Air filter and preparation process thereof

A preparation process and air filter technology, which is applied in mechanical equipment, dispersed particle filtration, machines/engines, etc., can solve the problems of low production efficiency, high process control difficulty, and unsightly appearance of air filters, and achieve a smooth and beautiful appearance of the product, The effect of low process control difficulty and few appearance defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

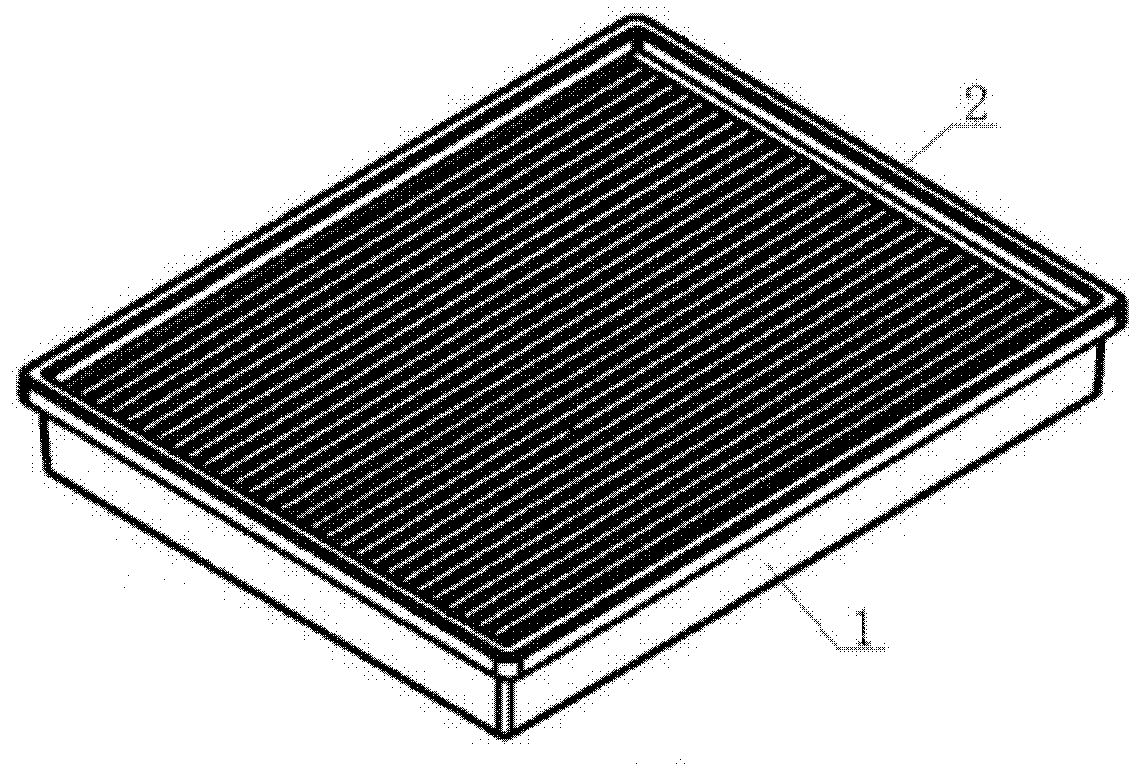

[0066] Reference figure 1 As shown, the air filter of the present invention includes a fixed frame 1 and a filter element 2. The peripheral edges of the filter element 2 are embedded in the frame of the fixed frame 1, the material of the fixed frame 1 is TPE, and the filter element 2 includes Two layers of iron nets and a non-woven fabric sandwiched between the two layers of iron nets, the fixed frame 1 and the filter element 2 are integrally formed through an insert molding process.

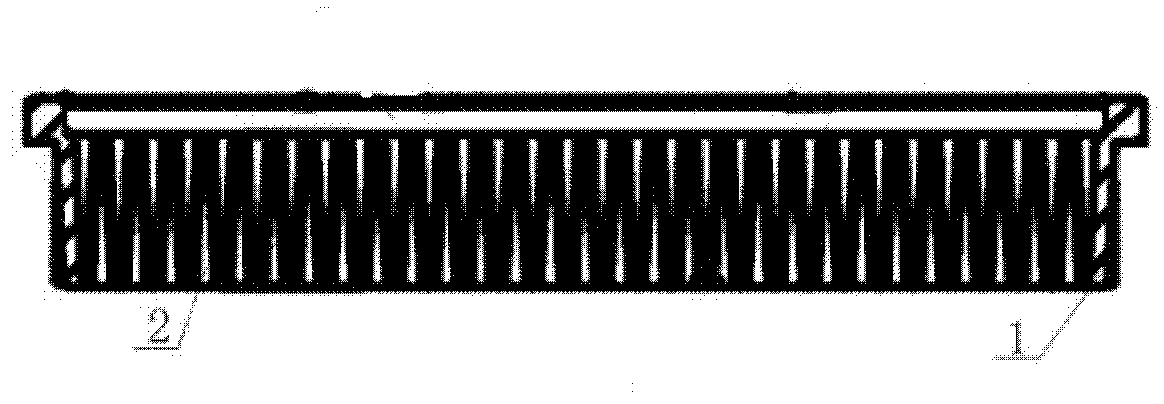

[0067] In Example 1, refer to figure 2 As shown, the non-woven fabric is a pleated non-woven fabric coated with an air filter. Coating air filter oil can not only ensure the air flow, but also effectively ensure the air filter's ability to capture dust; and the pleated design increases the surface area of the filter element, thereby increasing the air filter's air flow.

