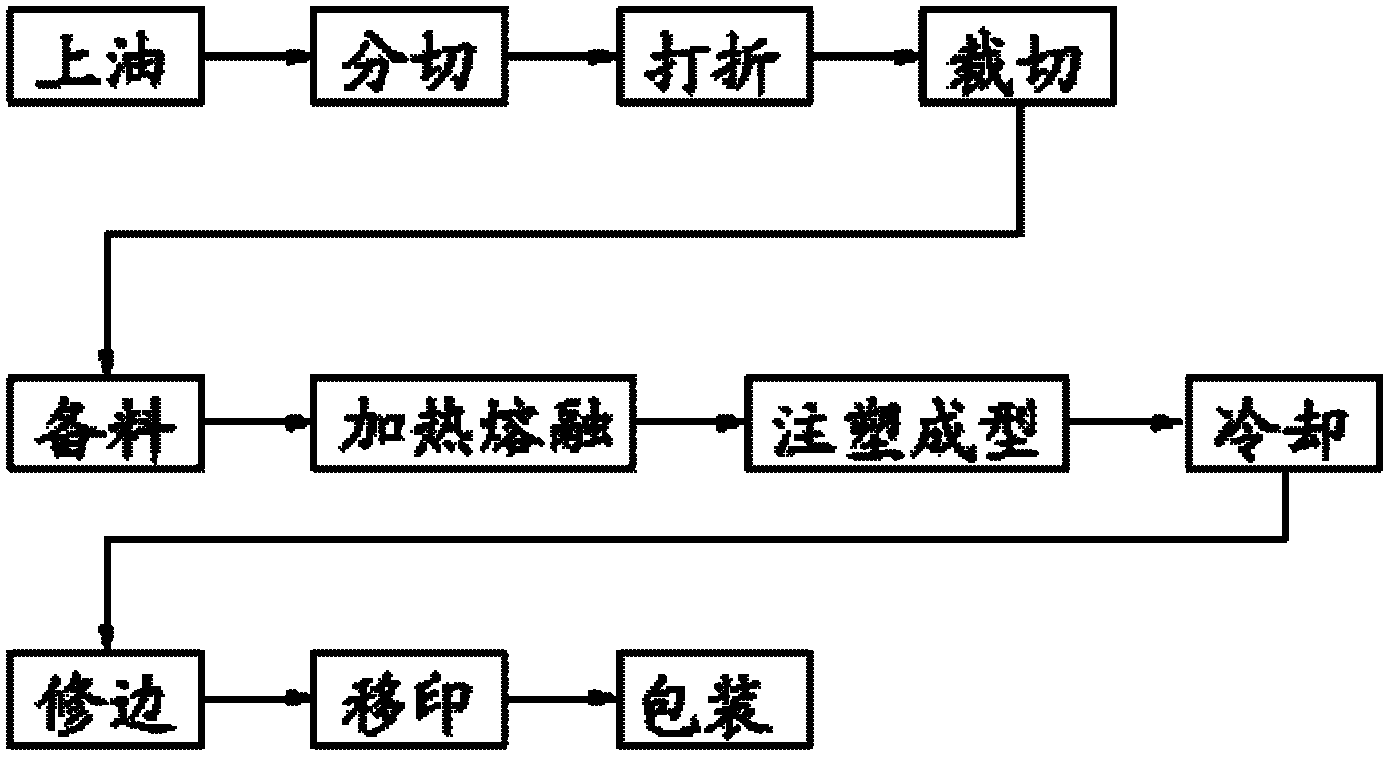

Air filter and preparation process thereof

InactiveCN102631816AEasy to separateGood sealing effectDispersed particle filtrationCombustion-air/fuel-air treatmentCombustionForming processes

The invention provides an air filter which comprises a fixed frame and a filter element, wherein the peripheral edges of the filter element are embedded into a frame body of the fixed frame; the fixed frame is made of a thermoplastic elastomer (TPE); the filter element is nonwoven cloth; and the fixed frame and the filter element are integrated through an insert forming process. The invention also provides a preparation method for the air filter. The preparation method comprises the following steps of preparing the filter element, forming inserts and treating after forming. According to the air filter and the preparation method thereof, the air filter is high in sealing property, large in ventilating amount and flat and attractive in appearance, can be recycled and degraded and is particularly suitable for automobile engines, so that the combustion efficiency and the power of the engine are improved effectively.