[0068] In Example 1, the production formula of the TPE includes the following components by weight:

[0069] 15 parts of EPDM ru...

Embodiment 2

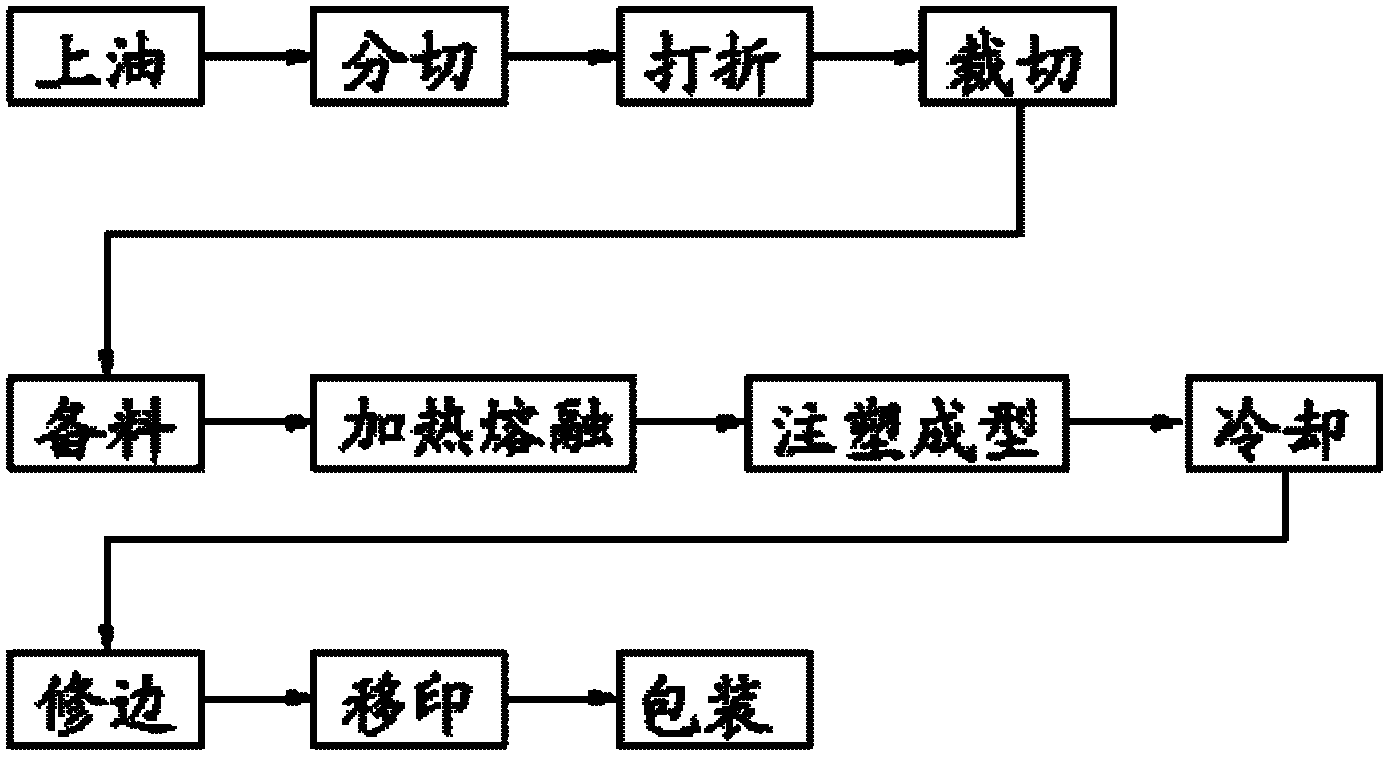

[0088] Reference figure 2 As shown, the preparation method of the air filter of the present invention includes the following steps:

[0089] Step 1. Prepare the filter element, including the following steps:

[0090] A. Oiling: spray the air filter oil evenly on the non-woven fabric;

[0091] The non-woven fabric coated with air filter oil can not only ensure the ventilation rate, but also effectively ensure the ability to capture dust;

[0092] B. Slitting: the non-woven fabric obtained in step 1 is cut according to the size required by the product using an infrared photoelectric correction slitting machine;

[0093] C. Discount: sandwich the cut non-woven fabric between two iron nets, and discount according to the product's required folding height, with a control accuracy of ±0.2mm;

[0094] The pleated design enlarges the surface area of the filter element, thus increasing the ventilation of the air filter.

[0095] D. Cutting: Cut the discounted non-woven fabric and iron mesh accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com