Owner:HKR SPECIALTY EQUIP +1

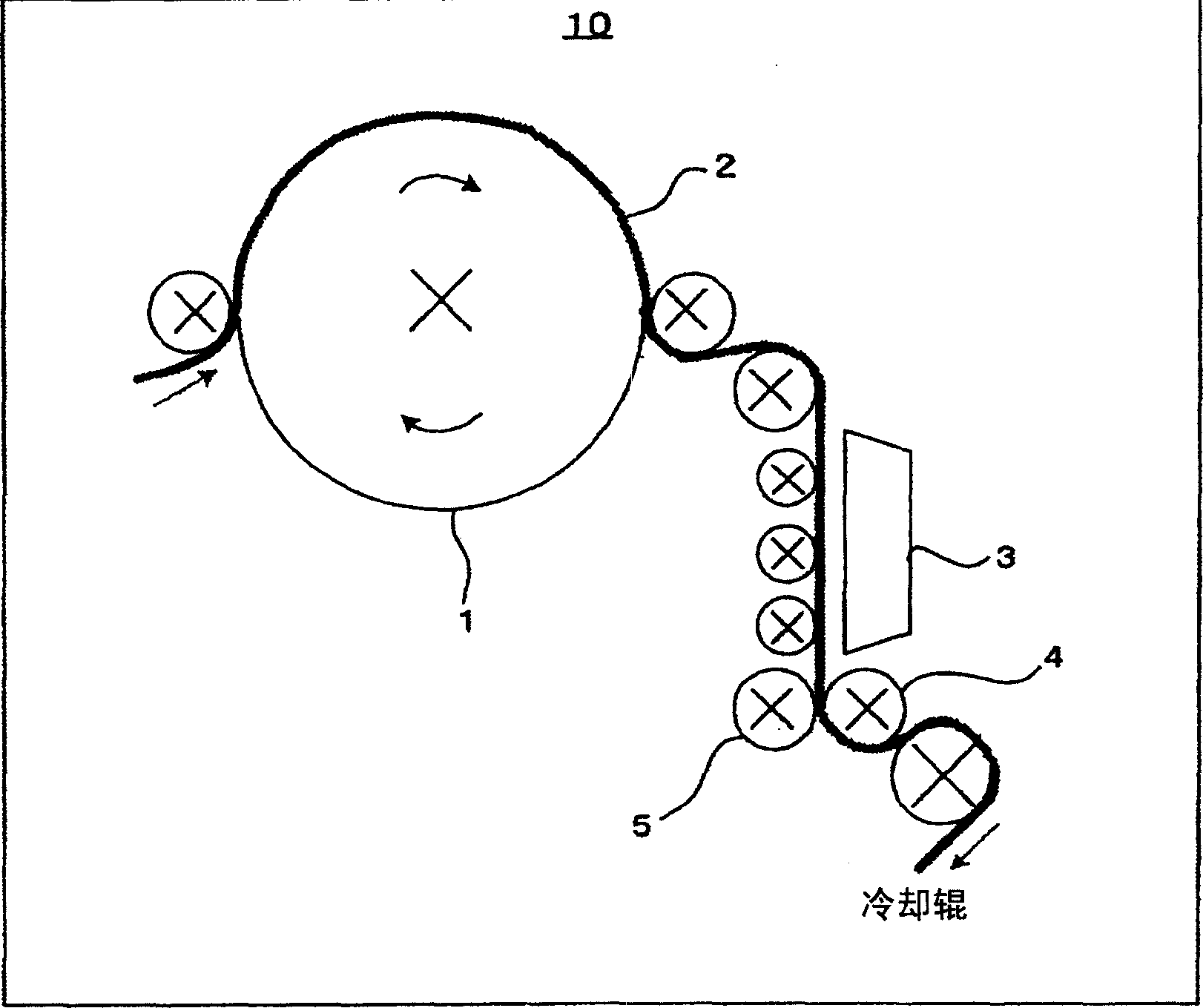

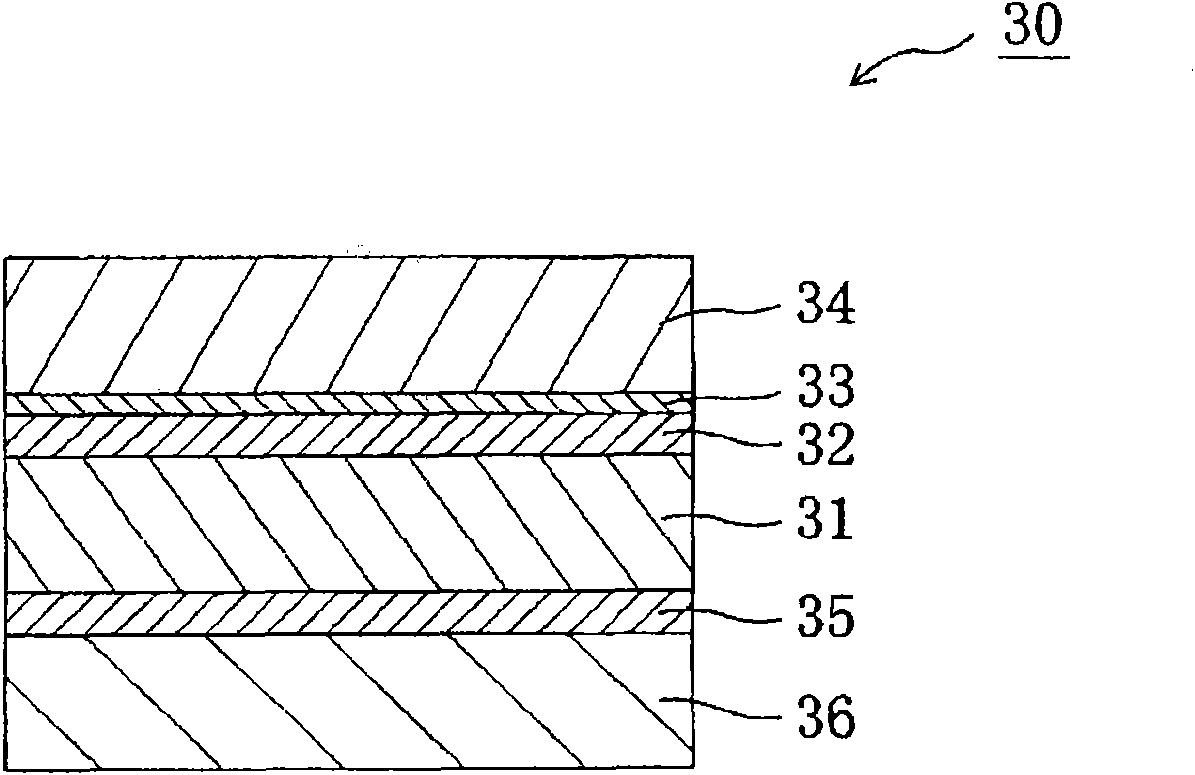

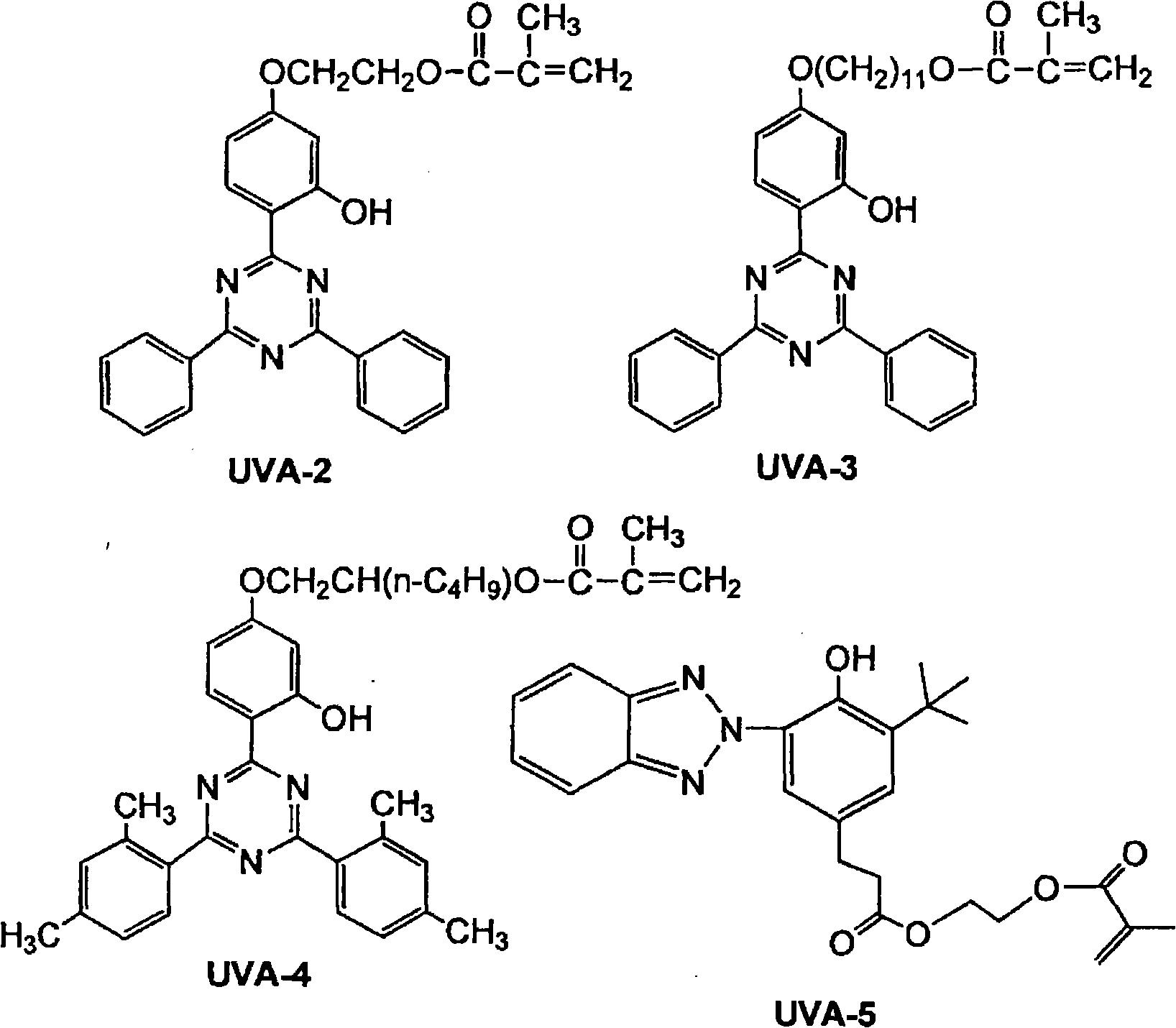

Polarizer protection film, polarizing plate and image display

InactiveCN101529285AImprove heat resistanceGood optical clarityPolarising elementsNon-linear opticsMonomer compositionMeth-

The invention provides a polarizer protection film which exhibits excellent ultraviolet absorption by using an ultraviolet-absorbing monomer as the raw material. The polarizer protection film also exhibits excellent heat resistance, excellent optical transparency, while having extremely little coloration and foaming. The invention also provides a polarizing plate with only a few appearance defects, which uses such a polarizer protection film, and a high-quality image display using such a polarizing plate. The polarizer protection film has a light transmittance of 380 nm of not more than 30% with a thickness of 80 [mu]m, and can be obtained by extrusion molding using a molding material containing a resin component mainly composed of a (meth)acrylic resin which is obtained by polymerizing a monomer composition containing an ultraviolet-absorbing monomer and a (meth)acrylic monomer.

Owner:NIPPON SHOKUBAI CO LTD +1

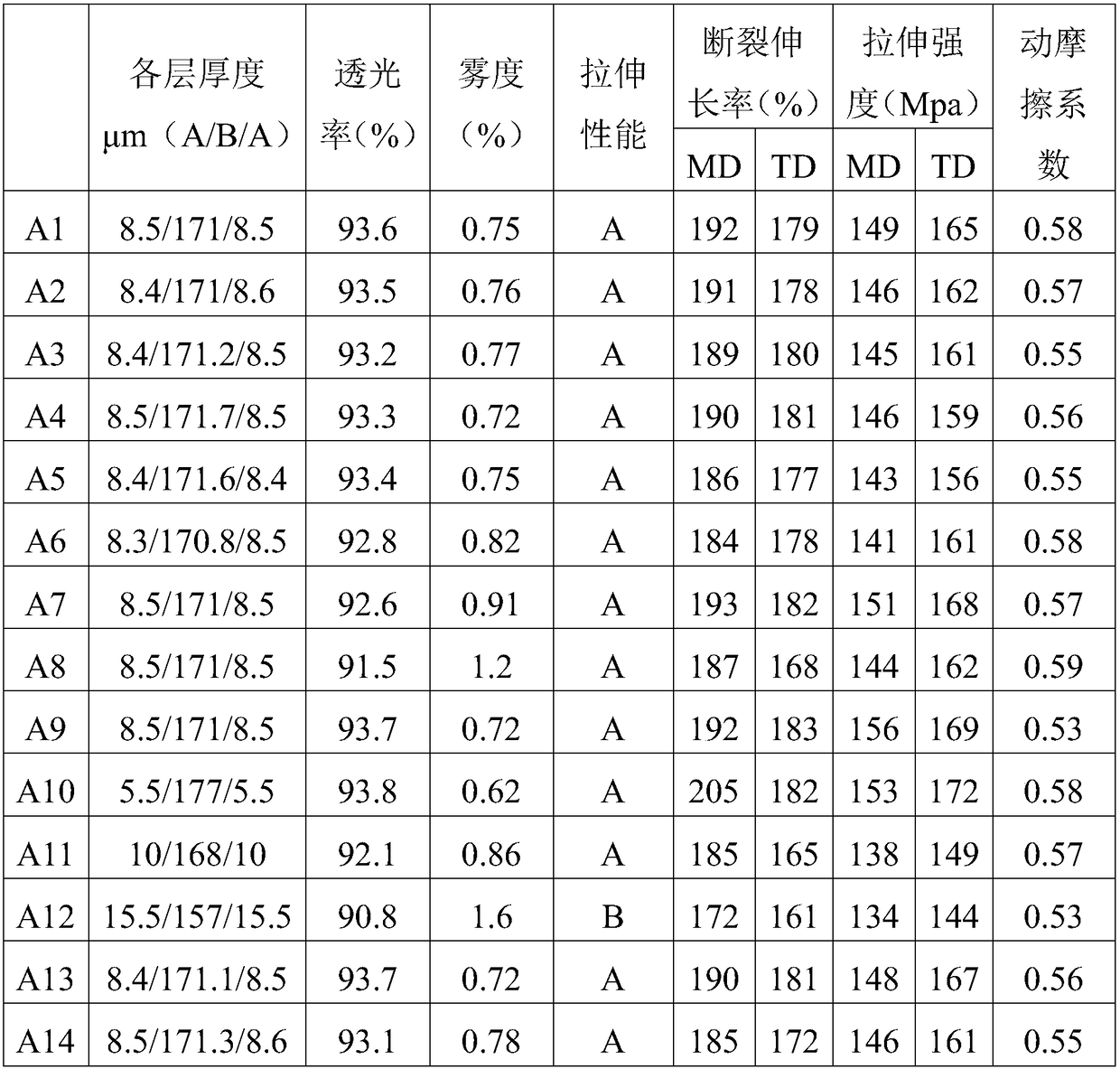

Antiblocking agent masterbatch for plastic film and preparation method of antiblocking agent masterbatch

ActiveCN109181242AReduce bad appearanceReduces Optical Performance DegradationTransmittanceSurface modification

The invention belongs to the technical field of antiblocking agents and specifically relates to an antiblocking agent masterbatch for a plastic film and a preparation method of the antiblocking agentmasterbatch. The antiblocking agent masterbatch is prepared from the following raw materials: carrier resin, modified inorganic particles and other auxiliaries; and a preparation method of the modified inorganic particles comprises the steps: ultrasonically dispersing the inorganic particles and a compatilizer in an organic solvent, recovering the organic solvent, and carrying out drying to obtainthe inorganic particles coated with the compatilizer. In the invention, the inorganic particles are subjected to surface modification, so that the binding force between the inorganic particles and plastics is increased, and the phenomenon of poor appearance caused by the falling-off of the inorganic particles on the surface of a plastic film is reduced; and the phenomenon that the optical performance of the plastic film molded by stretching is reduced, and the transmittance of rays is guaranteed; and the problem of film breaking in a production process is reduced, and the sustainability of production is improved.

Owner:宣城虹光新材料科技有限公司

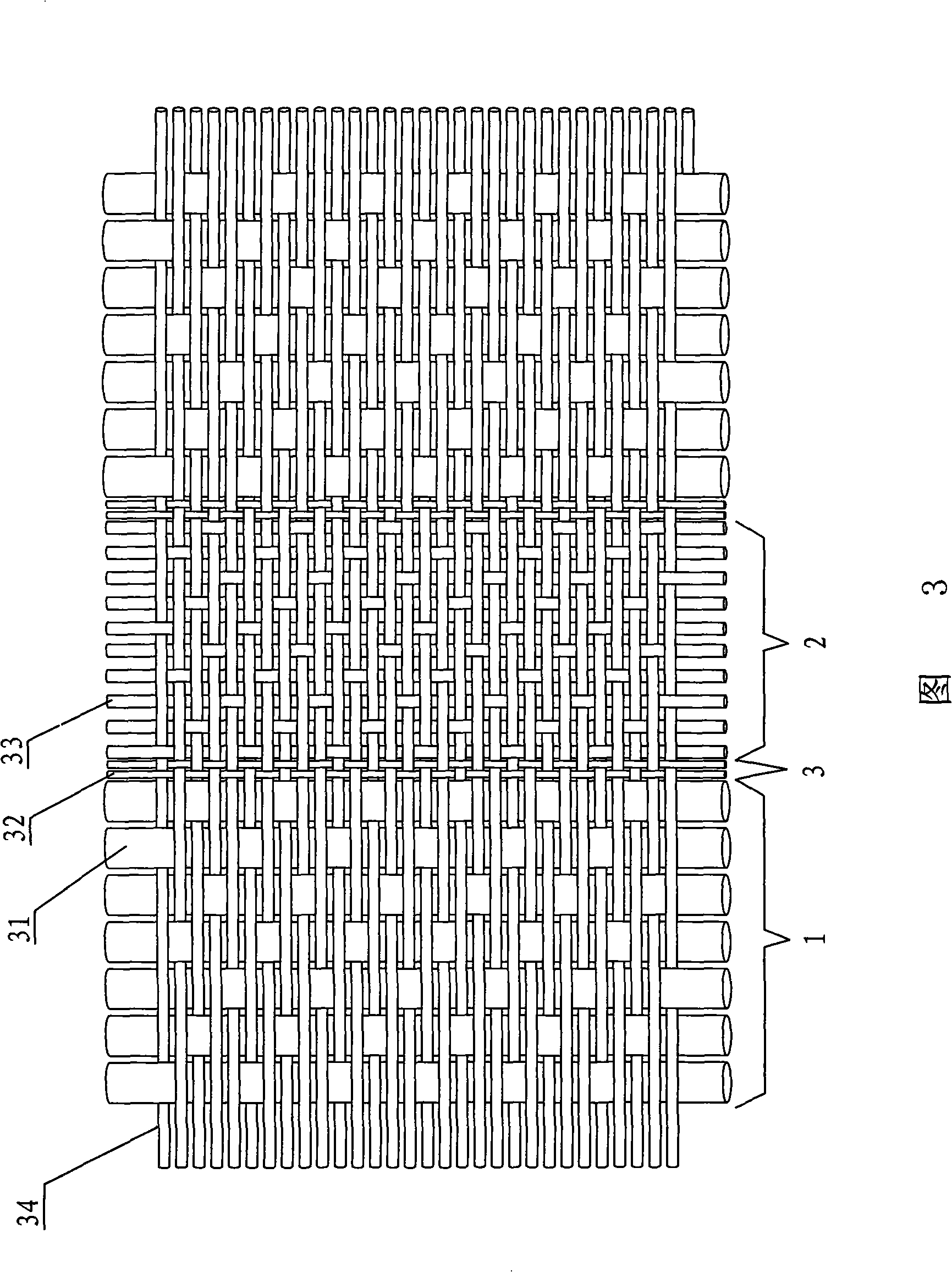

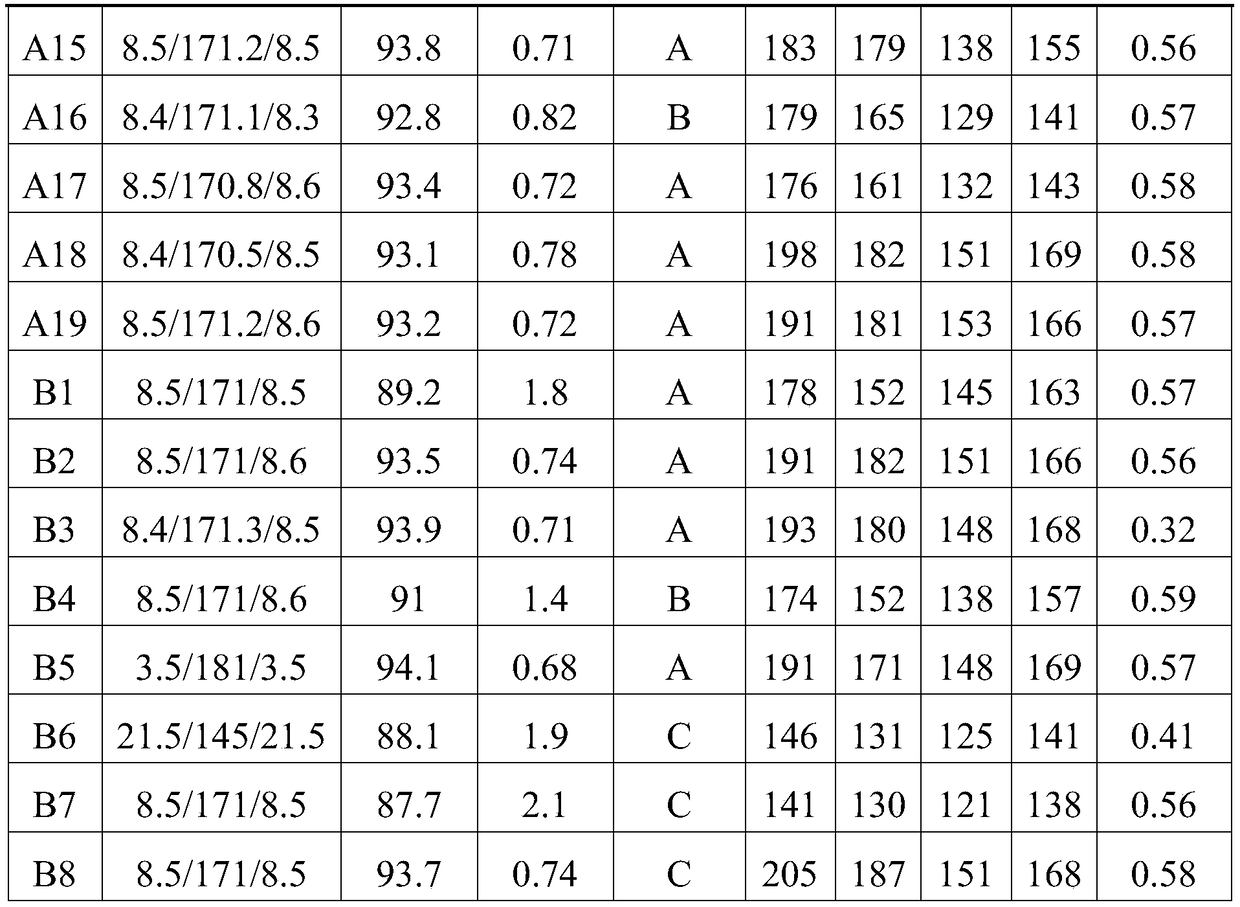

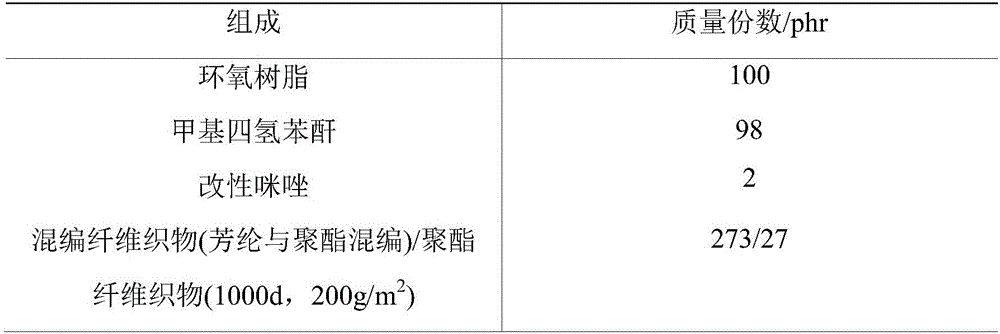

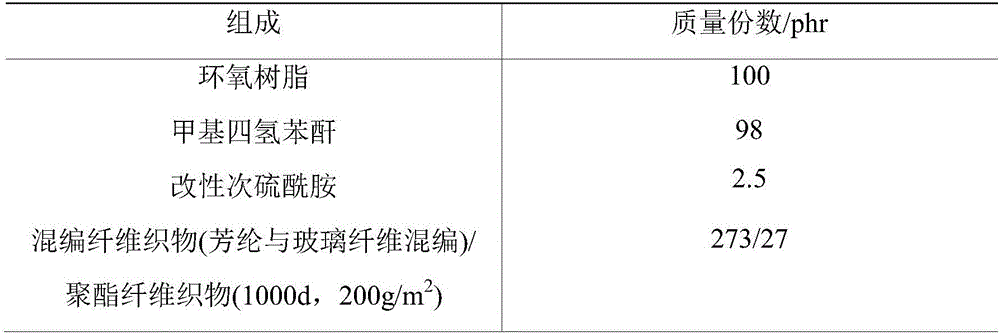

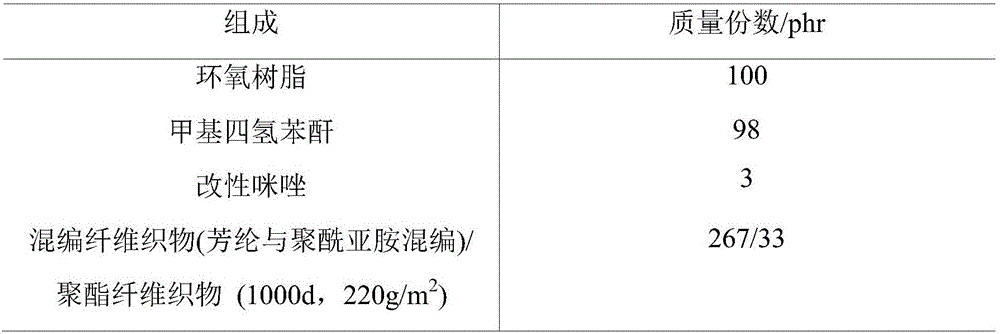

Insulation pull bar and preparation method thereof

InactiveCN106229170AGood effectImprove reliabilityContact operating partsDomestic articlesPolyesterGlass fiber

The present invention provides an insulation pull bar and a preparation method thereof. The insulation pull bar is formed by compositing a resin system and fabrics, and the resin is an epoxy resin system, a polyurethane resin system or a vinyl resin system; and the fabrics are mixed fabrics of one or two fabrics selected from the group of the aramid fabrics, glass fabrics, polyimide fabrics, basalt fabrics and polyester fabrics. According to the formation of the fabric wrapping, the design of the fiber fabrics weaving and the vacuum dipping technology of high temperature and pressurization, the optimal matching of the viscosity of the resin system and the system vacuum degree is regulated, a good interface combination between the resin and the fabrics is ensured, and the obtain insulation pull bar has good electrical insulation performance and machinery mechanical property.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

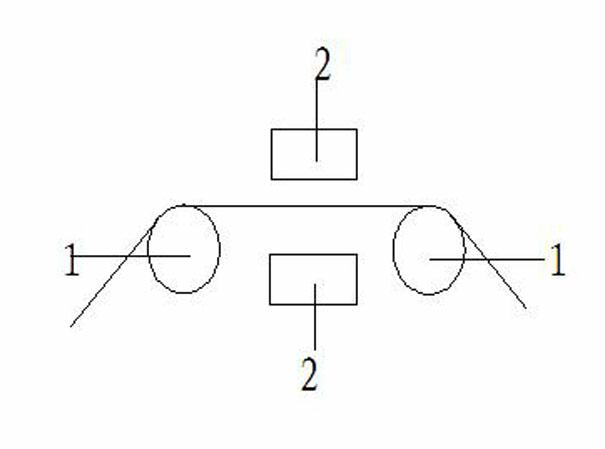

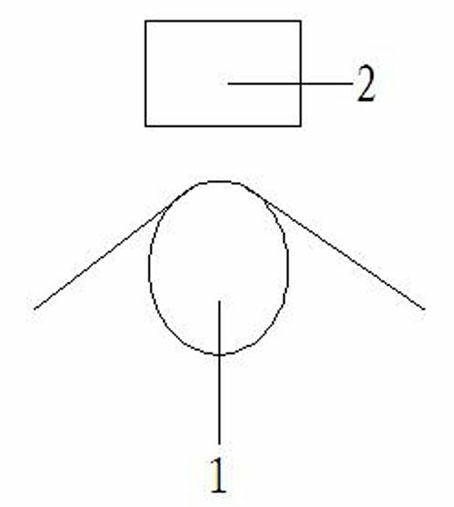

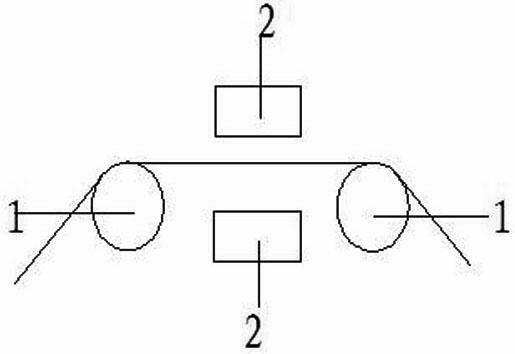

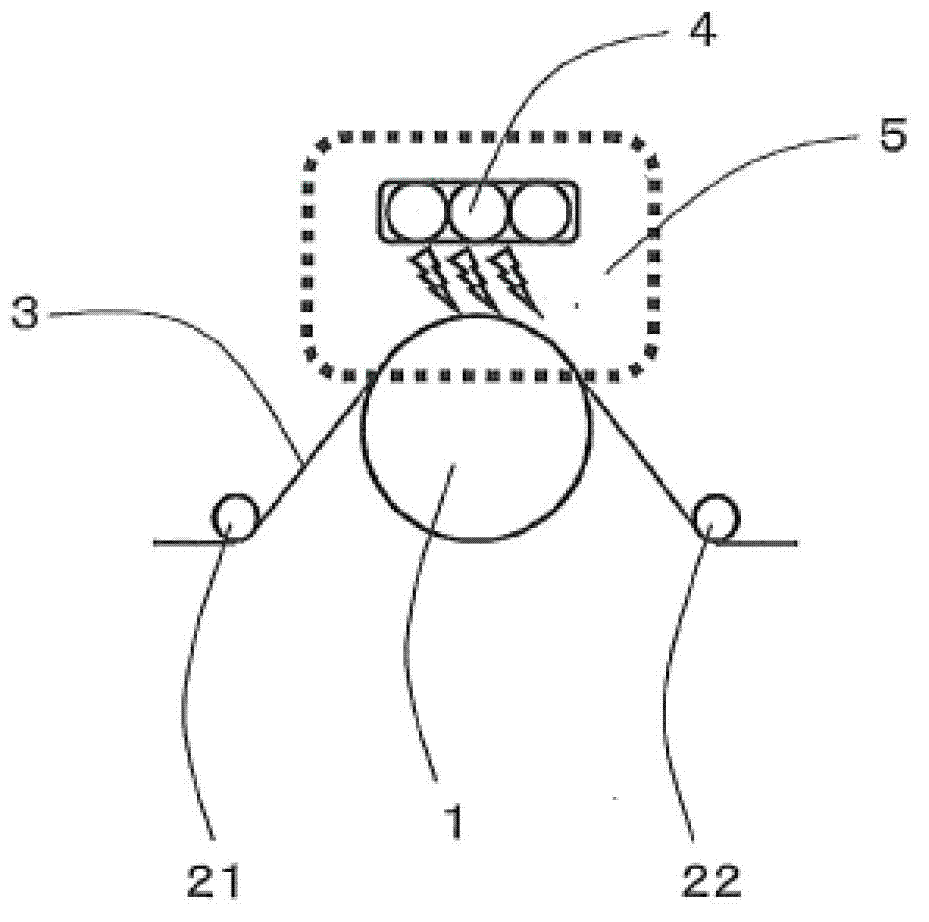

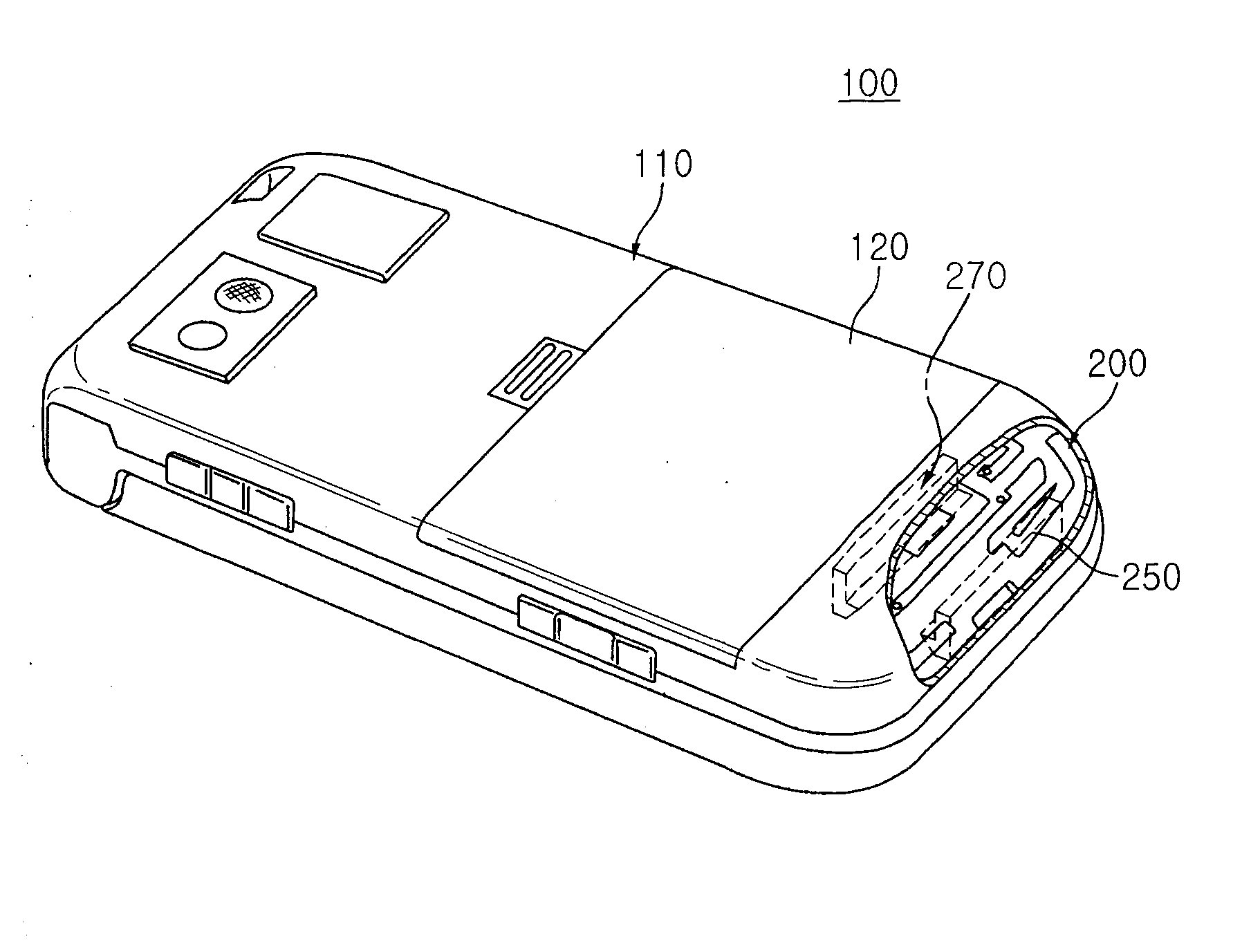

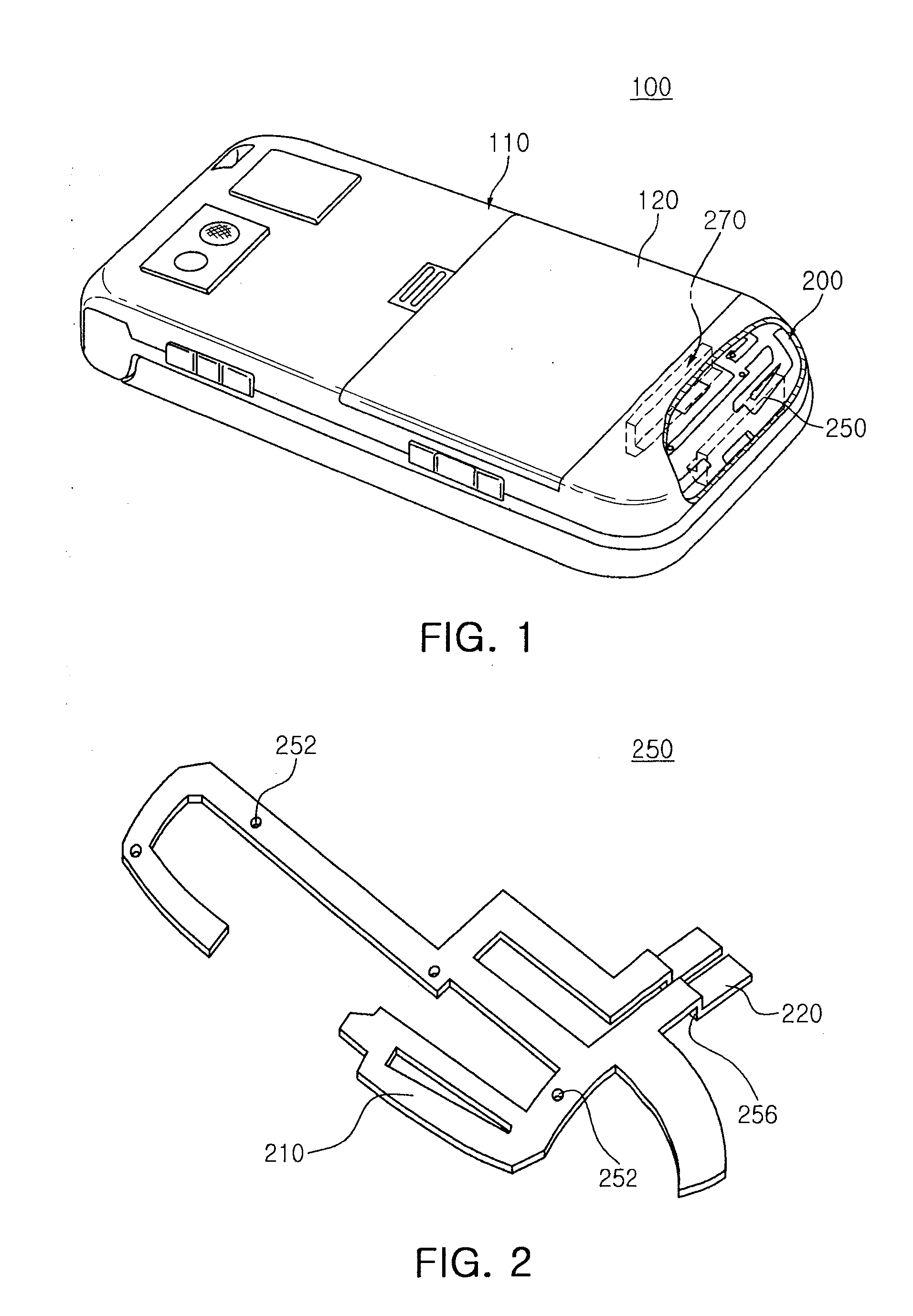

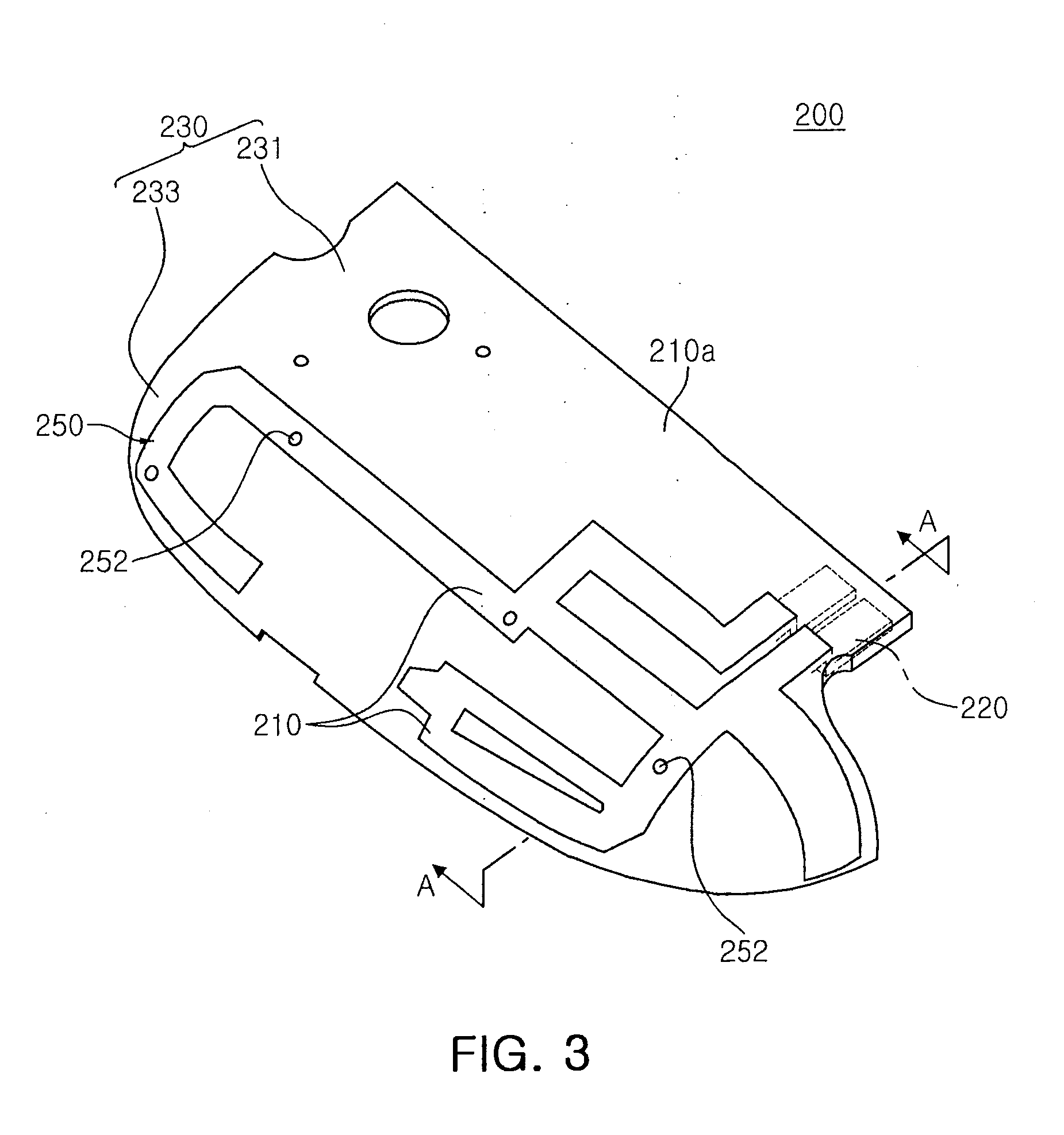

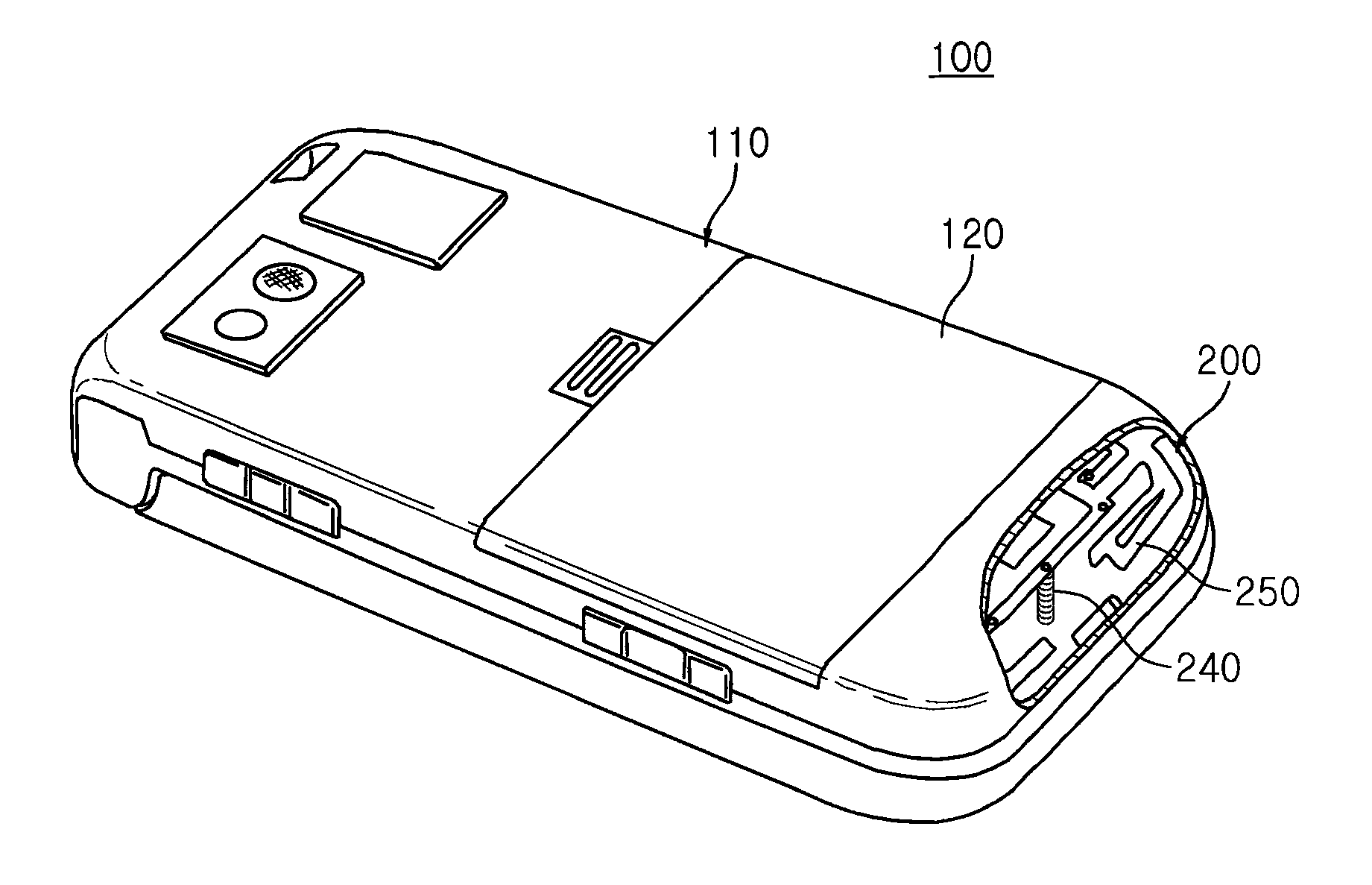

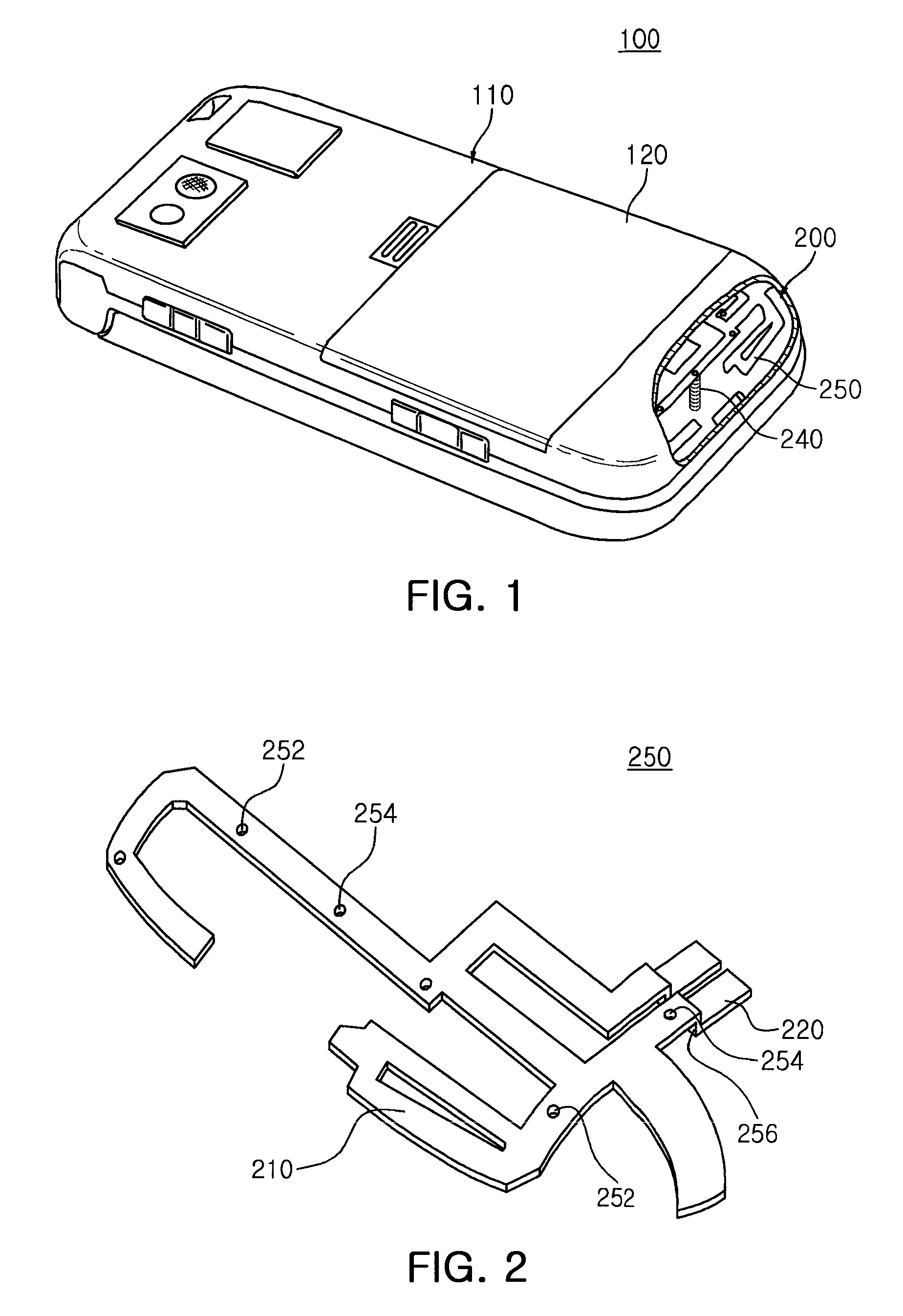

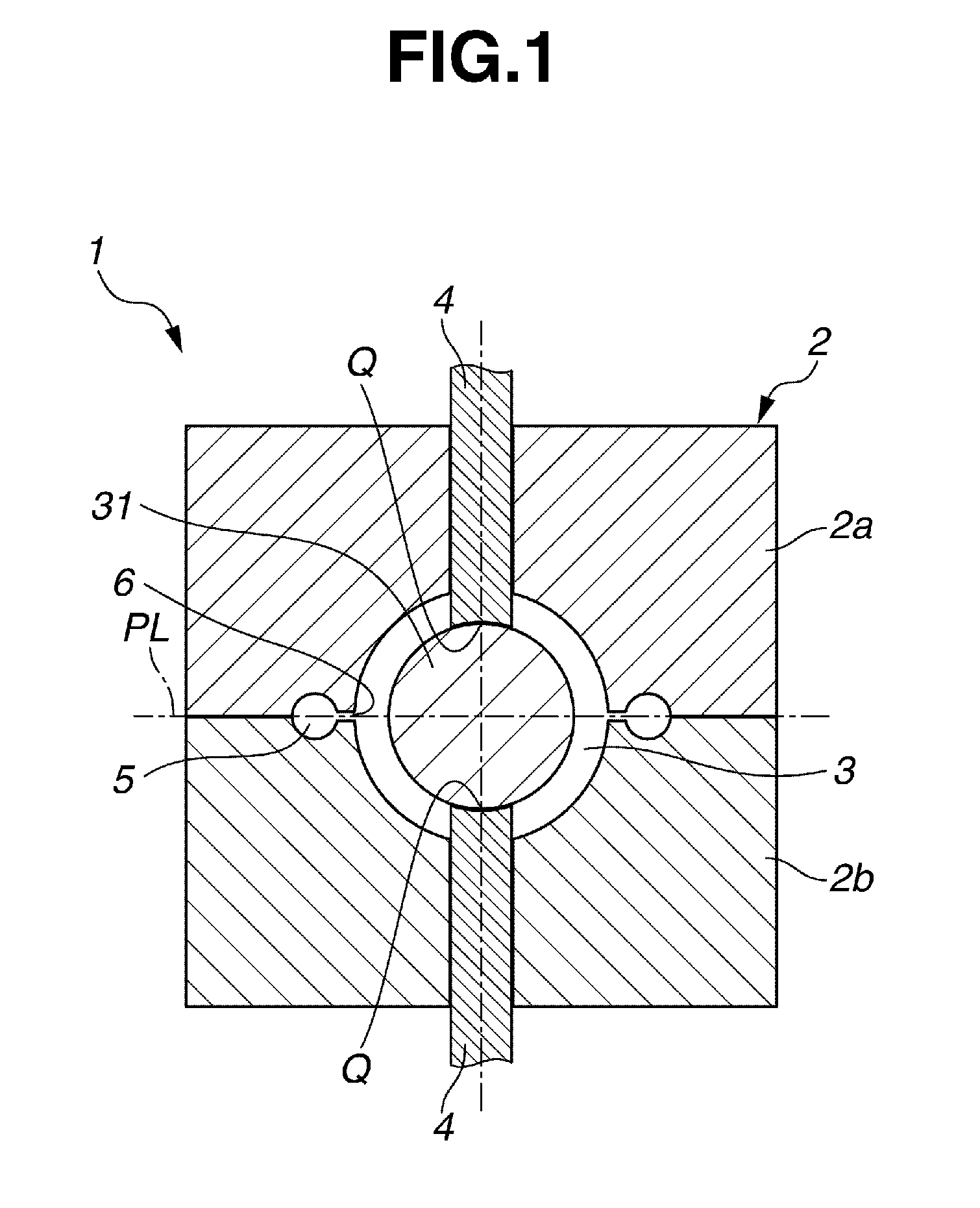

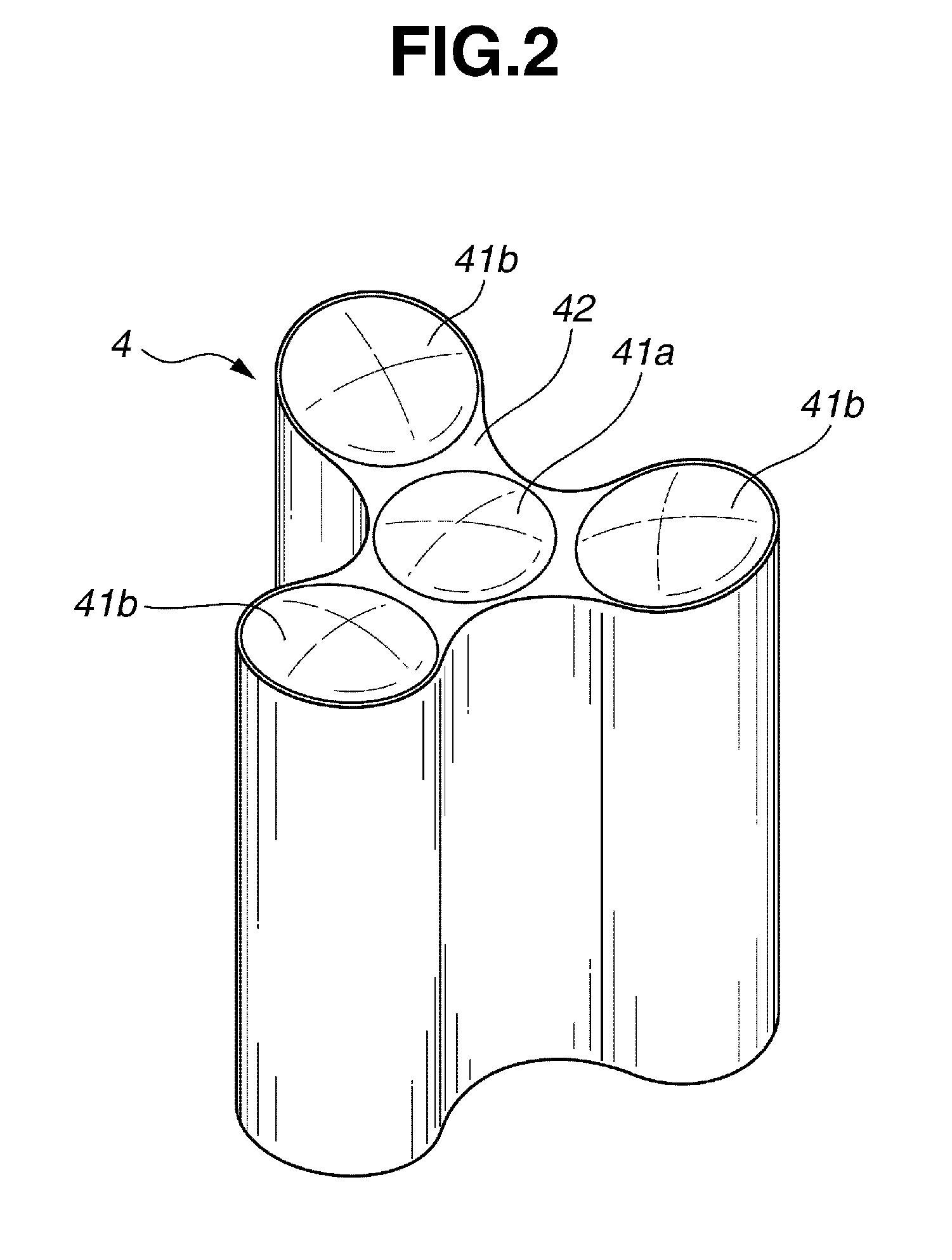

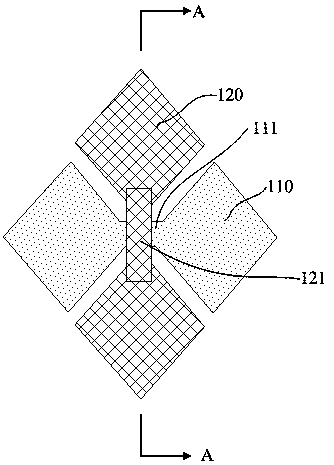

Antenna pattern frame, case of electronic device and mold for manufacturing the same

InactiveUS20110221639A1Reduce bad appearanceSimultaneous aerial operationsAntenna supports/mountingsInjection mouldingHeat spreader

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Antenna pattern frame, case of electronic device and mould for manufacturing the same

InactiveUS8773314B2Reduce bad appearanceTailstocks/centresAntenna supports/mountingsInjection mouldingElectron

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

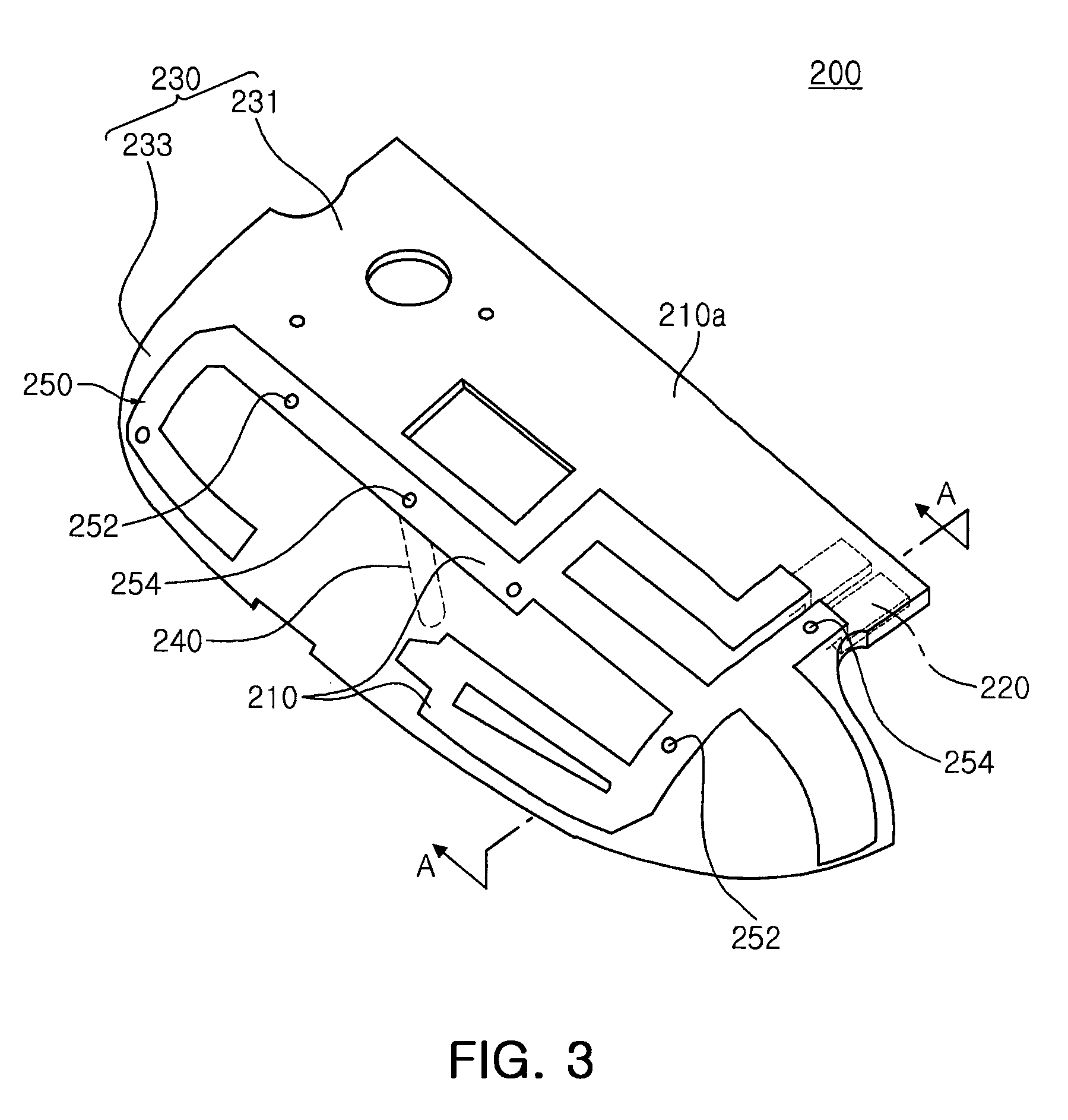

Ultrathin prepreg and preparation method thereof

ActiveCN106903909AStable quality controlSolve technical problems that are difficult to prepareComposite laminatesLarge size

The invention provides a preparation method of ultrathin prepreg. The preparation method of the ultrathin prepreg comprises the steps of preparation of a fiber layer, preparation of a resin layer, preparation of the ultrathin prepreg and the like. According to the preparation method of the ultrathin prepreg, technological control of each step is researched, and the high-quality large-size ultrathin prepreg can be prepared; and in addition, the prepared prepreg has the advantages of being good in appearance quality, excellent in performance, low in production cost and the like. The invention further provides the ultrathin prepreg prepared through the preparation method. Composite laminate made of the ultrathin prepreg is excellent in mechanical property.

Owner:BEIJING ONLYTOP HIGH TECH MATERIALS

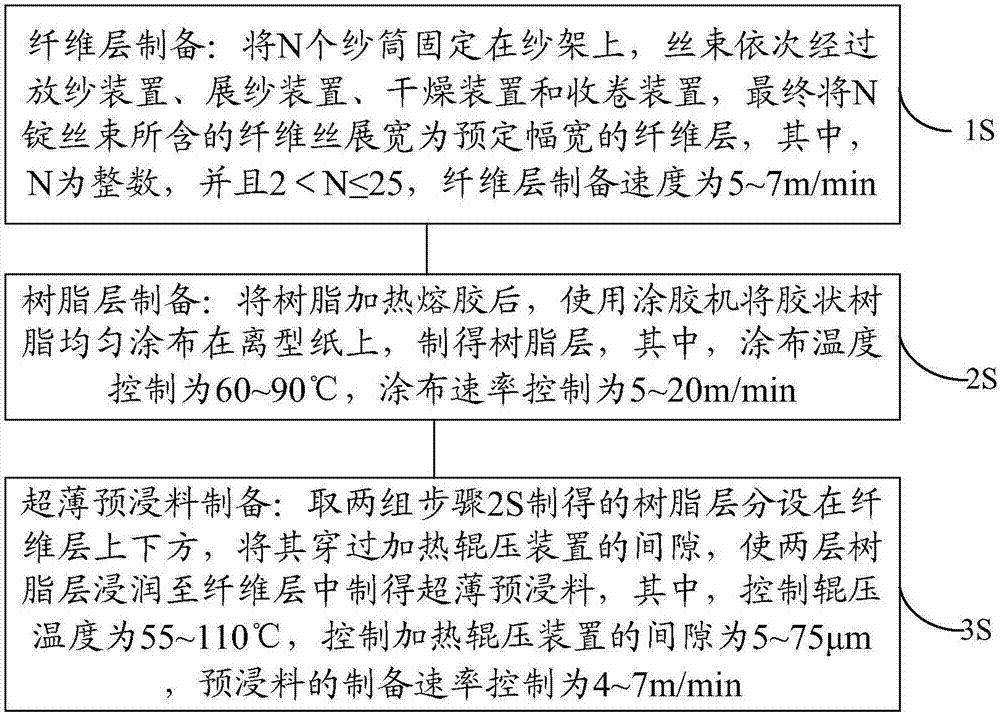

Golf ball mold and golf ball manufacturing method

ActiveUS8408891B2Reduce bad appearanceMolding stabilityTailstocks/centresConfectioneryProduction rateGolf Ball

Owner:BRIDGESTONE SPORTS

Method for manufacturing touch screen

InactiveCN101462423AReduce the generation of static electricityReduce bad appearanceOther printing apparatusInput/output processes for data processingEngineeringPrinting press

The invention relates to a method for manufacturing a touch screen. The method comprises the following steps: taking a clean screen; attaching a silver adhesive tape to the periphery of the screen; arranging the screen with a print on a printer; and moving a screen along the vertical upward direction, while moving a scraper along the horizontal direction from one side of the screen. The method for manufacturing the touch screen can reduce generation of static electricity during printing, and reduce poor appearance of the product caused by adhesive drawing.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

Technology capable of lowering reject ratio of appearance of anti-PID battery

InactiveCN105633175AReduce appearance defect rateReduce bad appearanceSemiconductor devicesSilicon nitrideUltrasound attenuation

The invention discloses a technology capable of lowering the reject ratio of the appearance of an anti-PID battery, which is mainly used for reducing the poor appearance caused by an anti-PID battery slice prepared by an ozone oxidization method. The method comprises the following steps: growing a silicon dioxide film on a textured, diffused and etched silicon wafer by the ozone oxidization method; putting the silicon dioxide film into a graphite boat deposited with a silicon nitride film; putting the graphite boat into a plasma vapor deposition furnace tube, pumping vacuum until 10Pa and heating the graphite boat to 350-450 DEG C; filling the tube with a nitrogen gas or an ammonia gas or a mixed gas of the nitrogen gas and the ammonia gas, keeping the air pressure at 230Pa, starting an excitation source and pre-cleaning an oxidation film on the surface of the silicon wafer for a period of time; pumping vacuum again, introducing the ammonia gas and silane, carrying out silicon nitride film deposition; and taking out the silicon wafer deposited with the silicon nitride film from the graphite boat. The technology effectively reduces the poor appearance caused by the anti-PID battery slice prepared by the ozone oxidization method, and does not affect the anti-attenuation effect of the battery slice.

Owner:泰州德通电气有限公司

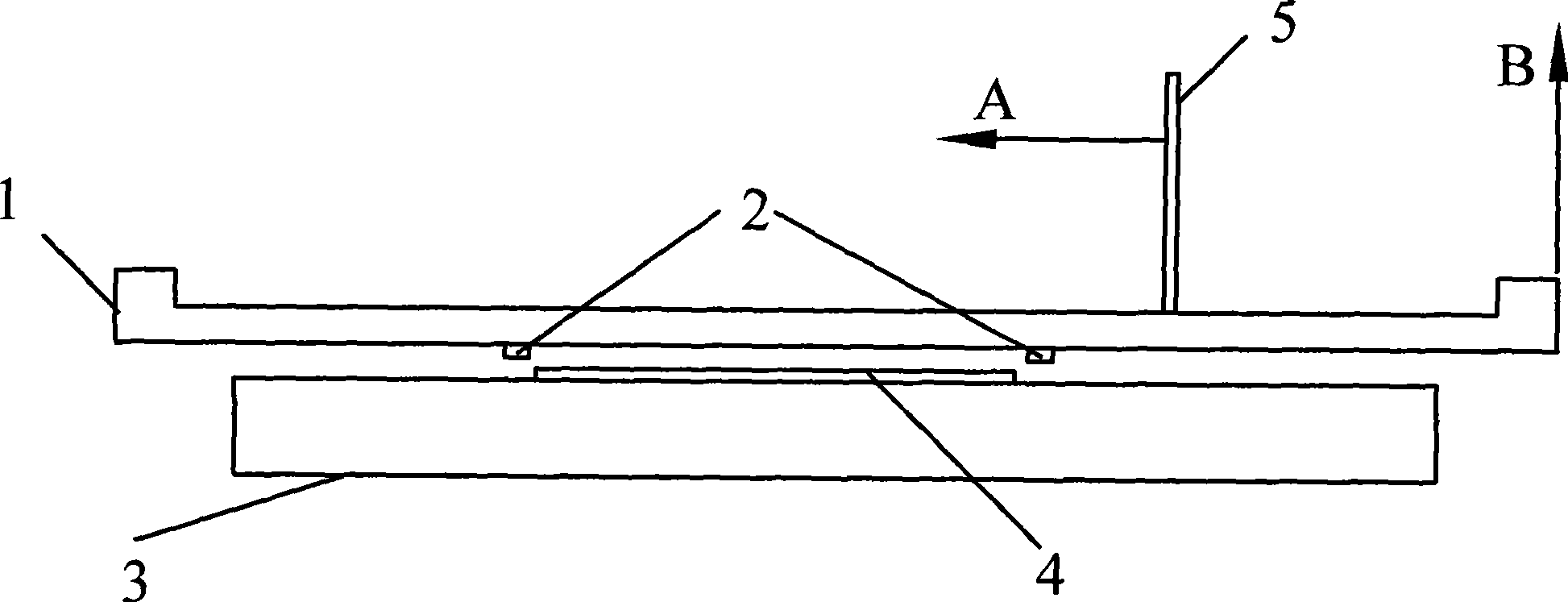

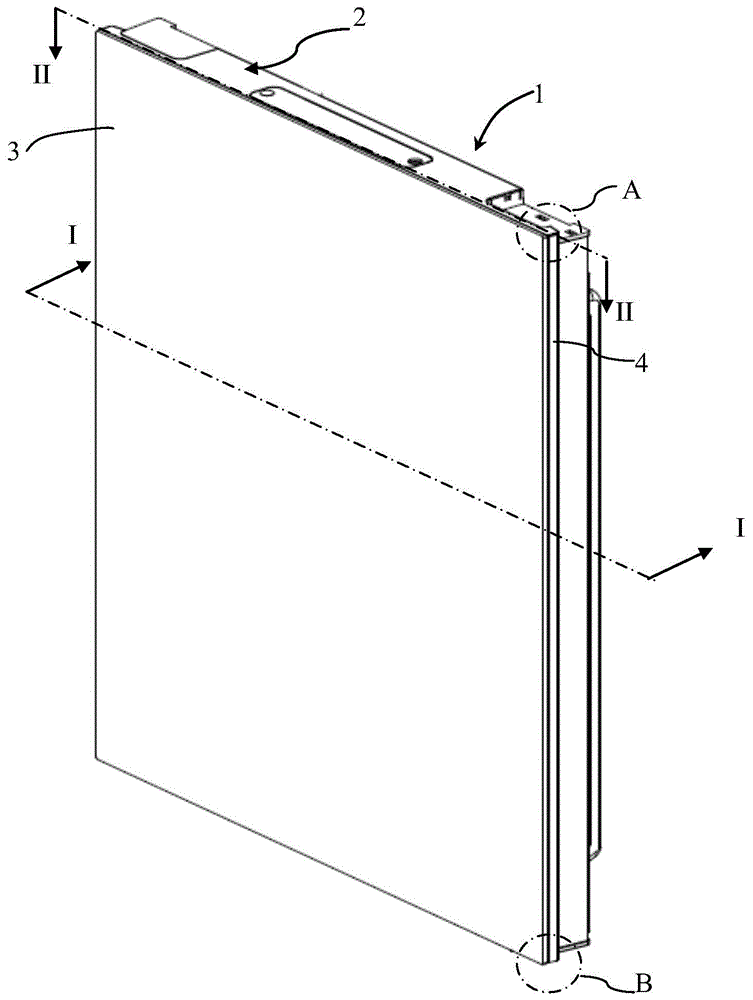

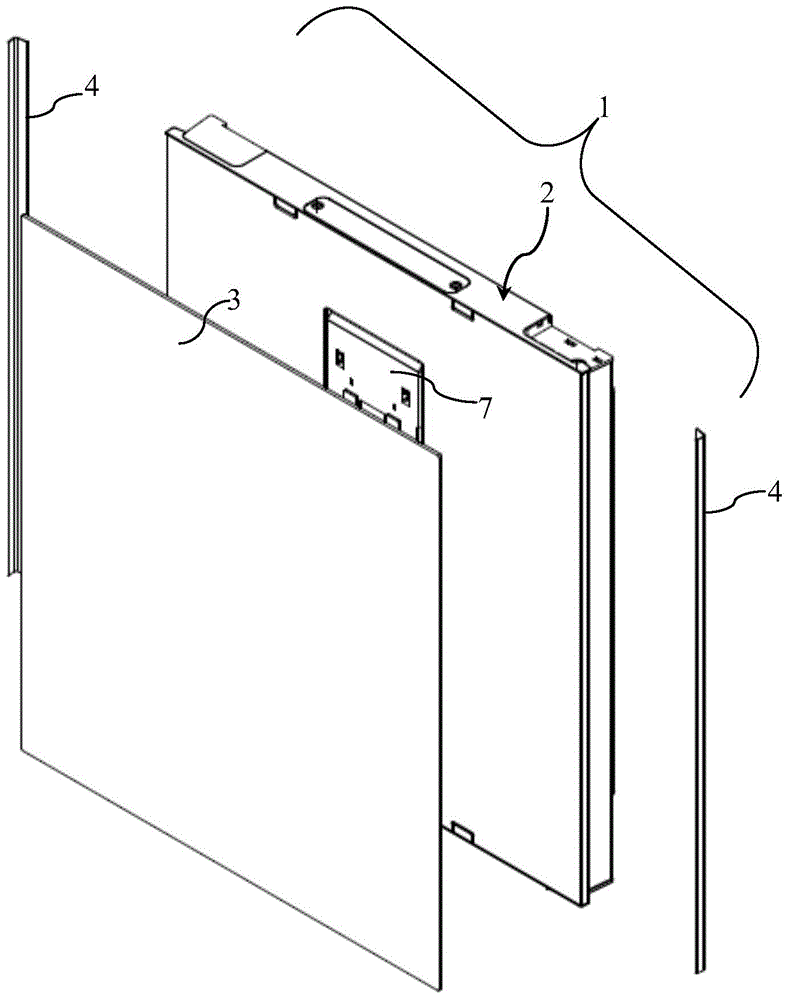

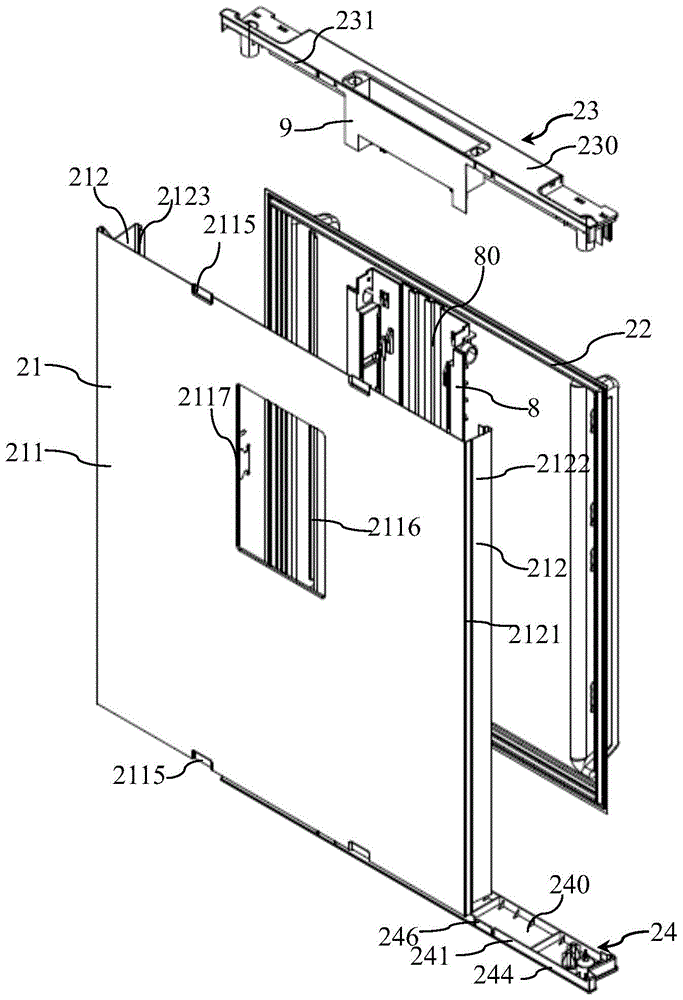

Refrigerating appliance and door for the same

ActiveCN104422236AIncrease the lengthReduce the difficulty of assemblyLighting and heating apparatusCooling fluid circulationThermal insulationMechanical engineering

The present invention relates to a door for a cooling appliance and a cooling appliance. A door (1) includes a door body (2) and at least one decoration strip (4) connected to the door body (2). The door body (2) includes a front plate (211), a door lining (22), a pair of side plates (212), an upper end cap (23), a lower end cap (24), and a thermal insulation space enclosed by these members. The decoration strip (4) is connected to a corresponding side plate (212). According to the present invention, one of the upper end cap (23) and the lower end cap (24) includes a stop portion (238) transversely protruding from the side plate (212), a tail end surface (45) of an end of the decoration strip (4) abuts the stop portion (238), and as viewed in a transverse direction of the door, the other end of the decoration strip (4) covers at least a part of a side end surface (249) of the other of the upper end cap (23) and the lower end cap (24).

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

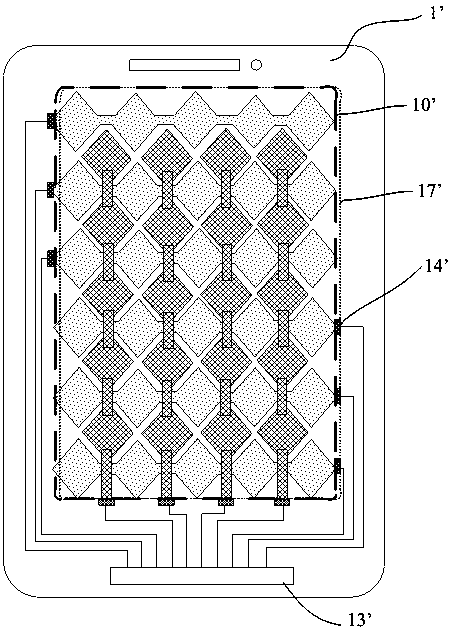

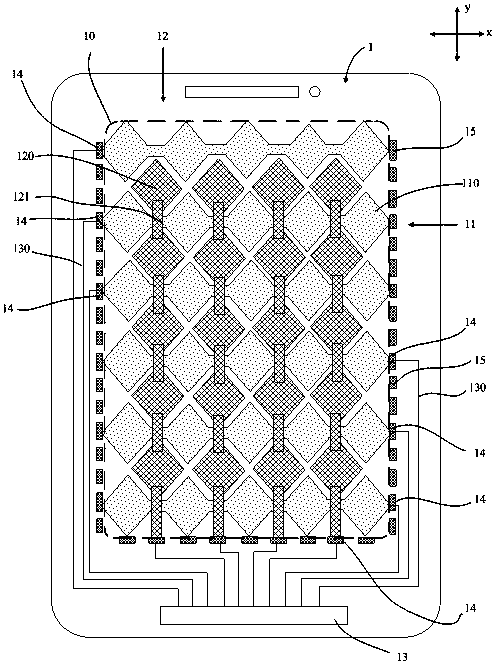

Touch screen and mobile terminal

ActiveCN108803951AReduce bad appearanceInput/output processes for data processingComputer terminalTouchscreen

The embodiment of the invention discloses a touch screen. The touch screen comprises a touch area, multiple first conducting lines and multiple second conducting lines which are arranged in a mutuallyinsulating and overlapped mode are arranged in the touch area; each first conducting line comprises multiple first sensing electrodes which are arranged at intervals and first connection parts, eachsecond conducting line comprises multiple second sensing electrodes which are arranged at intervals and second connection bridges, and each of the first conducting lines and the second conducting lines is connected with a binding area of which a wire extends to the touch screen through a lap joint block; virtual lap joint blocks are arranged at least one end of each lap joint block at intervals, and the virtual lap joint blocks are insulated from the first sensing electrodes, the second sensing electrodes and the lap joint blocks; and on each side, with the lap joint blocks, in the touch area,the lap joint blocks and at least one virtual lap joint block jointly form a complete shielding strip capable of shielding the side on the view. The invention further discloses a corresponding mobileterminal. According to the touch screen and the mobile terminal, the appearance badness capable of being visually observed by eyes can be reduced, and the wire badness of the touch area can be detected.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

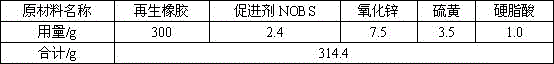

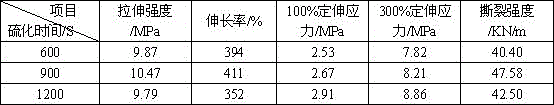

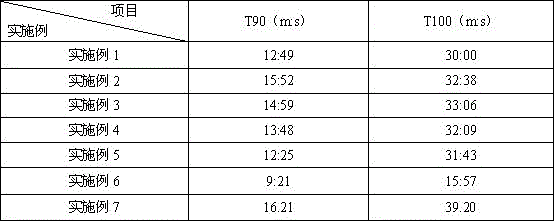

Agricultural tire crown compound of high filling tire reclaimed rubber

The invention discloses an agricultural tire crown compound of high filling tire reclaimed rubber. The agricultural tire crown compound is prepared from the following raw materials in parts by mass: 25 to 35 parts of standard rubber No.20; 15 to 25 parts of cis-butadiene rubber 9000; 10 to 50 parts of butadiene-styrene rubber 1502; 70 to 30 parts of tire reclaimed rubber; 3.0 to 5.0 parts of zinc oxide; 2.0 to 4.0 parts of stearic acid; 0.5 to 0.7 part of anti-aging agent BLE; 0.8 to 1.0 part of anti-aging agent RD; 1.5 to 2.5 parts of anti-aging agent 4020; 2.0 to 3.0 parts of protective wax; 55 to 65 parts of intermediate super carbon black N220; 9.0 to 12 parts of aromatic hydrocarbon oil; 1.5 to 2.5 parts of sulfur; 1.1 to 1.3 parts of accelerant NOBS; 1.0 to 2.0 parts of thermal oxidation resistant agent RF; 1.0 to 2.0 parts of homogenizing dispersant MS. The agricultural tire crown compound has the advantages that the processability of low-temperature emulsion aggregation of SBR (styrene butadiene rubber) is improved, resource recycling is realized, pollution is reduced, the environment is protected, and the production cost is reduced, etc.

Owner:江苏华冠橡塑制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com